Radioactive Waste Transportation

advertisement

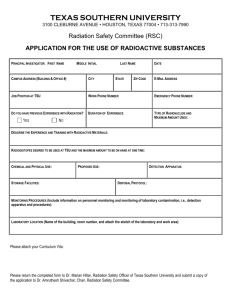

Radioactive Waste Transportation With contributions from by: Prof. John Poston, Sr (Texas A&M University) Brian Wolf (Purdue University) Alex Elman (Purdue University) 1 History • First regulations by U.S. Post Office in 1936. • IAEA regulations on safe transport issued in 1973. • Adopted by the Department of Transportation on July 1, 1983. • Adopted by the Nuclear Regulatory Commission on September 6, 1983. 2 Regulatory Organizations • Department of Transportation Act of 1966. • Transportation Safety Act of 1974. • DOT has regulatory authority on all modes of transport in interstate and foreign commerce. – Exception are postal shipments – U.S. Postal Service . – Non-interstate or foreign shipments are subject to state control. 3 Regulatory Organizations • Atomic Energy Act of 1954, as amended. • Nuclear Regulatory Commission has responsibility for safety in the possession and use, including transport, of by-product, source and special nuclear materials. • These regulations are found in 10CFR71. 4 Sources of Federal Regulations 5 10CFR 71 Transport of Radioactive Materials • • • • • • • • Subpart A-general B-Exemptions C-general licenses D-Applications E- approvals F-packages G-Operation procedures H-QA Transport Regulations • • • • Place primary responsibility on packaging Shipper is primarily responsible Carrier is less responsible Packaging requirements are commensurate with hazards 7 • HAZMAT Transportation Classes There are nine (9) classes of hazardous cargo as defined by the DOT: 1. 2. 3. 4. 5. 6. 7. 8. 9. Explosives Gases Flammable Liquids Flammable Solids Oxidizing Materials Toxic & Infectious Materials Radioactive Materials Corrosive Materials Misc. Dangerous Goods 8 DOE Shipments www.ntp.doe.gov/ question_answers.html 9 • • • • Materials Transported Uranium ores Nuclear fuel assemblies Spent fuel Radioisotopes To Medical Institutions 61.50% (research, defense, commercial) • Radioactive waste To Manufacturing Facilities 19.50% To Storage and Disposal Sites, 6.50% To Nuclear Power Plants, 4.20% To Research Facilities, 0.70% To Industrial Facilities, 7.60% Summary of Radioactive Shipment Destinations (Excluding weapons and weapons components) Data taken from: Tranportation of Hazardous Materials 10 How is it transported? Trucks Railcars Barge Ships Air- some medical isotopes that are short-lived require fast travel to a destination, but most waste is not transported in this manner. 11 Regulating Agencies • • • • • U.S. Department of Transportation (DOT) U.S. Nuclear Regulatory Commission (NRC) U.S. Department of Energy U.S. Postal Service State Agencies 12 Yucca Mountain http://www.state.nv.us/nucwaste/states/us.htm 13 Where is it going? http://www.state.nv.us/nucwaste/states/us.htm 14 Preparation • The shipper Prepares materials Classifies and packages materials Marks and labels packages Prepares shipping papers Signs papers certifying correct information • The carrier Examines certification papers Checks packages for proper labeling Placards vehicle Secures packages 15 Factors Determining Packaging Requirements 1) Type of waste: >0.002 цCi/g? 2 nCi/g? 74 Bq/g? 2) Quantity of radionuclides: Total activity in Bq? 3) Forms of the radionuclides – Special form – Normal form 16 Types of Packaging Containers • De minimus – Below threshold – no regulation. • Type A – Low to Modest Activity Waste – A1 – Special Form (non-dispersible) – A2 – Normal Form (dispersible) • Type B - High activity waste – Spent nuclear fuel – High Level Waste • TRU Waste – TRUPACT-II 17 TRUPACT II (for TRU Waste) More on this later 18 De minimus Requirements • Lowest transportation category – Specific activity < 2 nCi/g (< 74 Bq/g). – Poses no radiological safety problems. – Essentially “unregulated” • Limited quantities – – – – Specified allowable package activity. Allowable quantities in 49CFR 173.425. No exterior marking or labeling required. Packages containing less than one-tenth of these quantities are “mailable.” 19 Type A Shipping Containers • Contain Low Specific Activity (LSA) Waste • Pose low risk and are “inherently safe” – – – – Low activity solids Tritiated water Certain naturally occurring materials Surface contaminated objects (SCO) • Designed to withstand normal handling and minor accidents. – Fiberboard box – Wooden Box – Steel Drum 20 Packaging Requirements • Type A quantity limits – Rely only partially on package integrity. – Considers the radiation exposure from an unshielded source. – Considers the possible uptake of radioactive material. – Packages are designed to withstand certain test and environmental conditions. 21 Type A1 ad A2 Defined Activity Limits • A1 is “nondispersible” after release from package – Limits defined assuming an emergency exposure for 3 hours not exceeding 1 rem/h at 3 meters from the source. • A2 limit is for material assumed to be “dispersible” – Assumes 0.1% of package contents is released. – Assumes 0.1% of the amount released is taken into the body. – Limits intake to one-half allowable intake values. 22 Special /Normal Form - Special form source - double encapsulated - Has to undergo specific tests for pressure, penetration, submersion - Source has certificate - Normal form - Any source that does not have this special form certification - Usually single encapsulated, Be window Type A Package Quantity Limits for Selected Radionuclides 24 Activity Limits for Limited Quantities, Instruments and Articles 25 Type A • Low level radiation materials – radioisotopes (medical, industry, agriculture, and research) • Small packages tested to withstand rigors of routine transportation (rain, rough handling, slight mishaps) 26 Industrial • Low specific activity materials – – – – Contaminated tools Mine waste Medical isotopes Waste from soil cleanup • Ordinary strong industrial packages 27 DOT Spec. 17C Steel Drum (55 gal) 28 B-25 Container 29 Steel Container Box 30 Shipping Requirements - LSA • Non-exclusive use vehicles – Low levels only. – Individual packages are labeled. • Exclusive use vehicles – Packages are excepted from specific packaging, marking and labeling. – Specific requirements and administrative controls apply. • Exclusive use requirements – “Strong and tight” packaging. – Loaded by consignor and unloaded by consignee from transport in which originally loaded. – Packages blocked and braced to prevent movement. – Vehicle must be placarded by consignor. • Exclusive Use Requirements – Packages marked “radioactive LSA.” – Specific instructions for maintenance of shipment must be provided by shipper to the carrier. – Higher package/vehicle radiation levels are allowed. 31 Exclusive Use – Allowed Radiation Levels • 1 rem/hour at package surface. • 200 mrem/hour at vehicle surface. • 10 mrem/hour at 2 meters from the lateral surfaces of the vehicle. • 2 mrem/hour in cab of vehicle. 32 Type B Shipping Containers • Designed for the transport of very radioactive material (e.g., spent fuel). • Meet all ‘A’ requirements • Must also withstand serious accident conditions. • Certified by NRC to withstand severe accident conditions. • Very strong – can weigh up to 125 tons 33 Packaging Requirements • Type B quantities are also called a “Highway Route-Controlled Quantity” • Formerly called “large quantity” • Provide a high degree of integrity in a severe accident • Involve SNF and HLW • DOT regulations prescribe highway routes 34 Type B Package Tests (examples) • • • • • 30 ft. drop on an unyielding surface 40 inch drop onto a 6 inch diameter steel pin Thermal exposure at 1475 °F (800 °C) for 30 min. Submersion to 3 ft. for 8 hours (fissile materials) Submersion to 50 ft. for 8 hours 35 Shipping Cask Tests 36 “Crunch” Test of Package 37 Schematic of Drop Test 38 Free Drop Test 39 Free Drop Test 40 Impact from 30 feet 41 Puncture Test 42 Steel Spike 43 Thermal Test 44 Thermal Test 45 Thermal Test 46 Thermal Test Results 47 Immersion Tests 48 Crash Testing of Casks 49 Crash Testing Sequence (Rocket powered truck at impact) 50 Crash Testing Sequence (Truck - 120 mph impact on target) 51 Crash Testing Sequence (End of Test) 52 Results of Crash Test 53 Crash Testing (Cask hit by train at 80 mph) 54 The cask always wins! web.em.doe.gov/ emprimer/emorg4.html 55 Type B Packages • NRC maintains list of certified package designs • Shipper may use a container that meets the license requirements • Must have a quality assurance program approved by the USNRC • Must comply with 49CFR and 10CFR172 56 Shipping Cask on Truck 57 Radioactive Materials Packages Labeling Criteria (CFR Title 49 Section 172.403) 58 Identification Please! • • • • • • • Markings on package indicate shipping name, identification number, and shipper’s name and address Labels applied to package identify material, level of radioactivity, and transport index Transport index- indicates maximum radiation level at 1 meter from package Markings on package must be visible on all sides Markings on package must indicate what type of package it is Placards are placed on front, rear and both sides of vehicle Detailed shipping papers carried in cab of vehicle Containers are labeled I (white), II (yellow), and III (yellow) Higher the number, the greater the precautions required for safety 59 Radioactive I Label • Radioactive I or RadWhite I is for materials in which there is a low external radiation level Surface Radiation Level >0.5 mrem/hr Radiation Level at 1m NA 60 Radioactive II Label • Rad-Yellow II indicates that external radiation levels require consideration. Surface Radiation Level 0.5-50 mrem/hr Radiation Level at 1m <1 mrem/hr 61 Radioactive III Label • Rad-Yellow III indicates that radiation levels should be closely monitored and that the vehicle MUST be placarded “Radioactive”. Surface Radiation Level > 50 mrem/hr Radiation Level at 1m >1 mrem/hr 62 Radioactive Vehicle Placard • If any package on the vehicle has a Radioactive III label, the vehicle requires a RADIOACTIVE placard. • 49 CFR 172.556 63 Placards: More than Meets the Eye • Emergency responders should know that only the most hazardous condition is placarded. • Perchloric Acid for example under 50% concentration is placarded corrosive but above 50% it’s placarded as an oxidizer. • If a radioactive material has a non-radioactive hazard greater than the radioactive hazard it WON’T be placarded radioactive. 64 Monitoring • Transportation Communication (TRANSCOM) uses communication equipment and a satellite positioning and reporting system to track DOE shipments of spent fuel, high-level waste, and other radioactive materials. web.em.doe.gov/ emprimer/emorg4.html 65 No Secrets. • On all shipments of high-level radioactive waste and spent fuel, State authorities are notified in writing in advance of transporting through that State. • This written notice includes the planned schedule, route, shipment description, and carrier name and address. • States and Tribal govenments can become authorized to use TRANSCOM 24 hrs a day to observe movement of shipments 66 Leak Testing • Leak testing is used to determine if a sealed source is damaged • If it is damaged you may not ship it unless you get approval • Why would a source leak – Damaged physically – Damaged chemically – Improper manufacturing Leak Testing • Leak testing is done by wiping the source with a smear, wipe, Qtip, etc and counting it on an appropriate instrument • Instrument has to be able to “see” 50% of the limit • Limit for leak testing is .005 microcuries Leak Testing • When does a leak test need to be done? – At time of manufacture – Before shipping – At time of receipt – In the field • Every six months for normal form sources • Every six months or time period suggested by the manufacturer (usually 3 years for special form sources) • Any time the unit has been damaged Questions?

![tutorial #14 [nuclear physics and radioactivity] .quiz](http://s3.studylib.net/store/data/008407305_1-1884988a9e5162a6b7a2b0d0cf8c83c5-300x300.png)