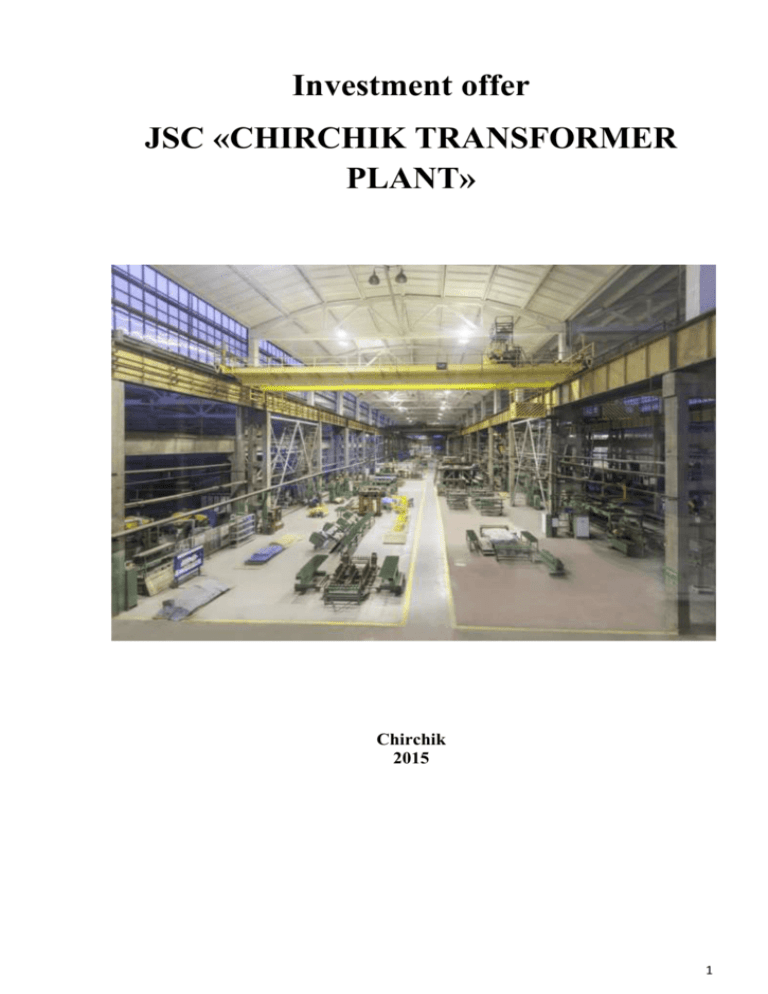

JSC «Chirchik transformer plant» have modern

advertisement

Investment offer JSC «CHIRCHIK TRANSFORMER PLANT» Chirchik 2015 1 Contents Contents …... ………………………………………………………………………2 Chapter 1. Basic data on project……………………………………………………3 Chapter 2. Description of plant …...………………………………………………5 Chapter 3. Organization of production...…………………………………………..8 Chapter 4. Description of producing product ……..………………………...……14 Chapter 5. Market review…………………………………………………………17 Chapter 6. Financial plan ….…………………………………………………….20 Chapter 7. Analysis of basic risks…...…………………………………………...22 Chapter 8. Contact information…………………………………………………..23 2 1. General information about plant Name of plant Joint Stock Company «CHIRCHIK TRANSFORMER PLANT» Registered address Electromashinostroiteley Square 1, Chirchik city, Tashkent region, Republic of Uzbekistan Form of activity Electric machine industry Basic activities Production and repairing of power transformers, transformer substations of I-IV size, highvoltage equipment Legal organization form Joint Stock Company Number of state registration in inspection on № 106 УЗГ от 14.07.2014г. registration of enterprise subjects by city hall of Chirchik city. Taxpayer Identification Number 200 941 525 All-Union Nomenclature of Enterprises and 00212908 Organizations Code All-Union Nomenclature of Sectors of the 14171 National Economy Code Indications System of State Administration 70064 Bodies Code Legal organizational form code 1150 Indications System of Administrative- 1727419 Territorial Formations Code Form of ownership code 144 Headcount of plant 538 piece. unit Registered capital 52 441 035 400 sum Stockholders: Equity position of state 23,72 % Stock Company «Uzeltexsanoat» 75,95 % 3 Company «Seten Enterprises Ltd» 0,15 % LLC «TransTradeComplect» 0,11% Equity position of physical bodies 0,07 % Plan of second production site of JSC “Chirchik transformer plant” № 1 2 3 4 5 6 7 8 9 Explication of buildings and constructions Name of premise Checkpoint Obelisk Canteen Engineering Laboratory Building Light vehicle storage building Hotel Electric power substation 35/6 kV Main engineering building ABK with built in boiler-house 4 10 11 12 13 14 15 16 17 18 19 20 21 23 24 25 26 27 28 29 30 Commercial vehicles storage building Storage № 3 ABB module Storage № 18 Track of column crane Awning of transportation department Fuel station Premise fuel station Underground storage of fuel station Compressor house Fuel-oil storage tank Oil storage tank Storage of metal ware Storage of gas Frame of old boiler-house Bomb-proof shelter Water draw-off Pumping house Kennel Kennel JSC «Chirchik transformer plant» on presence of productive capacity and condition of planning able to provide necessary production capacity of transformers 10,35 and 10 kV. Production space equipped with newest equipment of leading producer countries. The plant right along carry out research in the area of creation of technology for transformers and substations of new generation, using new materials and modeling. On base of JSC “Chirchik transformer plant” there are testing centre “Transformator”, and central and metrology laboratories, bureau of certification, which are only accredited in Central Asia. JSC “Chirchik transformer plant” have unique opportunities and resources, but for realization and revelation his potentials, not enough complementary financial investments for replenishment of floating assets, purchasing necessary raw and other materials. According to resolution of President Republic of Uzbekistan № PP 2340 from 28.04.2015, for transfer to investor pertain equity position at the rate of 48,6% of JSC “Chirchik transformer plant” authorized fund. 2. Description of plant Formation history of plant Formation history of JSC «Chirchik transformer plant» begin from 1932 when was formed electric shops of complex of enterprises “Chirchik-stroy” for manufacturing and repair electrical equipment of building cascade of Chirchik hydro-electric power stations and nitrogen composting plant. 5 1942. on base of electric shops of complex of enterprises “Chirchik-stroy” and evacuated from Leningrad equipment and staff of “Electropult” plant organized “Electroshit” plant, which become only plant in Central Asia, producing during Second World War electric boards, power transformers, electric power substations and other electro-devices. 1942. on 12 april for plant assumed name “Electroshit”. 1962. the plant renamed into Chirchikskiy transformatorniy zavod. 1995. After the independence of Republic of Uzbekistan, the plant reincorporated as a joint-stock company and with decision of stockholders` meeting renamed into Public Corporation “Transformator ”. In 2001. the plant renamed into Open Joint Stock Company “Transformator” with decision of stockholders` meeting. In 2004 realized state owned shareholding, and the plant changed into joint venture with foreign capital in the form of open joint stock company and again renamed in Chirchikskiy transformatorniy zavod. In 2013 block of stocks 99.97% of authorized fund transfer into ownership of State committee of the Republic of Uzbekistan for privatization, demonopolization and development of competition. Adoption history of producing product: 1945 . Adopted and produced power step-down transformers with power 50, 100, 180, 320 kVA, with voltage 6/0,4 and 10/0,4 kV. 1945-1954. Adoption of production power transformers TM-50 kVA, with voltage 6,0/0,4 V, welding apparatus ST-22, SA-P, SАМ-P. Certificates of quality management system. 1952. For the first time in USSR developed and manufactured distributing gears 6 kV (KRU-6kV) for application on electric stations and substations; and in the same year carried out production of transformer type TMO-50 for concrete heating. 1954. Adopted production of inventory complete transformer substations IKTP, with power 180 kVA. 1955. Developed and adopted more powerful types of welding apparatus STN-500. 1958. Developed and adopted city type complete transformer substations GKTP 180/6/0,4.1. 1961. Developed and adopted new complete transformer substations KNTP -1000 complete with power transformer TMZ-1000. At the same time adopted production of new transformers type TMZ with power 630-1000kVA. 1963. Production of substations with transformers TMZ630-1000 in aluminum version of coil instead copper, manufactured transformer TMN-2500/100, and transformer 6 with voltage level 35kV type TM-1000-35; 1600/35. 1965. Adoption and production of transformer ТD-1000/35. 1970. Developed and produced transformers with non-burning filling TNZ1600/10, power transformers TMN-1000-6300/35, TMN-2500/110, ТМN and ТМТN -6300/110, transformer substations KTP-630-1600/10 with automation "Elektron". 1973-1976. Adopted and produced transportable unit transformer substations on automobile and railway motion. 1977. Started production of transformers for electric locomotive type ODCE8500/10. 1982. Adopted production of small size single-phase transformers ТS, ТSТ, with power from 6,3 to 25 kVA. 1991. Adopted serial production of following types of products: Transformers ТD – 10000/35-87; ТD – 16000/35-87; ТМN – 2500/110 with switch RS-12 ТDN10000/110-80, unit substations APKTPB-2x4000, 6300/35 HL. 1993-2000 y. Formed and equipped production of single-phase transformers ТSU 1,0-2,5; ТS-ТSТ, electromagnets МО-100, МP-301, МP-101, unit transportable Complete Transformer Substations and other type products. 1995-2001. Adopted serial production of following types of products: Transformers ТDТN-40000/110; ТDТN63000/110 ТRDN-40000/110; ТRDN-63000/110. 2010. Developed and adopted production of transformer ТRDCN-63000/220 U1. 2008-2012. realized large-scale modernization of production technology, purchased more than 50 units of modern technological equipment. 2012 -2015 In 2015 block of stocks of JSC “Chirchik transformer plant” divided as follows: Equity position of state – 12 441 035 400 (twelve billion four hundred forty one million thirty five thousand four hundred) sum 62 205 177 (sixty two million two hundred five thousand one hundred seventy seven) pieces of common nominal stocks, which equal to 23,72% from registered fund of Company; Equity position of stock company “Uzeltexsanoat” - 39 826 787 400 (thirty nine billion eight hundred twenty six million seven hundred eighty seven thousand four hundred) sum, 199 133 937 (one hundred ninety nine million one 7 hundred thirty three thousand nine hundred thirty seven) pieces of common nominal stocks, which equal to 75,95% from registered fund; Equity position of «Seten Enterprises Ltd» - 80 315 400 (eighty million three hundred fifteen thousand four hundred) sum, 401 577 (four hundred one thousand five hundred seventy seven) pieces of common nominal stocks, which equal to 0,15 % from registered fund of Company; Equity position of LLC «TransTradeComplect» - 56 733 200 (fifty six million seven hundred thirty three thousand two hundred) sum, 283 666 (two hundred eighty three thousand six hundred sixty six) pieces of stocks, which equal to 0,11 % from registered fund of Company, among them: 283 369 (two hundred eighty three thousand three hundred sixty nine) pieces of common nominal stocks; 297 (two hundred ninety seven) pieces of preferred nominal stocks; Physical bodies физические лица – 36 164 000 (thirty six million one hundred sixty four thousand) sum, 180 820 (one hundred eighty thousand eight hundred twenty) pieces of stocks, which equal to 0,07 % from registered fund of Company, among them: 165 061 (one hundred sixty five thousand sixty one) pieces of common nominal stocks; 15 759 (fifteen thousand seven hundred fifty nine) pieces of preferred nominal stocks. Management of plant since 23 October of 2014 carry out interim director A.E. Konishev, appointed by the decision of Supervisory Board of Company. Number of employee come up to 538 staff units. Among them office and management personnel 89 persons, specialists – 86, technical staff – 42, maintenance staff – 60, production staff – 261 persons. Average level of salary of production staff come up to 427 631 sum, technical staff – 517 502 sum, specialists – 581 905 sum, maintenance staff – 456 565 sum, management staff – 1 015 851 sum. Over a period of 2010 -2015. Company reach following indexes 2010 2011 2012 2013 2014 Volume of 32 660,3 mln. production 60 746,2 mln. 51 646,6 mln. 7 692,5 mln. 20 078,7 mln. Volume sales 62 082,9 mln. 46 484,90 mln. 5 889,2 mln. 7 434,9 mln. 10 053,6 mln. 3 307,60 mln . -16 749,1 mln. 250,3 mln. Clean (loss) of 33 070,9 mln. profit 4 993,5 mln. 3. Organization of production 8 Process design of transformer production carry out on base of constructive and process documentation of plant. Schematically production technology of transformers be as follows: - procuring, stamping and machining production; -welding production; -insulating production; - production of winding wire; - coil-winding production (all types of winding) - production of core plate manufacturing; - magnet core assembly; -paint production; - assembling production (I-assembling, II-assembling, III-assembling) Technologies, used in production of JSC “Chirchik transformer plant” spaced out on main shop floors. 1. Transformer shop: Cutting of transformer steel carried out on dial lines of longitudinal cutting “Komeks” (France) (productivity as much as 195 m/min), line of crosscutting AH 123 (productivity 2,7 tons/hour of plates 980x1500mm), AH 132 (productivity 14-18 pieces/min on L=1500mm), AH 217 (productivity 46 m/min) production of Zaporozhye plant (Ukraine). Assembling of magnetic core carried out in transformer shop floor on special stands model AH 054, AH 055 production of VIT (Ukraine). Copper or aluminum wire rod SMV-1-5m and SMV 1-9m stretched on wiredrawing machines until intended sizes of sections, with subsequent annealing of copper wire in electric oven OKB-185N at a temperature of 750C. Paper insulation cut-sized on bobbins (with thickness from 6 to 30mm) with paper cutting machine type «KAMPE ACF 400» (Germany). Conductor insulation carry out on insulation machines model “Purtye” 9 (France) (productivity as much as 30 m/min), model «VP2/3» (Austria) (productivity as much as 30 m/min), model BIM-02 (productivity as much as 36 m/min). Coil winding station consist of 27 units of coil winding machines TT-21, TT-23 of different purpose. Possible types of coil winding: spiral, multilayer, continuous disk. Maximum quantity of parallel 32. Vacuum steam drying chamber in quantity 4 units with capacity V=146 m3 , V=148 m3 , V=319 m3 and V=80 m3 , is destined for technological drying of transformers active parts windings, allow carry out technological mode for active parts of transformers to 125000 kVa. 2. Preparation-welding shop: Cutting and plasma cutting of plate steel in thickness to 60 mm carry out on preset sequence on machines for plasma cutting of metal with CHPU “Kristall” – 2 pieces, on machines for thermal and plasma cutting of metal with CHPU “RUR2500” (USA) – 2 pieces and installations of hydro-abrasive cutting WJ2060B-IZ-D (Czechia). In the shop also present: forging and stamping equipment with technological equipment set. Maximal effort of presses to 1000 tons. Hydraulic plate cutter «Schroder Fasti» (Germany) for cutting of sheet metal with thickness to 20 mm, sheet bending press for machining of sheet metal with thickness to 20 mm production of company «Schroder Fasti» (Germany), roll mills with diameter of rolls D=300mm, welding semi-automatic stations for arc welding in environment СО2 and welding tractors KA-1 UP production of company «Kjellberg» (Germany), device for stud welding VMK-12W production of company «Hayns Soyer» (Germany), shot-blasting and painting-drying line production of company «Getrasur SAS» (France), universal shearing press «BensHcrop» production of company «GEKA» (Spain). 10 3. Shop of Unitized Transformer Substations: Production space and equipment allow to execute metal fabrication, assembling, welding, fettling and test of components, painting of steel constructions with powdery enamels in electrostatic field. Shop area equipped with metal working machines type «HAAS»: milling-machining center VF-2 – 3 pieces, turning-machining center SL20-2. Metal-processing center on cutting plate sheet with thickness from 0,5 mm to 3 mm «TruPunch-1000», rolling and bending machine «TruBend-3120», multipurpose shearing machine «Bendicrop» production of company «GEKA» (Spain), hydraulic plate cutter «Schroder Fasti» (Germany), band saw machine – «PEGAS 240x280 SHI-R» production of company «PEGAS GONDA» (Czechia). Execution of welding job carried out on devices «COMBI1-162» (Italy) – 2 pieces, devices «SELMA» (Ukraine) – 3 pieces. Station equipped with air filtering adjustable ventilation «CORAL» (Italy) – 3 pieces. For delivery high-pressure air on stations of shop mounted compressors «ATLAS-COPCO» - 2 pieces. Machining of bar carried out on bar machining tool with CHPU type М12125 production of company «Doganer Makine» (Turkey). In addition shop of Unitized Transformer Substations KTP have own test center for carrying out routing tests, qualification tests of substations and electric equipments from 0,4 кV to 100 кV. Used mobile 11 installation «Petom-21» for relay parameter setting of differential and current protection, and for controllers using processor techniques. Shop of high-voltage testing: Seven proving grounds equipped with stands for carrying out all types of high-voltage testing of power and measuring transformers on preset sequence (acceptance test, type test, certification test etc.). There is park of measuring device, including exemplary: current transformer type TLP-35 with primary current from 5 to 3000А; exemplary set of potential transformers ТNОТNМО with primary current from 18 to 220 кV. Power equipment presented: with loading transformers allowing get current to 12000А with frequency 50Hz, with intermediate transformers with capacity 750кVА, 3200кVА, 5600кVА and with machine hall with synchronous generator of voltage from 0,4 and 6 кV with total capacity 10000кVА. There is separate hall of impulse test laboratory with generator GIN-2000 of company «WEB-TUR» (Germany), allowing to get impulse voltage to 2000 кV. 4. Insulation and component shop: 12 Production of paper cylinder, lath and other insulating details by dipping of paper with bakelite lacquer on installations «General» (France) with subsequent winding on technological. On stations also there are winding machines of Bakelite cylinder and winding Bakelite pipe. Station allow produce cylinders to 1500 mm in diameter, glass binding tape, cardboard products in the form of lath, between-coil gaskets. 5. Tool shop: Park of metal cutting equipment allow to produce mechanical facility, pressing molds, stamps and holders for winding of cylinders, repair and tooling setup. There is erosion equipment for burning and production of die holes: coordinate boring, milling, grinding and cutter grinding machines; universal hearing press «Bendicrop» production of company «GEKA» (Spain), cutter grinding machines of company «Talmek» (Italy), bandsawing machine «PEGAS 240x280 SHI-R» (Czechia), pipe-bending machine InekoMaster 3m production of company INEKO (Spain.) 6. Oil economy: Consist of underground tank for storage 1000 м3 of transformer oil and oil pipeline system, oil filtering station, filtering drying installations, vacuum dispersive installation VDU and mobile oil station SMM-4,3 (oil recovery) Plant asset of the plant equal to 7384763 Euro. Full capacity of plant - 3000 thousand кВА Under carrying-out of a programme on modernization of production purchased and installed newest technological equipment of Austrian company «Gebauer & Griller» on broaching and insulating of winding wire, newest semiautomatic line on welding of power transformer tanks, sheet bending press with CHPU type Trubend 3120 and coordinate punching center for sheet metal working with CHPU type TruPunch 1000 production of company «TRUMPF» (Germany), vertical milling work center VF-2ВНЕ and turning work center SL20THE of Belgian company HAAS, hydro-abrasive cutting machine WJ2060B1Z-D production of company «PTV s.r.o.» (Czechia), universal shearing press «Bendicrop» of company GEKA (Spain), band sawing machine PEGAS 240-280 SHI-R of company «PEGA GONDA» (Czechia), pipe bending machine «InekoMaster» of company «PМЕСО» (Spain), bar machining center with CHPU type М12125 production of company «Doganer Makine» (Turkey), two gas and plasma cutting machines with CHPU «RUR 2500GP» complete with plasma source «Hypertherm HPR-130» USA, guillotine-shears for cutting and sheet bending press for machining of plate metal production of company «Schroder Fasti» (Germany), shot blasting pneumatic camera production of company 13 «Getrasur SAS» (France), paint line of transformer substation shells with powdery enamel in electrostatic field. The plant on presence of production capacity and on condition of planning able to provide necessary production capacity of transformers 10,35 and 10 kV. For production of transformers 220 кV necessary modernization of operational capacities, design and manufacture of special technological equipment Raw base of materials and components, which used in production of transformers and complete substations 90% consist of imported raw material from CIS countries and Russia. From the territory of plant into the atmosphere injected on typical operation —51,858 t/g, and on real operation —17,286 t/g pollution agents of 30 names: metal dust, manganese dioxide, carbon monoxide, nitrogen oxides and dioxide, chromic anhydride, iron oxide, white spirit, xylol, nefras, natrium hydroxide, aerosol of emulsol, divinyl (butadiene), aluminium oxide, lead, phenol, formaldehyde, ethyl alcohol (ethanol), paper dust, oil aerosol, aminoplast dust, styrene, plastic dust, hydrocarbon, gasoline vapor, diesel fuel vapor, abrasive metal dust, ammonia. In accordance with list of activity type, on which carried out State Environmental Expertise (Appendix №2 to decree of Cabinet of Ministers from 31 December 2001. №491), JSC «Chirchik transformer plant» (production of transformers) fall into second category of ecological hazard. 4. Description of production JSC «Chirchik transformer plant» have modern production base, well developed infrastructure and communications: production shops, local railway, own substation, side lines and other infrastructure, which allow to produce annually at least 3000 МВА of modern high voltage productions: measuring transformers, power transformers, unitized transformer substations, to produce guarantee repair and service of high voltage equipment. Own constructive, technologic, project departments, high voltage testing center allow ably provide technological process and certification of producing of dry type and oil transformers with capacity to 63 mW of voltage class to 110 kV. On the plant produced following production: 1. Oil and dry type power transformers for cold, temperate and tropical climate: - Oil-immersed power transformers with voltage 6 (10) kV with capacity 25 – 4000 kVA; - Dry type power transformers with voltage 6 (10) kV with capacity 63 – 2500 kVA (with insulation type «NOMEKS»); 14 - Power transformers with voltage 35 кV, 110 кV with capacity to 63000 кВА two and three-winding; - Traction transformers for electric locomotive to 1600, 4350, 5000, 5700, 8000, 8500, 10000 kVA. 2. Unitized transformer substation: - Pole-mounted substation type КТPs with capacity from 25 кVА to 250 кVА, meant for power service of small pumping stations, housing settlement,farms; - Substation of external installation КТPN (type of «Kiosk») dead-end and transmission version with capacity from 63 to 630 кVА, with voltage 6(10)/04 кV meant for power service of population centre and village, small industrial objects; - Urban substations of internal and external installation type of GКТP, meant for power service of housing estate of cities with capacity from 160 to 1000 кVА on voltage 10/04 кV; - Railway substations type of КТPg with capacity from 25 to 250 кVА on voltage 35/04 кV; - Substations of indoor installation type of КТP, with capacity from 250 to 2500 кVА on voltage 10/04 кV for production organizations; - Stationary and adjustable unit substations type of КТPB and PКТPB, with capacity from 1000 to 25000 кVА on voltage 35(10)/6 кV and with capacity from 2500 to 40000 кVА on voltage 110(10)/6, 110/35/(10)/6 кV; -Distributing gear of voltage class 6-10 кV type of КRUV-10, - Distributing gears consisting of cabinets SHО-70, voltage class 0,4 - Complete distributing gear of indoor installation compact of series VМ-1 - Assembly cameras of unilateral service series КSО-205 15 3. High voltage components: - Add-in current transformer, type of ТVТ-35 and ТVТ-110; - Measuring current transformers, type of ТFZМ-35Б and ТFZМ-110B; - Measuring voltage transformers, type of ZNОМ-35-65 and NКF 110-83; - Load interrupter switch of alternating current, type of VNRu -10/400, VNRup 10/400, and RVZ -10/400; - High voltage disconnecting device, type of RLND1- 10B/400, RD31(2)-35/1000, RD31(2)-110/1000; Production of JSC «Chirchik transformer plant» securely worked in electrical power distribution systems in plants of oil, gas, coil, mining, metallurgical branches of industry, in agricultural industry and on railway transport. Safety and quality of plant production, verified with conformity certification of GosStandart Republic of Uzbekistan. 16 JSC «Chirchik transformer plant» while delivery its production on request of customer, provide a service on after sales service of product, on delivery of spare parts and training of service and repair personnel. 5. Market review Over the last 30 years production of plant be supplied more than in 30 farabroad countries: India, Pakistan, Afghanistan, China, Mongolia, Egypt, Turkey, Vietnam, Korea, Morocco, Greece, Bulgaria, Poland, Iraq, Iran, Cuba and a number of other countries. In 1982 on special order of Moscow City Government was produced universal two transformer substation КTP-1000/10 кV, completed with dry transformers of own production. Its installed and successfully functioning at a height of 300 meters of Ostankino television tower. For the first time in USSR, in 1983 transformer substations produced by plant type of KTPN-1600 installed on objects of government buildings of the Kremlin. Electric power supply of launching plant on implementation of Russian – American space program SOYUZ-APPOLON provided by transformers “SISTEMA”, special developed and produced in JSC «Chirchik transformer plant». Analysis of competitive environment testify that there is serious competition on the part of CJSC «Group of companies «Electroshit»- ТМ Samara», which buy JV JSC «Uzelectroapparat-Electroshit» and supply plant with modern technologies and components. With that biggest competitive capacity of plant be achieved in sector of 3-4 size transformers, corresponding traditional specialization of plant. There is stiff competition in the market of 1-2 size transformers on the side of specialized plants (for example Minsk electro technical plant, CJSC «Group of companies «Electroshit» - ТМ Samara», which have higher technological capability and possibilities on uninterrupted supply of raw material for mass production of given type transformers. Russian market of unitized transformer substations described with saturation and with very high level of competition.This is in first place explained that barriers of entrance on given market are low enough, in association with, in the past decade be observed considerable increase of integrated transformer substation KTP producers number in many regions of CIS. Plants competitors in the territory of CIS countries on production of power, oil, dry transformers and unitized transformer substations, of voltage class 6,10, 35,110 кV, (only in the territory of Russia their number more than 30, but in CIS countries plants with similar nomenclature about 20), have long experience of commercial work with enough material and technical base and with financial and economic oppotunity. 17 Plants – competitors producers of power, oil and dry transformers of voltage class 6,10,35,110 кV CIS Azerbaijan, Baku JSC«Baku transformer plant» ТМ 25-4000/10 ТМ 1000-6300/35 ТМ 2500-6300/110 ТS 16-4000/10 ТDNS 25000/35 ТDN 10000-63000/110 Kazakhstan Kentau JSC «Kaztransformer» ТМ 25-1600/110 ТМ 40-250/20 ТМ 25-4000/35 ТS 100-1600/110 RUSSIA Tolyatti JSC«Transformer» ТМ 63-4000/10 М 25-6300/35 ТDNS 10000-25000/35 ТМ 2500-16000/10 ТRDN 25000-63000/10 ОNDCE 5700/25 Birobidhan JSC«Birobidhan power transformers plant» ТМ 25-2500/10 ТМ 100-1000/20 ТМ 100-10000/35 ТS 1000-6300/35 Samara CJSC «Russian transformer» ТМ 25-2500/10 Plants – competitors in Republic of Uzbekistan on production of power transformers and unitized transformer substations of voltage class 6,10,35,10 кV. REPUBLIC OF UZBEKISTAN Tashkent JV JSC «Uzelectroapparat» «Samara-Electroshit» КТP 25-2500/10 SHО 70, ЩО 85 Units К63, К59, К26 КSО 285, 298, 366, 386 КRU 6,10 Tashkent JV «NVA» LLC«SITAN» КТP 25-2500/10 SHО 70 КSО 366, 386, 272, 285, 298 КRUV 10 Tashkent region, Kibray LLC «Vostokenergiya» КТP 25-2500/10 КТP 1000-25000/35 КТP 1000-25000/110 КSО 366, 386, 272, 298 КRU 10, КRUV 10 Tashkent region, Kibray SPA «Аziyaelektroenergiya» КТP 25-25000/10 КRUV 10 Chirchik SPE«ELUS» ТМ 25-2500/10 ТМ 1600-25000/35 ТМ 1600-25000/110 ТS 1000, 1600/10 КТP 25-2500/10 КSО КRUN 10, КRUV 10 - Strategy of marketing and sales of finished product For increase in volume of sales necessary to expand production of power transformers of voltage class 110 - 220 кV., achieve competitive ability of production on quality in the markets CIS and total absence of claims for quality on the part of customer. For achievement given goals necessary to select low 18 expenses strategy, which provide cost cutting by means of reduction of staff number, process optimization, technological development of production by resource-saving. For returning on lost sales markets the plant will be necessary to apply policy of dumping prices and aggressive marketing. Main regions sales of production: Russia, Kazakhstan, Kirghizia, Afghanistan. Also necessary to carry out vast questionnaire of potential customers on CIS countries. Organization of sales of products through electronic trading floor UzRTCB. Organization of participation in Republican Industrial fairs, exhibition. Formation of schedule visiting Ministry, design institute, regional electric network. 5. Financial plan Offers, used in construction of financial model № i/n Unit of meas ure. Item of index 2015 2016 2017 2018 2019 2020 1. Number of contract on production of transformer product. unit. 12 13 14 15 15 15 2. Capacity of net sale on orders without notice of capital assets. mln. sum. 16 000 17 000 18 000 19 000 20 000 21 000 3. Number of transformer production customers with annual capacity of order more than 1 bln. sum. unit. 5 5 6 6 7 7 4. Number of regular staff perso n. 538 550 570 590 600 600 4.1 Among them technical staff of perso n. 128 130 135 140 140 140 5. Number of stuff for whom plant is principal place of business perso n. 536 548 568 588 598 598 6. Capacity of technological equipment which is necessary mln. 20 331 20 631 20 631 20 631 20 631 20 631 number 19 for production of transformer product (on residual cost) Total area 7. sum. ha 48,4255 48,4255 48,4255 48,4255 48,4255 48,4255 Data on key plan numbers of project Gross financing requirement of project in break down on main categories of investment outlay on 2015 № Item Total i/ n 1. Size of financing, mln. sum. Salary fund with fringe benefit expenses Subsidy means Own means Attracted funds 3 300,0 3 300,0 2. Technological re-equipment (start-up, fettling) – start-up of line on production of corrugated tanks 300,0 300,0 3. Purchasing of TMC (including import) 3 000,0 3000,0 4. Repair and preparation of compartments, area 500,0 500,0 5. Expenses on training, retraining and personnel development 20,0 20,0 6. Marketing expenses, including participation in an exhibition, opening of trading house, travel expenses 5,0 5,0 7. Consultation service 3,0 3,0 8. Other overheads (calibration, repairing, fettling, certification of Measuring device; Certification; insurance of transport and personal of plant), electric energy, gas; maintenance of auxiliary departments (tool shop, CVILIM, SGM, SGE, TC ) 500,0 500,0 20 9. Total 7 628 3 828 3800 Results of project financial model (forecast of profit and loss on 5 years): (mln.sum) Forecast 2015 г. 2016г. 2017г. 2018г. 2019г. 2020г. Net profit 270,0 300,0 350,0 400,0 450,0 500,0 Analysis of attraction as an investment: Economic status of plant generally stable, but there is modifications from normative standards on separate indexes Conclusion: Plant high investment attractive. Plant bear the mark of financial and economical strains, for negotiation of which it has potentiality. Conclusion: Plant described with middle level of attraction as an investment Plant of moderate risk, which able to improve own financial and economic status by means of changing of ownership, owner. Plant in final stage of reconstruction productive and administrative premise. Conclusion: Plant is investment attractive. 6. Analysis of basis risks Risk of project funding gap. One of most significant in project financing of plant. Particular risk is presented on plant and funding gap of given, consider priority orientations result in risk of great drop of production volume, sales volume and project economics. Frustration of strategy realization and failure to achieve of plan numbers what with limitation of Society financial recourses for production development. Exchange risks. Risk of loss, arising during buying and sale of foreign exchange on different exchange rate. Present unstable situation in difference of exchange rate, presented in most countries of the world, as well as in space of CIS, what with global financial crisis are generally negative. Change of foreign exchange movement exert at present time more considerable influence on desired 21 money flow – as in import, and on export operation. Due to the fact that, currently in plant absent exchange cash assets and temporarily stopped export-import operations in plant particular risk minimal. (carry out monthly general authorized revaluation of accounting balance-sheet exchange articles on available debts unclosed off shore contracts). Contract risk. Violation of contractual commitment up to cancellation of a contract, deviation of actual cost on execution of a contract from planed. At present time on plant contract risks essentially aligned with fulfillment of treaty obligations of customers concerning timely paying under contract. Particular risks also not big as production of made to order transformers not beginning until the moment of prepayment mentioned cost of work by customer, and finished good shipment not carry out until 100% of payment, that is final calculation for actual production (works, services). Usually, in the point in question necessary carefully access to select partner: Accounting of reliability and reputation while selection partner;-Analysis of accounting; - Control of suppliers activity. Working on contract option: - Entering in contract penalties for violation of obligations; - Entering in cost sheet possible deviations. Creation of financial and so on reserves. Marketing risks. It is a risk of receiving less sales than one's due as a result of non achievement of planed sales. Given type of risk is key project risk. Possible factors: change in the market, improvement of competition, loss of market power, lowering or absence of demand on project production, lowering of market capacity, price cutting on production and others. Given type of risk on plant aligned with contract risks (mentioned above), there is a demand for product of our own make – stock of orders on 2015 formed, competition on local market is presented in temperate scale, loss of positions on foreign market happen to be. For lowering particular risk necessary in depth examination of market, identification of key factors, which can effect on project, forecast of their creation or strengthening, method of neutralizing negative influence given factors. Its risks of receiving less profits than one's due in consequence of administrative factor influence. Administrative risks. Interest of administrative authority in project, his support essentially lower particular risks. By superior controlling authorities forms favorable conditions for further development and restructuring of production. Conclusions and recommendations. JSC «Chirchik Transformer Plant» have unique possibilities and recourses. But for realization and revelation its potentials, not enough additional financial investment for replenishment of floating assets, purchasing of materials and component parts. 22 7. Contact information Konishev Abdurakhim Ermanovich Interim director of JSC “ChTZ” +998936003608 Khodjiniyazov Nurulla Yunusovich Deputy director on financial and commercial matters of JSC “ChTZ” +998947049585 Taymanov Sadirjan Rikhsibayevich Chief engineer of JSC “ChTZ” +998944031610 Reception of JSC "ChTZ" +998707130324 +998707130167 Fax: +998707130162 +998707130347 23