storemanagementpresentation - Warrington College of Business

advertisement

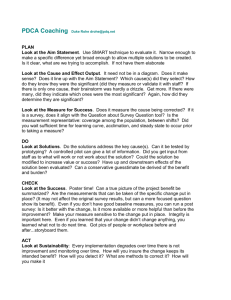

Store Management March 2008 Advance Auto Parts • Aftermarket Automotive Parts and Accessories Retailer • 3200+ Stores in 40 States and Puerto Rico • Projected over $5 Billion in Sales for Fiscal 2008 – Approx $3.9 Billion Retail – Approx $1.1 Billion Commercial Sales • Over 45,000 Team Members • 7 Distribution Centers 2 Store Management Key Area’s of Concentration • • • • • 3 People Process Product Promotion/Presentation P&L Statement (Operating Statement) People • • • • 4 Selection Onboarding Communication/Engagement Training/Development Making The “Right” People Decisions Selection • Needs Assessment – – – – Determine Position or Positions needed Identify Specific Skill Set Required Assess Internal Candidates Identify Recruiting Support for External Candidates • Interviewing – What you can or can not say – Federal Guidelines to be aware of: • HIPPA • ADA • EEOC 5 Making the “Right” People Decision Onboarding: • Most companies put the new employee through a process that resembles “drinking water from a fire hose”. • Every person will assimilate information at their own rate • The first week is one of the most critical times for all new employees – Set Expectations of Employee – Communicate what they should expect of the Company – Create a warm welcoming environment 6 NHOST New Hire Onboard Store Training Validation Project High Levels of Performance New Team Member with Training Standard of Performance $$ Low Time 7 $$ New Team Member without Training NHOST Validation Project At Nine Weeks…. Sales per labor hour • NHOST Team Members averaged $100 sales per labor hour • Non-NHOST Team Members averaged only $80 sales per labor hour Customer Average • NHOST Team Members had an $18 Customer Average • Non-NHOST Team Members had a $16 Customer Average Customer Count • NHOST Team Members averaged 200 transactions • Non-NHOST Team Members averaged 100 transactions 8 Communication “Good Communication leads to better understanding and mutual confidence” Six Steps of Effective Communication 1. 2. 3. 4. 5. 6. 9 Plan it Keep it simple Be Consistent Communicate with urgency Remember WIIFM Be supportive, encourage, thank Communication/Engagement • • • • • Store/Department Team Meetings Management Staff Meetings Communication Centers (Bulletin Boards) Email blast updates 1:1 Meetings – Informational Meetings – Coaching Sessions – Counseling/Disciplinary Meeting • • • • 10 1st sessions should always be corrective & developmental Correct/instruct on process Validate understanding Behavior Change Importance of Monthly Store Sales Meetings • • • • • • • • • Sales Profits Opportunities Upcoming Promotions/Events Team Recognition SPIFs – Team Sales Incentives Show Appreciation - Thank Them! Listen and Ask Questions! An Informed Team is an Engaged 11 Team Communications Timeline Day Week Complete MPT To Do List Update Communications Center Weekly Store Staff Meetings Sales Goals Hot Topics Game Plan Planning Calendar Team Member Schedule Sales Goals 12 Month Store Team Sales Meeting Campaigns / Contests FrontRunner-Quarterly Publication Sales Goals Benefits of Training WIIFM • • • • Better performing Team Members Better Customer Service Better Team Retention Better Sales Training Creates Leverage! You should considerTraining an investment, your return is improved effectiveness, efficiencies and performance! 13 How to Train..... Formula to presenting Training Content: 1. 2. 3. 4. 5. Tell them Show them Watch them do it Let them do it on their own Follow through days later • • 14 If they did it right---give them praise and recognition If they did it wrong---repeat steps 3-5 Training Resources • Retail Academy – Product Information • Product Features and Benefits – On Line Learning Center • New E Learning System in 2008 • Interactive format – In Store Training Programs • Ops Training Class • Leadership Training – Tech Trainers • Automotive Systems Technical Skills Training • Automotive Systems Sales Training – Project Selling (the complete job) – Attachment (related item) Selling) “Would you like fries with your order”? 15 StoreNet Site Map / SOP Site Or use the SOP Hot Key Click here to access the SOP Site 16 Process Management Management Planning and Training (MPT) Store Process Management • • • • 18 Planning Forecasting Work Flow Management Scheduling Mission of MPT To provide Store Management with the proper tools and reporting to manage labor to its maximum yield, not its lowest cost while driving sales. 19 Sweep The Floor Clean the Bathrooms 20 MPT….Driving Sales Drive sales by planning to….. • Have the Right Person – In the Right Place – At the Right Time – Doing the Right Things • You will serve your customers better! • You will increase your sales! 21 Seven Steps to MPT Plan 22 Scheduling to Sell Work Flow Management • Forecast Sales Expectation • Forecast of Payroll Dollars/Percent • Project Peak Selling Periods • Schedule to support Peak Sales Periods • Schedule to complete non-selling task – Planogram updates – Stock Put away – Maintenance 23 Store Manager “What Matters Most” Daily To Do’s – Meeting Week Sunday Monday Tuesday Wednesday Thursday Friday Saturday Review prior day’s sales, payroll and shrink results, complete paperwork and Refund Shelf Audit/Reverse Logistic Process Review prior day’s sales, payroll and shrink results, complete paperwork and Refund Shelf Audit/Reverse Logistic Process Review prior day’s sales, payroll and shrink results, complete paperwork and Refund Shelf Audit/Reverse Logistic Process Review prior day’s sales, payroll and shrink results, complete paperwork and Refund Shelf Audit/Reverse Logistic Process Review prior day’s sales, payroll and shrink results, complete paperwork and Refund Shelf Audit/Reverse Logistic Process Review prior day’s sales, payroll and shrink results, complete paperwork and Refund Shelf Audit/Reverse Logistic Process Review prior day’s sales, payroll and shrink results, complete paperwork and Refund Shelf Audit/Reverse Logistic Process Review/Adjust MPT Plan Actual Review/Adjust MPT Plan Actual Review/Adjust MPT Plan Actual Review/Adjust MPT Plan Actual Review/Adjust MPT Plan Actual Review/Adjust MPT Plan Actual Review/Adjust MPT Plan Actual Complete/review MPT To Do List Complete/review MPT To Do List Complete/review MPT To Do List Complete/review MPT To Do List Complete/review MPT To Do List Complete/review MPT To Do List Complete/review MPT To Do List Update communication board and post productivity report Update communication board and post productivity report Update communication board and post productivity report Update communication board and post productivity report Update communication board and post productivity report Update communication board and post productivity report Update communication board and post productivity report Complete price changes before 9:00AM and verify execution using Storenet Price Change List Review planning calendar on Storenet (Print/Post) Print , deliver and collect weekly account statements Process Negative On Hands from Store Net Print and post Gameplan/“Hot Issues” Price Changes take place after 6:00PM Complete/submit MPT Forecast and schedule by COB Review prior week’s results and prepare for DM call Ensure all Cycle Counts, the 5 Walk Outage Process and Planograms for the week are completed Store Manager Attends DM/SM Meeting Ad Prep / POP signs every 4th or 5th week per calendar Finalize and transmit payroll Prepare weekly mail/Send Blue Bags Conduct Store Meeting following Store Meeting Calendar (New Flexie) 24 Review StoreNet Reports; 1. HR Exceptions 2. Reviews Due 3. OLC % Complete 4. Negative On Hands Management Staff Meeting once a week, preferably at the beginning of the week to review previous week’s results. Store Manager “What Matters Most” Variable Truck Delivery Day Overlay with MPT Workload Forecast Planning Monday Delivery Day Sunday Work Daily Back Stock Report Receive PDQ/MST/Store to Store ASN’s Review SOLO Viewer and Organize PDQ Section Review return batteries Prepare Truck Returns and confirm ATIs Monday TRUCK DAY Wednesday Thursday Friday Saturday Work Daily Back Stock Report Work Daily Back Stock Report Work Daily Back Stock Report Work Daily Back Stock Report Work Daily Back Stock Report Work Daily Back Stock Report Receive PDQ/MST/Store to Store ASN’s Receive PDQ/MST/Store to Store ASN’s Review PDQ/MST/Store to Store ASN’s Receive PDQ/MST/Store to Store ASN’s Receive PDQ/MST/Store to Store ASN’s Receive PDQ/MST/Store to Store ASN’s Review SOLO Viewer and Organize PDQ Section Review SOLO Viewer and Organize PDQ Section Review SOLO Viewer and Organize PDQ Section Review SOLO Viewer and Organize PDQ Section Review SOLO Viewer and Organize PDQ Section Review SOLO Viewer and Organize PDQ Section Process Store Use/Known Theft Items Process Store Use/Known Theft Items Process Store Use/Known Theft Items Process Store Use/Known Theft Items Process Store Use/Known Theft Items Enter Back Stock Quantities From Truck into scan gun Complete This Weeks Cycle Counts Complete Call Backs & Overstock Directives * Note All Tasks should be completed by 5 p.m Complete The 5 Walk Outage Process and Perform Maxi Requests as Needed 25 Tuesday Confirm Truck ASN when truck is unloaded Put away truck (24 Hours) Supply / Add Order (Check Store Net for specific time) Complete This Weeks POG’s Complete a Positive Shrink Hunt as Needed Daily To-Do List 26 6. Team Member Scheduling 27 Product Management Basics • • • • • • • • 28 Inventory Basics Maxi Adjustments Cycle Counts Reverse Logistics Planograms Back Stock (overstock) PDQ Program Daily / Weekly Duties Inventory Basics Managing your store’s inventory is really about managing different facets of the inventory process • Proper Stock Levels and Variety – Too little merchandise means we miss sales – Too much merchandise means we waste inventory dollars on product we don’t need • Every Store has a different “selling mix” • Generally speaking 20% of your inventory produces 80% of your sales. • Stock levels are driven by On Hand quantity and a Maxi quantity 29 On Hand Integrity Ways On Hand integrity is compromised: • • • • • • • 30 Cycle Count inaccuracy Refunds processed incorrectly Ringing multiple quantities incorrectly Overring (Post Voids not processed) POS Exchanges / Defect Exchanges processed incorrectly Theft Shipping errors Maxi Adjustments • Maxi is the amount of inventory needed to support sales until the next DC shipment arrives – A Maxi that is too low will not support sales – A Maxi that is too high will lead to excessive backstock • Request a new maxi through the Inventory Adjustment menu, or by using the RF Scanner • Maxis are calculated based on last 4 weeks sales except for bulk chemicals & batteries which use a 2-3 week supply – If lost sales are recorded properly using F10 "Lost Sale" function, Inventory Management will adjust maxis accordingly 31 Cycle Counts • Cycle Count Basics: • Cycle counts are mini inventories, and if done properly, are the best way to maintain on hand integrity • Before cycle counting, make sure merchandise is fronted, faced and in proper location • Complete by the weekly due date – We schedule approximately 1200 – 2000 pieces per week • Count items in multiple locations – back room, endcaps, wing panels, and backstock • Confirming a cycle count without actually counting the merchandise (F8’ing) is considered fraud 32 Reverse Logistics (Distribution Center Returns) The process of returning cores, defects and new saleable merchandise to the DC, PDQ, or Master PDQ to ensure proper credit. 33 Reverse Logistics (Distribution Center Returns) The process of returning cores, defects and new saleable merchandise to the DC, PDQ, or Master PDQ to ensure proper credit. You should think of Reverse Logistics as the Register at your backdoor! 34 Planogram Management 35 Planograms The planogram includes the following: • A Cover Sheet: ― Provides the purpose of the planogram ― Provides notes on how to set the planogram ― Provides what you need to do to complete it • A Contact Sheet: ― Provides the person and phone numbers to call • Planogram: ― Visual presentation of where and how to place the merchandise ― Line Listing of the items, description, facings, and the minimum amount of merchandise 36 Back Stock (Overstock) • Back Stock Worked Daily – Run Back Stock Move Report – Work Backstock on Sales Floor • Back Stock Worked Weekly – Use Back Stock cart on Truck Day – Scan in Back Stock after stocking is complete – Organize Back Stock area with new items 37 PDQ Program (Special Order Program) • PDQ Program Maintained 100% Daily • All items awaiting pick up have slips attached • All items Paid (including Team Member purchases) unless for Commercial Account or for Warranty Replacement • PDQ Defective Item for Replacement use POS/Def Exchange Hot Key • PDQ Returns Sent Back Weekly • Returns assigned to Totes Daily using the Parts Not in Totes Report 38 Inventory Daily / Weekly Duties Day Store Recovery Review / assign totes Receive ASNs Review ATIs Review Order Viewer / PDQ shelf Process Store Use items Complete Cycle Counts Return to stock Cycle Count Work Backstock 39 Week Review “Planning Calendar” on Store Net Review “Game Plan” Print manifests for weekly returns Complete Planograms Process outages / variances Complete callbacks and overstock returns Scan in new Backstock Complete Cycle Counts (No F8’ing) Confirm DC Truck ASN Complete Maxi adjustments Complete Price Change Front Tags Place Store Supply Order (One order per week) Place Add Order The Advance Way to Manage Inventory 40 Store Presentation/Promotion Daily Store Inspection 41 Store Presentation/Promotion Daily Store Inspection Daily Outside “Store Inspection” • Use this process daily when walking the exterior of your store! – – – – – – – 42 Green Areas and Landscaping Parking Lot and Striping Dumpster Area Lighting Sidewalks Windows and Doors Window Signage Store Presentation/Promotion Daily Store Inspection Daily Inside “Store Inspection” • Use this process daily when walking the exterior of your store! • Consistency is the key! • 4 ft X 4 ft Section – Start with the Interior Walls – Then Sales Floor Aisles – Then Sales Floor End Caps and Wing Panels – Then Sales Floor Stack Out Displays – Then Parts Counter including the Register Displays – Then Parts Department End Caps – Finish with the Parts Department Aisles 43 4-3-0 Parallel Merchandising 0 Feet (if there is not 4’ between stackouts) 4 Feet minimum between displays 3 Feet (to fixture) 44 Customer Convenience • Place where customers will need them: – Front Ad Display – Oil Rack – Chemical Wall • The more customers can carry, the more they buy! • EZ Cart customers spend about $40 on average 45 Store Display & Signage (Daily, Weekly, Monthly) • • • • • • Ending promotional signs removed New Monthly Ad Signs Displayed POP (Point of Purchase) Signage updated OSP (Off Shelf Display) Rotated Stack-outs faced and filled End Cap Displays faced and filled or Updated (Seasonal) • BOGO (Buy-one Get-one Free) Merchandise Displayed 46 Operating Statement Four Key Result Areas • • • • 47 Sales Gross Margin Expenses Profits Operating Statement Basics Budgets/Goals • Performance is measured as a % of Sales and % of Profits – – – – – 48 Sales % to Budget Comp Sales % Profit % to Budget Comp Profits % Bonuses are often tied to Sales Performance Operating Statement Basics Basis Point • A basis point is a financial term used to describe One one-hundredth of a percent • If a store’s payroll budget is 12.45% and the operating statement shows they ran a 12.25% they were 20 basis points under their budget 49 Operating Statement Basics Flow Through • Flow through is a term used to describe the profit you earn on the bottom line from incremental top line sales • For every dollar over budget in sales, 30% should drop directly to the bottom line 50 Operating Statement Basics Top Line – Combined Retail and Commercial Sales • Retail Sales are sales from walk-in DIY customers • Commercial Sales are sales from DIFM customers – Delivery – Walk-In 51 Operating Statement Basics Bottom Line Total Gross Profit - Total Operating Costs = Operating Income/(Loss) 52 Operating Statement Basics Controllable Expenses • Utilities • Maintenance and Repairs • Telephone • Trash Removal • Payroll 53 • Supplies • Bad Checks • Cash Variance Operating Statement Basics “High Exposure” Controllable Expenses • Worker’s Comp • Liability Claims • Vehicle Accidents Safety is important both your Team, Customers and shareholders! 54 Where Does All The Money Go? Total Store Sales ―Cost of Goods Sold (COGS) ―Shrink, Allocated Warehouse and Other ―Payroll, Taxes & Benefits ―Net Advertising Expenses ―Expenses / Other Operating Costs __________________________ = Operating Income / (Loss) 55 56 57 58 Store Management Conclusion • • • • • The Best Business Plan The Best Processes The Most Efficient Operation The Best Pricing The Most Inventory Won’t Guarantee Success! All things being equal............ 59 The Store With The Best People Wins!!