Bakery Technology final part

CAKE

cake is richest and sweetest bakery product

Classification of cake

1.

Batter

shorten type cake

contain high shortening by creaming (corporate air in batter)

uniform distribution of air cell

ex. fruit cake

2. Foam

contain no shortening

leavening by whipping white egg to incoperate fine air cell in foam

ex. sponge cake, angel food cake

3. Chiffon

combination of batter and foam

no shortening but add vegetable oil instead

Ingredients

1.

Toughener

- cake flour : soft wheat flour, weak gluten (7-9%)

- egg : provide structure of cake, moisture, flavour, color, nutritive value

: trap air cells to delicate structure (white egg foam)

2. Tenderizers

softener

sugar : provide tenderness+sweetness+color

: soften protein gluten

: absorb moisture

syrup : provide elasticity

shortening : trap air in moisture

: provide tenderness, flavour and color

chemical leavening agent : provide tenderness

Three actions occurred in cake

1. gas production from chemical leavening agent

2. Expansion of air

3. Evaporation of moisture during baking

3. Moistener (milk, syrup, liquid sugar, egg)

provide moistness

dissolve sugar

form gluten

react with baking powder

4. Flavorer

flavoring agents and spices

from natural

5. Dryer

absorbs moisture

flour milk, powder, cocoa powder

Baking soda (NaHCO3)

reduce soap flavor

it produces at least 12% CO2

type of baking powder

1.

Fast acting powder : release most CO2 at room temp.

2. Slow acting powder

3. Double acting powder

CAKE MAKING

1.

cake preparation

2.

Mining

purpose : to combine all ingredient and to form and incorporate air cell

mixing method ;

2.1 creaming method : use with pound cake/high volume cake

2.2 blend method : for high ratio cake (sugar > 100%)

2.3 sugar-water method

2.4 single-stage method : blend all ingredient at high speed 1 min.

Over mixing

create heat : break down foam —> loss of entrapped air from batter

when bake —> cake will be too tender and tends to crumble easily

Egg-foam cakes

- low shortening or no shortening)

use sponge method ; 2 basic steps

1.

whip eggs and sugar to thick foam

2.

sift flour and fold in egg foam

Angle food method

- not contain fat in recipe

base on white egg foam

overwhipped egg will not expand during baking

Chiffon

leaven by egg foam

contain baking powder in recipe

batter+foam = chiffon

Factors affecting stability of egg foam

1.

Quality of egg : high amount of thick egg white

2.

Protein concentration

3.

pH : add cream of tartar to reduce pH

4.

Egg temperature : cold egg is not beaten well

5.

Suger : dissolve sugar in egg white to help increase viscosity and stabilize egg foam

3. Pan preparation

1.

for high-fat cakes : grease pan and lightly dust

2.

for sheet cakes : line pan with grease parchment

3.

for angel food cake + chiffon cake : use tube pan and no grease them

4.

for sponge cake : layer with little/no fat, grease of bottom

4. Baking

not open oven during early stage baking to allow cake rise rapidly

temperature : too hot temperature—> lumpy, low volume

too low temperature —> low volume, poor crumb and cake fall

time (vary with type of cake)

: short time —> ex. layer cake (15-20 min)

: long time —> ex. pound cake (1 hr)

: depend on size of pan and cake concentration ex. sponge cake

Changes during baking cake

1.

cell structure

at beginning, batter rheology change helps reduce solubility and viscosity making air cell expand

at higher temperature, water evaporate and expansion

at elevated temp, baking powder react with acid and water to produce CO2 making increase cake volume

2. Protein denaturation

batter become less soluble and loss of flexibility

protein between space of air denature and stiffen the cell

gluten protein from flour and egg protein coagulate to form structure of cake crumb

3. Starch gelatinization

-

Starch pulls water from protein denaturation to use in gelatinization to help

4. Crust formation and after development

crust form slowly as moisture at the top evaporate and leave the cake surface

-

Chemical browning reaction occurred from reaction of sugar and amino acid

-

Intermediates from Miallard reaction react and produce compounds contributing flavour and color development

Test doneness;

cake is springy and centre springs back when lightly pressed

shortened cake will shrink from pan side

wood stick come out clean after inserting into cake

5. Cooling

cooling pan before removing out 15 mins.

Balancing cake formula

1.

pound cake ; equal amount of fats, sugar, egg, and flour

2.

high-ratio cake : cake that contain sugar more than flour

3.

sponge cake : more flour added which other ingredients should increase too

Adjusting basic formula

if liquid high = lower shortening

if egg high = higher shortening

if cocoa powder high = water 75-100% weight of cocoa higher

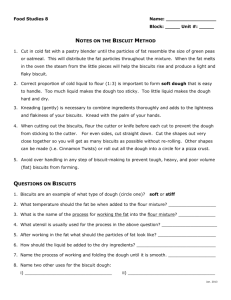

Cookies, biscuits and cracker

Cookies originated from Dutch refer to small cake or sweet biscuit. Cookies are the smallest bakery products, usually in flatted sweet pieces.

Cookies dough ranges from soft to very stiff consistency and may come in many shapes forms and texture.

Classification of cookies

1. According to ingredients

2. According to mixing method

3. According to the dough is shaped

Classification based on ingredients

Butter (soft and hard)

Soft – the highest amount of liquid

Hard – lower liquid content

Foam ( meringue shell, macaroon, and sponge)

Meringue shell- white eggs are whipped with sugar to smooth dry foam.

Macaroon – almond paste, sugar and white eggs.

Sponge cookies – similar to sponge cakes.

Classification according to the way the dough is shaped

Drop cookies made from soft dough containing high liquid.

Rolled cookies made from stiff dough with higher fat content and lower sugar than drop cookies.

Pressed cookies or bagged cookies have highest ratio formula (high fat and sugar)

Brownies bar and square cookies moist and chew bar outside but slightly underdone inside.

Ingredients in cookies

Tenderizers – sugar, syrup, egg yolk, baking soda

Tougheners - flour, eggs, milk, acid from baking soda

Flour

Soft wheat flour from long patent flour, 9-10% protein content.

Egg

Egg yolk gives tenderizer and egg white is usually whipped to a wet peak.

Shortening

Contributes to richness, taste, tenderness, and keeping quality.

Sugar

Fine granulated sugar is used to ease distribution and dissolving in dough. Coarse sugar provides softer texture but gives wider spread cookies.

Liquid

High liquid produces soft dough

Leavening agent

Helps expansion and controlling size of cookies

Baking soda

As source of 𝐶𝑂

2

, soften gluten and produce undesirable flavor

Cream of tartar or baking cream

It composes of acid salt and starch to decrease rate of 𝐶𝑂

2

Other ingredients production.

Emulsifier, milk, salt, flavoring and coloring agents

Cookies preparation

1. Mixing

2. Cookies makeup

3. Panning

4. Baking

5. Cooling

Mixing depending on the type of cookies

One stage method : suitable for low moisture content cookies and all ingredients mixed at low speed

Two stage method : blend all except, flour and baking soda

Three stage method : add egg and remaining liquid and fold in flour

Creaming method : do not over mix the cookies dough. If so, gluten will develop and producing too stiff the dough

Blending method : to develop soft gluten

Foam cookies

Similar to sponge cake method

Bagged or piped cookies and drop cookies

Are made from soft dough

Rolled and molded cookies

Rolled made from stiff dough and molded made from soft dough

Icebox or refrigerated cookies

Characterized by crisp with low spreading

Browning and bar

Is baked into long narrow strip or in a square cake pan and cut while it is still warm

Panning

Grease pan evenly with minimum used of grease, drop cookies even size dough and spacing evenly on the pan.

Baking

Used short time and cookies should be removed from the oven soon after they are done.

Baking change in cookies

Crust formation

Leavening action

Structure development

Flavor and color development

Cooling

As cookies cool down, they become harder.

Cookies characteristics

Crispness is caused from very low moisture in the cookies such as low amount of liquid, high sugar, small size, etc.

Softness is opposite of crispness such as high amount of liquid, low sugar and fat, under baked, larger size, etc.

Chewiness is related to moisture, high sugar and liquid content, strong flour, baking temp. and time.

Spread is a ratio of a diameter to thickness of cookies piece.

Factors affecting spread

Sugar – high sugar and coarse granulated will increase spread

Leaving agent – high will increase spread

Creaming – until light, it will increase spread

Temperature – low will increase spread

Liquid – high liquid content will increase

Flour – strong flour decrease spread

Crackers

It is soft wheat products that contain little or no sugar and moderate levels of fat.

There are three kinds of crackers

1. Saltine crackers

2. Chemically leavened

3. Savory crackers

Saltine

Saltine crackers are unique in long fermentation time and light and flaky texture, that made from sponge-dough process.

Dough is gradually sheeted and sheeted dough is laminated or lapped into 8 layers and cut by a rotary cutter and docked with a blunt docker pin in order to secure different layers together. And baked in a tunnel oven at 230 ℃ .

Chemical leavened cracker – they are leavened by chemical leavening agent.

Snack cracker is cut in a more unique shape than the saltine cracker. Texture is heavier.

Flavored or savory crackers

It is added in the dough or on the surface of the laminated sheet or dip included in the pack.

For cheese crackers, dough is fermented. pH drops from yeast fermentation intensifying cheese flavor.

Puff pastry

The origin of puff pastry and Danish pastry is thought to be the Turkish baklava. Baklava is a rich, sweet pastry made of layers of filo pastry filled with chopped nuts and sweetened with syrup or honey.

It is characteristic of the cuisines of the former Ottoman Empire. Filo dough is paper-thin sheets of unleavened flour dough used for making pastries. By adding yeast to the dough, puff pastry becomes

Danish pastry.

It is important to understand all these types of products (puff pastry, croissant, Danish pastry) are made by creating alternating layers of dough and fat by folding and rolling the dough.

Raw materials and recipes

As with most bakery products, there are as many recipes as there are bakers. Therefore the following recipe is just an illustration of a possible – but excellent – recipe for Danish pastry and for puff pastry.

Levels of ingredients may vary slightly due to the richness desired for the finished product. We must also note that the amount of roll-in shortening used in relation to dough is important to the richness of the dough. Some of the standard amounts of roll-in shortening used per kilogram of dough are as follows:

Lean Danish: 12.5 to 17 %i.e. 125 to 170 g per kg of dough)

Medium Danish: 18 - 24 %

Rich Danish: 25 - 35 %

Flour

Quality, like beauty, is in the eye of the beholder. When one looks at a painting, he doesn’t look at the different strokes the artist has put on the canvas or when one listens to a piece of music, he does not listen to the separate notes. No, one enjoys the ensemble of the work. One cannot discuss quality without defining quality for what purpose. This is particularly true for biological materials such as wheat flour. A good quality flour to produce white pan bread is not necessarily good to produce a sugar-snap cookie. Yet to the layman or casual observer all wheat flours look alike.

With regards to the quality of wheat flour not only are there large differences found between bread, cake, pastry, and cookie flours, but differences are also found within each of those types. Taking pastry flour as an example, good quality flour to produce puff pastry is certainly different from that intended to produce croissants or Danish pastry. It is also true that a good quality pastry flour for line

1 in plant A is not necessarily a good quality flour for line 2 in the same plant. Differences in the equipment that make up the line, or even the physical layout of the line, will demand that the flour be different to perform at its optimum. The same would certainly hold for different plants. The variation can be true even if the plants contain the same equipment and have essentially the same layout. The rheological properties of dough are greatly affected by their temperatures. Thus, a plant in a tropical country may need different flour than does the same plant in Scandinavia or northern Canada. It is also true that the relative humidity of the location is important as it controls how much water is lost from the doughs during processing.

Bread flour with protein content of 11,5–12,5% is normally acceptable for the production of pastries.

If the protein content is too high the Danish will be tough to eat. Strong flour can be blended with

30% pastry flour to improve extensibility of dough during laminating.

During lamination, the flour must provide the gluten structure to form a strong dough film that is able to entrap the water vapour as it is formed during baking. Good bread flour with a protein content of

11.5-12.5 % and an ash content of not more than 0.5% will usually produce puff pastries of good volume and with a very flaky texture, Flours with higher ash content often lack extensibility during sheeting and make-up. Higher protein levels tolerate slightly more lamination, but may not produce a better pastry.

Fat

We have to make a distinction between roll-in fat and the fat that is sometimes added to the dough as such.

The roll-in fat can be butter or margarine at a dosage level of as much as 50 % of flour weight. Fat contributes significantly to the flavour and colour. Butter is preferred but cost and limitations with processing temperature range mean margarine is frequently used.

Butter is an excellent roll-in fat. It is functional and contributes a pleasant taste, aroma, and mouthfeel to the pasty. For good performance, however, butter must be processed within the relatively narrow temperature range of 15-20°C. When butter warms to 21 - 22°C or more, it becomes soft and is absorbed by the dough during lamination.

The fat added to the dough improves dough handling properties and the tenderness of the pastry crumb. It can be butter in butter dough or margarine or vegetable shortening in regular pastry dough.

Amount ranges from 8% (lean dough) to 20 % (very rich dough). While the major amount of fat used in puff pastry is the fat “rolled” into the dough (discussed below), a lesser amount (O - 20%, flour basis) is usually added directly to the dough. Dough fat serves to lubricate the gluten structure and facilitates the laminating process. However, good quality pastries can be produced without dough fat.

When butter is used as a roll-in fat, then butter is usually also used as dough fat. However, doughs made with a salted margarine or butter may require a slightly longer mixing time than doughs made with regular shortening since salt retards gluten development.

In many bakery products, fat is layered between sheets of dough, and this is manipulated to make a dough sheet consisting of up to 100 alternating layers of dough and fat. Such roll-in doughs include

Danish pastry, puff pastry, and croissants. The dough is mixed, divided into pieces of about ten kilograms each, and then cooled to 5 – 10°C in a retarder. The cooled dough is rolled out, two to three kilograms of fat is spread over part of the sheet, and the dough is folded over to cover the fat. The

‘‘sandwich’’ is then rolled out and folded; this is repeated several times, often with a retarding step included to keep the dough/fat mass cool.

The primary goal during the roll-in process is to preserve the structure of alternate layers of dough and fat. There are several important factors to consider in selecting the correct shortening or margarine for such a process. Some of them are: solid fat index (SFI) and plasticity of the fat; complete melting point of the fat; consistency (softness) of the dough; retarder temperature; number of folds given the dough before returning it to the retarder; and proofing temperature. Many of these factors are unique to a given product in a particular bakery, and they influence the specification for the roll-in fat which gives the best final product in that bakery.

The dough for Danish pastry contains higher levels of sugar and water than a bread dough, making it quite soft at the usual mixing temperature of around 20°C. After it is mixed (the gluten matrix is fully developed) it is divided and cooled as described above. The cooling and rest time (during which some fermentation occurs) makes the dough cohesive enough to handle, but if it is over-worked or allowed to warm up too much during the roll-in step, it again becomes soft, sticky, and easily torn. The plastic range of the roll-in fat must be rather broad. The consistency of the fat should nearly match that of the dough across the temperature range, which usually includes the temperature of the retarder (on the cool end) to room temperature or above. If the fat is significantly harder than the dough at the cool temperature, then when retarded dough is rolled out, the fat does not spread into a uniform layer between the dough layers, but is likely to tear holes in the dough sheet.

If the fat is softer than the dough at room temperature, then as the dough mass warms up (during rolling and folding) the shortening soaks into the dough, the adjacent dough layers knit together, and the layering effect is lost. The proper plasticity of roll-in fat requires a relatively shallow SFI profile and stabilization in the ß crystal phase. The latter is particularly important. If the shortening has begun to transform to the more solid ß phase, the additional hardness due to ß crystals will cause excessive tearing during roll-in. The melting point of the fat must be higher than the proofing temperature for the Danish. If the proof box temperature is above the fat melting point, the fat layers turn to oil. This allows the dough layers to knit together to some extent during proofing, and the final product is less flaky than desired. As a general rule, the complete melting point should be at least 5°C higher than proof box temperatures.

A standard all-purpose shortening having a complete melting point of about 45°C usually works well in most Danish pastry production lines. This gives a flaky finished product. Some manufacturers use an emulsified shortening containing 3% monoglyceride, but with similar SFI and melting point specifications. This produces a Danish having a somewhat gummier mouthfeel, which is preferred in some parts of the country.

Croissant dough is similar to Danish dough, although it generally contains somewhat less sugar and water, so it is somewhat firmer at the optimum mixed dough temperature of 20°C. As with Danish, the dough pieces are usually retarded before roll-in is begun. The best quality croissants are produced using unsalted butter for roll-in. The amount used varies from 20 to 35% of dough weight; higher levels give a product that has less volume and flakiness, and is often perceived as greasy in the mouth.

The optimum is usually about 25% roll-in fat.

The factors involved in successful processing of croissants are similar to those discussed above for

Danish pastry. Because butter has a steeper SFI curve than all-purpose shortening (it is much harder at retarder temperatures) more care is required to prevent tearing the dough as it is being rolled. The melting point is lower than that of shortening, so proofing temperatures are lower than for Danish.

Puff pastry margarine is an acceptable substitute, although it does not contribute as much flavour as butter. Since puff pastry margarine has a higher melting point, the proofing may be done at a higher temperature (and for shorter times) if time is a factor.

Rolled-in doughs that contain no yeast (puff pastry) depend upon steam generation in the oven for their leavening. Usually margarine (which contains about 17–20% water) is used for the roll-in fat for these doughs. The water is trapped and held in the fat layers in the dough. It evaporates and expands in the oven, giving an expanded structure to the final product. If the fat portion of the margarine is too soft, the water migrates into the dough during the roll-in step, and the leavening action in the oven is decreased. Puff pastry margarine has a higher SFI curve than all-purpose shortening, and it is some-what more brittle during roll-in. In this case a smooth, continuous layer of fat between dough layers is not particularly desirable. The roll-in process is adjusted somewhat to

achieve numerous discrete particles of margarine between the dough layers. These produce somewhat larger voids in the finished product, desirable in a puff pastry.

Whole eggs

Liquid whole eggs not only add liquids to the dough and strength to the baked product, but also contribute to crust colour. Dried whole eggs function as well. Puff pastries prepared with 10% (flour basis) liquid whole eggs develop a better crust colour and require a slightly lower baking temperature than the same products containing no eggs. The egg protein participates in the browning (Maillard) reaction that produces the attractive golden-brown crust colour. The crust colour also helps to mask the greying effect caused by fat crystallization (fat bloom) as the pasty ages.

If higher levels of sugar and shortening are used, the eggs should also be used at higher levels to carry their weight. Eggs are primarily used for structural strength in Danish and may be fortified with whites for added strength or yolks for added tenderness.

Sugar

In this application, sugar comprises granulated sugar (sucrose) and high-fructose corn syrup (HFCS).

Dextrose (glucose) may be used at levels not exceeding 10% of the flour weight. Higher levels of dextrose crystallise as monohydrates, causing the product to become dry and crumbly. However, sucrose and HFCS may be used interchangeably as long as adjustments are made for the 29% moisture content in HFCS.

Sugar affects the dough water absorption. Rich doughs (high sugar content) tend to absorb less water than lean doughs, but they also slow down yeast activity. To off-set this effect, the yeast is normally increased as more sugar is added to the dough. Generally, the amount of compressed yeast added to sweet doughs is about one-third the amount of sugar solids in the formula.

Processing

The puffing action in puff pastries involves neither a chemical leavening agent, nor microbiological fermentation as occurs in yeast-raised bread doughs. The puffing depends solely on the significant increase in volume when moisture, turning into steam, becomes trapped between dough layers separated by thin films of fat resulting from the laminating process.

The ability of the “roll-in-fat” to keep dough layers separated primarily determines the quality of puff pastry. During the laminating process, dough layers are reduced to an average thickness of about

0.015 mm. At this thickness, the gluten structure in the dough assumes a 2 dimensional orientation, as compared to the 3 dimensional cell structure in most other doughs and batters. The two dimensional orientation of the gluten structure resembles that of a film and is able to entrap steam during the baking process. This process finally produces the flaky structure in the pastry during the baking process.

Danish pastry on the other hand is a combination of puffing action and fermentation. The processing is composed of the following steps:

1.

dough mixing

2.

dividing the dough in dough pieces or sheets in the case of automated lamination

3.

lamination

4.

make-up

5.

fillng and/or decoration: can happen before or after proofing

6.

proofing in case of croissant or Danish pastry

7.

topping

8.

baking

9.

cooling

10.

packaging

We will discuss some of these steps in detail.

Dough mixing

The dough ingredients are all combines and mixed in one stage. As there is still further gluten development during the lamination stage, the mixing of the dough should not be overdone. Doughs are usually mixed until the gluten structure is partially developed; full gluten development occurs when the dough is sheeted for laminating.

Depending on the type of make-up used, production facilities may be confronted with a large amount of scrap dough. The scrap into special baked snack items, or they may get incorporated in fresh doughs. Large operations with automated laminating equipment prefer to add their scrap to new doughs near the end of the mixing cycle. Since scraps already contain the full amount of roll-in fat, there is usually no additional puff paste added for this dough portion. Care must also be taken that the scrap dough contains no traces of fillings because remnants of a pasty filling may cause dark spots to form on new pasty during baking. The basic recipes above should be adjusted for fat and sugar according to the amount of scrap used in a fresh dough.

Alternatively the scrap dough can be made in to some kind of sourdough by adding water and leaving the mixture for 24 hours in controlled conditions of temperature. This procedure improves the taste and the shelf life of Danish pastry.

Lamination

There are basically 3 methods to make puff pastry and Danish pastry: French method, Dutch method and the extruder system.

In the case of the French method, the roll-in fat is spread or spotted over 2/3 of the dough which previously has been weighed and sheeted into a rectangular shape. The uncovered portion of the dough sheet is folded over half of the fat covered portion and the other half is then folded over the doubled up dough portion. This results in three layers of dough with two layers of fat sandwiched between them. After 20 – 30 minutes rest in the retarder, the layered dough is sheeted to an uniformed thickness of 1,5 – 2,0 cm. The reduction of the thickness should happen slowly and smoothly by using a roller table and should not happen too abrupt.

The dough rest allows the dough to relax and gives the yeast the opportunity to adapt to its new environment.

The dough piece is then given a 3-fold by folding 1/3rd of the dough over the centre section and then the 3rd section of the dough is folded over the doubled up section. The dough should rest again in a retarder for about 20 – 30 minutes. This process is repeated a number of times in order to create more

layers. The number of folds vary based on the amount of roll-in fat and can be as much as 264 layers for puff pastry. For Danish pastry 48 to 64 layers normally are sufficient.

In a second method, the "Dutch system," (also sometimes called the Scottish method) a higher melt point roll-in shortening is combined in the mixer with a semi mixed dough. This method utilizes the same technology as used for mixing pie doughs. The roll-in fat must be firm and is cut into small cubes measuring about 3 centimetres on each side. These chunks are dispersed in the flour before the liquids are added. After all the ingredients are combined, water and eggs included, they are blended together without significant gluten development. The dough is then allowed to hydrate properly for about 30 minutes before lamination. Then, the dough is sheeted out to the desired sizes, folded, and retarded. From here a manual or semi-automated system is employed for the remaining process.

A third method, the "extruder system," has come about with the use of high speed sheeters. In this system, the roll-in shortening is applied to the dough piece by a shortening extruder. The dough is cut, folded into a threefold or four-fold unit, quarter turned, and sheeted again. The dough is retarded for up to six hours, and then it is returned to the make-up line where it is sheeted and folded again.

From here the dough is retarded for an additional period of time before the makeup process.

Equipment for continuous lamination is available to laminate pastry dough on a continuous basis.

There are essentially two different systems used for incorporation the roll-in fat and two systems for laminating. The products manufactured with this type of equipment are generally intended for wholesale distribution, and their flakiness and size are limited to reduce breakage during shipment.

Since puff pasty doughs become less extensible with increased lamination, most automated laminating lines utilize two reduction (sheeting) and laminating stations positioned in a 90 degree angle to each other to equalize directional stress in the dough.

The roll-in fat is either co-extruded on the inside of a hollow tube of extruded dough or deposited as a continuous layer of fat on top of a continuous layer of dough which is then covered with a second layer of dough. After some sheeting and cross-sheeting the laminated dough is folded in a back-andforth motion on the slowly moving stacking table. The speed of the stacking table conveyor determines how much each layer overlaps the previous layer and the degree of lamination. The dough can be stacked as high as 15 centimetres without causing problems at the reduction station, where a multiple roller system reduces the stacked dough to the desired thickness of about 1,5 centimetre.

Since these rotating rollers move with the dough and the gap between them and the take-away conveyer sections is gradually narrowing from roller to roller, this reduction in dough thickness is rather stress free and allows to obtain products with a regular shape.

Make-up

After retarding the dough for several hours (or even over-night) the dough is ready for make-up. This happens best at a low temperature (± 15°C). It is again important to reduce the thickness of the dough gradually using a sheeter to avoid rupture of the layers. The flakiness can be adversely affected if the dough is reduced too quickly. Once sheeted to the final thickness (2 – 3 mm) there are a number of ways in which the dough can be made up, including crimping, curling, filling, folding, twisting etc. depending on the desired end product.

Fillings

Important is to remember that the water activity of the filling has to studied in function of the type of product, the expected shelf life, stability during baking, packaging etc. Water migration from the filling to the dough has to be considered.

The filling should contain sufficient sugar to avoid that they boil (out) during baking.

Proofing

Proofing is a crucial step in the process. If the dough gets proofed at a too high temperature the rollin fat may melt and bleed out of the product. As the result the puff will be poor. Over-proofing can cause collapse of the product in the oven. Danish should be proofed at 26 - 29°C with a relative humidity of 65 – 70 % for 60 to 75 minutes. They should be proofed to 2 – 2,5 times their original size.

Baking

As for all bakery products, baking time and temperatures are dependent on the type of oven, the size and shape of the product and the type and quantity of the filling.

Danish pastries are usually baked at slightly lower temperatures than equivalent products made from regular sweet doughs. Also, leaner doughs are baked slightly hotter than rich, high sugar doughs. The baking temperature also varies with different oven types. For the same temperature settings, rack and other convection ovens tend to bake hotter than regular gas ovens (reel and travelling tray). Electric deck ovens often bake cooler and require longer baking times.

Danish sweet rolls may be baked at 200 - 210°C in a gas-fired reel oven. Coffee cakes should be baked a little cooler, at 185 - 200°C. Some toppings tend to char easily and require the lower temperatures. The baking times vary not only with the baking temperature, but also with the size of the baked food. A 50 g Danish pastry is usually baked for 15 - 17 minutes at 200°C.

Doughnut

Raw Materials

Ingredients vary depending on whether they are yeast or chemically leavened. Furthermore, homemade doughnuts generally include far few ingredients than mass- produced or those made from mixes. Chemically-raised doughnuts are made with ingredients such as flour, baking powder, salt, liquid, and varying amounts of eggs, milk, sugar, shortening and other flavorings. This type of doughnut uses baking powder in the batter to leaven the dough. Yeast-leavened doughnuts are made with ingredients that include flour, shortening, milk, sugar, salt, water, yeast, eggs or egg whites, and flavorings.

Doughnuts produced in sanitary baking conditions in grocery stores, bakeries, or franchises often come from pre-packaged mixes. These vary but can include: flour (wheat and soy flour), shortening, sugar, egg yolks, milk solids, yeast dough conditioners, gum, and artificial flavors. One franchise adds a yeast brew. Mixes require the bakeries to add fresh wet ingredients such as water, milk, and eggs in the mixing process. Doughnuts also require oil (usually vegetable oil) for frying. Glazes or frostings are often added after the product is fried and are made with flour, sugar, flavoring, and sometimes shortening.

The Manufacturing Process

This process will describe the manufacture of doughnuts in a mechanized doughnut bakery that makes only yeast-raised doughnuts. Because yeast requires time for kneading, time to rest and additional time to rise or proof, it takes at least an hour to take dry pre-packaged mix to completed product.

Acquiring the ingredients

1 Bakeries or franchises that do a brisk business (making hundreds of dozens in a day) acquire mixes in bags, often as large as 50 lb (22.7 kg). Chains have the ingredients shipped to them from company warehouses within the region and the mixes are stored on the premises and used as needed. The bakery must shop for large quantities of perishable fresh ingredients such as eggs and milk and keep them refrigerated.

Measuring the ingredients

2 A batch is referred to by weight of dry ingredients put into the mixture. The weight of the batch varies with doughnut type and amount to be made. The pre-packaged mix is poured from a bag onto a scale and the precise amount measured.

Mixing and kneading

3 The flour mixture is then poured into a large mixing bowl put onto an industrial mixer and the appropriate amount of wet ingredients are added depending on weight of the batch and type of doughnut in production. The wet yeast slurry (for leavening) is mixed separately and carefully added to the flour-water mixture at this time. The dough mixer then begins its work; a large dough hook first mixes and then simulates the human kneading process, pulling and stretching, as it homogenizes the ingredients and develops the dough by forming the gluten into elongated and interlace fibers that form the basic structure of the doughnut. The mix runs on an automatic timer and the entire mixture, including the softened yeast, is kneaded together for approximately 13 minutes.

Resting the yeast

4 It is essential that yeast dough "rests" or simply sits for about 10 minutes after it is mechanically kneaded. As the yeast grows, it converts its food into carbon dioxide (this is called fermentation) and causes the yeast dough to rise. As the dough sits, it allows the gas to develop and the dough starts to rise, indicating the fermentation process of the yeast reacting to sugar in the mix is beginning. If this does not happen, the dough yields flat, tough doughnuts and the mix should be discarded. At the end of this period, a good-quality dough is spongy and soft.

Shaping the doughnuts

5 The dough is then hoisted by hand and loaded into the hopper of a machine called an extruder—a machine that forms the individual doughnuts using a pressure-cutter system. The batch of yeast dough is put into the top of the open machine. A cover is then placed on the machine and the machine is pressurized, forcing the dough into tubes that extrude a predetermined amount of dough into the desired shape—rings for conventional doughnuts and circles for doughnuts that are to be filled with jam or creme. It takes about 15 minutes for the extruder to push out about 30 dozen doughnuts.

An automated doughnut stamper can also be used in conjunction with an extruder. In this case, the dough is extruded in a continuous, unshaped flow through a series of rollers that flatten the dough. Once flattened to 0.5 in (1.27 cm) thickness, the sheet of dough is stamped into doughnut shapes.

Proofing

6 The extruder is attached directly to the proofing box (a warm, oven-like machine), which is a hot-air, temperature-controlled warm box set to approximately 125° F (51.6° C). Here, the thin doughnuts are slowly allowed to rise or proof as the yeast ferments under controlled conditions. Proofing renders the doughnuts light and airy. (Yeast doughs must be allowed to rise slowly and at just the right temperature. If the proofing box is too hot, the yeast bacteria will be killed and the doughnuts will not rise. If too cold, the yeast remains inactive and cannot ferment thus preventing leavening. A machine attached to the extruder pushes the rings or circles onto small shelves that move through the proof box for about 30 minutes. The shelves are chain-driven and move down, up, and over during this 30 minute period. After 30 minutes, they are quite puffy.

Frying

7 Next, the raw doughnuts fall automatically, one row at a time, into the attached open fryer.

It is important to drop just a certain amount of raw doughnuts into the grease at a time. If too many are placed in the fryer at one time, the oil temperature is drastically lowered, fry time is longer, and the doughnuts absorb too much oil. The frying oil is the most expensive ingredient in the production process, and if the doughnuts absorb too much oil, it reduces the profit margin on the batch. As the doughnuts move through the fryer, they are flipped over by a mechanism. After two minutes, the doughnuts have moved completely through the fryer and are forced into the mechanism that applies glaze.

Glazing and drying

8 As the doughnuts leave the fryer, they move under a shower of glaze. Here, glaze is forced through holes from a bridge running several inches above the hot doughnuts. The glaze coats the top, sides, and part of the bottom of the doughnuts. The doughnuts are conveyored out of the production area to dry and cool.

Further finishing and sale

9 Once conveyored to a finishing station, the doughnuts may be sprinkled with candies or nuts or are given a thicker frosting. The disk-like doughnuts (those with no hole) are forced onto a machine that injects two doughnuts at a time with the desired, pre-measured filling. The completed doughnuts are placed on it.

References

The New Professional Chef, Culinary Institute of America, 6th edition [Van Nostrand Reinhold:New York]

1996 (p. 376)

The Sugar Association, Sugar’s functional roles in cooking and food preparation, hand book. (p. 5)

G. Pop. Journal of agroalimentary processes and technologies, researches regarding the chemical leavening agents’ role in quality of bakery products, volume xiii, no.1 (2007), 105-112

Penfield, M., and Campbell, A. Experimental Food Science. 3rd edition. San Diego: Academic Press, Inc.

1990.