Train Auto Control System based on OSGi

advertisement

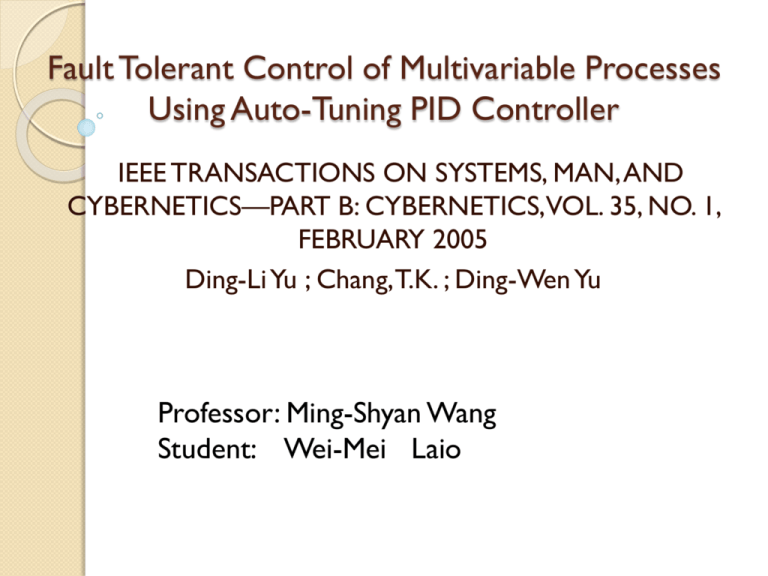

Fault Tolerant Control of Multivariable Processes Using Auto-Tuning PID Controller IEEE TRANSACTIONS ON SYSTEMS, MAN, AND CYBERNETICS—PART B: CYBERNETICS,VOL. 35, NO. 1, FEBRUARY 2005 Ding-Li Yu ; Chang, T.K. ; Ding-Wen Yu Professor: Ming-Shyan Wang Student: Wei-Mei Laio Outline Introduction CONFIGURATION OF FTC SCHEME ADAPTIVE NEURAL NETWORK MODEL PID CONTROLLER AUTO-TUNING ALGORITHM ADAPTIVE MODEL EVALUATION APPLICATION TO THE CSTR PROCESS CONCLUSION REFERENCES Abstract Abstract—Fault tolerant control of dynamic processes is inves-tigated in this paper using an auto-tuning PID controller. A fault tolerant control scheme is proposed composing an auto-tuning PID controller based on an adaptive neural network model. The model is trained online using the extended Kalman filter (EKF) algorithm to learn system post-fault dynamics. Based on this model, the PID controller adjusts its parameters to compensate the effects of the faults, so that the control performance is recovered from degradation. The auto-tuning algorithm for the PID controller is derived with the Lyapunov method and therefore, the model pre-dicted tracking error is guaranteed to converge asymptotically. The method is applied to a simulated two-input two-output continuous stirred tank reactor (CSTR) with various faults, which demonstrate the applicability of the developed scheme to industrial processes. INTRODUCTION WITH rapid increase in complexity of modern control systems, the importance of the fault tolerant control (FTC) concept and technology has been realized and accepted by in-dustry. Control system stability and reliability are not only crit-ical for some projects where strict safety conditions apply, e.g., nuclear power stations and passenger airplanes, but also essen-tial for large-scale productions, since most of modern industrial plants are complex and often include a number of subsystems which may compensate for the effects of sensor faults and com-ponent malfunction. This requires solutions that are very costly in both hardware and development effort. Therefore, FTC is very important from the viewpoint of safety, as well as reduced production costs. FTC offers the capability to avoid inadvertent process shut downs from simple faults, e.g. in instrumentation and control loops that could develop into production stoppages or plant failures. CONFIGURATION OF FTC SCHEME The main objective of the FTC is to obtain a control vari-able to drive the process to track the desired trajectory when the process is not subject to any fault, while to maintain the system stability and to recover from the performance degrada-tion as much and as fast as possible when fault occurs in the process. Considering that chemical or biological processes are complex and their mathematical models are usually unknown, an active fault tolerant control approach is developed in this sec-tion. The control scheme includes two parts, one is using a NN to model the process and the model is made adaptive to catch the dynamics change caused by the fault, another is an auto-tuning PID controller based on the model. When the model captures the post-fault dynamics, the PID controller is adapted to compen-sate the degradation of system stability and performance. The configuration of the FTC system is shown in Fig. 1. In Fig. 1 the MLP model is online adapted with the model prediction error using the EKF algorithm. The adapted model is used to predict process output at next sample time. The predic-tion is used by the auto-tuning algorithm to derive an optimal control variable. The framed part in Fig. 1 is the PID controller. PID controller adapts its parameters in the way that the produced control variable will drive the NN model output to track the de-sired reference. A recursive auto-tuning algorithm derived using the Lyapunov method will generate the optimal control that is guaranteed to minimize a squared tracking error. The thick line between the model used for prediction and that to be adapted indicates that the structure and weights are shared between the two models. CONFIGURATION OF FTC SCHEME ADAPTIVE NEURAL NETWORK MODEL ADAPTIVE NEURAL NETWORK MODEL ADAPTIVE NEURAL NETWORK MODEL ADAPTIVE NEURAL NETWORK MODEL ADAPTIVE NEURAL NETWORK MODEL ADAPTIVE NEURAL NETWORK MODEL ADAPTIVE NEURAL NETWORK MODEL ADAPTIVE NEURAL NETWORK MODEL ADAPTIVE NEURAL NETWORK MODEL Step 1) At sample time , obtain the desired trajectory , the past process output and the past control variable to form the NN model input vector . Step 2) Implement the PID auto-tuning algorithm given in (27), (34), (36)–(38) and (26) in iterative form to predict the optimum PID parameter vector . The initial value is assigned to be the value at the last sample time,. Step 3) Apply the obtained to the PID controller to calculate the optimal control variable in (29). Step 4) Apply the obtained to the NN model to calcu-late the model output in (11) and NN model tracking error, in (27) at iteration step . Step 5) Repeat Step 1 to Step 4 until the NN model tracking error, is less than a pre-specified threshold or a specified bound to the iterative step is reached. Step 6) Set to be equivalent to , and then apply it to the PID controller in the process. ADAPTIVE MODEL EVALUATION To evaluate the learning performance of the developed adap-tive network, the network is used to model a multivariable, non-linear CSTR process. The CSTR process used in this research is a typical nonlinear dynamic process used in chemical and biochemical industry. The process will also be used to evaluate the developed FTC scheme. A second order endothermic chemical reaction 2A B takes place in the tank. The schematic diagram of the process is shown in Fig. 2. The process works in the following way. The reactant A with constant concentration and variable temperature flows into the tank with the flow rate . An endothermic chemical reaction takes place in the tank, which is based on the temper-ature, and the reaction absorbs heat energy. As a result, the re-action influences the temperature and concentration of outflow liquid. The two inputs and two outputs are chosen as follows: CONCLUSION he proposed FTC scheme employs an auto-tuning PID controller to compensate the fault effects. The auto-tuning algorithm is derived with Lyapunov method to guarantee the convergence of the predicted tracking error. The MLP model is made adaptive online with the EKF algorithm, the post-fault dynamics can be modeled in time and thus, the degradation in the process tracking performance and in system relative stability is quickly recovered. The effectiveness of the method is demonstrated in the application to the simulated CSTR process for different faults. Actuator and component faults in abrupt and incipient modes with large amplitude can be tolerated with the developed FTC scheme. The tracking error is compensated within about 10 sample periods and the system stability is maintained. Table I shows the process tracking error indices in the simulations under different fault conditions. It should be noted that for the last two error indices the tracking errors caused by the control variable bound are in-cluded. Therefore, the error indices caused by the faults in the last two conditions should be in a similar level to that in condition two and three, respectively. CONCLUSION It is noted that sensor faults are not included in evaluations. In fact, sensor faults are not tolerable with the developed method. This is because that the adaptive NN model is online trained with measurement process input output data and consequently, the effects of sensor faults will also be modeled. This leads to a process tracking error of the size of the occurred sensor fault. Sensor fault tolerance in processes with unknown dynamics is the research being undertaken. Due to lack of a test rig for which the fault simulation mechanism is equipped, the devel-oped approach is evaluated only by simulated process with the simulated faults. The potential applications include different industrial processes with multivariables, nonlinear dynamics, and a considerable complexity, such as chemical or biological processes REFERENCES R. J. Patton, P. M. Frank, and R. Clark, Fault Diagnosis in Dynamic Sys-tems: Theory and Application. Englewood Cliffs, NJ: Prentice-Hall, 1989. M. Tyler and M. Morari, “Optimal and robust design of integrated con-trol and diagnostic modules,” in Proc. American Control Conf., 1994. J. Chen, R. J. Patton, and Z. Chen, “Active fault tolerant flight control systems design using the linear matrix inequality method,” Trans. Inst. Meas. Control, vol. 21, no. 2/3, pp. 77–84, 1999. Y. Ochi, “Application of feedback linearization method in a digital re-structurable flight control system,” J. Guid. Control Dyn., vol. 16, no. 1, pp. 111–117, 1993. I. Kaminer, A. M. Pascoal, P. P. Khargonekar, and E. E. Coleman, “A ve-locity algorithm for the implementation of gain-scheduled controllers,” Automatica, vol. 31, no. 8, pp. 1185–1192, 1995. W. D. Morse and K. A. Ossman, “Model-following reconfigurable flight control system for the AFTI/F-16,” J. Guid. Control Dyn., vol. 13, no. 6, pp. 969–976, 1990. D. P. Looze, J. L. Weiss, J. S. Eterno, and N. M. Barrett, “An automatic redesign approach for restructurable control systems,” IEEE Contr. Syst. Mag., vol. 5, no. 2, pp. 16–22, May 1985. Z. Gao and P. J. Antsaklis, “Stability of the pseudo-inverse method for reconfigurable control systems,” Int. J. Control, vol. 53, pp. 717–729, 1991.