Oxygen Barrier Coating

advertisement

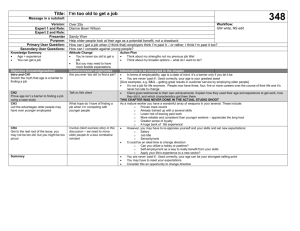

Delivering Innovation From Concept to Consumer…… working for you. Colin Smith Agenda Brief Introduction From Concept to Consumer – What does it mean? Five Innovative Packaging Solutions :- Oxygen Barrier Coating - UV Barrier Coating - Oxygen Barrier Adhesive - Laser Marking Technologies - Brand Protection 2 Sun Chemical’s global presence and leadership Strong Parent Company DIC (Japan) Color & Comfort by Chemistry $9.7 billion net sales 190 subsidiaries and affiliates 300 regional locations, 10 world-class R&D centers 21,572 employees in 64 countries 13% 18% Chemical Solution Materials 19% Synthetic Resins Neo-Graphic Arts Materials 1% Other 49% Printing Ink and Supplies 3 From Concept To Consumer….. 4 From concept to consumer….delivered! 5 -Oxygen Barrier Coating -UV Barrier Coating -Oxygen Barrier Adhesive -Laser Marking Technologies -Brand Protection 6 Oxygen Barrier Coating 7 Coating Applications - Barrier Market / Applications O2 Dry Food Chilled Food Liquid Packaging Market / Applications Fresh food Chilled/Frozen Food Dry Food Fast Food Bakery Barrier technology PVdC EVOH/PVOH Speciality Oxides Metallized Co-extrusions Barrier technology PVdC/Flurocarbons Silicones Wax based Co-extrusions/PE Package structure Bags Lidding Stand Up Pouches Forming Webs Wraps Package structure Outer cases Sacks & Bags Boxes & Trays Transient Containers - Oxygen Barrier - Aroma Barrier - Mineral Oil Barrier 8 Technical Data- SunBar O2 barrier SunBar performances: Untreated polyester film OTR 100-110 cc/m2/24 hrs 9 23ºC & 50% RH Oxygen Transmission Rate (cc / m² / 24 hrs) 8 Oxygen transmission rate measured using a MOCON OX-TRAN® 221 within 24 hours of coating. 7 OTR varies with PET grade. 6 5 4 PET / 50 PE:EVOH:PE Extrusion 3 0.3 dry coating weight 2 1 0 PVdC-PET Met-PET AlOx -PET SiOx-PET EVOH-PET SunBar-PET PVdC major disadvantage – contains chlorine & higher OTR AlOx / SiOx major disadvantage – brittle & higher OTR EVOH deteriorates over time in humid storage conditions SunBar coating replaces PVdC, EVOH, AIOx and SiOx for O2 barrier 9 Coating Applications Light weighting Commercial 3-Ply Laminate 2-Ply Laminate plus printable barrier coating Polymer Film Polymer Film Ink Barrier Coating Adhesive Ink MET Polymer Film Adhesive Adhesive Polymer Film Polymer Film Removal of barrier film or foil and one layer of adhesive Lighter weight packaging (up to 30% reduction) Improved laminate integrity (post flexing O2 barrier improvement) Lower material and / or operational costs Improved recycling Improved shelf life 10 Coating Applications- SunBar O2 Barrier Monoweb Commercial 2-Ply Laminate PVdC coated PET Ink Adhesive Polymer Film 1-Ply plus printable barrier coating OPV Ink Barrier Coating Polymer Film No chlorine No adhesive Improved O2 barrier Improved shelf life Increased sales opportunity for converter-monoweb Increased yield 11 Technical Data – SunBar O2 barrier Flexibility of barrier coatings 9 OTR @ 23oC & 50%RH (cc / m2 / 24 hrs) 8 7 6 5 AlOx-PET 4 SiOx-PET 3 Met-PET 2 PVdC-PET 1 EVOH co-ex/PET 0 SunBar-PET 0 5 10 20 50 Number of Gelbo Flexes Oxide coated and metallized films have poor flex resistance 12 SunBar value proposition – general summary Market Barrier Chlorine-free Excellent O2 / aroma / odor barrier Enables light weighting Replaces PVdC and EVOH barriers Improves sustainability Improves flex crack resistance of oxide / metallized Removes metal films Extends shelf life Transparent Improves ability to recycle Alternative to expensive barrier films Application Coating can be applied at conventional film weights Can be applied on existing equipment Enables removal of barrier film & adhesive in multi-ply laminates Allows duplex laminates to compete with triplex Reduces processing waste Reduces energy consumption Saves on inventory working capital Applied only where needed 13 UV Barrier Coating 14 SunBar UV barrier coatings potential uses Protects sensitive foodstuffs from degradation accelerated by UV light Improved visibility of UV sensitive products at point of sale Allows transparent packaging Potential to extend shelf life of UV sensitive foods 100.0 3 % Transmission 90 Absorbance 2.5 2 1.5 80 70 60 50 %T 1 0.5 40 30 20 10 0 0 -10.0 0 0.5 1 1.5 2 2.5 3 Coating Weight gsm dry 3.5 4 300.0 350 400 450 500 550 nm 600 650 700 750 800.0 Wavelength (nm) 15 SunBar UV barrier coatings transparent packaging for food applications Improved shelf life when using transparent film Results after 140 days in typical retail lighting and 20oC Scoring by trained sensory panellists Sensory Assessment Grades vs Days 9 Light exposed Window laminate bags 8 Sensory Grade 7 Light exposed UVAC laminate bags 6 5 Dark control laminate bags 4 3 Days 2 1 0 0 28 58 84 112 140 16 SunBar UV barrier coatings transparent packaging for food applications Reduced photo-bleaching of natural food pigments Cooked ham (results after 4 days at D65 and 4ºC) - carotene results after 2 weeks at D65 and RTP 17 SunBar UV barrier coatings The SunBar UV barrier coating acts as a barrier to UV light whilst allowing visible light to penetrate into the package. Some foods are affected by visible light as well as UV light. The SunBar UV barrier coating is not a barrier to visible light. Customers need to understand whether blocking the UV light will bring the required benefit. – SunBar UV barrier coating is only available in its pre commercialisation form and is not fully transparent. – Volume commitment is needed for scale up to the fully transparent version. 18 Oxygen Barrier Adhesive 19 What is PASLIM PASLIM is a new generation of patented solvent based adhesive, approved for food packaging application, offering additional oxygen barrier proprieties to the normal feature provided by conventional solvent based adhesive. PASLIM product range consist of two systems for following application: J40-OX+KX43C for non metallized substrates J40-OX+HX42M+AD42 for metallized substrates 20 Range of application PASLIM adhesives have been developed with aim of: Light weighting the laminate retaining the oxygen barrier proprieties Improve the oxygen barrier proprieties of existing laminates Retain the barrier proprieties of laminate after retort process Increasing the shelf life of food staff 21 Key feature of PASLIM adhesive PASLIM adhesive provide the following features: Be applied as conventional solvent based adhesive by rotogravure/semi flexo trolley at higher solid content (50-60%) Same level of performance in term of Bond and Heat seal strength of conventional adhesive (laminate related) Oxygen barrier proprieties Flexibility when compare with other barrier coating (eg SiOx, AlOx) avoiding lost of barrier by coating cracking Oxygen barrier proprieties independent to relative humidity (improve vs EvOH) Low retort resistance (121°C x 30 min) without loosing oxygen barrier proprieties 22 Flexibility feature Conven tional adhesiv e PASLIM OTR:cc/m2・day・atm(23℃) Coating weight: J40-OX/HX42M/AD42=about 4g/m2(dry) Conventional adhesive=about 3.5g/m2(dry) PASLIM protects the barrier layer from flexional stress. 23 Retort feature 24 Comparison data of barrier performance PASLIM gives barrier performance to conventional laminated films PET Conventional Adhesive Barrier Adhesive CPP Conventional adhesive Barrier Adhesive(J40-OX/KX43C) Films organization : Conventional Films OTR 0%RH 47 OTR 90%RH 53 PET12/PE60 105 PET12/CPP70 Ny15/CPP70 Ny15/PE60 MVTR OTR 0%RH 14 OTR 90%RH 9 MVTR 5.5 Ny15/PE60 4.7 80 5.2 PET12/PE60 17 11 4.5 116 92 5.9 PET12/CPP70 17 11 5.0 47 58 5.9 Ny15/CPP70 10 8 3.7 OTR:cc/m2・day・atm(23℃) MVTR:g/m2・day(40℃/90%RH) Coating weight: J40-OX/KX43C=about 5g/m2(dry) Conventional adhesive=about 3.5g/m2(dry) 25 Comparison data of barrier performance PASLIM enhances the barrier performance of metalized films. PET Conventional Adhesive Barrier Adhesive VM-CPP (AL Vacuumed Layer) Conventional adhesive Barrier Adhesive(J40-OX/HX42M/AD42) Films organization : Metal vaporized films PET12/VMPET12-PE60 OTR 0%RH 2.2 OTR 90%RH 2.1 0.3 PET12/VMPET12-PE60 OTR 0%RH 0.2 PET12/VMOPP15-PE80 8.5 11.1 0.4 PET12/VMOPP15-PE80 1.8 1.7 0.3 PET12/VMCPP25 5.0 5.4 0.4 PET12/VMCPP25 0.4 0.2 0.3 PET12/SiOxPET12-CPP70 0.5 0.2 0.7 PET12/SiOxPET12-CPP70 0.1 0.1 0.7 MVTR OTR 90%RH 0.1 MVTR 0.1 OTR:cc/m2・day・atm(23℃) MVTR:g/m2・day(40℃/90%RH) Coating weight: J40-OX/HX42M/AD42=about 4g/m2(dry) Conventional adhesive=about 3.5g/m2(dry) 26 Comparison data of barrier performance PASLIM replaces organic barrier films to conventional films. PET Conventional Adhesive Barrier Adhesive EVOH、PVDC PE Conventional adhesive Barrier Adhesive(J40-OX/KX43C) Films organization : Organic Barrier Films Films organization : Conventional Films OTR 0%RH OTR 90%RH MVTR 0.1 9 2.9 PET-K12 *1) /PE60 2 2 Ny-K12 *2) /PE60 8 13 Ny15/EVOH15/PE60 Ny15/ink/PVDC20 *2) /CPP70 *1):Made in Japan *2):Made in China OTR 0%RH OTR 90%RH MVTR Ny15/PE60 14 9 4.7 1.7 PET12/PE60 17 11 4.5 9 3.7 Ny15/PE60 14 9 4.7 15 4.1 Ny15/ink*3)/CPP70 12 10 3.7 *3):Two component ink OTR:cc/m2・day・atm(23℃) MVTR:g/m2・day(40℃/90%RH) Coating weight: J40-OX/KX43C=about 5g/m2(dry) Conventional adhesive=about 3.5g/m2(dry) 27 Project Simulation – Excel Spreadsheet To predict the comparative cost/m2, Yield and Barrier performance of alternative barrier structures © Chris Robinson October 2014 Creating alternative Barrier laminate structures with SunBar Coatings and Paslim Adhesives This calculator produces a quick assessment of Project viability in terms of Yield, Cost/m2, OTR and WVTR using Paslim Barrier Adhesives to replace traditional lamination films and adhesives within High Performance barrier laminates The savings estimated are only as good as the data it uses……..! They do not represent guaranteed savings. Using SunChemical products to replace Triplex laminate structures with Duplex alternatives Using SunChemical products to replace speciality barrier films in Duplex Structures Using SunChemical products to create Barrier Laminates from standard low-cost films Using SunBar coatings to replace Duplex laminate structures with Monoweb alternatives Note: for very thin films and very light coating weights, the prediction of barrier performance becomes less accurate. Pinholing and surface roughness effects can reduce the effective barrier to both Water and Oxygen. If barrier performance is critical to the end use of the final laminate, measure it. Developed to quickly assess alternative barrier laminate structures based on SunBar, Paslim, or a combination of both 28 Example 1 – Retort Sausage Packs (China) Lam Adh Price Paslim Price 4.00 Eur/kg SunBar Price 12.00 Eur/kg 7.00 Eur/kg TRIPLEX LAMINATE REPLACEMENT Original Structure 15u PA – polyamide Lamination Adhesive 25u EVOH CoEx Lamination Adhesive 50u PE – polyethylene 3.50 gsm Weight gsm 93.75 Yield m2/kg 10.67 Cost Eur/m2 0.24 OTR 0%RH cc/m2/day 0.10 OTR 85% RH cc/m2/day No data WVTR g/m2/day 1.91 3.50 gsm Alternative Structure 1 - Using Barrier adhesive to replace the Barrier Layer 15u PA – polyamide Barrier Adhesive 50u PE – polyethylene 5.00 gsm Weight gsm 69.3 Yield Cost OTR 0%RH OTR 85% RH WVTR m2/kg Eur/m2 cc/m2/day cc/m2/day g/m2/day 14.43 0.21 11.93 No data 2.94 35% -11% Yield improved by 35.3% producing 3763 additional m2 per Tonne, Laminate Cost reduced by 0.03 Eur/m2 Alternative Structure 2 - Using Barrier Coating and conventional adhesive to replace the Barrier Layer 15u PA – polyamide SunBar Barrier coating Lamination Adhesive 50u PE – polyethylene 0.30 gsm 3.50 gsm Weight gsm 68.1 Yield Cost OTR 0%RH OTR 85% RH WVTR m2/kg Eur/m2 cc/m2/day cc/m2/day g/m2/day 14.68 0.17 0.98 No data 3.65 38% -29% Yield improved by 37.7% producing 4017 additional m2 per Tonne, Laminate Cost reduced by 0.07 Eur/m2 SunBar is not chosen for this application because of the Retort requirement 29 Example 2 – PVdC Film replacement TRIPLEX LAMINATE REPLACEMENT Original Structure 12u PET – polyethylene terephthalate Lamination Adhesive 3.50 gsm 12u PVdC coated PET Lamination Adhesive 3.50 gsm 50u PE – polyethylene Weight gsm 87.98 Yield m2/kg 11.37 Cost Eur/m2 0.20 OTR 0%RH cc/m2/day 1.97 OTR 85% RH cc/m2/day No data WVTR cm3/m2/day 1.88 Alternative Structure 1 - Using Barrier adhesive to replace the Barrier Layer 12u PET – polyethylene terephthalate Barrier Adhesive 5.00 gsm 50u PE – polyethylene Weight gsm 69.3 Yield Cost OTR 0%RH OTR 85% RH WVTR m2/kg Eur/m2 cc/m2/day cc/m2/day g/m2/day 14.43 0.18 13.36 No data 2.87 27% -8% Yield improved by 27% producing 3063 additional m2 per Tonne, Laminate Cost reduced by 0.01 Eur/m2 Alternative Structure 2 - Using Barrier Coating and conventional adhesive to replace the Barrier Layer 12u PET – polyethylene terephthalate SunBar Barrier coating 0.30 gsm Lamination Adhesive 3.50 gsm 50u PE – polyethylene Weight gsm 68.1 Yield Cost OTR 0%RH OTR 85% RH WVTR m2/kg Eur/m2 cc/m2/day cc/m2/day g/m2/day 14.68 0.14 0.99 No data 3.55 29% -28% Yield improved by 29.2% producing 3318 additional m2 per Tonne, Laminate Cost reduced by 0.06 Eur/m2 OTR improved Depending on the end use application, both SunBar and Paslim offer cost effective alternatives. The choice will be based on other factors eg printing and lamination capability. 30 Example 3 – VMPET replacement 12u PET – polyethylene terephthalate Lamination Adhesive 3.50 gsm 12u Met PET Lamination Adhesive 3.50 gsm 50u PE – polyethylene Weight gsm 87.98 Yield m2/kg 11.37 Cost Eur/m2 0.19 OTR 0%RH cc/m2/day 0.99 OTR 85% RH cc/m2/day No data WVTR cm3/m2/day 0.78 Alternative Structure 1 - Using Barrier adhesive to replace the Barrier Layer 12u PET – polyethylene terephthalate Barrier Adhesive 5.00 gsm 50u PE – polyethylene Weight gsm 69.3 Yield Cost OTR 0%RH OTR 85% RH WVTR m2/kg Eur/m2 cc/m2/day cc/m2/day g/m2/day 14.43 0.18 13.36 No data 2.87 27% -3% Yield improved by 27% producing 3063 additional m2 per Tonne, Laminate Cost reduced by 0.01 Eur/m2 Alternative Structure 2 - Using Barrier Coating and conventional adhesive to replace the Barrier Layer 12u PET – polyethylene terephthalate SunBar Barrier coating 0.30 gsm Lamination Adhesive 3.50 gsm 50u PE – polyethylene Weight gsm 68.1 Yield Cost OTR 0%RH OTR 85% RH WVTR m2/kg Eur/m2 cc/m2/day cc/m2/day g/m2/day 14.68 0.14 0.99 No data 3.55 29% -25% Yield improved by 29.2% producing 3318 additional m2 per Tonne, Laminate Cost reduced by 0.05 Eur/m2 31 Laser Marking 32 1 SunLase™ - Description of principle (1) SunLase™ coating is used to print a white patch on a substrate The graphics are created when a low power CO2 laser changes the colour of the patch to black where marked PRINTING Low power CO2 laser MARKING FORMING, FILLING 33 2 SunLase™ - Description of principle (2) Sun Chemical has developed the SunLase™ coatings which are sensitive to specific low energy lasers, allowing the marking of high definition variable data on various substrates. SunLase™ coatings contain specific pigments, that change from white to black when hit by a low energy laser. There is no ablation. SunLase™ range offers packers and end-users the platform to introduce greater efficiencies and productivity as well as higher quality on their identification marking applications SunLase™ range covers most of printing and coating technologies: flexo, gravure, dry offset, water-based, solvent-based, oil-based, UV Surface imaging Reverse imaging Patch is printed with a SunLase™ coating When the coating is marked with a laser – a high definition black graphic appears 34 3 SunLase™ - Description of principle (3) Option 1 Main substrate Transparent substrate Adhesive Overprint lacquer Option 2 Main substrate SunLase™ coating Option 3 (plastic film, glass…) REVERSE PRINTING SunLase™ coating Laser Laser Image Laser SURFACE PRINTING Printing options: surface, surface lacquered, or reverse Other substrate 35 1 SunLase™ - Target markets and applications (1) Markets: all packaging printers/converters or packing companies: – – – – – – – Corrugated containers Flexible packaging Folding carton PE Films Reverse-printed sleeves Multiwall sack Liquid carton packaging Variable Data Applications: – – – – – – – Need of sequential numbers per pack / batch… Unique identifiers per pack, batch, consumer… Personalisation Network based coding Primary coding on flexible packaging Date / Price / Batch codes Language / ingredients / GDA & nutritional information 36 2 SunLase™ - Target markets and applications (2) End-uses: – High volume food producers with short shelf life products, for example: milk: sleeves and labels yogurts: PET/PP lids and labels beverage: beer bottle labels cereal primary packs – Personal care labels and sleeves – Pharmaceutical labels, foils, blisters – Existing production over 5 million outer cartons per year – Current users of Hi-Resolution ink jet – print and hand applied labels – Businesses that suffer fines for poor barcode quality – etc 37 SunLase™ - How it compares with labelling, inkjet, ablation Productivity 5 Quality control 4 Productivity 5 Quality control Downtime 3 2 Evolution ability 4 Downtime 3 2 1 Cost of mark 0 Image quality Waste Investment 1 Evolution ability 0 Image quality Waste Investment Productivity 5 Quality control 4 Cost of mark Ablation Downtime 3 2 Evolution ability 1 0 Cost of mark Labelling Image quality Waste Investment These comparisons are based on Sun Chemical’s internal rating, and would be slightly different case by case. 5 is the best score 38 Brand Protection 39 Brand Protection Solutions For mid- to high-level, overt and covert security solutions Taggant reader systems Hidden image technology Holograms Specialty inks and effects 40 Brand Protection & Anti Counterfeiting Portfolio Covert Hidden Indicia® Covert UV fluorescing inks Covert IR responsive Orion Inks Green 1022-073 Covert IR responsive Apollo Inks Covert Verigard™ authentication – yes/no Overt SunShift™ colour shifting inks Overt Smart Hologram® Covert non line of site authentication Forensic authentication Overt/Covert SunGram™ machine readable holograms/foils 41 Thank You! working for you. Please visit us at www.SunChemical.com or for more information contact us at packaging@sunchemical.com 42