Harley- Davidson in US

advertisement

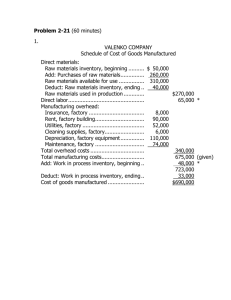

INDIVIDUAL CASE STUDY 2010 ASSIGNMENT COVER PAGE Subject Code OMGT2085 Subject Name: INTRODUCTION TO LOGISTICS AND SUPPLY CHAIN MANAGEMENT Location where you study RMIT SGS Campus Title of Assignment Individual Case Study (ICS) File(s) Submitted docx Student name: Tran Thi My Dung Student Number S3231518 Student Email Address: S3231518@rmit.edu.vn Learning Facilitator in charge: Assignment due date 24/4/2010 8AM Date of Submission: 24/4/2010 Number of pages including this one: 19 Word Count: (Main Content) 2706 Words Late Submission Approval 1 INDIVIDUAL CASE STUDY 2010 Table of Contents ASSIGNMENT COVER PAGE ..................................................................................................... 1 CHANNEL OF DISTRIBUTION FOR THE SUPPLY CHAIN OF HARLEY-DAVIDSON IN VIETNAM ............................................................................................................................. 3 I. Research and Analysis: ........................................................................................................... 4 1.1 Description: ........................................................................................................................... 4 1.2 SWOT analysis ..................................................................................................................... 5 1.3 Logistic and Supply Chains Management issues…………………………………………..8 II. Strategy Proposal: ................................................................................................................... 9 2.1 Strategies: .............................................................................................................................. 8 2.1.1 Transportation – based third party logistics (3PL): ....................................................... 8 2.1.2 Collaborative planning, forecasting and replenishment (CPFR): ................................ 11 2.1.3 Postposement ...............................................................Error! Bookmark not defined. 2.2 Explanation of the Multi-criteria Decision Matrix ..........Error! Bookmark not defined. 2.3 Key Performance Indicators (KPIs): ....................................Error! Bookmark not defined. 2.4 Costs and Benefits of CPFR implementation: .....................Error! Bookmark not defined. III. References: ..........................................................................Error! Bookmark not defined. 2 INDIVIDUAL CASE STUDY 2010 CHANNELS OF DISTRIBUTION FOR THE SUPPLY CHAIN OF HARLEYDAVIDSON IN VIET NAM Magnet Supplier Digital Sounder Supplier Raw materials Supplier Inbound Logistics Honk Factory Ltd in Viet Nam (Tier 1 Supplier -Klaxons) 3PL - Transportation Harley-Davidson’s Warehouse In Milwaukee, Wisconsin Harley- Davidson in US (Main Manufacturing and Assembling) Outbound Logistics Office and Warehouse in US Maintenance, Repair and Operating Centers in US, Japan and Europe Distribution Center of HarleyDavidson in US Office and Warehouse in Europe Distribution Center of Harley-Davidson in Europe Retailers End – Users Retailer Warehouse in Japan Distribution Center of Harley – Davidson in Japan Retailer 3 INDIVIDUAL CASE STUDY 2010 I. Research and Analysis: 1.1 Description Inbound Logistics: Magnet, Digital Sounder and Raw Material Suppliers provide sub-components and raw material for the Honk Factory in Viet Nam in order to produce klaxons for motorbikes and motorcycles. When the Honk Factory receives the orders from Harley–Davidson, USA (its requirement: ‘different honk classified different motorcycle models by different sounds’), the Honk Factory begins producing customized klaxons. After finishing the components, they will be transported to the Harley-Davidson warehouse in Milwaukee, Wisconsin by the third party logistics company. Next, finish klaxons in Harley-Davidson Warehouse will be delivered to Manufacturer of Harley-Davidson in US, All these components will be checked for right quantity as well as quality ( ensure there is no room errors) and then assemble different klaxons to their different motorcycle models. Finished motorcycles will be sent to Motorcycle Testing Departments in US before shipping to markets. Outbound Logistics: USA, Europe and Japan are three strong markets of Harley-Davidson. The finished goods will be stored in warehouses in US, Europe and Japan. From warehouses, motorcycles will be shipped to the American, European and Japanese Distribution Centers in order to 4 INDIVIDUAL CASE STUDY 2010 package and continuous improvement engineering, then delivering complete products to the retails. Finally, from retailers, Harley-Davidson motorcycles models with unique klaxons are sold to end-users. Maintenance, Repair and Operating Centers are located in three main markets: US, Europe and Japan. These centers provide services for Harley-Davidson’s customers. They maintain or repair motorcycles and sell spare parts such as klaxons, wheel and other motor accessories. 1.2 SWOT Analysis Strengths: The Honk Factory has the cutting-edge technology in the klaxons for motorcycles and motorbikes. ( digital-sound klaxons- 2cm x 2cm, with capturing various kinds of sound and sound level higher 125 decibels). Honk Factory has experience and skills in international colaboration. They won a big size contract to produce the klaxons for Tata Motors, India. Because of its small size operation, the labour costs were cheap so the factory can invest more in impormation technology Outsoucing the third party logistic companies, for example, transportation – based 3PL and warehousing/distribution- based 3PL, with their specialization, Honk Factory can concentrate on their core completency and reduce logistic costs, its supply chain be more responsive. 5 INDIVIDUAL CASE STUDY 2010 Weakness: when contrasting logistic for transportation and warehousing, the Honk Factory is mostly depended on third party providers so the status of inventory and the flow of goods might be loss of control. In-transit inventory carrying cost and inventory risk cost ( stolen , obsolete cost) could be increased. In production process, some equipments are broken down and need invest in the newest of mordern equipment in order to increase production capacity. Production capacity was not high and facing some difficulties on quality control. Lack of interaction of information , for example, the factory designs klaxons to the order and wait for the next ordering, here, the flow of information is one-side and it can reduce the reposiveness in supply chain . Opportunities: According to Nguyen (2009), since entering the WTO in 2009, the activities in import and export trades were sharply increase. Therefore, it leads to the strongly development of 3PLs logistic in Viet Nam. As the result, Honk Factory has more choices to outsource the third party logistic company which could provide a best supply chain performance for the factory. The Vietnamese economic has risen in 2009 ( GDP increase 5% to 7% compare in 2008). This is an opportunity for the Honk Factory increases its market share in Viet Nam and welcome more foreign investments. 6 INDIVIDUAL CASE STUDY 2010 After WTO asscession, more international companies will enter to Vietnamese market, setting up partnership and share technology as well as information with domestic companies (‘Vietnam Firms urged to invest in Technology’ 2010). Therefore, Honk Factory will be able to improve in its technology innovation and have opportunities to win big-size contracts. Thearts: Lack of professional labour force in Viet Nam’s logistics and supply chain. To illustrate, 600 local companies involed logistics employ about 35,000 people but about 40% are professional skill in logistics (‘Personnel shortage keeps logistics trade backward’ , 2009). Entering the WTO, the number of competitors has rising dramactically in Viet Nam, both domestic and foreign competitors companies. The Honk Factory is not the exception, the factory send time and money on its logistic system ( customer service), production and information sercurity in order to have better performance. 7 INDIVIDUAL CASE STUDY 2010 1.3Logistic and Supply Chains Management issues: 1. Order cycle time : the Harley-Davidson’s requirement for Honk Factory is ‘ consistent order cycle time of two week or less”, however, order cycle time might be longer because klaxons are customized components, it takes more time to find raw materials, design customized klaxons, package and transport to specific location of Harley-Davidson in the US. 2. Uncertainty in demand forcasting : lack of communication and no sharing information between two players in supply chain might lead to unaccurate (wrong) demand forcasting. 3. High cost of transportation : might due to the oil price increases in Viet Nam. Moreover, there is a long distance between Viet Nam and USA, that means the cost of transportaion is unavoidable and might be higher if using air cargo carrier to transport the finished components. 4. High level of inventory holding: because of the uncertainty in demand forcasting, the firm hold too much inventory, it leads to increase storage space costs, costs of holding inventory and inventory risk costs. 5. Weak performance of customer service: due to the uncertain in order cycle time and not have much experience in communication or exchange information. 8 INDIVIDUAL CASE STUDY 2010 II. Strategy Proposal: Consider the issues of the supply chain of Harley-Davidson in Vietnam, there are three feasible logistics and supply chain management strategies that could suggest to solve the problems: Transportation – based third party logistics, collaborative planning, forecasting and replenishment (CPFR) and Postponement. 2.1 Strategies 2.1.1 Transportation – based third party logistics (3PL): Third-party logistics (3PLs) can be defined as the ‘outside provider who carry out some logistics activities such as transportation, warehousing, distribution, financial services and so on ’(Coyle et al.2008). Also, these activities are not belonging to the company’s core business. In this case, Transportation based third-party logistics is proposed for the supply chain of HarleyDavidson in Vietnam. Transportation based 3PLs uses the outsourced company who will perform all parts of transportation activities involves the management of the way resource are move to the areas where they are required (Coyle et al.2008). Advantages: The company can outsource the Transportation based 3PLSs to carry out all the transportation activities (non- core business) so company can concentrate more on their core business, improving effectiveness in their core competency. 9 INDIVIDUAL CASE STUDY 2010 With their specialization, the transportation based 3PLs can deliver and manage the flow of products to the right place, shorter lead time and reduce costs efficiency. Disadvantages: Dependence on third-party logistics operations and later loss of control over the transportation activities. In case, if the company outsource an unqualified 3PLs, it will brings huge effect to the company supply chain, for example, longer lead time, decrease customers service and increase costs of carrying inventory. Disagreement on the opinion or different perception of the service level of the 3PL providers, conflict might occurs in collaboration. Transportation –based 3PL is highly recommended to be use in the supply chain of Harley-Davidson in Vietnam. Although the Vietnamese government has invested heavily in upgrading its transport infrastructure, there is still occurs risks and high cost of transporting. Today, the collaboration is very important and needed in supply chain management so outsource the transportation based 3PL providers will help the Honk factory focus on their core business (designing customized klaxons) and reduce logistics costs. The outside providers are specialized and expert in packaging, delivering right product to the right customer, right condition, right quality and quantity and shorter the order cycle time. With the long distance delivery ( from Vietnam to Harley-Davidson warehouse in Milwaukee, Wisconsin), transportation based 3PL providers can ensure the condition of inventory( klaxons) and help the Honk Factory to reduce in transit inventory carrying cost and on time delivery. Overall, it improves the responsiveness in the supply chain of Harley-Davidson in Vietnam 10 INDIVIDUAL CASE STUDY 2010 2.1.2 Collaborative planning, forecasting and replenishment (CPFR) CPFR is the collaboration process where combines the intelligence of supply chain trading partners in the business planning, sales for forecasting and stock replenishment (Coyle et al.2008). Using this approach, two or more parties in the supply chain include customer, manufacturers and retailers are work together in order to come to agreements in planning and improve forecasting by exchanging business information based on Web technology. There are nine major steps in order to set up CPFR process so it is said that CPFR is a dynamic process and need high level of integration in supply chain management. . Nine steps in CPFR process model (Steermann, H 2003, p. 48). 11 INDIVIDUAL CASE STUDY 2010 Advantages: CPFR helps improve forecasting and match between supplier and demand. With reliable and accurate demand forecast, the manufacture can make the product to order rather than making them to inventory. Therefore, CPFR helps the supply chain to reduce costs of holding inventory and out-of stock. Strengthen the relationship between trading parties in supply chain by exchanging information and sharing technology. Disadvantages: High cost of investing in IT system as well as cost of maintain and develop IT system. The risk of sharing inaccurate information could affect the whole supply chain. It results in wrong forecasting and increase unexpected costs. Although the high cost of investing in information technology system is highly, CPFR should be considered a best recommendation for the supply chain of Harley-Davidson for several reasons. Firstly, with the accurate demand forecasting between manufacturer and supplier, the Honk Factory will be able produce accurate amount of klaxons in order to match the demand, it could reduce cost of material handling and inventory. Moreover, by exchange information, Honk factory will know status of its klaxons in Harley-Davidson, US and if its components were stock out, the supplier will replenish stocks in time in order to avoid costs of lost sales. CPFR improve the customer services and responsiveness in the supply chain of Harley-Davidson in Vietnam. 12 INDIVIDUAL CASE STUDY 2010 2.1.3 Postponement Strategy: Postponement strategy ‘aims to delay some supply chain activities until customer demand order is appeared in order to maintain cost and fast response’ (Coyle et al.2008). In specific, postponement strategy is proposed for company, who produce customized products, the products are in semi-forms and after receiving the orders they continue finishing the product quickly and deliver to customers. Advantages: Improve competitiveness by providing customized products quickly. Reduce cost of holding inventory and inventory risk costs (reduce risk of obsolescence). Disadvantages: Increase transportation cost, set up cost, cost of training and cost of re-engineering in supply chain. Economics of scale are lost due to the customized processes. Trade off between mass production and customization in using postponement strategy. Postponement strategy is also highly recommended for the supply chain of Harley-Davidson in Vietnam. In case, the main role of the Honk Factory is designing klaxons to order, which are all customized components so postponement strategy helps the factory to shorter order cycle time , reduce holding high level of inventory , saving variable costs and have the fast response logistics when receiving Harley-Davidson’s orders. Consequently, the factory can be more competitive and better improve in customer services. 13 INDIVIDUAL CASE STUDY 2010 2.2 Explanation of the Multi-criteria Decision Matrix Strategy Consistent The Transportatio Level of Customer Order Cycle accuracy of n costs holding Service Time inventory Performance forecasting Total demand 0.2 0.35 0.15 0.2 0.1 1 9 (1.8) 3 (1.05) 8 (1.2) 5 (1) 8 (0.8) 33(5.85) C.P.F.R 8 (1.6) 9 (3.15) 7(1.05) 9 (1.8) 9 (0.9) 42(8.5) Postponement 9 (1.8) 6 (2.1) 3(0.45) 4 (0.8) 8(0.8) 30(5.95) Transportation –based 3PL 14 INDIVIDUAL CASE STUDY 2010 The result of Decision Matrix shows that CPFR is the best strategy that could address all the issues in the supply chain of Harley-Davidson in Vietnam. CPFR enhances the relationship between trading parties supply chain, so it improves forecast and customer services in the supply chain. By exchange accurate information, the Honk Factory will be able to reduce cost of holding inventory as well as cost of stock out. Moreover, CPFR is the best method to minimize the cost of lost sales of finished motorcycles or service parts of HarleyDavidson in the US and around the world because when sharing accurate information, goods will be replenished at the right time when level of inventory is end. Overall, CPFR helps to improve the responsiveness in the supply chain of Harley-Davidson in Vietnam. Transportation- based 3PL is the second effective logistics strategy to solve with these issues. It helps the Honk Factory to reduce order cycle time, however, the demand forecasting cannot be deal with this 3PLs provider. Postponement seems very appropriate with the customized production of Honk Factory. It helps to shorten order cycle time and improve the customer service in supply chain. However, some logistic cost might incurred and affect the company’s finance. One best practice Auto& Moto Industry example which approach CPFR successfully is General Motor (GM), one of the largest automotive manufacturers in the world. In order to increase the faster adapt and responsiveness of the supply chain, GM has implemented CPFP to 15 INDIVIDUAL CASE STUDY 2010 its suppliers. The auto company establishes the strong buyer-supplier relationship base on an IT framework. The parties in supply chain exchange sale information and technology through Web technology so if wrong information was exchange, the suppliers will easily respond to the manufacturer. The both parties can control inventory effectively and when end of level of inventory, the suppliers will know the exactly amount of inventory needed to replenish. As the result, the sale of GM absolutely increases, they has sold 30,109 units last year and the average order cycle time was shortened from 174 days to 52 days and 70 percent turnover time reduction (StanK, 1999) 2.3 Key Performance Indicators (KPIs) Shortening order cycle time from 14 days (2 weeks) to 11 days in three months. Control the quality of the finished klaxons to the Harley-Davidson by reducing from 48 to 40 defective parts per million or less in three months. 16 INDIVIDUAL CASE STUDY 2010 2.4 Costs and Benefits of CPFR implementation: Costs Training costs Benefits $10,000 Improve customer $60,000 projected annual service estimate Investing in IT system and $ 15000 Minimize inventory $40,000 projected annual maintenance (EDI) level lost time when meeting and $ 6000 estimate Improve in accurate of $ 20,000 projected annual set up agreements customer information ( estimate estimate accurate forecast ) Costs of information $ 5000 security New computer equipment $ 50,000 Increase sale $ 80,000 projected annual opportunities estimate Fast response logistics $ 30,000 projected annual ( reduce order cycle estimate time ) TOTAL $86,000 TOTAL $230,000 17 INDIVIDUAL CASE STUDY 2010 The total benefits is greater than the total costs so CPFR should be implement in the supply chain of Harley-Davidson in Vietnam. In the costs analysis: Training cost means cost of training employee how to using the IT system or software (10 employee/10 days x $1000/each). New computer equipment: – Software (sales support & CRM) : $20,000 – 10 new computers: $2,000 each – 1 server (web) : $6,000 – 2 printers : $ 2,000 each Other costs: opportunity costs, security information. In the benefits analysis: Improved customer service (current customers): $60,000 (projected annual estimate) Improved accuracy of customer information: $20,000 (projected annual estimate) Improved management of the logistics: a. Reduce inventory: $40,000 (projected annual estimate) b. Increase in sale of components: $80,000 (projected annual estimate) c. Shorten order cycle time: $30,000 (projected annual estimate) 18 INDIVIDUAL CASE STUDY 2010 III. Reference lists: Coyle, J, Langley, C, Gibson, B, Novack, R & bardi, E 2009, Supply Chain Management a Logistic Perspective, 8th edn, South-Western cengage, USA. Nguyen, H 2009, ‘Expectations for Vietnamese 3PL service businesses’, Vietnam Logistics Review (VLR), viewed 20 April 2010, < http://vlr.vn/index.php?option=com_content&view=article&id=187%3Akyvongv aodichvulogisticstheohuong3pl&catid=111%3Atng-hp&lang=en>. ‘Personnel shortage keeps logistics trade backward’ 2009, Vietnam Net, 22 November, viewed 20 April 2010, < http://english.vietnamnet.vn/biz/200911/Personnel-shortage-keeps-logistics-tradebackward-880212/> . Stank, T. P., Daugherty, P. J. & Autry, C. W. (1999), Collaborative Planning: Supporting Automatic Replenishment Programs, Supply Chain Management, Vol. 4, Issue 2, pp. 75-85. Steermann, H 2003, ‘A Practical Look At CPFR: The Sears-Michelin Experience’, Supply Chain Management Review, July, pp. 46-53. ‘Vietnam Firms urged to invest in Technology’ 2010, All Business, 5 March, viewed 21 April 2010, < http://www.allbusiness.com/trade- development/economic-development-emerging-markets/14050638-1.html>. 19