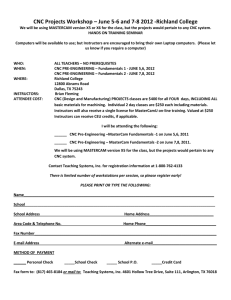

2015-2016 AAPP Machine Shop

advertisement

Annual Program Plan―2015‒2016 I. Department Industrial Technology Discipline or Program on which this plan focuses Machine Shop/CNC – Numerical Control Programming Date January 21, 2015 Version number 2 Program Description The Industrial Technology Dept. Machine Shop/ CNC program prepare students for gainful employment in various manufacturing enterprises in occupations including machine tool operators, machinists, cnc machinists, cnc programmers, machine shop owners, and supervisory positions in manufacturing. While this program is not specifically designed for transfer to institutions of higher learning, students/graduates of our programs have transferred to four-year colleges and universities and earned bachelor and masters degrees and one doctorate we know of. Five graduates of this program are now teaching full time and another four are teaching part time at the community college level. And numerous graduates own manufacturing companies or hold high level supervisory positions. Faculty are active in professional societies such as Society of Manufacturing Engineers, California Industrial Technology Educators Association and the National Tool & Machine Association. Faculty, both full and part time, mentor students through preparation and inter-collegiate competition in the SME sponsored Manufacturing Challenge contest and Skills USA in which Pierce students have won numerous awards and recognition. Because the majority of students in this program are part time students and often working fulltime and limited hours allocated to the programs due to cutbacks in leaner times, classes are only offered during the late afternoon, evenings, and Saturdays. The Machine Shop/CNC program was recently through the process of review by a Viability Committee. The Viability Committee report strongly recommended upgrading the Industrial Tech Computer Lab, Machine Tool, and CNC Labs; hiring a fulltime instructor who would be qualified and able to work across at least two disciplines (ie. Machine shop & CNC Programming, or Machine Shop & Mechanical Drafting, or CNC Programming & Mechanical Drafting. Enrollment for Machine Shop/CNC increased dramatically for Fall 2013 and classes filled earlier than in previous years. This program is not duplicated between Trade Tech and Ventura Community Colleges. II. Assessment of 2013-2014 Annual Goals Provide an assessment of 2013-2014 Annual Goals. List any continuing goals in Section VII. Goal A. Establish articulation agreement with a local High School program. 2015-2016 Annual Academic Program Plan Form Draft/May 16, 2014 Achieved Continuing Discarded x 2 II. Assessment of 2013-2014 Annual Goals Provide an assessment of 2013-2014 Annual Goals. List any continuing goals in Section VII. Goal Achieved Continuing Discarded B. Renew articulation agreement with SCULA x x C. Increase program recruiting effort with high schools and local industry x x D. Continue the SME Student Chapter Annual BBQ & Awards program x x E. Update COR’s for all machine Shop, CNC, and Print Reading (IT 105) courses. x (Press tab for additional rows.) III. Curriculum Changes During 2013-2014 Academic Year List any new programs and/or certificates OR changed programs and/or certificates approved by the Curriculum Committee during the 2013-2014 academic year. Check A. whether they are New or Changed, and provide the date they were approved by the Curriculum Committee. 1 New Changed Approval Date 2 3 (Press tab for additional rows.) B. List any new, updated, or changed courses approved by the Curriculum Committee during the 2013-2014 academic year. Provide the course number and the course title. 1 All Machine Shop, CNC, and the Print Reading courses New Check All That Apply. Distance Updated Honors Education x Approval Date 12/7/11 2 3 4 5 6 (Press tab for additional rows.) C. Course Outlines of Record 1 Number of courses in discipline or department 13 3 C. IV. Course Outlines of Record 2 Number of courses that have been updated since 2008 (CORs must be updated every 6 years) 13 3 Number of courses that require updating during 2015-2016 to maintain currency 0 Progress in the Student Learning Outcomes Cycle A. Learning Outcomes Development and Assessment Status Total B. 1. Number of courses in discipline or department 13 2. Number of courses with approved SLOs on the COR 13 3. Number of degrees and state-approved certificates in the discipline/department (If zero, please go to A.6.) 1 4. Number of degrees and state-approved certificates with program-level outcomes (PLOs) developed 1 5. Number of degrees and state-approved certificates with PLOs developed and courses mapped to the PLOs 2 6. Number of courses mapped to one or more General Education Learning Outcomes 0 Outcomes Assessment Results 1. Provide a narrative describing the significant findings from the course- and program-level outcomes assessed in 2013-2014. Place your narrative in the expandable row below. Students manage to complete the course requirements successfully even with the limitation of limited faculty/student interaction due to the combined courses scheduled. 2. Provide a narrative describing any steps taken or changes made as the result of these findings. Place your narrative in the expandable row below. 3. Provide a narrative that describes additional steps to be taken as the result of the findings, including any needed resources required to address shortcomings in student performance. Place your narrative in the expandable row below and specify any resource requests in Items X through XIV. While the assessment for IT 346 looks good on paper, what’s missing is that because this course is offered in combination with two other courses due to limited hours allocated to the program the students in this course have limited faculty/student interaction. The course is possible only because an excellent programmed learning text is available for students to teach themselves. The industrial advisory committee has recommended we offer MASTERCAM instead of SURFCAM. The course material would be similar but using a different CAM program and no “programmed learning text” is available for MasterCam. If and when implemented, the course should be offered as a stand alone separate course offering rather than competing with other courses simultaneously. Faculty expect to modify the IND TEK 346 COR to change the software used to MasterCam by 4 IV. Progress in the Student Learning Outcomes Cycle the end of Fall 2013 semester. V. External Influences (Environmental Scans) A. Report on course articulation status (from ASSIST or articulation officer) How many of your courses are transferable to CSU or UC? 13 Of these courses, how many are articulated with CSU or UC? 2 formally; 11 approved and have been accepted at CSULA Do you have an approved or in process Transfer Model Curriculum (TMC) for your discipline? If so, name of TMC: if so, please provide approval status: B. Provide relevant labor market data supporting demand for the program (if applicable) http://www.bls.gov/oco/ocos223.htm http://www.labormarketinfo.edd.ca.gov/cgi/databrowsing/occExplorerQSDetails.asp?searchCriteria=machinists&careerID=&menuChoice=occEx C. Describe Advisory Committee input (if applicable, including date of last meeting) Jan 2012: Committee recommended adding Mfg Processes, Jigs & Fixtures, and for the fourth year in-a-row MASTERCAM courses for both the Degree and certificate in Numerical Control Programming. Manufacturing Processes and Jigs & Fixtures are introduced within both CNC and Machine Tool Technology classes; but not to the depth the Advisory Committee expects. The department will change the software used for the Graphics Programming course to MASTERCAM. D. Discuss other pertinent data (such as interactions with four-year institutions, concepts derived from professional conferences and journals, outc from adjunct faculty, agreements with high schools or regional occupational programs, etc.) From CITEA (Calif. Industrial Technology Educator’s Association), SME (Society of Manufacturing Engineers), Haas HTEC (Haas cnc machine Technology Educator’s Commt), and our Advisory Committee we get the same input on three important points 1. The California secondary school system has abandoned the industrial technology disciplines for the most part, which severely limits the number of high school students exposed to these occupations. 2. There is a shortage of trained and qualified technicians available for the current openings. 3. We are rapidly approaching a crisis of large numbers of baby boomer’s retiring and leaving the workforce. 5 VI. Data Sets Provided by the Office of Institutional Effectiveness (Research Office) Please discuss any longitudinal trends within your program or the relation to college averages in these areas: changes in enrollment, FTES, section offerings, and FTES/FTEF; success and retention rates; degrees and certificates awarded (especially if few awards are made each year); and full-time/part-time faculty ratios. Included in the data sets are the Benchmarks and Goals for success and retention. If the most current success and retention rates fall below the Benchmarks, please discuss ways in which your program will address these areas. Please discuss ways in which your program hopes to meet the Goals in the coming year. A. Total enrollments, FTES (full-time equivalent students), FTEF (full-time equivalent faculty), and FTES/FTEF Fall 2010 Fall 2011 Fall 2012 Spr 2011 Spr 2012 Spr 2013 Total Census Enrollments: 135 227 235 215 182 293 FTES: 28.1 48.0 50.66 46.1 40.0 60.98 FTEF: 1.39 1.79 2.0 2.02 1.8 2.27 Program FTES/FTEF: 20.2 26.77 25.33 22.8 22.22 26.9 College FTES/FTEF: 20.57 20.99 21.16 20.8 21.12 20.47 B. Number of sections offered (combined classes counted as a single class), average class size, success and retention data Fall 2010 Fall 2011 Fall 2012 Spr 2011 Spr 2012 Spr 2013 Number of (Combined) Sections Taught: 4 5 5 5 5 6 Average Class Size at Census: 33.7 7.3 47. 43. 6.7 48.8 Program Success: 79.% 69.% 78.7% 75.% 76.% 76.1% College Success: 71% 72% 69% 68% 71% 69% Program Retention: 86.% 88.9% 89.8% 90.% 87.7% 92.5% College Retention: 88% 89% 87% 88% 89% 87% C. Benchmarks (5 year average X 95%) & Goals (current rates + ½%) Success Retention Benchmark: 71.5% 84.9% Goal: 76.6% 93.% D. Number of degrees and certificates awarded (if applicable) 2008-09 2009-10 2010-11 2011-12 2012-13 Degrees 4 3 2 2 1 TMCs Certificates 2 0 1 1 1 Skills Certificates 5 2 2 0 0 E. Comparison of full-time faculty hours to adjunct faculty hours Fall 2010 Fall 2011 Fall 2012 Spr 2011 Spr 2012 Spr 2013 Total Hours Taught: 22. 30. 30. 30. 30. 34. Percent of total program hours taught by full-time faculty 31.8% 30.% 50.% 20.% 30.% 35.3% Percent of total program hours taught by adjunct faculty 50.% 80.% 70.% 64.7% 68.2% 70.% 6 Pierce College Mission Statement and Values Pierce College is a student-centered learning institution that offers opportunities for access and success in a diverse college community. The college dedicates its resources to assist students in identifying and achieving their educational, career, and personal goals. Our comprehensive curriculum and support services enable students to earn associate degrees and certificates, prepare for transfer, gain career and technical proficiency, and develop basic skills. We serve our community by providing opportunities for lifelong learning, economic and workforce development, and a variety of enrichment activities. Pierce College values: Student success and engagement A student-centered environment conducive to learning Freedom to think, dialogue, and collaborate Commitment to excellence Access and opportunity Service to our communities Enrichment through diversity VII. 2015-2016 Annual Goals Based on the Pierce College Mission Statement and the Strategic Master Plan (Distinguish between goals and the resources required to achieve these goals.) Provide an action plan for achieving each goal. Press Ctrl + Click to identify the specific Pierce Strategic Master Plan goal addressed → Strat. Plan A. Renew articulation agreement with CSULA 1,2 B. Continue the Student Chapter of Society of Manufacturing Engineers 2,5 C. Establish articulation agreement with a local High School program. 1,2 D. (Press tab for additional rows.) Return to X, Human Resources VIII. Return to XI, Equipment/Software Return to XIV, Other Resources Planned Curriculum Changes List planned curriculum changes (new and/or modified courses, degrees, and certificates) that will be submitted to the curriculum committee during the 2015-2016 academic year. Press Ctrl + Click to identify the specific Pierce Strategic Plan Objective addressed →Strat. Plan A. B. C. D. Change software used for Graphics CNC Programming course (IT 346) to MASTERCAM 1, 2 7 IX. Long-Range Educational Goals (3–4 Years) Press Ctrl + Click to identify the specific Pierce Strategic Plan Objective addressed →Strat. A. Develop new program combining Mech Drafting/Desig, Machine Shop/CNC, and Welding courses into a broad coverage Manufacturing Technology program degree & Certificate 1,2 B. Identify and dispose equipment no longer used in the program(s) 3 C. Recruit potential adjunct/fulltime faculty to continue program when current faculty retire 2.1 Plan D. (Press tab for additional rows.) X. Additional Human Resources Needed to Implement Annual Program Goals in Section VII―Faculty, Staff, Student Workers, and Others Describe additional specific human resources required. Provide a comprehensive justification based on annual program goals, student learning outcomes, program data, and external scans. Link the request to an annual program goal in Section VII. Press Ctrl + Click to identify the specific Annual Program Goal addressed. A. Faculty 1. Hire Full Time Probationary Instructor to support Machine Shop, Mech Drafting, CNC courses in that order. This was a primary finding and recommendation of the Machine Shop & Mechanical Drafting Viability Committee Report received and approved by the Pierce College Academic Senate during Fall 2010 and approved by the faculty hiring priority committee as the #1 priority for hire. A looming factor is the fulltime Machine Shop/CNC faculty is fast approaching retirement! The time is right to bring in a new fulltime faculty to benefit from support and direction from the existing fulltimer while growing and moving the program in a direction to continue supporting our local manufacturing industry. Given the nature and organization of our program(s) it’s envisioned this new full time faculty would primarily cover Machine Shop and CNC. Cost Annual Goal 50,000. 2. (Press tab for additional rows.) B. Classified Staff 1. Increase .75 assignment of Instructional Assistant to 1.0 (Rodolfo Fajardo) Our Program Instructional Assistant is stretched over three distinct programs: Machine Shop/CNC, Welding, and support for Mechanical Drafting as needed. The current workload far exceeds a fulltime assignment and the assistant often must abandon necessary work in one area to deal with student needs in another lab. Cost Annual Goal 15,000. 8 B. Classified Staff The Industrial Technology Department is adamant this meager increase in paid assignment is warranted even without the pending shop relocation. Cost 2. Hire Departmental Instructional Assistant to support Computer Technology and Networking department needs. (This request would bridge both Auto Service and Machine Shop/CNC, Welding, & Mech Drafting) Currently, the Industrial Technology Department is dependent upon INFO TECH to service everything from minor computer glitches to software installations & updates and new equipment set-up/installations. Our high tech equipment and software needs outpace the ability of INFO TECH to respond in a timely manner. Waiting six or more months for installation of new/updated software is not acceptable. Specialized software we use sometimes requires online installation of software bug fixes immediately to function properly and we really need a dedicated employee who can keep the operations in the Automotive Computer Lab, Industrial Tech Computer Lab, and the Machine Shop/CNC mini computer lab up and running daily. NOTE: This position would support three programs within the Industrial Technology Dept 45,000. Annual Goal (Press tab for additional rows.) C. Student Workers/Tutors/Assistant Coaches 1. Cost Annual Goal 2. (Press tab for additional rows.) H D. Professional Experts/Contracts/Others 1. Cost Annual Goal 2. (Press tab for additional rows.) E. Scheduled Overtime/Sub and Relief 1. Cost Annual Goal 2. (Press tab for additional rows.) 9 XI. Additional Equipment and Software Needed to Implement Program Goals List additional/replacement equipment needed for the 2015-2016 academic year. Place all items in priority order. Provide a comprehensive justification based on program goals, student learning outcomes, program data, and external scans. Link the request to an annual program goal in Section VII. Press Ctrl + Click to identify the specific Annual Program Goal addressed. A. Purchases Item and Justification 1. CNC Lathe: current equipment is 15 years old and only machine available for IT 244 & IT 444 2. Vertical mill for machine Cost Annual Goal 75,000.00 15,500. (Press tab for additional rows.) B. Leases Item and Justification Cost Annual Goal 1. 2. (Press tab for additional rows.) C. Maintenance Agreements Item and Justification Cost Annual Goal 1. 2. (Press tab for additional rows.) D. Repairs Item and Justification 1. Recommend budgeting $5000 to cover possible emergency repairs Cost Annual Goal 5,000. 2. (Press tab for additional rows.) 10 E. List additional/updated software needed during 2015-2016—OTHER THAN MICROSOFT OFFICE AND ADOBE CREATIVE SUITE. Place all items in priority order. Provide a comprehensive justification based on program goals, student learning outcomes, program data, and external scans. Link the request to an annual program goal in Section VII. Press Ctrl + Click to identify the specific Annual Program Goal addressed. Item, Number of Licenses, New or Renewal, and Justification Cost Annual Goal 1. 2. 3. 4. ge (Press tab for additional rows.) XII. Supplies Budget Needed to Implement Program Goals Provide a comprehensive justification based on program goals, student learning outcomes, program data, and external scans. Categories of Items and Justification 1. Cost We’ve managed within the Supply Budget provided by the college 5,000. 2. 3. 4. (Press tab for additional rows.) XIII. Facilities A. Describe any new facilities or additional classrooms (leased or built) required to implement program goals. Provide a comprehensive justification based on program goals, student learning outcomes, program data, and external scans. B. Describe any improvements, alterations, and technological upgrades required for existing facilities to implement program goals. Provide a comprehensive justification based on program goals, student learning outcomes, program data, and external scans. 11 XIV. Other Additional Resources Needed to Implement Program Goals Include costs for student transportation related to educational programs, required insurance payments, and organizational memberships. Provide a comprehensive justification based on program goals, student learning outcomes, program data, and external scans. Link the request to an annual program goal in Section VII. Press Ctrl + Click to identify the specific Annual Program Goal addressed. Item and Justification Cost Annual Goal (Press tab for additional rows.) XV. Consolidated Priority Listing From the requests listed in Sections X (except full-time faculty), XI, and XIV, prioritize the items in the order you wish the Resource Advisory Task Force to consider them. 1. Emergency repair budget $5,000 2. CNC Lathe $75,000 3. Vertical mill for machine $15,500 4. Departmental instructional assistant $45,000 5. Full time probationary instructor $50,000 6. Technical supplies $5,000 (Press tab for additional rows.) Additional Comments or Information: Insert additional comments or information here: 12 Pierce College Strategic Master Plan 2014–2017 Return to VII, Annual Goals Return to VIII, Curriculum Return to IX, Long-Range Goals A. Engaging the Completion Agenda A1. Increase student completion of degrees, certificates, and college transfer requirements A1a. A1b. A1c. A1d. A1e. Increase student completion of associate degrees and Certificates of Achievement Increase the number of students who complete transfer requirements for the state universities and University of California Increase the number of Transfer Model Curricula (TMCs) in disciplines offered by the college by 2015 Approve Transfer Model Curriculum in areas of emphasis by 2016 Develop and implement a completion marketing campaign to focus on the importance of obtaining a degree, a certificate, or transfer preparation A2. Increase number of entering students who complete the matriculation process during the first semester A2a. A2b. A2c. A2d. Increase the number of new students completing assessment Increase the number of new students completing orientation Increase the number of new students completing an educational plan Increase the percent of new students who persist to the end of their first year and successfully complete 15 units A3. Increase the long-term persistence rate of students A3a. A3b. A3c. A3d. Increase the percentage of students who complete 30 units in three years Increase the percentage of students who complete 60 units in three years Increase the percentage of students who complete English 101 and Math 125 within three years Increase the percentage of students who complete English 101 and Math 125 within six years A4. Ensure equitable access to education—increase the percentage of eligible students receiving financial aid B. Demonstrating Accountability The first six goals in this category relate to Administrative Services functions and are not necessarily within the purview of Academic Affairs B7. Continue to meet FTES base and attempt to grow the college’s student FTES enrollment to 2006 levels and then 5% per year B7a. B7b. B7c. B7d. B7e Continue to analyze enrollment trends and effective scheduling models Ensure access to essential courses Maintain/increase efficiency Increase the number and the type of evening sessions offered (currently 24% below Fall 2008) Restore an active college marketing campaign to attract students who may have been lost 13 C. Cultivating Partnerships C1. Develop and enhance revenues generated through grants, entrepreneurial ventures, and community partnerships C1a. Expand educational partnerships that bring community events and community members to the campus for educational, cultural, social, and recreational activities C1b. Create an enterprise task force that will consider ways to expand revenue-generating opportunities within future and existing operations including bookstore, facilities rentals, and food services C1c. Develop a self-funding grants program that will increase college revenue C2. Expand productive sustainable community alliances C2a. Create a database of financial and equipment needs that can be shared with potential donors C2b. Pursue financial, material, and collaborative resources through enterprise activities and fundraising to create a sustainable stable source of income C3. Foster partnerships with business and industry C3a. Increase advisory committee participation of local business and industry C3b. Increase number of employers to participate in job fairs C3c. Develop internship programs with business and industry partners to foster community relations D. Ensuring Student Success D1. Address the basic skills needs of underprepared students in developmental and introductory courses D1a. Gather student input about the challenges faced in introductory courses and use this information to inform the development of strategies and solutions D1b. Increase the number of new students successfully completing at least one English class and one math class during their first year D1c. Increase the number of new students who successfully complete their developmental sequence within two years (English 20, 21, 28) (Math 105, 110, 115) D2. Enhance customer service interfaces considering timely responses and quality of experience D3 Maintain a robust and reliable information technology infrastructure with current computing equipment for the entire college population D3a. Establish a wireless network on the campus in areas that are used regularly by faculty, staff, and students D3b. Ensure that existing infrastructure, systems, equipment, and software are maintained to accomplish daily operations in all functional areas of the college D3c. Provide comprehensive training programs for faculty and staff for smart classrooms and conference rooms D3d. Improve customer service responsiveness and satisfaction rates for faculty and staff using the College Maintenance Management System (CMMS) D3e Standardize audio visual equipment in all classrooms to provide uniform experience and training 14 D4 Support faculty and staff by maximizing the effective use of technology, enabling academic innovation in instructional delivery D4a Develop plans to improve course effectiveness by fully integrating innovative tools and delivery methods D4b Increase online class offerings D5 Provide a learner-centered environment that promotes active learning and student engagement D5a D5b D5c D5d Review and revise Student Learning Outcomes (SLOs) and assessment mechanisms Ensure active learning and applied knowledge and skills are examined through authentic assessment Create a professional development focus that emphasizes student active learning and engagement Create programs that promote student and faculty contact outside the classroom D6 Increase student awareness and use of student support services and programs D7 Increase student participation in Associated Student Organization (ASO) activities and shared-governance committees D8 Enhance opportunities for student involvement in cocurricular and extracurricular activities that will enrich campus life