LCM-CMM-2-Approach - Life Cycle Initiative

advertisement

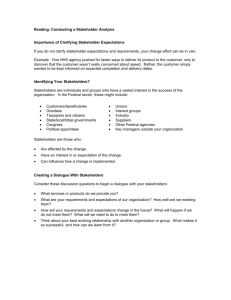

UNEP/SETAC Life-Cycle Initiative Life Cycle Management Capability Maturity Model (LCM-CMM) Building Capacity for Sustainable Value Chains International Life Cycle Partnership To bring science-based life cycle approaches into practice worldwide QUICK TOUR OF LCM – CMM CONTINUAL LEARNING LCM- CMM APPROACH (WHAT TO DO) Competitive Context SWOT Analysis Situation Analysis O T Improvement Plan • S • W Maturity Assessment Product Life Cycle Scan (HOW TO DO) Near term business objectives Long term org. development Action Learning • • Speed implementation Just enough analysis + just in time training CYCLES OF LEARNING Management Commitment Communicate vision and provide necessary resources Plan Identify key gaps to be addressed in next cycle Act Embed new practices in management system Linked to business strategy Integrated into organizational routines Assess performance against targets Capture lessons learned Learn Identify improvement priorities Set quantified targets Do Action learning Defined processes Roles & responsibilities Training & development ACTION LEARNING Directed by business manager Supported by LCM champion Training/ technical consultant Active learning Feedback from work outcome Accelerated implementation Situation Analysis SWOT Analysis ACTIONABLE TASKS Improvement Project QUALIFIED – Do No Harm Management Commitment Basic procedures to protect people and the environment Plan Identify key measurement gaps to define business case Act Roles & responsibilities Employee training Accountability Risk avoidance Legal compliance License to operate Inspections Corrective action Root cause Quantify outputs Set Targets Do Hazard ID Controls, procedures Emergency planning Learn QUALIFIED • Key capabilities – Environmental awareness, hazard identification, root cause analysis, numerical literacy • Business impacts – Legal compliance, license to operate, risk/ cost avoidance • LCA Methodology – Data quality, process mapping (gate- to- gate) • EMS Elements – Legal & regulatory requirements, environmental aspects, roles & responsibilities, operating controls, training, inspections, emergency response, incident investigation & corrective action QUALIFIED PLAN Inventory key waste streams and most frequent accidents. Establish baseline performance measures and set targets for improvement. Inventory toxic chemical uses. DO Conduct job hazard assessments & install procedures and controls to manage hazards. Characterize all waste streams. Implement procedures to ensure compliance activities are conducted as required. Implement inspections to reinforce required safety and environmental actions. Assess for potential incidents & identify necessary actions for response and containment LEARN Conduct emergency response drill. Review inspection findings and implement corrective action. Establish incident investigation process to drive to root cause. Conduct independent 3rd party compliance audit. ACT Key Activities Establish emergency response plan. Establish employee awareness training program, including new employee orientation. Formalize operational controls and management systems for ongoing safety and environmental compliance Implement corrective action to address any findings from third- party compliance audit. Publicly report compliance with legal and regulatory requirements & progress toward improvement goals. Identify key information needs to drive next cycle of improvement EFFICIENT Management Commitment Upgrade procedures to reduce impacts to lowest economically feasible level Plan Identify performance gaps that require redesign/ innovation Act Organization Accountability Public reporting Process efficiency Improve operating margins “Eliminate waste” Management system audit Track KPIs against targets Learn Aspects & impacts Energy & water use Chemical inventory Do Risk assessment Environmental costs Pollution prevention Process safety EFFICIENT • Key capabilities – Risk assessment, financial literacy & environmental accounting, quality improvement tools (e.g. statistical process control), cross- functional collaboration • Business impacts – Process efficiency/ operational excellence, improved margins, reduced inventory & working capital • LCA Methodology – Life cycle inventory, product system modeling (cradleto- gate; gate- to- grave; attributional), impact assessment • EMS Elements – Policy, environmental impacts, objectives & targets, organization & accountability, programs, management audits, external reporting (environmental) EFFICIENT PLAN Identify environmental & safety aspects and impacts of facility operations. Inventory energy uses. Compile a water balance for facility. Establish baseline performance and set targets for improvement DO Conduct a risk assessment of facility aspects and impacts & set priorities for improvement. Conduct pollution prevention/waste minimization projects as required to meet goals. Develop environmental accounting system to quantify costs of pollution and injuries. Conduct alternatives assessment for all uses of toxic chemicals LEARN Conduct management system audit of inspection process in reducing incidents. Define and monitor key performance indicators (KPIs) to assess progress toward targets. Review effectiveness of EH&S programs. Review adequacy of information system for supporting environmental accounting. ACT Key Activities Draft policy and formalize environment, health and safety programs. Standardize measurements & establish quality assurance procedures. Integrate measurement requirements into information technology strategic planning. Integrate EH&S requirements into employee development programs. Define plan for substitution of toxic chemical uses with safer alternatives. Establish communication plan for public reporting of company performance EFFECTIVE Create goods & services that improve human condition while continually reducing impacts and resource rqmts Management Commitment Plan Identify key policy barriers to sustainable business Act Sustainability reporting – e.g. GRI (partial) GHG/ water footprint/ eco- labels Top line growth New markets Innovative products Annual program review Stakeholder feedback Value chain impacts Scope 1 & 2 GHG Water footprint Materiality matrix Do LCA Design for environment Chemical substitution Learn EFFECTIVE • Key capabilities – Robust & user- centered design principles, systems thinking, multi- attribute decision- making, conflict resolution, inter- organizational collaboration • Business impacts – Product & business model innovation, new markets & expansion of existing markets • LCA Methodology – Interpretation & communication, cradle- to- grave modeling (consequential, scenarios), critical review • EMS Elements – Annual management review, design for environment, supplier environmental management, stakeholder engagement, external reporting (CSR) EFFECTIVE PLAN Identify environmental & safety aspects and impacts of company’s value chain. Compile scope 1 & 2 GHG inventory for company. Estimate water footprint. Develop preliminary materiality matrix of stakeholder issues. Establish baseline performance and set targets for improvement. DO Conduct streamlined LCA for key product family. Use results to upgrade design manuals or implement eco- design idea(s) in new product development. Conduct design for environment pilot on product with key customer designed to enhance customer value proposition with superior environmental performance. Conduct process improvement project with strategic supplier(s). Complete project to substitute a toxic chemical use with a safer alternative. LEARN Conduct management review of LCM programs. Engage stakeholders to review company progress and assess their understanding/ acceptance of KPIs used to communicate progress Assess progress against toxic used reduction plan. ACT Key Activities Update policy and extend environmental programs to cover full product life cycle system. Upgrade communication plan to ensure product marketing and public reporting aligned. Develop formal stakeholder engagement plan to inform strategic planning. Bring public reporting into compliance with GRI guidelines. ADAPTIVE Management Commitment Transform business model to support sustainable consumption & production Plan Co- create new markets for enhanced well- being! Act Sustainability mgmt. system Public policy reform Socio- economic profile Stakeholder engagement Balance sheet focus Capital preservation Sustainable prosperity Stakeholder review of performance Do System innovation Public- private partnerships Learn SUSTAINABLE CONSUMPTION & PRODUCTION WBCSD. (2010). Vision 2050: The new agenda for business http://www.wbcsd.org/WEB/PROJECTS/BZROLE/VISION2050-FULLREPORT_FINAL.PDF