What is good design

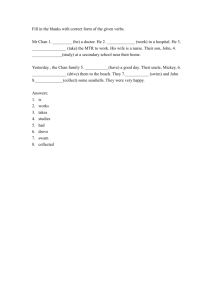

advertisement