P10711 Poster

advertisement

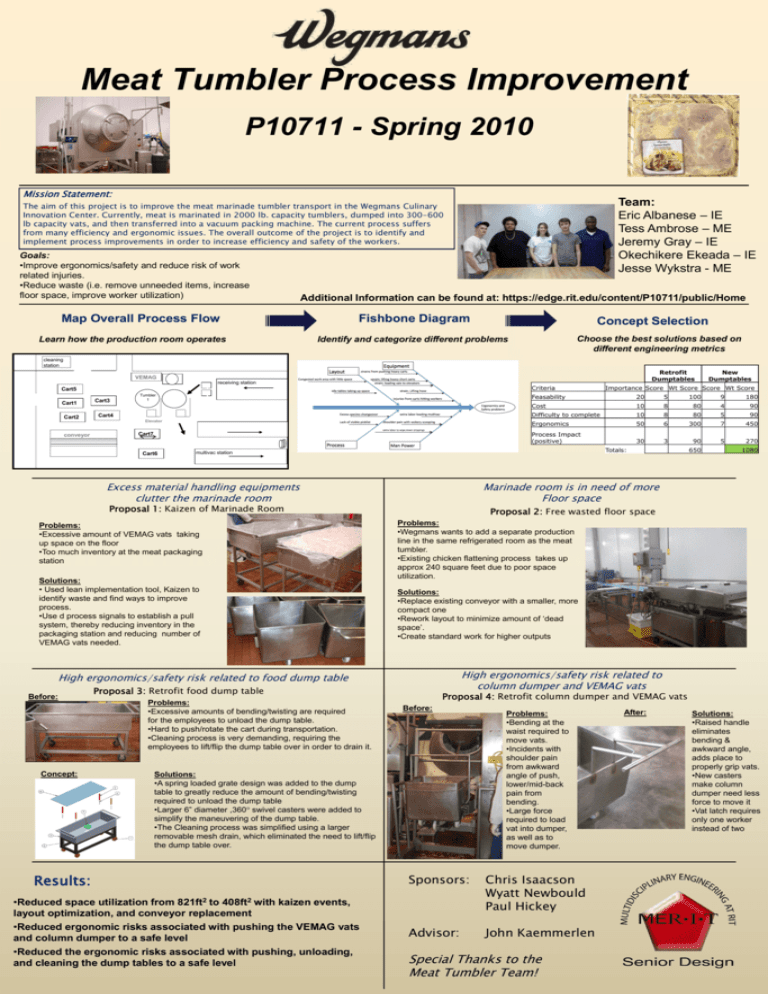

Meat Tumbler Process Improvement P10711 - Spring 2010 Mission Statement: Team: Eric Albanese – IE Tess Ambrose – ME Jeremy Gray – IE Okechikere Ekeada – IE Jesse Wykstra - ME The aim of this project is to improve the meat marinade tumbler transport in the Wegmans Culinary Innovation Center. Currently, meat is marinated in 2000 lb. capacity tumblers, dumped into 300-600 lb capacity vats, and then transferred into a vacuum packing machine. The current process suffers from many efficiency and ergonomic issues. The overall outcome of the project is to identify and implement process improvements in order to increase efficiency and safety of the workers. Goals: •Improve ergonomics/safety and reduce risk of work related injuries. •Reduce waste (i.e. remove unneeded items, increase floor space, improve worker utilization) Additional Information can be found at: https://edge.rit.edu/content/P10711/public/Home Map Overall Process Flow Learn how the production room operates Fishbone Diagram Concept Selection Choose the best solutions based on different engineering metrics Identify and categorize different problems cleaning station Retrofit Dumptables VEMAG receiving station Cart5 Cart1 Cart2 conveyor Cart3 Tumbler 1 V Criteria V Feasability 20 5 100 9 180 Cost 10 8 80 4 90 Difficulty to complete 10 8 80 5 90 Ergonomics 50 6 300 7 450 Process Impact (positive) 30 3 90 5 270 Cart4 Elevator Cart7 Cart6 Solutions: • Used lean implementation tool, Kaizen to identify waste and find ways to improve process. •Use d process signals to establish a pull system, thereby reducing inventory in the packaging station and reducing number of VEMAG vats needed. Concept: Problems: •Wegmans wants to add a separate production line in the same refrigerated room as the meat tumbler. •Existing chicken flattening process takes up approx 240 square feet due to poor space utilization. Solutions: •Replace existing conveyor with a smaller, more compact one •Rework layout to minimize amount of ‘dead space’. •Create standard work for higher outputs High ergonomics/safety risk related to column dumper and VEMAG vats Proposal 3: Retrofit food dump table Proposal 4: Retrofit column dumper and VEMAG vats Before: Solutions: •A spring loaded grate design was added to the dump table to greatly reduce the amount of bending/twisting required to unload the dump table •Larger 6” diameter ,360° swivel casters were added to simplify the maneuvering of the dump table. •The Cleaning process was simplified using a larger removable mesh drain, which eliminated the need to lift/flip the dump table over. Results: •Reduced space utilization from 821ft2 to 408ft2 with kaizen events, layout optimization, and conveyor replacement •Reduced ergonomic risks associated with pushing the VEMAG vats and column dumper to a safe level •Reduced the ergonomic risks associated with pushing, unloading, and cleaning the dump tables to a safe level 1080 Proposal 2: Free wasted floor space High ergonomics/safety risk related to food dump table Problems: •Excessive amounts of bending/twisting are required for the employees to unload the dump table. •Hard to push/rotate the cart during transportation. •Cleaning process is very demanding, requiring the employees to lift/flip the dump table over in order to drain it. 650 Marinade room is in need of more Floor space Proposal 1: Kaizen of Marinade Room Problems: •Excessive amount of VEMAG vats taking up space on the floor •Too much inventory at the meat packaging station Importance Score Wt Score Score Wt Score Totals: multivac station Excess material handling equipments clutter the marinade room Before: New Dumptables Problems: •Bending at the waist required to move vats. •Incidents with shoulder pain from awkward angle of push, lower/mid-back pain from bending. •Large force required to load vat into dumper, as well as to move dumper. Sponsors: Chris Isaacson Wyatt Newbould Paul Hickey Advisor: John Kaemmerlen Special Thanks to the Meat Tumbler Team! After: Solutions: •Raised handle eliminates bending & awkward angle, adds place to properly grip vats. •New casters make column dumper need less force to move it •Vat latch requires only one worker instead of two