an assessment of msc.nastran residual vector methodology

advertisement

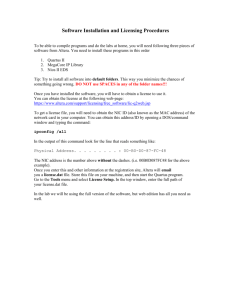

FEM FOR THE TEST ENGINEER Christopher C. Flanigan Quartus Engineering Incorporated San Diego, California USA 18th International Modal Analysis Conference (IMAC-XVIII) San Antonio, Texas February 7-10, 2000 Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. DOWNLOAD FROM THE QUARTUS ENGINEERING WEB SITE http://www.quartus.com Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM PEOPLE ARE REALLY SMART • Or so they would have you believe! Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM for the Test Engineer TOPICS • • • • There’s reality, and then there’s FEM FEM in a nutshell FEM strengths and challenges Pretest analysis – Model reduction – Sensor placement • Posttest analysis – Correlation – Model updating Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. There’s Reality, and Then There’s FEM REALITY IS VERY COMPLICATED! • • • • • • • • Many complex subsystems Unique connections Advanced materials Broadband excitation Nonlinearities Flight-to-flight variability Chaos Extremely high order behavior Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. There’s Reality, and Then There’s FEM FEM ATTEMPTS TO SIMULATE REALITY • Fortunately, reality is surprisingly linear – – – – Material properties ( vs. ) Tension vs. compression Small deflections (sin = ) Load versus deflection • Allows reasonable opportunity simulate reality using FEM 1 0.75 0.5 0.25 0 -0.25 -0.5 -0.75 -1 -1 -0.5 0 0.5 1 Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. There’s Reality, and Then There’s FEM REMEMBER THAT FEM ONLY APPROXIMATES REALITY • Reality has lots of hard challenges – Nonlinearity, chaos, etc. • FEM limited by many factors – Engineering knowledge and capabilities – Basic understanding of mechanics FEM Ahead! – Computer and software power • But it’s the best approach we have – Experience shows that FEM works well when used properly Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM Strengths and Challenges TEST IS NOT REALITY EITHER! • Test article instead of flight article – Mass simulators, missing items, boundary conditions • Excitation limitations – Load level, spectrum (don’t break it!) – Nonlinearities • Testing limitations – Sensor accuracy and calibration – Data processing • But it’s the best “reality check” available Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM in a Nutshell Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM for the Test Engineer FEM IN A NUTSHELL • • • • • • Divide and conquer! Shape functions Elemental stiffness and mass matrices Assembly of system matrices Solving Related topics – Element library – Superelements Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM in a Nutshell CLOSED FORM SOLUTIONS, ANYONE? • Consider a building – Steel girders – Concrete foundation • Can you write an equation to fully describe the building? – I can’t! • Even if possible, probably not the best approach – Very time consuming – One-time solution Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM in a Nutshell DIVIDE AND CONQUER! • Behavior of complete structure is complex – Example: membrane 1.00 • Divide the membrane into small pieces 0.80 0.60 0.40 0.20 – Buzzword: “element” • Feasible to calculate properties of each piece • Collection of pieces represents structure 0.00 -0.20 -0.40 -0.60 -0.80 -1.00 S1 S3 1 3 5 7 S5 9 S7 11 S9 S11 13 S13 15 S15 17 S17 19 S19 Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM in a Nutshell SHAPE FUNCTIONS ARE THE FOUNDATION OF FINTE ELEMENTS • Shape function – Assumed shape of element when deflected Spring • Some element types are simple – Springs, rods, bar K • Other elements are more difficult – Plates, solids • But that’s what Ph.D.’s are for! – Extensive research – Still evolving (MSC.NASTRAN V70.7) F X F=KX Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM in a Nutshell ELEMENT STIFFNESS MATRIX FORMED USING SHAPE FUNCTIONS • Element stiffness matrix – Relates deflections of elemental DOF to applied loads Spring • Forces at element DOF when unit deflection imposed at DOFi and other DOFj are fixed • Example: linear spring (2 DOF) K K spring K K K K F X F=KX Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM in a Nutshell ELEMENT MASS MATRIX HAS TWO OPTIONS • Lumped mass – Apply 1/N of the element mass to each node 1/4 1/4 1/4 1/4 • Consistent mass – Called “coupled mass” in NASTRAN – Use shape functions to generate mass matrix • In practice, usually little difference between the two methods – Consistent mass more accurate – Lumped mass faster 0 0.5 M Mspring 0 0 . 5 M Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM in a Nutshell SYSTEM MATRICES FORMED FROM ELEMENT MATRICES 2 2 K1 2 2 5 5 K2 5 5 1 1 K3 1 1 0 2 2 0 2 7 5 0 K 0 5 6 1 0 1 1 0 0 0 0.5 0 0 1.5 0 0 M 0 0 2.5 0 0 0 1.5 0 M=1 K=2 M=2 K=5 M=3 K=1 Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM in a Nutshell CALCULATE SYSTEM STATIC AND DYNAMIC RESPONSES • Static analysis P KX • Normal modes analysis K i Mi 0 • Transient analysis T C q T K q T P T M q Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM in a Nutshell COMMERCIAL FEM ISSUES • Element libraries – Springs, rods, beams, shells, solids, rigids, special – Linear and parabolic (shape functions, vertex nodes) • Commercial codes – NASTRAN popular for linear dynamics (aero, auto) – ABAQUS and ANSYS popular for nonlinear • Superelements (substructures) – Simply a collection of finite elements – Special capabilities to reduce to boundary nodes – Assemble system by addition I/F nodes Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM in a Nutshell HONORARY DEGREE IN FEM-OLOGY! Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM for the Test Engineer FEM STRENGTHS AND CHALLENGES Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM Strengths and Challenges FEM IS VERY POWERFUL FOR WIDE ARRAY OF STRUCTURES • Regular structures – Fine mesh • Sturdy connections – Seam welds • Well-defined mass – Smooth distributed – Small lumped masses • Linear response – Small displacements General Dynamics Control-Structure Interaction Testbed Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM Strengths and Challenges FEM HAS MANY CHALLENGES • Mesh refinement – How many elements required? – Stress/strain gradients, mode shapes • Material properties – A-basis, B-basis, etc. – Composites • Dimensions – Tolerances, as-manufactured • Joints – Fasteners, bonds, spot welds continued... Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM Strengths and Challenges FEM HAS MANY CHALLENGES • Mass modeling – Accuracy of mass prop DB – Difficulty in test/weighing • Secondary structures – Avionics boxes, batteries – Wiring harnesses • Shock mounts • Nonlinearities – (large deformation, slop, yield, etc.) • Pilot error! Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM Strengths and Challenges FEM ASSISTED BY ADVANCES IN H/W AND S/W POWER • Computers – Moore’s law for CPU – Disk space, memory • Software – – – – Sparse, iterative Lanczos eigensolver Domain decomposition Pre- and post-processing • Increasing resolution – Closer to reality Moravec, H., “When Will Computer Hardware Match the Human Brain?” Robotics Institute Carnegie Mellon University http://www.transhumanist.com/volume1/moravec.htm Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM Strengths and Challenges FEM CONTINUES TO IMPROVE ABILITY TO SIMULATE REALITY • Model resolution – Local details • Some things still very difficult – Joints • Expertise – Mesh size, etc. • FEM is not exact – Big models do not guarantee accurate models – That’s why testing is still required! Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM for the Test Engineer PRETEST ANALYSIS Develop FEM Pretest Analysis Test Posttest Correlation Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis MODAL SURVEY OFTEN PERFORMED TO VERIFY FINITE ELEMENT MODEL • Must be confident that structure will survive operating environment • Unrealistic to test flight structure to flight loads • Alternate procedure – Test structure under controlled conditions – Correlate model to match test results – Use test-correlated model to predict operating responses • Modal survey performed to verify analysis model – “Reality check” Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - TAM TEST AND ANALYSIS DATA HAVE DIFFERENT NUMBER OF DOF • Model sizes – FEM = 10,000-1,000,000 DOF – Test = 50-500 accelerometers • Compare test results to analysis predictions Ortho T M • Need a common basis for comparison Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - TAM TEST-ANALYSIS MODEL (TAM) PROVIDES BASIS FOR COMPARISON • Test-analysis model (TAM) – Mathematical reduction of finite element model – Master DOF in TAM corresponds to accelerometer • Transformation (condensation) Kaa Tga T Kgg Tga Maa Tga T Mgg Tga • Many methods to perform reduction transformation • Transformation method and sensor selection critical for accurate TAM and test-analysis comparisons Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - TAM Transformation Methods GUYAN REDUCTION IS THE INDUSTRY STANDARD METHOD • Robert Guyan, Rockwell, 1965 – Pronounced “Goo-yawn”, not “Gie-yan” • Implemented in many commercial software codes – NASTRAN, I-DEAS, ANSYS, etc. • Start with static equations of motion K oo K oa Uo Po K ao Kaa Ua Pa • Assume forces at omitted DOF are negligible Po 0 Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - TAM Transformation Methods GUYAN REDUCTION IS A SIMPLE METHOD TO IMPLEMENT • Solve for motion at omitted DOF Uo Koo 1 Koa Ua • Rewrite static equations of motion Uo K oo 1 K oa Ua U Iaa a • Transformation matrix for Guyan reduction K oo 1 K oa TGuyan Iaa Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - TAM Transformation Methods TRANSFORMATION VECTORS ESTIMATE MOTION AT “OTHER” DOF 1.0 0.8 Displacement 0.6 0.4 0.2 0.0 -0.2 1 2 3 4 Node ID Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - TAM Transformation Methods TRANSFORMATION VECTORS CAN REDUCE OR EXPAND DATA TAM Display Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - TAM Transformation Methods DISPLAY MODEL RECOVERED USING TRANSFORMATION VECTORS Standard Display 0.75 0.50 0.25 0.00 -0.25 -0.50 -0.75 -1.00 Enhanced Display 0.75 1 2 3 4 1 2 3 4 0.50 0.25 0.00 -0.25 -0.50 -0.75 -1.00 Node ID Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - TAM Transformation Methods IRS REDUCTION ADDS FIRST ORDER MASS CORRECTION • Guyan neglects mass effects at omitted DOF • IRS adds first order approximation of mass effects TGuyan GGuyan GIRS Iaa GGuyan Koo 1 Koa GIRS Koo 1 Moa Moo GGuyan Maa 1 Kaa Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - TAM Transformation Methods DYNAMIC REDUCTION ALSO ADDS MASS CORRECTION • Start with eigenvalue equation i K oo K oa o i Moo K M K ao ao aa a i Moa o Maa a Replace eigenvalue with constant value L K oo L Moo 1 K oa L Moa TDyn Re d I aa • Equivalent to Guyan reduction if L = 0 Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - TAM Transformation Methods MODAL TAM BASED ON FEM MODE SHAPES • Partition FEM mode shapes Uo o Ua a • Pseudo-inverse to form transformation matrix Uo Tmod al Ua T TModal o a a Iaa 1 T a Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - TAM Transformation Methods EACH REDUCTION METHOD HAS STRENGTHS AND WEAKNESSES Guyan ADVANTAGES DISADVANTAGES Easy to use, efficient Limited accuracy Works well if good A-set Bad if poor A-set Widely accepted Unacceptable for high M/K Better than Guyan Requires DMAP alter IRS Errors if poor A-set Better than Guyan Dynamic Requires DMAP alter Choice of Lamda? Limited experience Modal Exact within freq. range Requires DMAP alter Hybrid TAM option Sensitivity Limited experience Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - TAM Transformation Methods STANDARD PRACTICE FAVORS GUYAN REDUCTION • Guyan reduction used most often – – – – Easy to use and commercially available Computationally efficient Widely used and accepted Good accuracy for many/most structures • Use other methods when Guyan is inadequate – Modal TAM very accurate but sensitive to FEM error – IRS has 1st order mass correction but can be unstable – Dynamic reduction seldom used (how to choose L) Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - Sensor Placement SENSOR PLACEMENT IMPORTANT FOR GOOD TAM AND TEST • Optimize TAM – Minimize reduction error • Optimize test – Get as much independent data as possible • Focus on uncertainties – High confidence areas need only modest instrumentation – More instrumentation near critical uncertain areas (joints) • Common sense and engineering judgement – General visualization of mode shapes Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - Sensor Placement MANY ALGORITHMS FOR SENSOR PLACEMENT • Kinetic energy – Retain DOF with large kinetic energy • Mass/stiffness ratio – Retain DOF with high mass/stiffness ratio • Iterated K.E. and M/K – Remove one DOF per iteration • Effective independence – Retain DOF that maximize observability of mode shapes • Genetic algorithm – Survival of the fittest! Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - Sensor Placement SENSOR PLACEMENT ALGORITHM CLOSELY LINKED TO TAM METHOD • Guyan or IRS reduction – Must retain DOF with large mass – Iterated K.E. or M/K – Mass-weighted effective independence • Modal or Hybrid reduction – Effective independence • Genetic algorithm offers best of all worlds – Examine tons of TAMs! – Seed generation from other methods – Cost function based on TAM method Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Pretest Analysis - Sensor Placement PRETEST ANALYSIS ASSISTS PLANNING AND TEST • Best estimate of modes – Frequencies, shapes • Accelerometer locations – Optimized by sensor placement studies • TAM mass and stiffness – Real-time ortho and x-ortho • Frequency response functions – Dry runs/shakedown prior to test Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM for the Test Engineer TEST CONSIDERATIONS Develop FEM Pretest Analysis Test Posttest Correlation Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Test Considerations PRETEST DATA ALLOWS REAL-TIME CHECKS OF RESULTS • Traditional comparisons ORTHO test MTAM test T XORTHO T TAM MTAM test • What if test accuracy goals aren’t met? – Keep testing (different excitement levels, locations, types) – Stop testing (FEM may be incorrect!) – Decide based on test quality checks • Experienced test engineer extremely valuable! Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM for the Test Engineer POSTTEST CORRELATION Develop FEM Pretest Analysis Test Posttest Correlation Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Posttest Correlation CORRELATION MUST BE FAST! • FEM almost always has some differences vs. test • Very limited opportunity to do correlation – After structural testing and data processing complete – Before operational use of model • First flight of airplane • Verification load cycle of spacecraft • Need methods that are fast! – Maximum insight – Accurate Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Posttest Correlation NO UNIQUE SOLUTION FOR POSTTEST CORRELATION • More “unknowns” than “knowns” • Knowns – Test data (FRF, frequencies, shapes at test DOF, damping) – Measured global/subsystem weights • Unknowns – FEM stiffness and mass (FEM DOF) • No unique solution • Seek “best” reasonable solution “When you have eliminated the impossible, whatever remains, however improbable, must be the truth.” Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Posttest Correlation MANY CORRELATION METHODS • Trial-and-error – Stop doing this! It's (almost) the new millenium! – Too slow for fast-paced projects – Not sufficiently insightful for complex systems • FEM matrix updating • FEM property updating • Error localization FEM Updates Test OK? Done Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Posttest Correlation MATRIX UPDATE METHODS ADJUST FEM K AND M ELEMENTS • Objective – Identify changes to FEM K and M so that analysis matches test • • • • • • Baruch and Bar-Itzhack (1978, 1982) Berman (1971, 1984) 2 2 Kabe (1985) K 0 Kammer (1987) 0 Smith and Beattie (1991) 0.5 0 … and many others M 0 0 2 0 0 0 0 7 5 0 5 6 1 0 1 1 0 1.5 0 0 0 2.5 0 0 0 1.5 Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Posttest Correlation MATRIX UPDATE METHODS HAVE LIMITATIONS • Lack of physical insight – What do changes in K, M coefficients mean? • Lack of physical plausibility – Baruch/Berman method doesn't enforce connectivity • Limitations for large problems – Great for small “demo” models, but ... – “Smearing" caused by Guyan reduction/expansion • What if test article different than flight vehicle? • Requires very precise mode shapes (unrealistic) Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Posttest Correlation PROPERTY UPDATE METHODS ADJUST MATERIALS AND ELEMENTS • Objective – Identify changes to element and material properties so that FEM matches test • • • • • • Hasselman (1974) Chen (1980) Flanigan (1987, 1991) Blelloch (1992) Smith (1995) … and many others FEM Updates* Test OK? Done * Calculate updates using design sensitivity and optimization Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Posttest Correlation COMMERCIAL SOFTWARE FOR CORRELATION • SDRC/MTS – I-DEAS Correlation (MAC, ortho, x-ortho, mapping) • LMS – CADA LINK (parameter updating, Bayesian estimation) • MSC – SOL 200 design optimization (modes, FRF) • Dynamic Design Solutions (DDS) – FEMtools (follow-on to Systune) • Others (SSID, ITAP, etc.) Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Posttest Correlation MODE SHAPE EXPANSION FOR CORRELATION IMPROVEMENT TAM Display Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. Posttest Correlation SHAPE EXPANSION IS AN ALTERNATIVE TO MATRIX REDUCTION • Expand test mode shapes to FEM DOF Ug Tga Ua • Expansion and reduction give same results if same matrices used • Dynamic expansion based on eigenvalue equation oi Koo i Moo Koa i Moa ai Computationally intensive – But computers are getting faster all the time! Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM for the Test Engineer SUMMARY • FEM is a simple yet powerful method – Complex structures from simple building blocks • FEM must make many assumptions – Joints, tolerances, linearity, mass, etc. – Big models do not guarantee accuracy • Testing provides a valuable “reality check” – Within limits of test article, excitation levels, etc. • FEM can work closely with test for mutual benefit – Pretest analysis to optimize sensor locations – TAM for providing test-analysis comparison basis – Correlation and model updating for validated model Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM PEOPLE REALLY ARE SMART! • And maybe test people are smart too! Quartus Engineering Copyright Quartus Engineering Incorporated, 2000. FEM for the Test Engineer RECOMMENDED READING • Finite element method – Concepts and Applications of Finite Element Analysis, 3rd ed.; Cook, Robert D./Plesha, Michael E./Malkus, David S.; John Wiley & Sons; 1989 – Finite Element Procedures, Klaus-Jurgen Bathe; Prentice Hall; 1995 • Correlation and model updating – Finite Element Model Updating in Structural Dynamics; M. I. Friswell, J. E. Mottershead; Kluwer Academic Publishers; 1995. • Optimization – Numerical Optimization Techniques for Engineering Design, 3rd edition (includes software); Garret N. Vanderplaats, Vanderplaats Research & Development, Inc., 1999 Quartus Engineering Copyright Quartus Engineering Incorporated, 2000.