Electrical Problems May Have Sparked Swiss Air Flight 111 Crash

advertisement

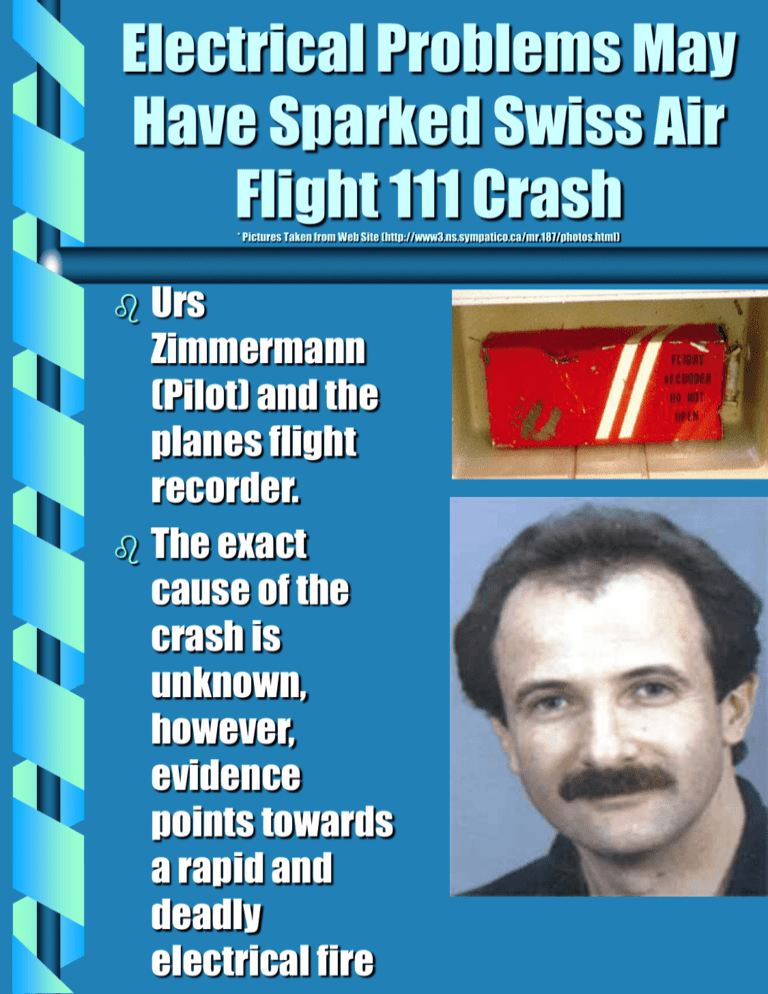

Electrical Problems May Have Sparked Swiss Air Flight 111 Crash * Pictures Taken from Web Site (http://www3.ns.sympatico.ca/mr.187/photos.html) Urs Zimmermann (Pilot) and the planes flight recorder. The exact cause of the crash is unknown, however, evidence points towards a rapid and deadly electrical fire Rapid Fire * Pictures Taken from Web Site (http://www3.ns.sympatico.ca/mr.187/photos.html) According to record Zimmerman noticed smoke at approximately 10,000m and 16 minutes later, the plane slammed into the Atlantic Ocean off Peggys Cove, N.S. Canada. • According to Susan Bradley, a spokeswoman for Boeing, Kapton was the primary coating on the wiring in Swissair Flight 111 (Maclean’s Sept 21, 1998 v111 n38 p20(1)) How Safe is Kapton Wiring Picture taken from web site (www.ece.msstate.edu/hvl/research.html) Patrick Price (Expert with the former Boeing Co. in Seattle) on Kapton wiring • “It’s like taking an incendiary bomb on board” (Maclean’s, Sept 21, 1998 v111 n38 p20(1)) In 1982 the U.S. navy stopped using Kapton wiring in jet fighters when cracks in wires coated with Kapton were linked to on-board fires. (Maclean’s, Sept 21, 1998 v111n38 p20(1)) Scientists have found Kapton is prone to rare but catastrophic “arc tracking” when the wire is subjected to chafing, vibration, and moisture. U.S. News and World Report, Sept 28, 1998 v125 n12 p44(1)) If a wire cracks, electricity can arc to nearby material, setting it on fire. This is known as a flash over which burns at a searing 1,000 C. Deadly Games Swiss Air Flight 111 had approximately 240 km of wires running through it to bring passengers a premium video and gambling system in today’s intensely competitive market for business and first-class flyers. Each seat aboard Swiss Air Flight 111 had a video screen that pops out of the armrest like a tray table. Passengers could play video games, music, or even gamble. • It was this luxury which could have lead to the crash. The system costs about 2 million or more dollars per plane and was developed by Interactive Flight TechnologiesTM. A struggling company which said it wants out of the in-flight-entertainment business. • This web of wires from each seat to central computers aboard the plane generates a greater possibility for an electrical disaster. (Time, Nov 9, 1998 p58(1)) Advanced Kapton Material is Being Used Today Since 1993 Kapton has been improved by wrapping it in a tough Teflon coating. In an article I found from 1998 FAA officials said that old forms of Kapton may soon be removed from hundreds of planes. Boeing company spokesman John Thom said that “Kapton was and is certified for use on commercial airplanes” (Maclean’s, Sept 21, 1998 v111 n38 p20(1)) Some Pictures from the aftermath Picture taken from web site (http://www3.ns.sympatico.ca/mr.187/photos.html) At left is one of the most recognizable photos from the tragedy as rescuers try in vain to find survivors. Pictured at right is the Emergency Service Paying tribute to Flight 111 Fire Prevention in Planes Picture taken from web page (http://www.airliners.net/open.file?id=13250) The Federal Aviation Administration or FAA announced in October of 1998 that Mylar insulation used in nearly 12,000 passenger jets must be replaced to reduced the chance of fire. (U.S. News and World Report, Oct 26, 1998 p17(1)) • It is believed that this type of insulation was set ablaze by a short circuit in the electrical equipment aboard the Swiss Air Flight 111 Luxury is not always better Picture from web site (http://www.tsb.gc.ca/ENG/TSB_Investigations/Swissair/) The high tech video system aboard Flight 111 used Microsoft Windows NT software, with wires connected to a central computer. (Time, Nov 9,1998 p58(1)) • Investigators found that the wires had been connected to the same electrical pathways that powered vital parts of the aircraft. – Therefore, if there is a problem with the video system, then there is a problem with the whole plane. In the future this type of video system should be connected to a separate area of the plane where vital networks in the plane will not be affected thus buying time for an emergency landing. Firefighting Training for Pilots and Prevention Web site (http.www.tsb.gc.ca/EN/TSB_Investigations/Swissair/site_pages/saf…/FireRecs_2000dec4.ht) The investigation into Swiss Air Flight 111 revealed safety deficiencies in crew training and awareness, and procedures related to in-flight firefighting. • The TBS safety board issued the following recommendations to address safety deficiencies – A lack of a coordinated and comprehensive approach to in-flight firefighting. – Smoke/fire detection and suppression systems are insufficient – There are no smoke/fire detection and suppression systems in the cockpit or cabin or any area not considered a fire zone. – The importance of making prompt preparations for a possible emergency landing is currently not recognized. – This is due to company policy and the feeling that it is an inconvenience. – Access to critical areas within the aircraft are inadequate. – There has been little or no training provided to aircraft crew on how to access areas behind electrical or other panels Material For Fire Prevention Halon (Washington Monthly, Sep 1997 v29 n9 p44(2)) • Pressurized bottles of Halon – a highly effective fire fighting agent – have long been used in the cargo holds of larger jets but is not used in smaller planes – Brings us to the fact that in general the larger the vehicle the safer it usually is due to greater regulations. A Plastic Called PHA (Discover, August 1999 v20 i8 p11) • PHA is a plastic which only emits water vapor when it burns, and it brakes down into a flame-resistant compound. There is also the possibility of Flame Retardant Material (Class Notes) • Chlorine and Fluorine when added to material help in fire resistance. – Trade off would be the hazardous smoke this type of compound produces when it does burn. – Flash overs due to electricity arcing burn at a searing 1,000 C. Crash Statistics Larger The Vehicle the Safer Some airline safety facts (Web Site (http://www.air- transport.org/public/speeches/view1997.asp?UniqueID=38)) • You are more likely to die by being kicked to death by a donkey than in a plane crash • You are more likely to be crushed by a falling object • You are much more likely to be killed by your spouse You have one chance in about 7 million from dying in an plane crash Average Time To React To A Fire (http://www.nifc.gov/gallery/manter.html) The average time between when an in-flight fire is detected and when the aircraft either ditches, conducts a forced landing, or crashes is about 17 minutes. (http://www.tsb.gc.ca/ENG/TSB_Investigations/Swissair/site_pages/saf…/FireRecs_2000dec4.ht) • Some examples Type Date Minutes AN-12 B-707 B-747 MD-11 1967 1973 1987 1998 <10 ~7 19 20 Increase Your Chances Handy Hints For The Nervous Traveler (http://www.amigoingdown.com) • 70% of incidences in recent year occur on take-off or landing – Try to book non-stop flights • Take note of where the nearest emergency exit is • Choose a large aircraft – The larger the vehicle the better your chances Does Fate Alone Decide Who Survives Most Likely No 71% of the people who die in crashes die after the plane comes to a compete stop. You can increase your chances by knowning your surroundings (People Weekly, Oct 20, 1997 v48 n16 p125(3)) • How many isles to the exit • In case of fire if you can hold your breath for 30 seconds that’s how long it takes to exit the aircraft normally. • Don’t try and get your duffel bag in case of a crash • Pay attention to the safety procedures (life vests) Where To Sit (http://www.aircrash.org/burnelli/) If you’re worried about impact (People Weekly, Oct 20, 1997 v48 n16 p125(3)) • Sit in the back If you’re worried about a fuel fire • Sit forward of the leading edge of the wing If your worried about the plane breaking up • Sit by the over-wing exits – This is the strongest part of the aircraft due to the fuel being carried in the wings Improved Electrical Apparatus Insulation Material One way to improve Wiring in planes is to use an improved insulation material • Currently many electrical wires use porcelain and glass insulators • An ethylene and vinyl acetate copolymer (EVA) tested better in the lab these forms of insulation (Polymer Engineering and Science:Jul. 1996, V.S. Ivanov, I.I. Migunova, N.A. Kalinina, G.N. Aleksandrov) – As discussed in class copolymers usually increase a materials ability to withstand an impact – Copolymers would help in wires that would be subjected to rough conditions – Kapton currently has problems under rough conditions Radiation-Induced Current (ChemAbsStudent, “Studies on radiation-induced current in polymeric insulating materials and their fine sturcture”, J. Master. Sci 17 no 10 (1982):3052-6) Degradation in crystalline materials such as Polyethylene Degradation in non-crystalline materials such as ethylenepropylene rubber used for wire insulation • For radiation-induced current degradation is affected more by the degree of crystallinity than its perfection. Method For Improving The Environmental Stress-Crack Resistance or (ESCR) (J. Appl. Poym. Sci. 16, no 9 (1972): 2375-86) (ESCR) is a critical factor in wire insulation • In studying the effect of rubber on (ESCR) the choice of a base resin is important – Depending on the resin and rubber combination you choose the (ESCR) can double or increase by 50-fold. – Kapton could be improved with slight variations in its production and perhaps different types of resins should be looked at • For example – The higher the molecular weight of Polyisobutylenes the more effective its performance as a stress crack additive Polymers – Good Insulators Polymers are good insulators because they are covalently bonded and their electrons are all tightly bound. Polymers – Conductors!? Doping of polymers with strong electron acceptors such as iodine can cause polymers to conduct nearly as well as metals. Doping to polyacetylene causes it’s conductivity to be 1010 times higher than pure polyacetalylene. Polymers - Good Conductors!? This flexible electronic circuit functions even when it’s bent. http://focus.aps.org/v6/st18.ht ml Uses of KAPTON Properties Maintains its mechanical stability at very high and very low temperatures resists high mechanical stress during assembly operations has excellent electrical insulation and thermal properties has outstanding resistance to most chemicals, lubricants and fuels allows space and weight savings Uses of KAPTON Electronics In electronic equipment, KAPTON is used as substrate material for Flexible Printed Circuits and punched, bonded or formed high performance part in small miniature switches. It can be etched in alkaline solns. Bar Code Labels Heat Sinks, to ensure optimal heat transfer between film and power transistors Masking tapes Uses of KAPTON Bondable Application Can be bonded, coated or laminated to allow the following requirements • • • • • Belts Thermal insulator in irons Fuel sensors Smoke hoods Blood bags Uses of KAPTON Electronic Insulation Wire and cable insulation formed coil insulation of traction motors Magnet wire insulation transformer and capacitor insulation Uses of KAPTON Automotive Alternator heat sink insulator pads Air bag (diaphragm) Flexible circuits Spark plug boot Uses of KAPTON Aerospace Cockpit sun shade Speakers Flexible Curcuitry Acoustic insulation Thermal blankets Uses of KAPTON Thermal Management Heat sink Power supplies Heater circuits Copier belts Carrier belts Coil insulation Thermal Degradation – Experimental Methods Thermogravimetry(TG)- measures loss in weight Differential scanning calorimetry(DSC) Differential thermal analysisheat absorption or evolution due to either physical or chemical changes occurring within the polymer is measured Thermal Degradation Reactions Depolymerisation Reactions • Characterized by the breaking of the main polymer chain backbone so that at any intermediate stage the products are similar to the parent material in the sense that the monomer units are still distinguishable. The ultimate product may be monomer. Thermal Degradation Reactions Substituent Reactions • It is the substituents attached to the backbone of the polymer molecules which are involved so that the chemical nature of the repeat unit is changed although the chain structure may remain intact. • See reaction example, page 24 Radical Depolymerisation Reaction Degradation Reaction example • Poly(metyl methacrylate) • Between 300-400 oC, see example Oxidation of Polymers Degradation of polymers usually increases in the presence of oxygen R· + O2 ROO· ROO· + RH ROOH + R· Termination • 2R· R-R • R· + ROO· ROOR • 2ROO· ROOR + O2 Photo-degradation Wavelengths of light from sun range from infrared (>700nm) to the visible spectrum (400-700nm) to ultra-violet (<400nm). Energy of 700nm photon is 170 kJ/mol and energy of 300nm photon is 390 kJ/mol Strength of C-C and C-H bond are 420 and 340 kJ/mol respectively It is clear that the energies of the UV and possibly the visible components of sunlight are sufficient to break chemical bonds Insulation Requirements for Wires Requirements for Machinetool Wires and Cables Who Sets the Standards? Requirements specified in the National Electrical Code (ANSI/NFPA 70) Also used in the National Fir Protection Association Electrical Standard for Industrial Machinery (ANSI/NFPA 79) How Are the Standards Set? The polymer insulation and the finished wires must comply with a flame test and are for use at temperatures of 90 °C (194 °F) or lower in dry locations Must comply at 60 °C (140 °F) or lower where exposed to moisture, oil, or coolants Insulation Requirements for Wires Requirements for Machinetool Wires and Cables Who Sets the Standards? Requirements specified in the National Electrical Code (ANSI/NFPA 70) Also used in the National Fir Protection Association Electrical Standard for Industrial Machinery (ANSI/NFPA 79) How Are the Standards Set? The polymer insulation and the finished wires must comply with a flame test and are for use at temperatures of 90 °C (194 °F) or lower in dry locations Must comply at 60 °C (140 °F) or lower where exposed to moisture, oil, or coolants How Are the Standards Set? The polymer insulation and the finished wires must comply with a flame test and are for use at temperatures of 90 °C (194 °F) or lower in dry locations Must comply at 60 °C (140 °F) or lower where exposed to moisture, oil, or coolants NEC construction A (Nylon jacket not used) NEC construction B Minimum average Minimum thickness Minimum average Minimum thickness Minimum thickness thickness of the of any point of the thickness of the of any point of the of any point of Conduct insulation insulation insulation insulation nylon jacket mm Mils mm Mils mm Mils mm Mils mm ora size Mils 22 - 7; 20 - 30 0.76 27 0.69 0.38 13 0.33 4 0.1 12 AWG 15 10-Nov 30 0.76 27 0.69 20 0.51 18 0.46 4 0.1 9, 8 45 1.14 40 1.02 30 0.76 27 0.69 5 0.13 7, 6 60 1.52 54 1.37 30 0.76 27 0.69 5 0.13 5, 4 - 2 60 1.52 54 1.37 40 1.02 36 0.91 6 0.15 1/4/2000 80 2.03 72 1.83 50 1.27 45 1.14 7 0.18 213 - 500 95 2.41 86 2.18 60 1.52 54 1.37 8 0.2 kcmil 501 110 2.79 99 2.51 70 1.78 63 1.6 9 0.23 1000 a A conductor is appropriate for use with a cross-sectional area that does not correspond to one of the AWG or kcmil sizes in Table when the finished wire or cable complies with the marking requirement in and with each of the following: a) The conductor shall have a dc resistance that is not larger than the resistance determined by interpolation(by crosssectional area) between the resistances of the next larger and smaller sizes shown inthe applicable Table or . b) The number of strands, the thicknesses of insulation, the thickness of any nylon jacket, and other particulars shallcomply with the requirements applicable to the next smaller size shown in Table . Aircraft Crashes Due to Failure in Wires Short examples of Kapton related crashed in aircraft and what is being done to prevent any further mishaps August 19,1980 Saudi Arabian Airlines Tri-star After take off from Riyadh Airport a fire broke out in the rear cargo compartment. Plane returned to Riyadh as flames broke through the cabin floor and filled the cabin with smoke Upon investigation Kapton wires were found burnt out, and the insulation destroyed Also the wires had fractured ends , a sign of arcing, no other source for ignition could be found January 14, 1985 British Monarch Airline Boeing 757 On a flight from the Canary Islands to Luton the aircraft has a serious wire bundle explosion As smoke begins to enter the cabin the pilot is able to make a forced landing in Portugal An investigation showed that moister dripped onto the wiring below the lavatory and wet arc tracking occurred causing the bundle explosion November 5, 1990 Philippine Airlines Boeing 737 Plane is being delayed for take off when explosion occurs The explosion was in the fuel tank After investigation the most probable cause was determined to be a spark from a faulty wire creating an explosion March 17, 1991 Delta Airlines Lockheed Tristar Plane is on way to Atlanta from Frankfurt when a fire breaks out Aircraft makes an emergency landing in Goose Bay Upon an investigation the most probable cause of the fire was electrical arcing in the wire bundle Some Action Being Taken Following a Valujet crash in Florida in 1998 Al Gore has headed a special commissin to determine the ageing effects on airplane wiring Other countries plan on doing the similar thing However, the tests will be nonintrusive