Introduction: Min

advertisement

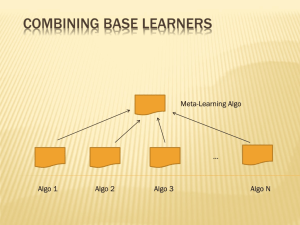

Boosting: Min-Cut Placement with Improved Signal Delay Andrew B. Kahng Igor L. Markov Sherief Reda CSE & ECE Departments University of CA, San Diego La Jolla, CA 92093 abk@cs.ucsd.edu EECS Department University of Michigan Ann Arbor, MI 48109 imarkov@eecs.umich.edu CSE Department University of CA, San Diego La Jolla, CA 92093 sreda@cs.ucsd.edu VLSI CAD Laboratory at UCSD Outline Introduction and motivation Controlling wirelength distribution Boosting min-cut placement Effect of boosting on cut values Experimental results Conclusions Introduction: Min-Cut Placement Min-cut objective: minimize cut partitions → minimizes total wirelength with the help of terminal propagation Min-cut partitioning produces slicing outlines Introduction: Min-Cut Placement Min-cut objective: minimize cut partitions → minimizes total wirelength with the help of terminal propagation Min-cut partitioning produces slicing outlines Motivation: Avoiding Global Interconnects Min-cut placers Sequentially minimize wirelength, i.e., the routing demand Do not treat global interconnects in any special way Global interconnects can severely increase propagation delay since delay is proportional to square of the wirelength take part of critical paths and degrade performance require buffering for electrical sanity have a propagation delay that is equivalent to several clock cycles Conclusion: try to prevent global interconnects Motivation: Example Case A Case B Cases A and B: same wirelength & number of cuts Case B: no global interconnects (cf. Case A) Outline Introduction and motivation Controlling wirelength distribution Boosting min-cut placement Effect of boosting on cut values Experimental results Conclusions Bounds on Net Length A net’s HPWL (Half Perimeter Wirelength) is bounded from below by distances between closest points of incident partitions from above by distances between furthest points of incident partitions These bounds are gradually refined during top-down placement at the beginning lower bounds are ~0s, upper bounds are determined by placement region at the end, the bounds are close to (or match) HPWL Net L Upper bound = ¾ chip width Lower bound = ¼ chip width Dichotomy of Lower and Upper bounds Net L Net L Upper bound reduces; lower bound stays the same Net L Upper bound stays the same; lower bound increases Net Extension Control Partitioning a block extends a net L if the next two equivalent conditions occur: (1) Cutting L increases the lower bound on its length Or equivalently (2) Not cutting L decreases the upper bound on its length We use the previous conditions to detect net extension and attempt to curb it via boosting Boosting Min-Cut Placement Boosting = multiplying a hyperedge (net) weight by a factor boosting factor Boosting is used only when a cut can increase a lower bound L Boost net L with a boosting factor of 2 L To Boost or Not to Boost? BOOST? YES BOOST? NO BOOST? YES BOOST? NO Effect of Boosting on Cut Value Case 1 v u v is connected to a net eligible for boosting, u is not either can be moved to the right Boosting factor is 2: the gain of v grows from 1 to 2 Tie is broken by moving v → no degradation in wirelength, and a global wire is avoided Effect of Boosting on Cut Value Case 2 v u v is connected to several nets eligible for boosting, u is not Boosting factor is 2 on each net: v’s gain grows from 3 to 6 v has a higher priority → no degradation in wirelength and a global interconnect is eliminated Effect of Boosting on Cut Value Case 3 v u v is connected to 2 nets eligible for boosting Boosting factor is 2 gain for v increases (from 2 to 4); gain for u is the same (3) v is moved → wirelength is degraded but global wires are prevented Summary Boosting helps in eliminating global interconnects Boosting may degrade wirelength in some cases To reduce wirelength degradation, we only boost during first 8 levels That is where long wires are determined anyway At the 8th placement level: → The average block perimeter is 1/256 of the original chip perimeter → Global interconnects are already established → No point in further boosting Outline Introduction and motivation Controlling wirelength distribution Boosting min-cut placement Effect of boosting on cut values Experimental results Conclusions Experimental Setup Benchmark Cells Nets Core region Whitespace Metal layers Clock period A 21103 21230 2142x1969 13.5% 4 9.456 B 33917 39153 23157x12732 49.8% 4 30.962 C 9585 10398 8705x86968 5 37.515 29.7% Three industrial benchmarks Two experiments: Effect of boosting on the wirelength distribution Effect of boosting on timing Experimental Results: Wirelength Histogram (Design A) Percentage change in number of nets (%) 20 10 0 -10 -20 -30 -40 1 2 3 4 5 6 7 Bins (in terms of half the chip’s perimeter) Boosting substantially reduces global interconnects Experimental Results: Wirelength Histogram (Design B) Percentage change in number of nets (%) 20 0 -20 -40 -60 -80 -100 1 2 3 4 5 6 7 8 Bins (in terms of half the chip’s perimeter) Boosting substantially reduces global interconnects Experimental Results: Timing benchmark A Flow TNS (ns) Mode Indust NTD 3491503 -0.660 28.107 TD 3570024 -0.368 12.022 Regular 3335483 -0.607 23.360 Boost 3260184 -0.342 5.107 NTD 9080259 -31.793 68253.5 TD 9100552 -31.750 56618.6 Regular 8375939 -29.595 44951.8 Boost 8711281 -25.757 49627.6 NTD 839408 -1.882 1870.3 TD 841585 -1.878 1750.8 Regular 835962 -1.875 1810.6 boost 872089 -1.878 1799.5 Indust Capo C Slack (ns) Tool Capo B Wirelength Indust Capo Conclusions and Future work By tracking lower/upper bounds, we identify potential long wires By additionally increasing net weights, we decrease # of long wires This alters wirelength distribution and reduces global interconnects Routability is slightly affected, but generally preserved Boosting tends to improve circuit delay (timing) measured by the worst slack and total negative slack (TNS) Ongoing work examines the impact of boosting on the number of inserted buffers Thank you for your attention