A&m

advertisement

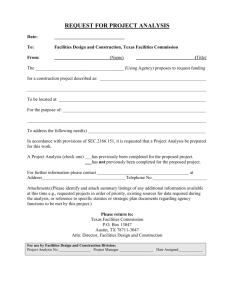

Texas A&M University Texas A&M University Module 2 ENVIRONMENTAL CHALLENGES: OVERVIEW FACING INDUSTRY Texas A&M University Purpose of Module 2 During the past years, the perceptions of pollutions have changed, industry has to find ways to make products without creating pollution or to recover and reuse the materials that we have considered wastes, this philosophy is called pollution prevention. Process Integration is highly compatible with this philosophy and complementary to it. This discipline encompasses a number of methodologies for designing and changing industrial processes, based on the unity of the whole process. This module presents an overview of the major environmental problems facing various industries in North America. It also presents Process Integration as a systematic approach to solving environmental problems. Two major industries (pulp and paper and petroleum refineries) are used as proof of the concept. Texas A&M University STRUCTURE OF MODULE 2 The module is divided into three tiers as follows: TIER 1: Basic Concepts TIER 2: Case Study TIER 3: Computer-Aided Module Texas A&M University TIER 1 : BASIC CONCEPTS This tier will provide a background including a general description of the major industries in North America, and focus on current environmental challenges facing the pulp and paper as well as the petroleum refining industries. Texas A&M University TIER 1 : BASIC CONCEPTS CONTENTS This section in broken into three sections: 1. Major Industries in North America. 2. Petroleum Industry 2.1 Driving forces, hurdles and potential. 2.2 Environmental discharges. 2.3 Regulatory issues in North America. 2.4 Best available environmental technologies for specific processes 3. Pulp and Paper Industry 3.1 Driving forces, hurdles and potential. 3.2 Environmental discharges. 3.3 Regulatory issues in North America. 3.4 Best available environmental technologies for specific processes Texas A&M University Texas A&M University 1. MAYOR INDUSTRIES IN NORTH AMERICA The most important industrial sectors in North America were sought not through their production but reviewing the quantity of their releases and pollutants. Some statistics are organized by country : CANADA USA MEXICO Texas A&M University CANADA INDUSTRIAL SECTORS RELEASING THE LARGEST QUANTITIES OF POLLUTANTS OFF-SIDE Tonnes 45000 40000 35000 30000 25000 20000 15000 10000 5000 0 Water, Sewage and Other Systems Pulp, Paper and Pulp, Paper and Paperboard Paperboard Mills mills Electricity Generation, Transmission and Distribution Pesticide, Fertilizer and Other Agricultural chemical Manufacturing Oil and Gas Extraction Canada is the world’s largest exporter of commodity-grade pulp and paper products, making this industry one of the most important pollutant sector. More information: Top 20 pollutants More Statistics: Canadian NPRI Texas A&M University Top 20 Pollutants Released On Site in the Largest Quantities, 2001 Ammonia Nitrate ion in solution at pH<6.0 Methanol Hydrochloric acid Sulphuric acid Hydrogen sulphide Xylene (mixed isomers) Toluene Methyl ethyl ketone Carbon disulphide n-Hexane Zinc (and its compounds) Hydrogen fluoride Ethylene Ethylene glycol Manganese (and its compounds) Styrene Dicloromethane Isopropyl alcohol Formaldehyde Cyclohexane 2-Butoxyethanol Acetaldehyde Benzene n-Butyl alcohol Total Releases (tonnes) 40915.0 22500.8 20427.5 16595.3 9387.3 7234.3 6327.4 5908.5 4137.6 4065.3 3562.8 3310.0 3257.7 2472.0 2347.4 2195.4 1833.0 1777.2 1751.0 1727.0 1382.3 1223.1 1095.4 1047.1 1047.1 CANADA Top 5 Pollutants Released On Site in the Largest Quantities, 2001 45000.0 40000.0 35000.0 30000.0 Tonnes Pollutant 25000.0 20000.0 15000.0 10000.0 5000.0 0.0 Ammonia Nitrate ion in solution at pH<6.0 Methanol Hydrochloric acid Sulphuric acid Texas A&M University U S A Refineries and petroleum subproducts are included. T he U.S. petroleum industry is a strong contributor to the economic health of the United States, T its production represents about the 25% of global production. he Pulp and Paper industry is also important since the U.S. is the world’s largest consumer or these products, both in total tones per year and in terms of consumption per capita. More information: Top 20 pollutants More Statistics: TRI Texas A&M University U S A Chemical Top 10 Chemicals with the Largest Total Releases, 2001 2,000,000,000 1,500,000,000 1,000,000,000 500,000,000 Co pp er nHe Le xa ad ne Co m po un ds Cu m en e et ha no l To Hy lu en dr oc e hl or ic Zi ac nc id co m Co po un pp ds er co m pu nd s Et hy le ne - M Total Production Related Waste Managed (Pounds) 2,500,000,000 Methanol Toluene Hydrochloric acid Zinc compounds Copper compunds Ethylene Copper n-Hexane Lead Compounds Cumene Ammonia Propylene Nitrate compounds Sulfuric acid Ethylene glycol 1,2-Dichloroethane Chlorine Xylene Manganese compounds Nitric acid Total Production Related Waste Managed (Pounds) 2,331,011,667 1,787,944,977 1,504,105,058 1,355,504,817 1,263,772,355 1,256,806,620 1,088,001,030 970,193,833 965,794,108 832,570,075 800,432,076 797,566,959 701,130,070 583,305,201 565,972,276 561,860,469 552,091,471 479,477,559 477,625,043 411,681,261 Subtotal (top 20) 19,286,846,925 Total (all chemicals) 26,735,591,638 Texas A&M University M E X I C O Petroleum industries provide raw material for the chemical industry.e.g. Gas natural Ammonia Fertilizers Hazardous Pollutants produced by Industry I n Mexico, the petroleum industry development is strongly linked to the employment rate, inflation, economic growth and capital investment. More information Texas A&M University As we showed in the statistics section, there are two industries which are very important for the economy and development and also are causing serious environmental problems, making a link between the three countries. This research is attempting to show the way in which Process Integration can be used successfully. For this challenge we use the two major industries in North America: Pulp and Paper Petroleum Texas A&M University No energy industry today is more engaged than petroleum in serving the global transportation, power generation, agricultural and consumer products sectors. Oil and natural gas are essential drivers of economic growth, that implies enormous social and environmental responsibilities.. Texas A&M University 2. Petroleum Industry 2.1 Driving forces, hurdles and potential. 2.2 The Petroleum Refining Industry 2.2.1 2.2.2 2.2.3 2.2.4 Definition Primary Products Industrial Processes in the Petroleum Refining Industry Refinery flow diagram 2.3 Environmental discharges. 2.3.1 Refinery air emission sources 2.3.2 Types of wastewater produced in refineries 2.3.3 Refinery Residuals 2.3.4 Environmental discharges by process 2.4 Regulatory issues in North America. 2.4.1 U.S. Regulations 2.4.2 Mexican Regulations 2.4.3 General Regulations 2.5 Best available environmental technologies for specific processes Texas A&M University 2.1 DRIVING FORCES, HURDLES AND POTENTIALS The characteristics of the Petroleum Industry are related. In order to understand them, the following diagram in shown. According to Abdallah S. Jum’ah, president of Saudi Aramco, energy today, must have three characteristics which are totally interdependent: RELIABILITY OF SUPPLY ENVIRONMENTAL PROTECTION Environment should be protected in order to achieve a sustainable development. In order to secure reliable supplies of oil and natural gas, there must be a price mechanism sufficiently fair and stable to maintain inflows of investment capital. In turn, the investment will help fund the industry’s considerable measures to protect environment. Any nation’s ability to sustain domestic development will depend on a ready resource of fuels and feedstock. No other energy supplier today is more capable of assuring such a continuity of supply than the petroleum industry. REASONABLE PRICE These three characteristics can act as: •DRIVING FORCES •HURDLES The petroleum industry is one of the most capital-intensive, high-maintenance, heavily regulated and excessively taxed industries operating worldwide. •POTENTIALS First beak volume 20. 10 October 2002 Texas A&M University •The petroleum refining industry is a strong contributor to the economic health of the United States and Mexico. •For Mexico, this industry has become the most important part in the national economy, it is the first source of currency for the country. •Hydrocarbons will long remain the resource of choice to fuel future economic progress worldwide. This is a reason not only to protect air, water and land resources, but also to keep serving society through these products. DRIVING FORCES Economic and environmental situations are involved in the development of the petroleum industry, but its final challenge must be to fulfill the society needs. Texas A&M University Volatile crude prices HURDLES The petroleum industry has been dramatically impacted over the last three decades by geopolitical disruptions and volatile world oil prices. Today refiners must deal with: Crude quality variability Low marketing and transport profit margins Increasing capital and operating costs of environmental compliance. Texas A&M University HURDLES The environmental impact produced by the petroleum industry covers the effects of all and each step in the energetic cycle, which means: •explotation •extraction •refining •transportation •storage •consumption •releases Texas A&M University The natural source itself and the reliability of supply must be the greatest potential for the country that posses them. Technology plays an important role in developing the petroleum industry. Also, research and development have a great deal to do with keeping petroleum prices reasonable. In the past, new technologies had improved our methods of exploration and production, along with downstream efficiencies that yield cleanerburning automotive fuels and higher-value products from every barrel of crude oil, allowing the increase and the improvement of the industry. The U.S. is the largest, most sophisticated producer of refined petroleum products in the world, representing about 25% of global production. POTENTIALS Social and environmental issues will be decisive for the framework conditions for the future oil and gas industry. Technology is a tool that could help in achieving this task. Texas A&M University 2.2 PETROLEUM REFINING INDUSTRY 2.2.1 DEFINITION Petroleum refining is the physical, thermal and chemical separation of crude oil into its major distillation fractions which are then further processed through a series of separation and conversion steps into finished petroleum products. Petroleum refineries are a complex system of multiple operations and the operations used at a given refinery depend upon the properties of the crude oil to be refined and the desired products. Texas A&M University 2.2.2 The primary products of this industry are divided into three categories: FUELS motor gasoline, diesel and distillate fuel oil, jet fuel, residual fuel oil, kerosene and coke CHEMICAL INDUSTRY FEEDSTOCKS naphtha, ethane, propane, butane, ethylene, propylene, butylenes, butadiene, benzene, toluene and xylene FINISHED NON FUEL PRODUCTS solvents, lubricating oils, greases, petroleum wax, petroleum jelly, asphalt and coke These products are used as primary input to a vast number of products: fertilizers, pesticides, paints, waxes, thinners, solvents cleaning fluids, detergents, refrigerants, anti-freeze, resins, sealants, insulations, latex, rubber compounds, hard plastics, plastic sheeting and synthetic fibers. Texas A&M University 2.2.3 INDUSTRIAL PROCESSES IN THE PETROLEUM REFINING INDUSTRY In order to understand where the environmental discharges come from, we will make a review of the refining process. The process of oil refining involves five major processes which are briefly described: SEPARATION CONVERSION TREATING BLENDING AUXILIARY SEPARATION PROCESSES These processes involve separating the different fractions of hydrocarbon compounds that make up crude oil base on their boiling point differences. Additional processing of these fractions is usually needed to produce final products to be sold within the market. ASSOCIATED OPERATIONS • Atmospheric distillation • Vacuum distillation • Light ends recovery (gas processing) Texas A&M University 2.2.3 INDUSTRIAL PROCESSES IN THE PETROLEUM REFINING INDUSTRY SEPARATION CONVERSION TREATING BLENDING AUXILIARY ASSOCIATED OPERATIONS CONVERSION PROCESSES Include processes used to bread down large longer chain molecules into smaller ones by heating using catalysts. • • • • • • • Cracking (thermal and catalytic) Reforming Alkylation Polymerization Isomerization Coking Visbreaking Texas A&M University 2.2.3 INDUSTRIAL PROCESSES IN THE PETROLEUM REFINING INDUSTRY SEPARATION CONVERSION TREATING TREATING PROCESSES Petroleum-treating processes are used to separate the undesirable components and impurities such as sulfur, nitrogen and heavy metals from the products. BLENDING AUXILIARY ASSOCIATED OPERATIONS • • • • • Hydrodesulfurization Hydrotreating Chemical sweetening Acid gas removal Deasphalting Texas A&M University 2.2.3 INDUSTRIAL PROCESSES IN THE PETROLEUM REFINING INDUSTRY SEPARATION CONVERSION TREATING BLENDING/COMBINATION PROCESSES These are used to create mixtures with the various problem fractions to produce a desired final product, some examples of this are lubricating oils, asphalt, or gasoline with different octane ratings. BLENDING AUXILIARY ASSOCIATED OPERATIONS • • • • Storage Blending Loading Unloading Texas A&M University 2.2.3 INDUSTRIAL PROCESSES IN THE PETROLEUM REFINING INDUSTRY SEPARATION CONVERSION TREATING BLENDING AUXILIARY AUXILIARY PROCESSES ASSOCIATED OPERATIONS Processes that are vital to operations by providing power, waste treatment and other utility services. Products from these facilities are usually recycled and used in other processes within the refinery and are also important in regards to minimizing water and air pollution. • • • • Boilers Waste water treatment Hydrogen production Sulfur recovery plant Texas A&M University LPH and Gas 2.2.4 REFINERY FLOW DIAGRAM Refinery fuel gas Gasoline Stabilizer Sweetening Unit Sweet Gasoline LPG Naphta Hydrotreating Middle Distillates Solvents Gas Washed Crude Gasoline Gas Oil Lube-Base Stocks Vacuum Distillation Catalytic Cracking Solvent Extraction and Dewaxing Visbreaker Light Gas Oil Lube Oil Treating and Blending Middle Distillates Gasoline Aviation fuels Diesels Heating oils Lube oils Waxes Greases Gasoline, Naphtha and Middle distillates Asphalts Fuel Oil Industrial fuels Asphalt Refinery fuel oil Texas A&M University 2.3 ENVIRONMENTAL DISCHARGES Now, that we have seen an overview of the Refinery Process, we can make some questions: What is this industry discharging? How is it discharged? Where does it come from? In order to answer these questions, this section will show: Air emission sources Wastewater sources Residuals Environmental discharges by process Texas A&M University 2.3.1 REFINERY AIR EMISSIONS SOURCES COMBUSTION EMISSIONS: associated with the burning of fuels in the refinery, including fuels used in the generation of electricity. EQUIPMENT LEAK EMISSIONS (fugitive emissions): released through leaking valves, pumps, or other process devices. They are primarily composed of volatile compounds such as ammonia, benzene, toluene, propylene, xylene, and others. WASTEWATER SYSTEM EMISSIONS from tanks, ponds and sewer system drains. PROCESS VENT EMISSIONS: typically include emissions generated during the refining process itself. Gas streams from all refinery processes contain varying amounts of refinery fuel gas , hydrogen sulfide and ammonia. STORAGE TAND EMISSIONS released when product is transferred to and from storage tanks. Texas A&M University 2.3.2 TYPES OF WASTEWATER PRODUCED IN REFINERIES COOLING WATER which normally does not come into contact with oil streams and contains less contaminants than process wastewater. It may contain chemical additives used to prevent scaling and biological growth in heat exchanger pipes. SURFACE WATER RUNOFF is generated intermittently and may contain constituents from spills to the surface, leaks in equipment and materials in drains. PROCESS WASTEWATER that has been contaminated by direct contact with oil accounts for a significant portion of total refinery wastewater. Many of these are sour water streams and are also subjected to treatment to remove hydrogen sulfide and ammonia. Texas A&M University 2.3.3 REFINERY RESIDUALS Most refinery residuals are in the form of sludge, spend caustics, spend process catalysts, filter clay, and incinerator ash. These residuals could be classified as follows: NON-HAZARDOUS RESIDUALS are incinerated, landfilled or regenerated to provide products that can be sold off-site or returned for re-use at a refinery. HAZARDOUS WASTES are regulated under the Resource Conservation and Recovery Act (RCRA). Listed hazardous wastes include oily sludge, slop oil emulsion solids, dissolved air flotation floats, leads tank bottom corrosion solids and waster from the cleaning of heat exchanger bundles. TOXIC CHEMICALS are also use in large quantities by refineries. These are monitored through the Toxic Release Inventory (TRI). Texas A&M University 2.3.4 DISCHARGES LIQUID EFFLUENTS AIR EMISSIONS Po llutant Particulate matter Sulfur oxides Nitrogen oxides Benzene, toluene and xylene (BTX) VOC Average rate kg/t o f crude 0.8 1.3 0.3 0.0025 1 SOLID WASTES Refineries generate solid wastes and sludges ranging from 3 to 5 kg per ton of crude processed, 80% of this sludges may be considered hazardous because or the presence of toxic organics and heavy metals. Approximately 3.5-5 cubic meters of wastewater per ton of crude are generated when cooling water is recycled. Po llutant BOD COD Phenols Oil Benzene Benzopyrene Heavy metals Chrome Average rate mg/l of wastewater 150-250 300-600 20-200 100-300 1-100 1-100 0.1-100 0.2-10 Texas A&M University 2.3.4 ENVIRONMENTAL DISCHARGES BY PROCESS PART 1 Process Air Emissions Process Waste Water Residual Wastes Generated Crude oil desalting Heater stack gas (CO, SOx , NOx , hydrocarbons and particulates), fugitive emissions (hydrocarbons) Flow = 2.1 Gal/Bbl Oil, H2S, NH3, phenol, high levels of suspended solids, dissolved solids, high BOD, high temperature Crude oil/desalted sludge (iron rust, clay, sand, water, emulsified oil and wax, metals) Atmospheric distillation Heater stack gas (CO, SOx , NOx , hydrocarbons and particulates), fugitive emissions (hydrocarbons) Flow = 26 Gal/Bbl Oil, H2S, NH3 suspended solids, chlorides, mercaptans, phenol, elevated pH. Typically, little or no residual waste generated. Vacuum distillation Steam ejector emissions (hydrocarbons), heater stack gas (CO, SOx , Flow = 2.0 Gal/Bbl Oil, H2S, NH3, phenol, suspended solids, high pH, BOD, COD. Typically, little or no residual waste generated. NOx , hydrocarbons and particulates), vents and fugitive emissions (hydrocarbons). Thermal Heater stack gas (CO, Cracking/Visbreaking SOx , NOx , hydrocarbons and particulates), vents and fugitive emissions (hydrocarbons) Coking Heater stack gas (CO, Flow = 1.0 Gal/Bbl High Coke dust (carbon particles and SOx , NOx , hydrocarbons pH, H2S, NH3, and particulates), vents suspended solids, COD. hydrocarbons). and fugitive emissions (hydrocarbons) and decoking emissions (hydrocarbons and particulates). Texas A&M University 2.3.4 ENVIRONMENTAL DISCHARGES BY PROCESS PART 2 Process Catalytic Cracking Catalytic Hydrocracking Air Emissions Process Waste Water Residual Wastes Generated Heater stack gas (CO, SOx , NOx , hydrocarbons and particulates), fugitive emissions (hydrocarbons) and catalyst regeneration (CO, NOx , SOx , and particulates). Heater stack gas (CO, Flow 1.5 Gal/Bbl High levels of oil, suspended solids, phenols cyanides, H2S, NH3, high pH, BOD, COD. Spent catalysts (metals from crude oil and hydrocarbons), spent catalyst fines from electrostatic precipitators (aluminum silicate and metals). SOx , NOx , hydrocarbons and particulates), fugitive emissions (hydrocarbons) and catalyst regeneration (CO, NOx , SOx , and dust).gas (CO, Hydrotreating/Hydrop catalyst Heater stack rocessing SOx , NOx , hydrocarbons and particulates), vents and fugitive emissions (hydrocarbons) and catalyst regeneration (CO, NOx , SOx , and catalyst dust). Flow = 2.0 Gal/Bbl High Spent catalysts fines COD, suspended solids, (metals from crude oil, H2S, relatively low levels and hydrocarbons). of BOD. Flow = 1.0 Gal/Bbl H2S. Spent catalyst fines NH3, High pH, phenols (aluminum silicate and metals). suspended solids, BOD, COD. Alkylation Heater stack gas (CO, SOx , NOx , hydrocarbons and particulates), vents and fugitive emissions (hydrocarbons) Low pH, suspended solids, dissolved solids, COD, H2S, spent sulfuric acid. Isomerization Heater stack gas (CO, Low pH, chloride salts, SOx , NOx , hydrocarbons caustic wash, relatively and particulates), vents low H2S and NH3. and fugitive emissions (hydrocarbons) Neutralized alkylation sludge (sulfuric acid or calcium fluoride, hydrocarbons). Calcium chloride sludge from neutralized HCl gas. Texas A&M University 2.3.4 ENVIRONMENTAL DISCHARGES BY PROCESS PART 3 Process Air Emissions Process Waste Water Residual Wastes Generated Polymerization H2S from caustic washing. H2S, NH3, caustic wash, Spent catalyst containing phosphoric mercaptans and acid. ammonia, high pH. Catalytic Reforming Heater stack gas (CO, SOx, NOx , hydrocarbons and particulates), HCl potentially in light ends), vents and fugitive emissions (hydrocarbons) Flow = 6.0 Gal/Bbl High levels oil, suspended solids, COD. Relatively low H2S. Spent catalyst fines from electrostatic precipitators (alumina silicate and metals). Solvent Extraction Fugitive solvents Oil solvents Little or no residual wastes generated. Dewaxing Fugitive solvents, heaters Oil solvents Little or no residual wastes generated. Propane Deasphalting Heater stack gas (CO, Oil solvents SOx , NOx , hydrocarbons and particulates), fugitive propane. Little or no residual wastes generated. Merox treating Vents and fugitive Little or no wastewater emissions (hydrocarbons generated and disulfides). Spent Merox caustic solution, waste oildisulfide mixture. Wastewater treatment Fugitive emissions (H2S, Not Applicable API separator sludge (phenols, metals and oil), chemical precipitation sludge (chemical coagulants, oil), DAF floats, biological sludges (metals, oil, suspended solids), spent lime. NH3, and hydrocarbons) Texas A&M University 2.3.4 ENVIRONMENTAL DISCHARGES BY PROCESS PART 4 Process Gas Treatment and Sulfur Recovery Blending Air Emissions Process Waste Water SOx , NOx , and H2S from H2S, NH3, amines, vent and tail gas Stretford solution. emissions. Fugitive emissions Little or no wastewater (hydrocarbons) generated Residual Wastes Generated Spent catalyst. Little of no residual waste generated. Heat Exchanger cleaning Periodic fugitive emissions (hydrocarbons) Oily wastewater generated Heat exchanger sludge (oil, metals, and suspended solids) Storage Tanks Fugitive emissions (hydrocarbons) Water drained from Tank bottom sludge (iron tanks contaminated with rust, clay, sand, water, tank product emulsified oil and wax, metals) Blowdown and flare Combustion products Little or no wastewater generated (CO, SOx , NOx , and hydrocarbons) from flares, fugitive emissions Little or no residual waste generated. Texas A&M University 2.4 REGULATORY ISSUES IN NORTH AMERICA The Petroleum Refining Industry is unique in that the environmental requirements aimed at the industry are of two basic types: Requirements mandating specific product qualities for the purpose of reducing the environmental impacts associated with the downstream use of the product. Requirements directed at reducing the environmental impacts of the refineries themselves. For the purpose of this module, we focus on refineries, which will be used to show some Process Integration techniques. Petroleum refineries are complex plants, and the combination and sequence of processes is usually very specific to the characteristics of the raw material and the products. For this reason the regulations for this sector become very specific and dispersed because an unit have regulations for water, air and land discharges, all of these managed by different official documents. Texas A&M University 2.4.1 U.S. REGULATIONS EPA website In the case of the United States, there are numerous federal regulations affecting the Refinery Industry. The Environmental Protection Agency (EPA) contains several regulatory documents depending on the kind of resource that they pretend to protect, (e.g. Air, water and soil). Each one of these documents presents requirements which apply for every industrial sector. Then, when the requirements for a certain industry are needed, specific parts of the document should be used. For example, The Clean Air Act Amendments of 1990 has some programs for reducing air emissions from industry in which refineries are included: New Source Review, New Source Performance Standards National Emission Standards for Hazardous Air Pollutants At the same time, the New Source Performance Standards have some sections for Refineries: Subpart J Standards of Performance for Petroleum Refineries Subpart KKK Standards of Performance for Volatile Organic Liquid Storage Vessels. Subpart GG Standard of Performances for Stationary Gas Turbines. Subpart GGG Standards of Performance for Equipment Leaks of VOC in Petroleum Refineries Texas A&M University 2.4.1 U.S. REGULATIONS All these sections contain flow diagrams, where depending on the process that is being used, it must be applied certain norm. To find more information: http://www.tnrcc.state.tx.us/permitting/airperm/opd/60/60hmpg.htm Texas A&M University FEDERAL REQUIREMENTS AFFECTING THE REFINERY INDUSTRY Requirement Clean air Act of 1970 (CAA) and regulations Provisions That Affect Petroleum Refining National Ambient Air Quality Standards (NAAQS) fix six constituents; new standards under NAAQS that require control of particulate matter of 2.5 microns or smaller; lead-free gasoline; low sulfur fuel; reformulated gasoline; hazardous air pollutants; visi Clean Air Act Amendments of 1990 (CAAA) and Oxygenated Fuels Program for “ nonattainment areas” low sulfur highway diesel fuel; regulations thereunder. Reformulated fuels Program; Leaded Gasoline Removal Program; Reid Vapor pressure regulations to reduce VOCs and other ozon precursors; New Source Review for new or expande Resource Conservation and Recovery Act Standards and regulations for handling and disposing of solid and hazardous wastes. (RCRA) Clean Water Act (CWA) Regulates discharges and spills to surface waters; wetlands. Safe Drinking Water Act (SDWA) Regulates disposal of wastewater in underground injection wells Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) “superfund”, liability for CERCLA hazardous substances could apply to wastes generated during refining, includes past releases, exempts petroleum and crude oil; provides for natural resource damages. Emergency Planning and Community Right-toKnow (EPCRA). Requires annual reporting on the releases and transfers of listed toxic chemicals; reporting presence of “extremely hazardous substances’ in excess or threshold planning quantities; reporting certain releases of CERCL hazardous substances and EPCRA extrem 1990 Oil Pollution act and Spill Prevention Control Liability against facilities that discharge oil to navigable waters of pose a threat of doing so. and Countermeasure Plans OSHA Health Standards and Process Safety Management Rules Toxic Substances Control Act Limits benzene and other chemical exposures in the workplace, safety plans required in all refineries. Collection of data on chemicals for risk evaluation, mitigation and control; can ban chemicals that pose unreasonable risks. Energy Policy Act of 1992 Use of alternative fuels for transportation; efficiency standards for new federal buildings, buildings with federally backed mortgages, and commercial and industrial equipment; R&D programs for technologies; will reduce demand for petroleum products. Texas A&M University 2.4.2 MEXICAN REGULATIONS In Mexico, SEMARNAT (Secretaria de Medio Ambiente y Recursos Naturales) is in charge or the environmental regulations, but it does not cover all aspects of a refinery because some of them are very specific, for example, Proyecto NOM-088-ECOL-1994 Establish the maximum permissible levels of pollutants in the water discharges that become from storage and distribution of petroleum and its derivates. A classification of these norms is found in this website: http://www.semarnat.gob.mx Then, if the complete document is needed, you can check here: http://cronos.cta.com.mx/cgi-bin/normas.sh/cgis/index.p Texas A&M University 2.4.3 GENERAL REGULATIONS Besides all these complicated regulations, an specialized agency of the United Nations, the World Bank, has established emission levels for the design and operation of refineries, although country legislation should be accomplished. The guidelines given below present emissions levels normally acceptable to the World Bank Group. Emissions from the Petroleum Industry Effluents from the Petroleum Industry (milligrams per normal cubic meter) (milligrams per liter) Parameter PM Nitrogen oxides a Sulfur oxides Parameter pH BOD COD TSS Oil and grease Chromium Hexavalent Total Lead Phenol Benzene Benzo(a)pyrene Sulfide Nitrogen(total)a Temperature increase Maximum value 50 460 150 for sulfur recovey units; 500 for other units Nickel and vanadium 2 (combined) Hydrogen sulfide 152 Solid Wastes Generation of sludges should be minimized to 0.3 kg per ton of crude processed, with a maximum of 0.5 kg per ton of crude processed. Maximum value 6--9 30 150 30 10 0.1 0.5 0.1 0.5 0.05 0.05 1 10 <=3 C World Band Group, 1998. Pollution Prevention and Abatement Handbook. World Bank Group. Pages 377-381. Texas A&M University 2.5 ENVIRONMENTAL TECHNOLOGIES USED IN THE PETROLEUM INDUSTRY Primary wastewater treatment Consists on the separation of oil, water and solids in two stages. 1st stage API separator or Corrugated plate interceptor. 2nd stage Chemical and physical methods are utilized to separate emulsified oils from the wastewater. More information about the equipment www.panamenv.com Physical methods may include the use of series of settling ponds with a long retention time, or the use of dissolved air flotation (DAF). More information about the equipment Chemicals, such as ferric hydroxide or aluminum hydroxide are used to coagulate impurities. www.panamenv.com Texas A&M University 2.5 ENVIRONMENTAL TECHNOLOGIES PETROLEUM INDUSTRY Secondary wastewater treatment Dissolved oil and other organic pollutants may be consumed biologically. Biological treatment may require oxygen through different techniques: • Activated sludge units • Trickling filters • Rotating biological contactors. Polishing Some refineries employ it as an additional stage of wastewater treatment to meet discharge limits. Generates bio-mass waste which is treated anaerobically. • Activated carbon • Anthracite coal • Sand Texas A&M University 2.5 ENVIRONMENTAL TECHNOLOGIES PETROLEUM INDUSTRY Gas treatment and Sulfur Recovery In order to meet the SOx emissions limits and to recover saleable sulfur, refinery process off-gas streams should be treated. These fuel gases (methane and ethane) need to be separated before elemental sulfur can be recovered. Process off-gas streams contain high concentrations of: hydrogen sulfide + light refinery fuel gases. Amine + hydrogen sulfide hydrogen sulfide This is accomplished by: • Dissolving the hydrogen sulfide in a chemical solvent such as diethanolamine (DEA) in an absorption tower. • Using dry adsorbents such as molecular sieves, activated carbon, iron sponge and zinc oxide. Is then heated and steam stripped to remove the hydrogen sulfide gas. Two processes are typically combined to remove sulfur from the hydrogen sulfide gas streams: Beaven Process Claus Process Scot Process Wellman-Land Process Texas A&M University 2.5 ENVIRONMENTAL TECHNOLOGIES PETROLEUM INDUSTRY Gas treatment Other emissions sources come from periodic regeneration of catalysts, these emissions may contain: high levels of carbon monoxide + particulates + VOCs. www.e2t.com/E2T/app_pc05.htm Before being released to the atmosphere CARBON MONOXIDE BOILER To burn carbon monoxide and VOCs ELECTROSTATIC PRECIPITATOR OR CYCLONE SEPARATOR To remove particulate matter Solid waste treatment Sludge treatment use bioremediation or solvent extraction, followed by combustion of the residues or by use for asphalt. The residue could require stabilization before disposal to reduce the leachability of toxic metals. More information: www.ppcesp.com Texas A&M University As we showed in the statistics section, there are two industries which are very important for the economy and development and also are causing serious environmental problems, making a link between the three countries. This research is attempting to show the way in which Process Integration can be used successfully. For this challenge we use the two major industries in North America: Pulp and Paper Petroleum Texas A&M University The uses and applications for paper and paper products are limitless. It is important because it gives us the opportunity or recording, storage and dissemination of information. Also, it is the most widely used wrapping and packaging material and it is also used for structural applications. Texas A&M University 3. Paper Industry 3.1 Driving forces, hurdles and potential. 3.2 Overview of the Pulp and Paper process. 3.2.1 Different methods 3.2.2 Main steps of the process 3.3 Environmental discharges. 3.4 Regulatory issues in North America. 3.4.1 U.S. Regulations 3.4.2 Canadian Regulations 3.4.3 General Regulations 3.5 Best available environmental technologies for specific processes Texas A&M University 3.1 DRIVING FORCES The Pulp and Paper Industry provides employment for vast number of people and plays a vital role in the overall economy of both the United States and Canada. The U.S. forest products industry makes a strong contribution to the national economy, producing 1.2% of the U.S. GDP. The industry employed almost 1.3 million people just in the United States. Pulp and paper is the third largest industrial polluter to air, water and land in both Canada and the United States, and releases well over a hundred million kg of toxic pollution each year. Paper and wood products are used in many different applications both at home and at work. Texas A&M University 3.1 HURDLES The Pulp and Paper industry in North America is threatened by: Plantation forests of fast growing tree species are being developed such countries as Brazil, Indonesia, Chile. Quality-stand of timber have become more difficult and costly to access. New competitors, with lower fiber costs, have entered the market (e.g. Russia, Austria, Chile, Australia, New Zealand and Indonesia). Texas A&M University 3.1 POTENTIALS The Pulp and paper industry producers have some advantages: •The high quality of woodfiber derived from them. •Potential of the US and Canadian market. •Access to a substantial endowment of timber suitable for harvesting as saw and pulp logs. •Access secure energy. to low-cost, supplies of The strong U.S. economy of the late 1990s has revived the pulp and paper industry. Now, this industry is one with the biggest average annual pace growth. Texas A&M University 3.2 OVERVIEW OF THE PULP AND PAPER PROCESS The manufacture of pulp for paper and cardboard employs different methods: CHEMICAL MECHANICAL Chemical pulps are made by cooking the raw materials, using the kraft (sulfate) and sulfite processes. Kraft processes produce a variety of pulps used mainly for packaging and highstrength papers and board. Oxygen, hydrogen peroxide, ozone, peracetic acid, sodium hypochlorite, chlorine dioxide, chlorine, and other chemicals are used to transform lignin into an alkali-soluble form. Separates fibers by such methods as disk abrasion and billeting, this pulp can be used without bleaching to make printing papers for applications in which low brightness is acceptable. For other applications, bleaches like peroxides and hydrosulfites must be used. CHEMIMECHANICAL A combination of the previous processes. Texas A&M University 3.2 OVERVIEW OF THE PULP AND PAPER PROCESS The main steps in pulp and paper manufacturing are: Wood yard Pulping These steps are common for the three processes, although the difference is the units they use for each task. Bleaching The significant environmental impacts of the manufacture of pulp and paper result from the pulping and bleaching processes. Paper manufacture Texas A&M University 3.2 OVERVIEW OF THE PULP AND PAPER PROCESS This table presents the purpose of each one of the processes presented before and the technologies used to reach their task. PROCESS PURPOSE MAJOR TECHNOLOGIES PULPING Convert wood chips of wastepaper into fibers suitable for papermaking. Chemical (Kraft, sulfite)digesters, mechanical – refiners, semi chemical – digesters & refiners. CHEMICAL RECOVERY (KRAFT PULPING) Recovery of inorganic chemicals from spend pulping liquor and combustion of organic residuals to produce energy. Evaporation concentration recovery boiler, causticizing, calcining. BLEACHING Brighten of whiten pulps by using chemicals to selectively remove lignin. Chlorine dioxide, oxygen, hypochlorite, peroxide, ozone, of chlorination- upflow of downflowtowers, vacuum washers, pumps, mixers. PAPER MANUFACTURE Prepare stock from pulp, sheet, dewater, dry, caleder. Heat box, sheet forming table. Texas A&M University 3.3 ENVIRONMENTAL DISCHARGES LIQUID EFFLUENTS AIR EMISSIONS Po llutant Av e ra g e ra te s Kg /t o f AD P Bla ck liq u o r o xid a tio n Reduced sulfur compounds: 0.3-3 Hydrogen sulfide Methyl mercaptan Dimethyl sulfide Dimethyl disulfide Particulate matter Sulfur oxides Nitrogen oxides Volatile organic compounds (VOCs) 75 -150 0.5 - 30 1--3 15 15-30 Ste a m a n d e le ctricity g e n e ra tin u n its Fly ash Wastewaters BOD Total suspended solids COD Chlorinated organic compounds: Dioxins Furans Adsorbable organic halides Av e ra g e ra te s Kg /t o f AD P 20-250 m3/t 10--40 10--50 20-200 0-4 SOLID WASTES Pu lp in g Sulfur oxides Pollutant 100 ADP: Air dried pulp, defined as 90% bone-dry fiber and 10% water. t:metric ton. The principal solid wastes of concern include wastewater treatment sludge : 50-150 kg/t of ADP. Texas A&M University 3.4 REGULATORY ISSUES U.S. REGULATIONS The key federal group responsible for the environment is the EPA, which is a regulatory agency that establish and enforce environmental standards. AIR REGULATIONS The purpose of the EPA is to conduct research and suggest solutions to environmental problems. Simultaneously, it has an obligation to monitor and analyze the environment. The components of the legislation that most influence the pulp and paper industry are the effluent limitation WATER REGULATIONS guidelines that define minimum effluent conditions for 1977 and 1983. Texas A&M University WATER REGULATIONS BACKGROUND BACKGROUND PARAMETERS PARAMETERS TOXIC TOXIC POLLUTANTS POLLUTANTS NewUp source performance stardard in kg/kkg to 1970, stream quality standards in the United States were largely Maximum 30-day average Maximum /day the responsibility of individual states. The federal government became Subcategory BDO5 TSS BDO5 TSS dominant until 1970, when the Environmental Protection Agency Dissolving kraft 6.1 8.35 11.75 15.5 (EPA) Market kfaftwas established. 2.65 2.9 5.15 5.35 1972, the Federal Water3.7 Pollution Control Act stipulated a stepBCTInkraft 5 7.05 9.3 Finewise Draft schedule for meeting2.55 7 conventional3.75 discharge 4.95 criteria, the first Papergrade sulfite 4.65 2.9 8.98 5.35 target level by 1977 being equivalent to “best practical technology” Market sulfiteand the second target 4.65 2.9 being equivalent 8.95 5.35 (BPT), level by 1983 to “best Low alpha dissolving sulfite 11.15 10 21.45 18.6 available technology economically achievable”(BATEA). High alpha dissolving sulfite 13.8 9.45 26.5 17.6 GW:Inchemimechanical 3.3 7.5 or sub-toxic 6.15 the early 1980’s these 3.9 regulations included toxic GW:substances thermomechanical 2.3 3.15 Discharge 4.45 Elimination 5.85 through the National Pollutant GW:CMN papers 2 3.15 3.85 System (NPDES). Among these were a number of byproducts5.85 of GW: fine papers 1.9 3 5.6 5.6 the chlorine bleaching process. Later, the EPA has increased the list Soda 3.15 4.3 60 7.95 of priority pollutants. Deink 3.9 4 7.5 7.45 NI fine 1.35 1.4 environmental 2.6 2.6 Thepapers U.S federal regulations that deal with protection NI tissue papers 2.15 2.2 4.15 4.1to change every four years. It is a constant challenge to this industry NI tissue papers (FWP) 1.9 1.95 3.7 3.65 keep up-to-date. GW: groundwood Other agencies: NI: nonintegrated • Effluent Standards and Water Quality Information Advisory Committee (ES&WQIAC). • The Council of Environmental Quality. • National Commission on Water Quality Texas A&M University TOXIC POLLUTANTS Acenaphthene Acrolein Acrylonitrile Aldrin/dieldrin Antimony and compounds Arsenic and compounds Asbestos Benzene Benzidine Beryllium and compounds Settlement agreement toxic pollutants: Cadmium and compounds Carbon tetrachloride Chlordane Chlorinated benzenes Chlorinated ethanes Chloralkyl ethers Chlorinated napthalene Chlorinated phenols Chloroform 2-Chlorophenol Chromium and compounds Copper and compounds Cyanides Naphtalene Nickel and compounds Nitrobenzene Nitrophenols Nitrosamines DDT and metabolites Dichlorobenzene Dichlorobenzidine Dichloroethylenes 2,4-Dichlorophenol Dichloropropane and dichloropropene 2,4-Dimethylphenol Dinitrotoluene Diphenylhydrazine Endosulfan and metabolites Endrin Ethylbenzene Haloethers Halomethanes Heptachlor and metabolites Hexachlorocyclohexane Hexachlorocyclopentadiene Isophorone Lead and compounds Mercury and compounds Silver and compounds 2,3,7,8-Tetrachlorodibenzo-p-dioxin Tetrachloroethylene Thalium and compounds Toluene Toxaphene Trichloroethylene Pentachlorophenol Phenol Phthalate esters Polychlorinated bephenyls Vinyl chloride Polynuclear aromatic hydrocarbons Zinc and compounds Selenium and compounds Texas A&M University AIR REGULATIONS The Clean Air Act of 1963, was a benchmark piece of legislation. It represented Representative MACT II limits the first allocation by the federal government of significant funds for air pollution problems. GENERAL INFORMATION BACKGROUND BACKGROUND PARAMETERS Talking about the Pulp and Paper industry, the objective of air Mill regulations is Emission the elimination of tohazardous air pollutants type pointdecided PMform HAP the U.S. TGO HAP In 1970, President Richard Nixon Environmental Recovery funace PM < 0.015 grains/dry < 0.025 lb/tonControl of black Protection Agency, which absorbed the National Air Pollution such as methanol, total reduced sulfur gases, and chlorine. Administration. standard cubic foot at 8% liquor solids (BLS) Maximum achievable control technology (MACT) is the level Kraft of andcontrol soda oxygen at the average of the best 12% of the mills in the The Clean Air Act Amendments of 1970, covered primary areas: Smelt dissolving tank PM < 0.12 three lb/ton BLS None EPA data base of that category. •Attainment and maintenance of National Ambient Air Quality Standards (NAAQS). Lime kiln PM < 0.01 grains/dry None •Establishment regulations the sorted emission ofmill The MACTofrules have covering three tiers type.pollutants from standard cubicby foot atcertain 8% mobile and stationary sources. •MACT I is for chemical oxygen pulp mills including kraft, •Establishment of New Source Performance Standards (NSPS). Sulfitesulfite. combustion PM < 0.02 grains/dry semichemical, and EPA established standards for seven pollutants: sulfur dioxide, total suspended units kraft, soda, standard cubic foot at 8% and sulfite •MACT II is for particulates, carbon monoxide, nitrogen semichemical oxides, photochemical oxidants, Sulfite oxygen combustion sources including units, smelt hydrocarbons, and lead. NAAQS needed reviewrecovery every five years. Chemical recovery None < 2.97 lb/ton BLS or dissolving tanks, and lime kilns. Stand alone semichemical combustion units 90% reduction The 1990 CAA is probably the most dramatically impacting air pollution legislation •MACT III is for paper machines, mechanical pulping and of all time became law in 1990. Possibly most important to the pulp and paper secondary fiber and nonwood fiber. HAP:the particulate matter hazardous industryPMwas new air toxics controlmaterial. program. The 1990 law relied on TGO to HAP: totalemissions gaseous organic material. technology control of 189hazardous hazardous air pollutants. Texas A&M University CANADIAN CANADIANREGULATIONS REGULATIONS BACKGROUND BACKGROUND BACKGROUND PARAMETERS In first 1992, federal Canadian government released The set the of regulations for the pulp and paper industry, REGULATIONS newWATER Pulp and Paper Effluent Regulations under the which came into force in 1971, did not limit the total amount of Fisheries pollution, Act. but rather permitted the discharge of pollutants MAXIMUM AND MAXIMUM in proportion to theBDO production of the mill. QUANTITY OF TheSUSPENDED PPER set limits on BOD5, TSS, and FOR acuteMILLS. toxicity SOLIDS AUTHORIZED had numerous reporting requirements. Regulations In and 1991, the federal government responded to public limiting the discharge of chlorinated dioxins and pressure by introducing a regulatory scheme that furans required also went into effect in 1992 under the Canadian mills to implement secondary treatment systems and abide Protection (CEPA). of certain harmful byEnvironmental limits to control the Act discharge AIR REGULATIONS pollutants, including dioxins and furans. TheTHERE CEPA and massive AREPPER NO regulations LEGALLY resulted BINDINGin a CANADIAN investment to change bleaching processes and install FEDERAL OR PROVINCIAL FOR AIRset In 1992, the Pulp and Paper REGULATIONS Effluent Regulations EMISSIONS FROM before PULP the MILLS FOR AMBIENT AIR secondary treatment end of 1996 at a many minimum standards. QUALITY. Canadian mills. Texas A&M University MAXIMUM BDO AND MAXIMUM QUANTITY OF SUSPENDED SOLIDS AUTHORIZED FOR MILLS. Except where an authorization or transitional authorization is issued authorizing the deposit of BDO matter or suspended solids, the maximum BDO of all BDO matter and the maximum quantity of all suspended solids that may be deposited in the case of a mill is determined by: In respect of any 24-hour period, the formula: Qd F * 2.5 * RPR In respect of any month the formula: Qm F * D *1.5 * RPR Where : F = is equal to a factor of 5 in respect of BDO and 7.5 in respect of suspended solids, expressed in kilograms per tonne of finished product. RPR = is the reference production rate. D = number of days in a month. Original source: Department of Justice Canada Texas A&M University 3.4.3 GENERAL REGULATIONS Emissions levels for the design and operation of each project must be established throuth the environmental assessment process on the basis of country legislation and the Pollution Prevention Handbook, which establishes the following. Air Emissions Liquid effluents (milligrams per normal cubic meter) Parameter PM Hydrogen sulfide Total sulfur emitted Sulfite mills Kraft and other Nitrogen oxides Maximum value 100 for recovery furnace 15 (for lime kilns) 1.5 kg/t ADP 1.0 kg/t ADP 2 kg/t ADP Parameter pH COD AOX Total phosphorus Total nitrogen Temperature Maximum value 6--9 300 mg/l and 15 kg/t for kraft and CTMP pulp mills; 700 mg/l and 40kg/t of sulfite pulp mills; 10 mg/l and 5kg/t of mechanical and recycled fiber pulp; 250 mg/l for paper mills 40 mg/l and 2 kg/t (aim for 8 mg/l and 0.4 kg/t and retrofits and for 4 mg/l and 0.2 kg/t for new mills) and 4 mg/l for paper mills 0.05 kg/t 0.4 kg/t <3C Source: Pollution Prevention and Abatement Handbook 1998. World Bank Group. P 395-399 Texas A&M University 3.5 ENVIRONMENTAL TECHNOLOGIES PULP AND PAPER INDUSTRY Gas treatment In the kraft pulping process, highly emissions of reduced sulfur compounds, measured as total reduced sulfur (TRS) and including hydrogen sulfide, methyl marcaptan, dimethyl sulfide, and dimethyl disulfide, are emitted. Sulfur oxide emissions are scrubbed with slightly alkaline solutions. More information: www.jrfindia.com The reduced sulfur-compounds gases are collected using headers, hoods, and venting equipment. Condensates from the digester relief condenser and evaporation of black liquor are stripped of reduced sulfur compounds. More information: www.wesinc.com Stripper overhead and noncondensable are incinerated in a lime kiln or a combustion unit. Texas A&M University 3.5 ENVIRONMENTAL TECHNOLOGIES PULP AND PAPER INDUSTRY Wastewater treatment To remove suspended solids: • • • • To remove the organic content: Neutralization Screening Sedimentation Flotation • Activated sludge • Aerated lagoons • Anaerobic fermentation More information: www.sequencertech.com Solid waste treatment Solid waste treatment steps include dewatering of sludge and combustion in an incinerator, bark boiler, or fossil-fuelfired boiler. Texas A&M University TIER 2 : STUDY CASE This tier will demonstrate the relevance of Process Integration for specific examples of key processes in the Pulp and Paper Industry as well as in Refineries. Texas A&M University STUDY CASE 1 KRAFT PULPING PROCESS (Dunn and El-Halwagi, 1993) As we saw in Tier 1, the Pulping Process can be accomplished by chemical, semichemical or mechanical methods. About 80% of the wood pulp in the United States is produced through the kraft chemical pulping process. A environmental problem associated with the kraft process is the atmospheric emission of considerable quantities of hydrogen sulfide. The serious health and environmental problems of discharging hydrogen sulfide to the atmosphere call for effective sulfur-waste reduction processes in a pulp and paper plant. The purpose of this study case is to employ the Mass Exchange Network methodology to develop an optimal design of recycle/reuse networks for reducing the emission of hydrogen sulfide for pulp and paper plants. Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester Lime Kiln Washers Causticizers PULP Weak Black Liquor Evaporators Lime Mud Contaminated Condensate Slaker Strong Black Liquor Recovering Furnace Smelt Dissolving Tank Green Liquor Lime Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester Lime Kiln Wood chips, containing ligning, PULP cellulose and hemicellulose are added to white liquor (NaOH, Na2S, Na2CO3). The chips are cooked to solubilize the lignin. Washers Weak Black Liquor Evaporators Causticizers Lime Mud Contaminated Condensate Slaker Strong Black Liquor Recovering Furnace Smelt Dissolving Tank Green Liquor Lime Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester Lime Kiln Washers Weak Black Liquor Evaporators Causticizers PULP Contaminated Condensate The solubilized lignin leaves as black liquor, leaving the cellulose and hemicellulose which are the constituents of pulp. Slaker Strong Black Liquor Recovering Furnace Smelt Lime Mud Dissolving Tank Green Liquor Lime Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester Lime Kiln Washers Weak Black Liquor Evaporators Causticizers PULP Contaminated Condensate It is sent to the bleaching of papermaking process, depending on the end product desired. Slaker Strong Black Liquor Recovering Furnace Smelt Lime Mud Dissolving Tank Green Liquor Lime Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester Lime Kiln Washers Weak Black Liquor Evaporators Causticizers PULP Contaminated Condensate The main constituents of White Liquor are: NaOH, Na2S, Na2CO3, Na2SO4, Na2S2O3, NaCl, water. Slaker Strong Black Liquor Recovering Furnace Smelt Lime Mud Dissolving Tank Green Liquor Lime Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester Lime Kiln Washers Weak Black Liquor Evaporators Causticizers PULP Contaminated Condensate The Weak Black Liquor is processed through a series of evaporators to increase the solid content from 15% to 70% approximately. Strong Black Liquor Recovering Furnace Smelt Dissolving Tank Green Liquor Lime Mud Slaker Lime Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester Lime Kiln Washers Weak Black Liquor Evaporators Causticizers PULP Contaminated Condensate Slaker Strong Black Liquor Recovering Furnace Smelt Lime Mud The Strong Black Liquor is incinerated to supply energy for the pulping process and to form inorganic smelt. Dissolving Tank Green Liquor Lime Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester Lime Kiln Washers Causticizers PULP Weak Black Liquor Evaporators Lime Mud Contaminated Condensate Na2CO3 and Na2S Slaker Strong Black Liquor Recovering Furnace Smelt Dissolving Tank Green Liquor Lime Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester Lime Kiln Washers Causticizers PULP Weak Black Liquor Evaporators Lime Mud Contaminated Condensate Smelt is dissolved in water to form the Green Liquor. Slaker Strong Black Liquor Recovering Furnace Smelt Dissolving Tank Green Liquor Lime Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester Lime Kiln Washers Causticizers PULP Weak Black Liquor Evaporators Lime Mud Contaminated Condensate NaOH, Na2S, Na2CO3 and water. Slaker Strong Black Liquor Recovering Furnace Smelt Dissolving Tank Green Liquor Lime Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester Lime Kiln Washers Weak Black Liquor Evaporators Causticizers PULP Lime (CaO) is converted to CaOH2 in presence of water. Lime Mud Contaminated Condensate Slaker Strong Black Liquor Recovering Furnace Smelt Dissolving Tank Green Liquor Lime Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester Lime Kiln Washers CaOH2 reacts with Na2CO3 to form NaOH and a CaCO3 as precipitant. Weak Black Liquor Evaporators Causticizers PULP Lime Mud Contaminated Condensate Slaker Strong Black Liquor Recovering Furnace Smelt Dissolving Tank Green Liquor Lime Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester The CaCO3 is heated to regenerate the CaO and release CO2. Lime Kiln Washers Causticizers PULP Weak Black Liquor Evaporators Lime Mud Contaminated Condensate Slaker Strong Black Liquor Recovering Furnace Smelt Dissolving Tank Green Liquor Lime Texas A&M University DESCRIPTION OF THE KRAFT PROCESS CHIPS White Liquor Clarifier White Liquor Digester Lime Kiln NaOH, Na2S, NaCO3 and water. Washers Causticizers PULP Weak Black Liquor Evaporators Lime Mud Contaminated Condensate Slaker Strong Black Liquor Recovering Furnace Smelt Dissolving Tank Green Liquor Lime Texas A&M University EMISSION SOURCES OF THE KRAFT PROCESS CHIPS White Liquor White Liquor Clarifier Digester Three major sources in the Kraft Process are Responsible for the majority of the H2S emissions. PULP Washers Lime Kiln Causticizers R3 Air Emission Weak Black Liquor R2 Evaporators Contaminated Condensate Evaporators Air Lime Mud Air Air Stripping Stripping Lime Slaker Wastewater Strong Black Liquor R1 Recovering Recovery Furnace Furnace Smelt Dissolving Tank Green Liquor Texas A&M University INTERNAL MASS SEPARATING AGENTS CHIPS S1 Several Mass-Exchange operations such as absorption or adsorption can be White White Liquor Liquor White Liquor employed to reduce the H2S emissions. Digester Clarifier Three liquid streams that already exist in the plant (process MSAs) can be used. PULP Washers Lime Kiln Causticizers Weak Black S2 Liquor Black Weak Air Emission Lime Mud Liquor Evaporators Contaminated Condensate Air Smelt Slaker Wastewater Strong Black Liquor Recovering Furnace Lime Air Stripping Dissolving Tank S3 Green Green Liquor Liquor Texas A&M University EXTERNAL MASS SEPARATING AGENTS Three external MSAs will be considered potential candidates for recovering H2S: • S4, Diethanolamine (DEA) • S5, Activated Carbon • S6, 30 wt% Hot potassium carbonate solution Texas A&M University Evaporator Emissions, R2 R3, Air Stripping Emissions White Liquor, S1 S1 Green Liquor, S2 S2 REACTIVE Black Liquor, S3 DEA, S4 S3 MASS-EXCHANGE NETWORK Activated Carbon, S5 S4 S5 Hot K2CO3 solution, S6 S6 R1 R2 To atmosphere R3 Texas A&M University Evaporator Emissions, R2 R3, Air Stripping Emissions Dissolving Causticizer DigesterTank Evaporators Digester Slaker White Liquor, S1 S1 Green Liquor, S2 S2 REACTIVE Black Liquor, S3 DEA, S4 S3 MASS-EXCHANGE NETWORK Activated Carbon, S5 S4 S5 Hot K2CO3 solution, S6 S6 R1 R2 To atmosphere R3 Texas A&M University DATA FOR THE KRAFT PROCESS PROBLEM DATA FOR THE WASTE STREAMS Stream R1 R2 R3 Emissions stream Gi description Recovery furnace Evaporator Air stripping m3/s 170.000 0.433 465.800 yi s kmol/m 3 3.08 x 10-5 8.20 x 10-5 1.19 x 10-5 yi t kmol/m 3 2.1 x 10-7 2.1 x 10-7 2.1 x 10-7 DATA FOR THE MASS SEPARATING AGENTS Stream S1 S2 S3 S4 S5 S6 Stream description White liquor Green liquor Black liquor DEA Activated carbon Hot KCO3 solution Max. available flowrate m3/s 0.040 0.049 0.100 x js x jt kmol/m 3 3.2 x 10-1 2.9 x 10-1 0.2 x 10-1 2.0 x 10-6 1.0 x 10-6 0.3 x 10-2 kmol/m 3 3.10 x 100 1.29 x 100 1.00 x 10-1 2 x 10-2 1.7 x 10-3 2.8 x 10-1 Texas A&M University DESIGN METHODOLOGY We are looking forward the potentials for waste reduction in the Kraft Process by establishing tradeoffs between environmental and economic objectives in order to obtain the optimal configuration for a Waste-reduction system. The solution of this problem will follow two different approaches: GRAPHICAL ALGEBRAIC Texas A&M University OBTAIN PINCH POINT PLOT LEAN STREAM CREATE ONE-TO-ONE CORRESPONDENCE PLOT RICH STREAM INTERPRET THE RESULTS GRAPHICAL APPROACH These are the main steps that we will follow to find an optimal design of recycle/reuse networks for reducing the emission of hydrogen sulfide from a pulp and paper plant using a GRAPHICAL APPROACH. Texas A&M University 0.01 R2 0.00907 0.009 0.00904 0.008 R1 Mass Exchanged kmol H2S/s 0.007 0.006 The first step is to plot the mass exchanged or each rich stream versus its composition. 0.005 0.00544 The slope of the arrows will be equal to the stream Each stream represented as an arrow whose flowrate and isthe vertical distance between thetail tail Each arrow should be placed starting with the waste corresponds to its supply composition and its and the head of each arrow represents the mass of stream having the lowest composition. head to itsthat target composition. pollutant is lost by eachtarget rich stream: MRi=Gi(yis – yit), i=1,2,…,NR. 0.004 0.003 R3 0.002 0.001 0 0.00E+00 y1,2,3t 1.00E-05 y3s 2.00E-05 3.00E-05 y1s 4.00E-05 5.00E-05 6.00E-05 7.00E-05 8.00E-05 y2s y 9.00E-05 GRAPHICAL APPROACH RICH COMPOSITE STREAM Texas A&M University GRAPHICAL APPROACH RICH COMPOSITE STREAM 0.01 0.01 0.009 0.009 0.008 0.008 Mass Mass Exchanged Exchanged kmol H2S/s kmol H2S/s 0.007 0.007 This rich composite stream represents the cumulative mass of the pollutant lost by all the streams. 0.006 0.006 0.005 0.005 The rich composite stream is obtained by applying superposition to the rich streams. 0.004 0.004 0.003 0.003 0.002 0.002 0.001 0.001 00 0.00E+00 0.00E+00 1.00E-05 1.00E-05 y 2.00E-05 2.00E-05 3.00E-05 3.00E-05 4.00E-05 4.00E-05 5.00E-05 5.00E-05 6.00E-05 6.00E-05 7.00E-05 7.00E-05 y 8.00E-05 9.00E-05 9.00E-05 8.00E-05 Texas A&M University The second step is to generate a one-to-one correspondence among compositions of the three waste streams and the six MSAs. Consider a waste stream i, and and MSA, j, for which equilibrium is given by: yi*= fi(xj*) For any mass-exchange operation to be thermodynamically feasible, some conditions must be satisfied: xj<xj* and/or yi>yi* To generate the one-to-one correspondence, we use the following equation: y=f(xj+εj) Where εj is the minimum allowable composition difference, which means that we are adding a driving force to allow mass transfer. A deep explanation of these concepts is given in Module 3. GRAPHICAL APPROACH ONE-TO-ONE CORRESPONDENCE Texas A&M University Some examples of the generation of the one-to-one correspondence are the following: MSA1 White liquor MSA2 Green liquor Equilibrium equation y1= 2.0402 x 10-9(10)1.1786x1 y2= 2.5763 x 10-9(10)2.8136x2 Adding the driving force y1= 2.0402 x 10-9(10)1.1786(x1+ε1) ε1 = 7.64 y2= 2.5763 x 10-9(10)2.8136(x2+ε2) ε2 = 3.20 Supply correspondence y1s= 2.0402 x 10-9(10)1.1786(0.32+7.64) y1s= 4.91 y2s= 2.5763 x 10-9(10)2.8136(0.29+3.20) y2s= 17.00 Target correspondence y1t= 2.0402 x 10-9(10)1.1786(3.10+7.64) y1t= 9186 y2t= 2.5763 x 10-9(10)2.8136(1.29+3.20) y2t= 11068 The equilibrium equation for the MSA3 (Black liquor) is: y3=352.8 x30.71512 GRAPHICAL APPROACH ONE-TO-ONE CORRESPONDENCE Texas A&M University 0.18 0.18 The mass of pollutant that can be gained by each process MSA is plotted versus the composition scale Once again, we used the diagonal rule of of that MSA 0.16 0.16 superposition to obtain the cumulative mass of the pollutant gained by all the MSAs. 0.14 0.14 Mass of pollutant that can be gained by each MSA is calculated: Mass Exchanged kmol H2S/s 0.12 Mass Exchanged kmol H2S/s GRAPHICAL APPROACH LEAN COMPOSITE STREAM 0.12 0.1 MSj= Ljc (xjt – xjs) 0.1 j=1,2,…,NSP 0.08 0.06 0.08 Also in this case, the arrows represent each of the process MSA, being the tail the supply composition and the head the target composition. 0.04 0.06 0.02 0.04 0 0.02 0.00E+00 1.00E-05 0.32 0.29 y 2.00E-05 3.00E-05 4.00E-05 5.00E-05 6.00E-05 7.00E-05 8.00E-05 9.00E-05 1.00E-04 x 1 3.1 x2 1.29 0 0.00E+00 1.00E-05 0.02 2.00E-05 3.00E-05 4.00E-05 5.00E-05 6.00E-05 7.00E-05 8.00E-05 0.01 9.00E-05 x3 y 1.00E-04 Texas A&M University PICH POINT GRAPHICAL APPROACH 0.18 0.16 Mass Exchanged kmol H2S/s 0.14 Lean Composite Stream Thevertical lean composite can be slid The vertical overlap stream between two The distance referred asthe Excess To guarantee thermodynamic The next step is to plot both down until it touches the waste composite streamscorresponds is the maximum Mass Exchanged to the feasibility the lean composite composite stream. The point where composite streams on the same amount of the pollutant that can be capacity of the process MSAs to remove should be above and left touch of theis the two composite streams diagram.that transferred from the waste streams to pollutants cannot be used because waste composite stream. called “mass exchange pinch point”. process MSAs. ofthe thermodynamic infeasibility. 0.12 0.1 Excess Mass Exchanged 0.08 0.06 0.04 Rich Composite Stream 0.02 Pinch Point 0 0.00E+00 1.00E-05 2.00E-05 3.00E-05 4.00E-05 5.00E-05 6.00E-05 Integrated Mass Exchange 7.00E-05 8.00E-05 9.00E-05 y 1.00E-04 Texas A&M University The Algebraic Approach follows these steps: TABLE OF EXCHANGEABLE LOADS (TEL) COMPOSITION INTERVAL DIAGRAM CREATE ONE-TO ONE CORRESPONDENCE ALGEBRAIC APPROACH MASS-EXCHANGE CASCADE DIAGRAM Texas A&M University The CID is a useful tool for visualizing the mass exchange insuring thermodynamic feasibility. ALGEBRAIC APPROACH COMPOSITION-INTERVAL DIAGRAM (CID) Texas A&M University RICH STREAMS ALGEBRAIC APPROACH COMPOSITION-INTERVAL DIAGRAM (CID) LEAN PROCESS STREAMS y x 109 x1 x2 82000 1 2 3 4 5 6 7 0 30800 11900 11068 1. The composition 2. Corresponding composition scale for the waste stream is established. scales for the process MSAs are created. 9186 210 17.0 4.86 1 2 3 4 5 6 Texas A&M University RICH STREAMS LEAN PROCESS STREAMS y x 109 82000 1 30800 2 3 x1 x2 R2 These intervals are numerated From top to bottom. Horizontal lines are drawn at the heads and tails of the arrows to define composition intervals. R1 11900 S3 R3 3. Each process stream is represented as a vertical arrow 11068 4 ALGEBRAIC APPROACH COMPOSITION-INTERVAL DIAGRAM (CID) 9186 5 The tail of each arrow represents its supply composition and its head represents its target composition. 210 6 17.0 7 S2 4.86 0 S1 1 2 3 4 5 6 Texas A&M University By constructing the TEL, we want to determine the mass-exchange loads of the process streams in each composition interval. The exchangeable lead of each waste stream with passes through each interval is defined as: Wi,kR = Gi(yk-1 – yk) W1,1R = 0.433(0.000082-0.0000308) W1,2R = 117(0.0000308-0.0000119) W2,2R = 0.433(0.0000308-0.0000119) Wj,kS = Lj(xj.k-1 – xj,k) W1,4S = 0.049(1.29-1.261) W1,5S = 0.04(3.1-1.708) W2,5S = 0.049(1.261-0.678) WkR = Σ Wi,kR WkS = Σ Wj,kS W2R = W1,2R + W2,2R = 0.0022 W5S = W1,5S + W2,5S = 0.0842 ALGEBRAIC APPROACH TABLE OF EXCHANGEABLE LOADS (TEL) Texas A&M University ALGEBRAIC APPROACH TABLE OF EXCHANGEABLE LOADS (TEL) Material Balance of the key pollutant should be done for each interval. Residual Mass from Preceding Interval δ k-1 Mass Recovered From Waste Streams WkR WkS k δk Residual Mass to Subsequent Interval Mass Transferred To MSAs Texas A&M University 0 0.00002 1 0 0.00002 0.002219 2 0 0.00224 A negative δk indicates that the The most negative δk is the excess capacity of the process leans streams capacity of the process MSAs when at that level is greater than the load removing the pollutant. of the waste streams. 0.000477 3 0 0.00272 0.001106 4 0 0.00382 0.005235 5 0.05568 -0.04662 0 6 0.03708 -0.08370 0 7 -0.10214 0.01844 ALGEBRAIC APPROACH TABLE OF EXCHANGEABLE LOADS (TEL) Texas A&M University ALGEBRAIC APPROACH TABLE OF EXCHANGEABLE LOADS (TEL) 0 2.22E-05 1 0 0.00002 The excess capacity of the process MSA should be 2 0 reduced0.002219 by lowering the flowrate. 0.00224 The new flowrate is calculated as follows: 0.000477 L 0.04 0.001106 3 0 1.02 E 1 0.003259 m3/s 0.00272 3.10 0.32 4 0 Another TEL should be constructed after removing 0.00382 the excess capacity of the MSA. 0.005235 5 On the revised cascade diagram the location at which the residual mass was the most negative should be zero. It corresponds to the pinch point. 0.004608 0.00445 0 6 0.003068 0.00138 0 7 0.00 0.001526 PINCH POINT Texas A&M University Since the graphical approach, we saw that the pollutant could be removed just by using one MSA, so there is no need of a network. This problem has some different solutions that could be taken depending on how much we want to spend. The following figure is one solution, in which some material balance should be done in order to give the right flowrate to each absorber. R1 R2 m3/s 117 3.08e-5 kmol/m3 0.44 8.20e-5 kmol/m3 0.547 kmol/m3 Absorber 1 2.1e-7kmol/m3 R3 m3/s m3/s 465.8 1.19e-5 kmol/m3 0.547 kmol/m3 Absorber 2 2.1e-7kmol/m3 0.0158 m3/s 0.320 kmol/m3 0.547 kmol/m3 Absorber 3 2.1e-7kmol/m3 1.56e-4 m3/s 0.320 kmol/m3 White Liquor 0.0158 m3/s 0.320 kmol/m3 Texas A&M University R1 117 m3/s 3.08e-5 kmol/m3 R2 0.44 m3/s 8.20e-5 kmol/m3 R3 465.8 m3/s 1.19e-5 kmol/m3 3.10 kmol/m3 Absorber 581.24 m3/s 2.1e-7 kmol/m3 0.00326 m3/s 0.32 kmol/m3 White Liquor Another way of achieve this task is the following, in which the rich streams are for final disposal and can be mixed and treated as one stream, also, his arrange is more desirable in terms of costs because just one unit is needed. Texas A&M University STUDY CASE 2 PETROLEUM REFINERY WASTES A major concern in refineries is the release of phenols, although described as this, the category may include a variety of similar chemical compounds among which are polyphenols, chlorophenols, and phenoxyacids. The concern is because of their toxicity to aquatic life and the high oxygen demand they sponsor in the streams that receive it. Phenols are toxic to fish and also they can cause taste and odor problems when present in potable water. Texas A&M University PROBLEM STATEMENT The next study case applies some of the skills of Process Integration to show the methodology once again and make it more understandable. This case was taken from ElHalwagi, M. “Pollution Prevention through Process Integration”, 1997. “The process generates two major sources of phenolic wastewater; one from the catalytic cracking unit and the other from the visbreaking system. Two technologies can be used to remove phenol from R1 and R2: solvent extraction using light gas oil S1 (a process MSA) and adsorption using activated carbon S2(an external MSA). A minimum allowable composition difference, εj, of 0.01 can be used for the two MSAs. By constructing a pinch diagram for the problem, find the minimum cost of MSAs needed to remove phenol from R1 and R2. How do you characterize the point at which both composite streams touch? Is it a true pinch point?” DATA MSAs Rich stream Stream R1 R2 Gi kg/s 8.00 6.00 yis yit Stream 0.1 0.08 0.01 0.01 S1 S2 Lcj kg/s 10.00 xjs xjt mj bj 0.01 0.00 0.02 0.11 2.00 0.02 0.00 0.00 cj $/kg 0.00 0.08 Texas A&M University LPH and Gas Refinery fuel gas PROCESS DESCRIPTION Gasoline Stabilizer Sweetening Unit Sweet Gasoline LPG Naphta The first step in a petroleum refinery is to preheat the crude, then it is washed with water to remove various salts. Hydrotreating Middle Distillates Solvents Gas Gas Oil Lube-Base Stocks Vacuum Distillation Treating and Blending Middle Distillates Gasoline Aviation fuels Gas oil and heavy stocks are fed to a catalytic-cracking unit to be converted to lower molecular weight fractions. The The waste light gas oil Gasoline leaving fractionator can serve from as a main stream from thisthe process is the condensate Diesels lean-oil solvent in a phenol extraction process, being this a stripping Catalytic in the fractionating column. This condensate Light Gas Oil beneficiary mass transfer because in addition to purify Cracking contains ammonia, phenols and sulfides as commonly water, phenolsthis canhas acttoasbe oxidation andoils as color contaminants, strippedinhibitors to remove ammonia Heating stabilizers. and sulfides.Wastewater, The bottom product of the stripper must be R1 treated to eliminate phenols. Solvent Extraction and Dewaxing Lube Oil Lube oils Waxes Greases Gasoline, Naphtha and Asphalts The main objectives of visbreaking are to reduce the Middle distillates viscosity and the pour points of vacuum-tower bottoms Oil stocks to catalytic cracking. The and to increase theFuel feed Visbreaker Industrial fuels source of wastewater is Asphalt the overhead accumulator on the fractionator, where water is separated from the Wastewater, R2 water contains phenols, ammonia hydrocarbon vapor. This Refinery fuel oil an sulfides Texas A&M University 1. PLOT THE RICH STREAM 1.2 1 R1 Mass exchanged 0.8 0.6 0.4 R2 0.2 0 0 y1t, y2t 0.02 0.04 0.06 0.08s y2 0.1s y1 0.12 Texas A&M University 1. PLOT THE RICH STREAM 1.2 Mass exchanged 1 0.8 R1 0.6 0.4 R2 0.2 0 0 y1t, y2t 0.02 0.04 0.06 0.08 y2s 0.1 y1 0.12 Texas A&M University 2. ONE-TO-ONE CORRESPONDANCE To generate the one-to-one correspondence, we use the following equation: y=f(xj+εj) Where εj is the minimum allowable composition difference. εj=0.01 In this case the equilibrium equation is linear: y = m(x+ε) + b y1s = 2(0.01+0.01) = 0.04 y2s = 0.02(0.00+0.01) = 0.0002 y1t = 2(0.02+0.01) = 0.06 y2t = 0.02(0.11+0.01) = 0.0024 Texas A&M University 3. PLOT THE LEAN STREAM 1.2 1 0.8 0.6 0.4 0.2 S1 MS1 y 0 0 0.02 0.04 x1s S2 0.06 x1t 0.08 0.1 0.12 x1 x2 Texas A&M University 4. OBTAIN THE PINCH POINT 1.2 1 Mass exchanged 0.8 Stream 1 would not be useful, since external MSAs should be used before and after using this stream. That means that this is not a true pinch point. 0.6 0.4 0.2 y 0 0 0.02 0.04 0.06 0.08 0.1 0.00 0.01 0.02 0.03 0.04 1.00 2.00 3.00 4.00 5.00 0.12 x1 x 2 Texas A&M University 5. INTERPRET THE RESULTS 1.2 Unit 1 1 0.1 The lean stream can be moved to remove the pollutant in another range of composition, but still three units would be needed. 0.8 Mass exchanged Unit 2 0.6 Unit 3 0.4 0.2 y 0 0 0.02 0.04 0.06 0.08 0.1 0.12 Texas A&M University 5. INTERPRET THE RESULTS 1.2 Unit 1 1 0.8 If the lean stream remove the pollutant since its higher composition, just 2 units are needed. 0.6 Unit 2 0.4 0.2 y 0 0 0.02 0.04 0.06 0.08 0.1 0.00 0.01 0.02 0.03 0.04 1.00 2.00 3.00 4.00 5.00 0.12 x1 x 2 Texas A&M University 5. INTERPRET THE RESULTS 1.2 Mass removed by Process MSA Mass exchanged 1 0.8 0.6 Mass removed by External MSA 0.4 0.2 0 y 0 0.02 0.04 0.06 0.08 0.1 0.12 Texas A&M University •Alan P. Rossiter. Waste Minimization through Process Design. pp 43-49. McGraw Hill. 1995. •Nicholas P. Cheremisinoff, Handbook of Pollution Prevention Practices. pp 269-313, 353-358. Marcel Dekker Inc. 2001. •The World Bank Group. Pollution Prevention and Abatement Handbook 1998. pp 377-381, 395-399. 1998 •El-Halwagi, M. M. Pollution Prevention through Process Integration. Academic Press. 1997. •Dunn R., El-Halwagi, M. M. Optimal Recycle/Reuse Policies for Minimizing the Wastes of Pulp and Paper Plants. J. Environ. Sci. Health, A28(1), 217-234 (1993). •El-Halwagi, M.M., El-Halwagi, A.M., Manousiouthakis, V. Optimal Design of the Phenolization Networks for Petroleum-Refinery Wastes. Trans IChemE, Vol 70, Part B, pp 131-139. August 1992. •Environmental Update #12, Hazardous Substance Research Centers/Southwest Outreach Program, June 2003. •Abdallah S. Jum’ah, president and CEO, Saudi Aramco. Petroleum and social responsibility: and agenda for action. News Feature. First bread volume 20. 10 October 2002. •Energy and Environmental Profile of the U.S. Petroleum Refining Industry. December 1998. U.S. Department of Energy, Office of Industrial Technologies •EPA Office of Compliance Sector Notebook Project, Profile of the Petroleum Refining Industry, September 1995. •National Pollutant Release Inventory (Canada) •2001 Toxic Release Inventory Executive Summary (US) •Input to the AMG Working Group Studying the Impact of Greenhouse Gas Abatement on the Competitiveness of Canadian Industries. Pulp, Paper and Paperboark Mills. Manufacturing Industries Branch. Industry Canada. March 11, 2002 •Instituto Nacional de Estadistica, Geografia e Informatica (Mexico)