Chapter 6 by Miss Anis

advertisement

ERT 210

Process Control & dynamics

CHAPTER 8

Dynamic Response Characteristics of

More Complicated Processes

Miss Anis Atikah binti Ahmad

OUTLINE

1. Poles and Zeros

and Their Effect on

Process Response

6 6

Chapter

Chapter

2. Process with

Time Delays

Dynamic Response

Characteristics

3. Approximation of

Higher-Order

Transfer Functions

4. Interacting and

Noninteracting

Processes

2

5. Multiple-Input,

Multiple-Output

(MIMO) Processes

1. Poles and Zeros and Their Effect on Process Response

• General Representation of standard transfer function form:

- There are two equivalent representations:

6 6

Chapter

Chapter

m

G s

i

b

s

i

i 0

n

i

a

s

i

bm s m bm 1s m 1 ... b0

(4-40)

n

an s an 1s n 1 ... a0

(6-2)

i 0

s zm

G s

an s p1 s p2 s pn

bm s z1 s z2

(6-7)

where {zi} are the “zeros” and {pi} are the “poles”.

3

Poles and Zeros and Their Effect on Process Response

• Consider a particular transfer function;

6 6

Chapter

Chapter

K

, where 0 < 1.

G( s)

2

s( 1s 1)( 2 s 2 2 2 s 1)

The roots of these factors are

s1 0

s2

1

1

1 2

s3

j

2

2

1 2

s4

j

2

2

The values of s

that are the

denominator

polynomial-refer

as poles

(6-1)

Poles and Zeros and Their Effect on Process Response

POLES:

s1 0

s2

1

1

Chapter 6

1 2

s3 j

2

2

1 2

s4 j

2

2

5

Figure 6.1 Poles of G(s) plotted

in the complex s plane.

(X denotes a pole location)

Summary: Effects of Pole and Zero Locations

1. Poles

• Pole in “right half plane (RHP)”: results in unstable system (i.e., unstable

Example

step responses)

Chapter 6 6

Chapter

Imaginary axis

x

x

x = unstable pole

Real axis

(grows with time)

x

• Complex pole: results in oscillatory responses (contains sine and cosine terms)

Imaginary axis

Example

x = complex poles

x

Real axis

x

6

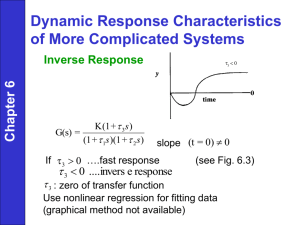

2. Zeros

Note: Zeros have no effect on system stability.

6 6

Chapter

Chapter

• Zero in RHP: results in an inverse response to a step change in

the input

Imaginary axis

x

Real

axis

y

inverse

response

0

t

• Zero in left half plane: may result in “overshoot” during a step

response (see Fig. 6.3).

7

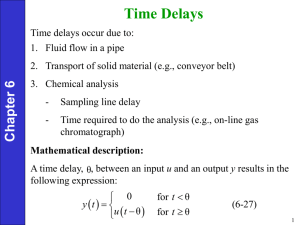

2. Process with Time Delays

Transportation

lag/ transport

delay/ dead time

Chapter 6

θ

Ѳ= Time taken to transport

fluid from point 1 to point 2

Mathematical description:

• A time delay, between an input u and an output y results in the

following expression:

for t θ

0

y t

(6-27)

u t θ for t θ

Transfer Function Representation:

Y s

8

U s

e θs

(6-28)

Chapter 6

2. Process with Time Delays

(cont’)

9

3. Approximation of Higher-Order Transfer

Functions

• Two widely used approximations are:

1. Taylor Series Expansion:

Chapter 6

e

θs

θ 2 s 2 θ3 s 3 θ 4 s 4

1 θs

2!

3!

4!

(6-34)

The approximation is obtained by truncating after only a few

terms.

2. Padé Approximations:

Many are available. For example, the 1/1 approximation is,

e θs

10

θ

1 s

2

θ

1 s

2

(6-35)

3. Approximation of Higher-Order Transfer Functions

(cont’)

• The 2/2 Padé Approximations approximation;

Chapter 6

e θs

θs θ 2 s 2

1

2

12

G2 ( s )

θs θ 2 s 2

1

2

12

(6.37)

Note:

• Please refer page 138 and 139 for more explanations.

11

Example 6.5

Chapter 6

The trickle-bed catalytic reactor shown in Fig. 6.8 utilizes product

recycle to obtain satisfactory operating conditions for temperature

and conversion. Use of a high recycle rate eliminates the need for

mechanical agitation. Concentrations of the single reactant and the

product are measured at a point in the recycle line where the

product stream is removed. A liquid phase first-order reaction is

involved.

Under normal operating conditions, the following assumption may

be made:

1.

2.

3.

4.

12

The reactor operates isothermally so that the reaction rate k is

constant.

All flow rates and the liquid volume V are constant.

No reaction occurs in the piping. The dynamics of the exit and recycle

lines can be approximated as constant time delay θ1 and θ2, as

indicated in the figure. Let c1 denote the reactant concentration at the

measured point.

Because of the high recycle flow rate, mixing in the reactor is

complete.

Example 6.5 (cont’)

6 6

Chapter

Chapter

Question:

'

'

C

(

s

)

/

C

i ( s ).

1. Derive an expression for the transfer function 1

2. Using the following information, calculate ci' (t ) for a step change

'

3

in ci (t ) 2000 kg/m .

Parameter Values:

V = 5 m3

q = 0.05 m3/min

k = 0.04 min-1

13

α = 12

θ1 = 0.9 min

θ2 = 1.1 min

Figure 6.8: Schematic diagram of a trickle-bed reactor with recycle line.

(AT: analyzer transmitter; θ1: time delay associated with material flow

from reactor outlet to the composition analyzer; θ2: time delay associated

with material flow from transmitter to reactor inlet.

6 6

Chapter

Chapter

Solution

(a) Equation 2.66 is applicable only to an isothermal stirred-tank reactor

without recycle. Hence, we make component balance around the

reactor.

(6.39)

dc

V

qci qc2 (1 )qc Vkc

dt

where the concentration of the reactant is denoted by c. Equation 6.39

is linear with constant coefficients. Subtracting the steady-state

equation and substituting deviation variables yields

dc '

V

qci 'qc2 '(1 ) qc 'Vkc'

dt

(6.40)

Additional relations are needed for c2'(t) and c1'(t). They can be

obtained from assumption (iii), which states that the exit and recycle

lines can be modeled as time delays:

(6.41)

c ' (t ) c' (t )

1

14

1

c2 ' (t ) c1 ' (t 2 )

(6.42)

Equations 6-40 through 6.42 provide the process model for the

isothermal reactor with recycle. Taking the Laplace transform of each

equation yields

sVC ' ( s ) qCi ' ( s ) qC2 ' ( s ) (1 )qC ' ( s ) VkC' ( s )

6 6

Chapter

Chapter

C1 ' ( s ) e 1s C ' ( s )

(6.43)

(6.44)

C2 ' ( s ) e 2 s C1 ' ( s )

e (1 2 ) s C ' ( s )

e 3 s C ' ( s )

(6.45)

where θ3 = θ1+ θ2. Substitute (6.45) into (6.43) and solve for the output

C'(s):

C ' (s)

15

sV qe 3 s

q

Ci ' ( s )

(1 )q Vk

(6.46)

Equation 6.46 can be rearranged to the following form:

C ' ( s)

K

Ci ' ( s )

3 s

s 1 K (1 e )

(6.47)

where

q

q Vk

V

q Vk

(6.48)

6 6

Chapter

Chapter

K

(6.49)

Note that, in the limit as 3 0, e s 1 and

3

C ' ( s)

K

Ci ' ( s )

s 1

(6.50)

hence K and can be interpreted as the process gain and time constant,

respectively, of a recycle reactor with no time delay in the recycle line,

which is equivalent to a stirred isothermal reactor with no recycle.

16

The desired transfer function C1'(s)/Ci' (s) is obtained by combining

Eqs. 6-47 and 6-44 to obtain

6 6

Chapter

Chapter

C1 ' ( s )

Ke 1s

Ci ' ( s ) s 1 K (1 e 3 s )

(6.51)

(b) To find c1'(t) when ci'(t) = 2000 kg/m3, we multiply (6.51) by 2000/s

2000 Ke1s

C1 ' ( s )

s[s 1 K (1 e 3s )

(6.52)

and take the Laplace transform. From (6.52), it is clear that the numerator time

delay can be inverted directly; however, there is no transform in Table 3.1 that

contains a time-delay term in the denominator.

• To obtain an analytical solution, the denominator time delay term must be

eliminated by introducing a rational approximation, for example, the 1/1 Padé

approximation in (6.35).

G1 ( s ) G1 ( s )

17

1

1

2

2

s

s

(6.35)

Substituting (6.35) and rearranging yields

2000 K 3 s 1e 1s

2

C1 ' ( s )

s 3 s 2 3 K 3 s 1

2

2

(6.53)

6 6

Chapter

Chapter

This expression can be written in the form

2000 K a s 1e 1s

C1 ' ( s )

s ( 1s 1)( 2 s 1)

(6.54)

where a = θ3/2 and 1 and 2 are obtained by factoring the expression in

brackets. For αKθ3 > 0, 1 and 2 will be real and distinct.

The numerical parameters in (6.53) are:

q

0.05

0.2

q Vk

0.05 (5)(0.04)

V

20 min

q Vk

K

18

Substituting the values in (6.53), we obtain

400s 1e0.9 s

400s 1e0.9 s

C1 ' (s)

2

s 20s (20 1 (24)(0.2)(1)) s 1 s(25s 1)(0.8s 1)

(6.55)

Taking inverse Laplace and introducing the delayed unit step function

S(t - 0.9) gives;

Chapter 6

c1 ' (t ) 400(1 0.99174e (t 0.9) / 25 0.00826e (t 0.9) / 0.8 ) S (t 0.9)

(6.56)

19

Figure 6.9 Recycle reactor composition measured at analyzer:

(a) complete response; (b) detailed view of short-term response.

3. Approximation of Higher-Order Transfer

Functions

6 6

Chapter

Chapter

In this section, we present a general approach for approximating

high-order transfer function models with lower-order models that

have similar dynamic and steady-state characteristics.

In Eq. 6-34 we showed that the transfer function for a time delay

can be expressed as a Taylor series expansion. For small values

of s, after the first-order term provides a suitable approximation:

e θ 0 s 1 θ 0 s

e θs

20

θ 2 s 2 θ3 s 3 θ 4 s 4

1 θs

2!

3!

4!

(6-57)

(6-34)

• An alternative first-order approximation consists of the transfer

function,

6 6

Chapter

Chapter

e

θ 0 s

1

e

θ0 s

1

1 θ0 s

(6-58)

where the time constant has a value of θ0 .

• Equations 6-57 and 6-58 were derived to approximate timedelay terms.

• However, these expressions can also be used to approximate

the pole or zero term on the right-hand side of the equation by

the time-delay term on the left side.

21

Skogestad’s “half rule”

• Skogestad (2002) has proposed a related approximation method

for higher-order models that contain multiple time constants.

6 6

Chapter

Chapter

• He approximates the largest neglected time constant in the

following manner.

• One half of its value is added to the existing time delay (if any)

and the other half is added to the smallest retained time

constant.

• Time constants that are smaller than the “largest neglected time

constant” are approximated as time delays using (6-58).

1

e θ 0 s

e

22

θ0 s

1

1 θ0 s

(6-58)

Example 6.4

Consider a transfer function:

6 6

Chapter

Chapter

G s

K 0.1s 1

5s 1 3s 1 0.5s 1

(6-59)

Derive an approximate first-order-plus-time-delay model,

Keθs

G s

τs 1

using two methods:

(6-60)

(a) The Taylor series expansions of Eqs. 6-57 and 6-58.

(b) Skogestad’s half rule

Compare the normalized responses of G(s) and the approximate

23 models for a unit step input.

Solution

(a) The dominant time constant (5) is retained. Applying

the approximations in (6-57) and (6-58) gives:

0.1s 1 e0.1s

(6-61)

Chapter 6

and

1

e3s

3s 1

1

e0.5 s

0.5s 1

(6-62)

Substitution into (6-59) gives the Taylor series approximation GTS s :

Ke 0.1s e3s e0.5 s Ke 3.6 s

GTS s

5s 1

5s 1

24

(6-63)

(b) To use Skogestad’s method, we note that the largest neglected

time constant in (6-59) has a value of three.

6 6

Chapter

Chapter

• According to his “half rule”, half of this value is added to the

next largest time constant to generate a new time constant

τ 5 0.5(3) 6.5.

• The other half provides a new time delay of 0.5(3) = 1.5.

• The approximation of the RHP zero in (6-61) provides an

(6-61)

additional time delay of 0.1. 0.1s 1 e0.1s

• Approximating the smallest time constant of 0.5 in (6-59) by

(6-58) produces an additional time delay of 0.5.

• Thus the total time delay in (6-60) is,

θ 1.5 0.1 0.5 2.1

G s

25

K 0.1s 1

5s 1 3s 1 0.5s 1

(6-59)

and G(s) can be approximated as:

Ke2.1s

GSk s

6.5s 1

(6-64)

6 6

Chapter

Chapter

The normalized step responses for G(s) and the two approximate models

are shown in Fig. 6.10. Skogestad’s method provides better agreement

with the actual response.

Figure 6.10 Comparison

of the actual and

approximate models for

Example 6.4.

26

Example 6.5

Consider the following transfer function:

6 6

Chapter

Chapter

G s

K 1 s e s

12s 1 3s 1 0.2s 1 0.05s 1

(6-65)

Use Skogestad’s method to derive two approximate models:

(a) A first-order-plus-time-delay model in the form of (6-60)

(b) A second-order-plus-time-delay model in the form:

Keθs

G s

τ1s 1 τ2 s 1

(6-66)

Compare the normalized output responses for G(s) and the

approximate models to a unit step input.

27

Solution

(a) For the first-order-plus-time-delay model, the dominant time

constant (12) is retained.

6 6

Chapter

Chapter

• One-half of the largest neglected time constant (3) is allocated to

the retained time constant and one-half to the approximate time

delay.

• Also, the small time constants (0.2 and 0.05) and the zero (1) are

added to the original time delay.

• Thus the model parameters in (6-60) are:

3.0

θ 1

0.2 0.05 1 3.75

2

3.0

τ 12

13.5

2

28

6 6

Chapter

Chapter

(b) An analogous derivation for the second-order-plus-time-delay

model gives:

0.2

θ 1

0.05 1 2.15

2

τ1 12,

τ 2 3 0.1 3.1

In this case, the half rule is applied to the third largest time

constant (0.2). The normalized step responses of the original and

approximate transfer functions are shown in Fig. 6.11.

Figure 6.11 Comparison

of the actual model and

approximate models for

Example 6.5. The actual

and second-order model

responses are almost

indistinguishable.

29

4. Interacting and Noninteracting Processes

• Consider a process with several invariables and several output

variables. The process is said to be interacting if:

Each input affects more than one output.

6 6

Chapter

Chapter

or

A change in one output affects the other outputs.

Otherwise, the process is called noninteracting.

• As an example, we will consider the two liquid-level storage

systems shown in Figs. 4.3 and 6.13.

• In general, transfer functions for interacting processes are more

complicated than those for noninteracting processes.

30

6 6

Chapter

Chapter

Figure 4.3. A noninteracting system:

two surge tanks in series.

31

Figure 6.13. Two tanks in series whose liquid levels interact.

6 6

Chapter

Chapter

Figure 4.3. A noninteracting system:

two surge tanks in series.

dh1

qi q1

dt

Mass Balance:

A1

Valve Relation:

1

q1 h1

R1

(4-48)

(4-49)

Substituting (4-49) into (4-48) eliminates q1:

32

dh1

1

A1

qi h1

dt

R1

(4-50)

6 6

Chapter

Chapter

Putting (4-49) and (4-50) into deviation variable form gives

dh1

1

A1

qi h1

dt

R1

(4-51)

1

q1 h1

R1

(4-52)

The transfer function relating H1 s to Q1i s is found by

transforming (4-51) and rearranging to obtain

H1 s

R1

K1

Qi s A1R1s 1 τ1s 1

(4-53)

where K1 = R1 and τ1 = A1R1. Similarly, the transfer function

relating Q1 s to H1 s is obtained by transforming (4-52).

33

Q1 s 1

1

H1 s R1 K1

(4-54)

6 6

Chapter

Chapter

The same procedure leads to the corresponding transfer functions

for Tank 2,

H 2 s

R2

K2

(4-55)

Q2 s A2 R2 s 1 τ 2 s 1

Q2 s

1

1

H 2 s R2 K 2

(4-56)

where K2 = R2 and τ2 = A2 R2. Note that the desired transfer

function relating the outflow from Tank 2 to the inflow to Tank 1

can be derived by forming the product of (4-53) through (4-56).

34

Q2 s Q2 s H 2 s Q1 s H1 s

Qi s H 2 s Q1 s H1 s Qi s

(4-57)

Q2 s

1 K 2 1 K1

Qi s K 2 τ 2 s 1 K1 τ1s 1

(4-58)

6 6

Chapter

Chapter

or

which can be simplified to yield

Q2 s

1

Qi s τ1s 1 τ 2 s 1

(4-59)

a second-order transfer function (does unity gain make sense on

physical grounds?). Figure 4.4 is a block diagram showing

information flow for this system.

35

Block Diagram for

Noninteracting Surge Tank

System

Figure 4.4. Input-output model for two liquid surge tanks in series.

36

6 6

Chapter

Chapter

Dynamic Model of An Interacting Process

Figure 6.13. Two tanks in series whose liquid levels interact.

1

q1 h1 h2

R1

(6-70)

The transfer functions for the interacting system are:

37

H 2 s

R2

2 2

Qi s τ s 2ζτs 1

(6-74)

6 6

Chapter

Chapter

Q2 s

1

2 2

Qi s τ s 2ζτs 1

H1 s

K1 τ a s 1

2 2

Qi s τ s 2ζτs 1

(6-72)

where

τ1 τ 2 R2 A1

τ= τ1τ 2 , ζ =

, and τ a = R1R2 A2 / R1 R2

2 τ1τ 2

In Exercise 6.15, the reader can show that ζ > 1 by analyzing the

denominator of (6-71); hence, the transfer function is

overdamped, second order, and has a negative zero.

38

Model Comparison

Noninteracting system

Q2 s

1

Qi s τ1s 1 τ 2 s 1

(4-59)

where τ1

= A1 R1 and τ 2 = A2 R2 .

• Interacting system

Q2 s

1

2 2

Qi s τ s 2ζτs 1

where ζ 1 and τ

= τ1τ 2

• General Conclusions

1. The interacting system has a slower response.

(Example: consider the special case where = 1 2.

2. Which two-tank system provides the best damping

of inlet flow disturbances?

39

5. Multiple-Input, Multiple-Output

(MIMO) Processes

6 6

Chapter

Chapter

• Most industrial process control applications involved a

number of input (manipulated) and output (controlled)

variables.

• These applications often are referred to as multiple-input/

multiple-output (MIMO) systems to distinguish them

from the simpler single-input/single-output (SISO)

systems that have been emphasized so far.

• Modeling MIMO processes is no different conceptually

than modeling SISO processes.

40

• For example, consider the system illustrated in Fig. 6.14.

• Here the level h in the stirred tank and the temperature T are to

be controlled by adjusting the flow rates of the hot and cold

streams wh and wc, respectively.

6 6

Chapter

Chapter

• The temperatures of the inlet streams Th and Tc represent

potential disturbance variables.

• Note that the outlet flow rate w is maintained constant and the

liquid properties are assumed to be constant in the following

derivation.

(6-88)

41

6 6

Chapter

Chapter

Figure 6.14. A multi-input, multi-output thermal mixing process.

42

6 6

Chapter

Chapter

Figure 6.15. Block

diagram of the MIMO

thermal mixing system

with variable level.

43

6 6

Chapter

Chapter

THANK YOU

44