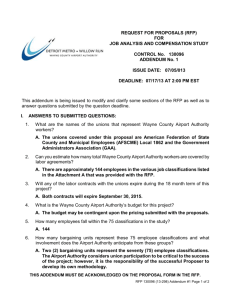

756-2013_Addendum_1_Form_P(R1)

advertisement