Production and Operations Management: Manufacturing and Services

advertisement

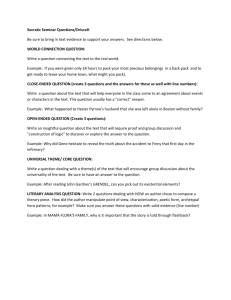

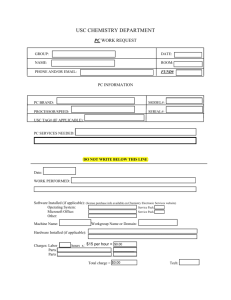

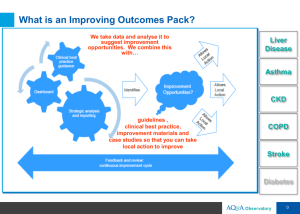

Chapter 11 Strategic Capacity Management Strategic Capacity Planning Defined Capacity Utilization & Best Operating Level Economies & Diseconomies of Scale The Experience Curve Capacity Focus, Flexibility & Planning Determining Capacity Requirements Capacity Utilization & Service Quality Slides used in class may be different from slides in student pack 1 Strategic Capacity Planning Defined Capacity: Strategic capacity planning is an approach for determining the Slides used in class may be different from slides in student pack 2 Capacity Utilization Capacity utilizatio n rate Where Capacity used – rate of output actually achieved Best operating level – capacity for which the process was designed Slides used in class may be different from slides in student pack 3 Best Operating Level Average unit cost of output Underutilization Overutilization Best Operating Level Volume Slides used in class may be different from slides in student pack 4 Example of Capacity Utilization During one week of production, a plant produced 83 units of a product. Its design capacity (best operating level) is 120 units per week. What is this plant’s capacity utilization rate? Answer: Capacity utilization rate = Capacity used Design Capacity = = Slides used in class may be different from slides in student pack 5 Economies & Diseconomies of Scale Economies of Scale and the Experience Curve working Average unit cost of output 100-unit plant 200-unit plant 300-unit plant 400-unit plant Diseconomies of Scale start working Volume Slides used in class may be different from slides in student pack 6 The Experience Curve As plants produce more products, they gain experience in the best production methods and reduce their costs per unit. Cost or price per unit Total accumulated production of units Slides used in class may be different from slides in student pack 7 Capacity Focus The concept of the focused factory holds that production facilities work best Plants Within Plants (PWP) (from Skinner) – Extend focus concept to operating level Slides used in class may be different from slides in student pack 8 Capacity Flexibility Flexible plants - Flexible processes - Flexible workers - Slides used in class may be different from slides in student pack 9 Capacity Planning: Balance Units per month Stage 1 Stage 2 6,000 7,000 Stage 3 5,000 Maintaining System Balance: Output of one stage is the exact input requirements for the next stage Units per month Stage 1 Stage 2 6,000 6,000 Slides used in class may be different from slides in student pack Stage 3 6,000 10 Capacity Planning Frequency of Capacity Additions - External Sources of Capacity - Slides used in class may be different from slides in student pack 11 Determining Capacity Requirements Typical steps: Forecast sales within each individual product line. Calculate equipment and labor requirements to meet the forecasts. Project equipment and labor availability over the planning horizon. Slides used in class may be different from slides in student pack 12 Example of Capacity Requirements A manufacturer produces two lines of mustard, FancyFine and Generic line. Each is sold in small and family-size plastic bottles. The following table shows forecast demand for the next four years. Year: FancyFine Small (000s) Family (000s) Generic Small (000s) Family (000s) 1 2 3 4 50 35 60 50 80 70 100 90 100 80 110 90 120 100 140 110 Slides used in class may be different from slides in student pack 13 Example of Capacity Requirements: The Product from a Capacity Viewpoint Question: Are we really producing two different types of mustards from the standpoint of capacity requirements? Answer: Slides used in class may be different from slides in student pack 14 Example of Capacity Requirements: Equipment and Labor Requirements Year: Small (000s) Family (000s) 1 150 115 2 170 140 3 200 170 4 240 200 Three 100,000 units-per-year machines are available for small-bottle production. Two operators required per machine. Two 120,000 units-per-year machines are available for family-sized-bottle production. Three operators required per machine. Slides used in class may be different from slides in student pack 15 16 Question: What are the Year 1 values for capacity, machine, and labor? Year: 1 2 3 4 Small (000s) 150 170 200 240 Family (000s) 115 140 170 200 Small Family-size Mach. Cap. Mach. Cap. 300,000 240,000 Labor Labor 6 6 Small Percent capacity used Machine requirement Labor requirement Family-size Percent capacity used Machine requirement Labor requirement Slides used in class may be different from slides in student pack 16 Capacity Planning Process Forecast Demand Develop Alternative Plans Quantitative Factors (e.g., Cost) Compute Rated Capacity Evaluate Capacity Plans Qualitative Factors (e.g., Skills) Compute Needed Capacity Select Best Capacity Plan Slides used in class may be different from slides in student pack Implement Best Plan 17 Managing Existing Capacity Demand Management Capacity Management Vary prices Vary promotion Change lead times (e.g., backorders) Offer complementary products Slides used in class may be different from slides in student pack Vary staffing Change equipment & processes Change methods Redesign the product for faster processing 18 Planning Service vs. Manufacturing Capacity Time: Location: Volatility of Demand: Slides used in class may be different from slides in student pack 19 Capacity Utilization & Service Quality Best operating point is near 70% of capacity - From 70% to 100% of service capacity, what do you think happens to service quality? - Slides used in class may be different from slides in student pack 20