PowerPoint-presentasjon

How the Norwegian Service Industry was developed

-Competence and Capacity

Sjur E Bratland

Regional Director, INTSOK, Norway

Willy H Olsen www.intsok.com

The presentation

1. What were the instruments used?

Policies, legislation and external factors

2. The role of people, technology, research and development

3. Where is Norway today?

Willy H Olsen

Legislation approved before oil was found

The Petroleum Law is the foundation

1.

The petroleum resources shall be managed with a long term perspective

2.

The whole society shall benefit from the resources

3.

Resources shall be managed to secure revenues to the country

4.

Oil and gas shall contribute to welfare, employment, improved environment and industrial development

5.

Take care of regional interests

We wanted to develop a oil and gas service industry

Source: The Petroleum Law of 1965 – paragraph 1A

Policies were adapted to national traditions

Sharing of technology and creating a local working environment

• The government worked deliberately to Norwegianize the oil sector

• US and French domination in the first decade

• Labour relations were built on strong trade union influence

• Worked in favour of domestic firms relative to foreign firms

– But did not jeopardize economic efficiency

– Ownership no issue

• Environmental friendly – take care of the resources

• The Ministry monitored the tendering process and bid evaluations

• Norwegian based firm got early access to all tendering information

Willy H Olsen

Using Norway’s competitive advantages

1.

Harsh environment - taking care of the environment

2.

Deep water

3.

Technological challenging

4.

Expensive labor cost

1.

Innovative an risk willingness

2.

Established yards could convert to oil and gas industry

3.

Willing to use the Norwegian continental shelf as a test bench

4.

Deep fjords allowed building of concrete substructures

Source:

Cornerstone in developing the Norwegian Oil industry

Predictability – Risk reducing

BP production mill b/d oe

Source: BP

• Established a competitive and transparent environment

– Concession rounds every year, based on nomination from oil companies

– Ownership not important

– Today 60 active oil companies – many independents

– A lot of the service industry are owned by non

Norwegian companies

• External factors worked in the favour of Norway

– IOCs were looking for new opportunities after the nationalisation

– Quite willing to accept tough terms

• Transfer of knowledge and experience to

Norwegian firms

• Stick and the carrot used

Willy H Olsen

Taxpaying oil workers in every community

More than 1300 companies

• But clusters established

Maritime

R&D

Willy H Olsen

Operators

Drilling

Subsea

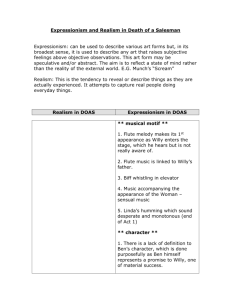

Have to follow EU rules and regulations

No preference to Norwegian firms

• Norway joined the European Economic Area

• Had to introduce EU regulations

• The legislation from 1972 on in-country value had to be scrapped

• Legislation is based on competition as the key principle

– Predictability, transparency, traceability

– Prohibited to discriminate on the basis of nationality and to use standards and specifications to obstruct competition

Infant industry argument no longer applicable

Willy H Olsen

The government stimulated technology partnership

Fiscal incentives and financial support

Willy H Olsen

Universities and

R&D centers

The tax system made fields into laboratories

Testing and verifying new solutions

Troll Oil Kristin Tyrihans Tordis IOR

Tapping a thin oil layer

Drilling systems

Advanced software

High pressure

High temperature

Advanced wells

Record long pipeline heating

Subsea raw seawater injection

Willy H Olsen

Subsea separation boosting and injection system

Government top priority - EOR

Squeeze out the last barrel adds value

Revitalizing and extending the life of the Ekofisk field

The initial plan

• The Ekofisk field, Norway’s first oil field, began production in 1971

• Was hoping for 20% recovery

• ConocoPhillips is now aiming for 50%

• Field life extended to 2050

• Norway’s average recovery factor is now close to 50%

• The government aim is 55%

• Huge R&D program to succeed

• 1%-point increase in recovery represents $35 billion in additional revenues to Norway

Willy H Olsen

Willy H Olsen

Statoil is the dominating player - operating 80% of new projects

The CEO will always be under pressure to add in country value

INTSOK was a new government initiative

Stimulating international growth

Willy H Olsen

180

160

140

120

100

80

60

40

20

0

Total Oil & Gas Expenditure for 2012-2015

Source: INTSOK Annual Market Report - Rystad Energy (2011)

Norwegian Oil & Gas ”World-class” Clusters

Catalogue presenting Norway’s world class capabilities

Minimizing discharges and emissions

Solutions for cleaner production

Capabilities in the Norwegian oil and gas industry for reducing energy consumption and minimizing discharges and emissions

Catalogue presenting industry’s IOR capabilities

Delivering increased oil recovery

Solutions for increased recovery

Capabilities in the

Norwegian oil and gas industry for solutions that can increase oil recovery

Rogaland Training & Education Centre

“- Local skilled workers are the fundament for local content”

Certified provider to the Oil & Gas sector in

Norway and Denmark

Achilles ID # 26088

Regional development

Colleges

Companies

RKK

Samples of content skills training for the Oil &

Gas sector

Training and continuing education for the offshore and mechanical industry:

Subject areas:

RKK

Oil & Gas

Rules & regulations

Health, environment and safety

Economics and management

Petroleum technology

Drilling and well technology

Automation

Electro and electronics

Heating, ventilation and sanitation

Valve technology

Mechanical processes

Pressure testing

Certified provider to the Oil & Gas sector in

Norway and Denmark

Achilles ID # 26088 Hydraulics and pneumatics

Scaffolding and rigging

Surface treatment

Welding and plating

Flanges and gaskets

Isolation and casing

Chemistry and processes

Materials administration

Sub sea technology

Instrumentation

Safety and emergency preparedness

Navigation

Kvaerner Caspian -Vision

Vision

Create a top class Kazakhstani contracting company through technology transfer and training of employees.

Execution of Oil & Gas projects with the maximum possible workload ‘inside’ Kazakhstan

21

• Kvaerner Caspian Group is jointly owned by KGNT and

Kvaerner AS

• This is a true Kazakh company - Shareholding and Board representation are equal

• Initial activities are targeted towards fabrication and engineering

• Kvaerner Caspian aims to be the first full fledged EPC offshore contractor in the Caspian Region

© Kvaerner 2011

10.04.2020

Kvaerner Caspian -Capabilities

• Kvaerner Caspian’s business model is to deliver Offshore EPC

Contracts. This is achieved through the following capabilities:

• Fabrication – Kvaerner Caspian currently building a new offshore module fabrication yard in Aktau.

• Engineering – Kvaerner Caspian have engineering offices in Atyrau and Aktau.

• Training – Kvaerner Caspian is the largest shareholder in the Aktau

Training Centre (ATC) - be closely associated with the Aktau fabrication yard

22

© Kvaerner 2011

10.04.2020

Thank you for your attention

Looking forward to the B2B meetings