Concept Generation

advertisement

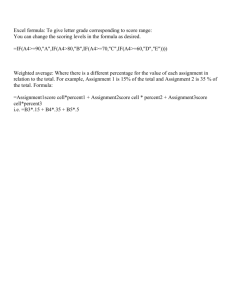

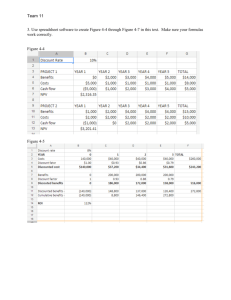

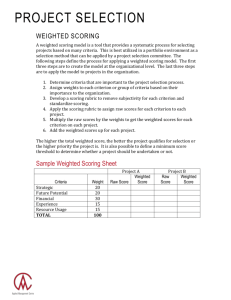

Concept Generation and Selection Document Microfluidic Impedance Spectroscopy Project Matthieu Giraud-Carrier Kyra Moon February 16, 2011 1 Table of Contents Table of Contents................................................................................................................. 1 Introduction ......................................................................................................................... 2 Overview .......................................................................................................................... 2 Purpose............................................................................................................................. 2 Procedure ......................................................................................................................... 2 Body of Facts........................................................................................................................ 3 Proposed Design .................................................................................................................. 4 Concept Selection & Scoring ............................................................................................... 5 Material Selection ............................................................................................................ 5 Leakage Prevention Design .............................................................................................. 7 Signal Path Geometry ....................................................................................................... 8 Conclusion ......................................................................................................................... 10 2 Introduction Overview Our goal is to build a microfluidic impedance spectroscopy system. In other words, we will build a chip with a small channel which can be filled with fluids (primarily protein solutions) and then analyzed. There are several possible geometries and implementations that will meet our design specifications. Each solution has both advantages and disadvantages. Purpose The purpose of this document is to lay out all possible design concepts and decisions and to document the reasoning for our eventual concept selection. While many of our decisions have little effect on the overall operation of our final product, a few decisions are critical to proper operation. These concepts are considered in greater detail and explained in greater depth. This document is designed to be easily understandable and a good reference for anyone trying to familiarize themselves with this project and the decisions that led to our particular implementation of the microfluidic impedance spectroscopy system. Procedure The simplest way to outline the decisions to be made and the reasons they are made in certain ways is by using decision matrices. They enable us to take into consideration a variety of weighted factors and put a numerical value on each solution. The matrices in this document list the proposed concepts for a few of the key components needed for microfluidic spectroscopy. In order to assess the nature and weight of each factor in the leftmost column we refer to our technical advisors and customer (Agilent). The matrices make clear the reasons for each major choice made in the design process. 3 Body of Facts Specifications Bandwidth: 100MHz to 7GHz Volume of channel: 0.5mm X 1mm X 2cm (10uL) Temperature stability: Within 1 degree Final outputs: Conductivity and Permittivity (from S-Parameters) Develop a numerical model for the waveguide Interface between Network Analyzer and Plotting Mechanism (LabView, Matlab) Sufficient reservoir volume for a 5-minute test Known Facts The microfluidic channel on the board will allow for the study, characterization and experimentation of many liquids (particularly protein solutions). We know that we will be using SMA connectors and Nanoport pressure ports. We will have to use LabVIEW, HFSS and Matlab to interface with our Network Analyzer and to accurately model our system. Proteins are expensive, so we a need cheap and small system. The microfluidic channel will be set up parallel to the waveguide. We know that the behavior of the protein solutions will not be linear. Assumptions We are assuming that PCB will bond to itself easily and well so that we can get a tight seal around the channel. We are assuming that there is actually a way of getting a temperature-stable system. We are making many assumptions about how quickly we will be able to learn new languages, fabrication processes and technical vocabulary and background knowledge. We are assuming of course that the software and hardware involved will function as expected and that we will not encounter glitches or broken machines. 4 We are assuming that the cohesive properties of these liquids are still intact in our small rough-edged channel. We are assuming an evaporation rate low enough that we will have time to take our measurements. We assume that the network analyzer is specific and powerful enough to give valuable data even while working with tiny systems. Proposed Design The design constraints are placed on our microfluidic chip. Below is a block diagram of the chip operation and the other necessary instrumentation as well as the connections we use. Those connections outline the most basic system requirements. Size and geometry will be discussed in the following sections. Figure 1: Overall Design Block Diagram The most basic need for our system is a small channel that the liquid passes through; this will need to be close to a waveguide. All of the materials must be relatively cheap and easy to use. Besides those few set things, there is a lot of flexibility in design. For that reason, we select the following concept areas to develop our final design plan. 5 Material Selection: Decide what PCB type material will be optimal for our system. Leakage Prevention: Design the board so that the protein solution can be confined properly to the channel. Signal Path Geometry: Consider how to align the channel and waveguide and how to fit all the connections on the board. We focus on these three because they are the essential concepts; all other decisions do not affect the system operation and can therefore be made fairly easily based on convenience and other trivial factors. Those include the actual size of the device and the width of the boards, amongst others. Concept Selection & Scoring Material Selection There are a variety of materials that we can use to create our chip. We will use two pieces with the same dimensions and then bond them together to create a channel between them. The material we choose will affect our fabrication process as well as the functionality of our final chip, so it is definitely a critical point. Concept Definitions Clear Acrylic – Simple clear solid plastic. Quite easy to obtain and some of our team members are familiar with it already due to prior research. FR-2 PCB – Low grade standard PCB material. This is the kind you would get in a cheap PCB kit at Radioshack for example. FR-4 PCB – Higher grade standard PCB. The typical FR-2 material is woven with fibers of glass to make it more resistant and solid. This is more standard In applications throughout engineering and is the kind we will readily find in the department shop. Concept Evaluation Bonding – It is critical that we be able to bond the material to itself AND to copper (the waveguide traces). If it does not bond, we cannot create a channel and therefore we cannot create a microfluidic system at all. 6 Easy to cut and form – We will be using milling machines or laser cutter to shape the material, the easier it is to cut and form with these machines, the faster we can fabricate the chips and begin testing. Transparency – While transparency is not critical, it will be very convenient during testing to be able to actually see fluid flow down the channel. It would also be useful to check for leaking problems. Customer Approval – Obviously, whatever material we use has to be approved by our supervisors as well as by Agilent. If they do not like it for some reason or it is an unfamiliar material to them, it is probably a poor choice. Concept Scoring Matrix Weighing Factors – Once we have established what factors are involved in this particular concept, we can rank them using a weight system. We realize that the most important factors to consider are how well the material can bind and how easy it is to cut and form. Since neither of these is really more important than the other, we assign them the same weight of 30. Transparency is quite important also but not at all as important as the previous two ideas. We assign it a value of 20. Finally, customer approval is given a weight of 20. We chose this because even though customer approval is actually quite important, we could obtain customer approval quite easily on any of our choices if we had a good reason to present to our supervisors and customer. Note: For all design matrices, the scores range from 1-10, 10 being the best score. Clear Acrylic Weighted Score Weighted Bonding 30 1 30 10 300 10 300 Easy to cut and form 30 8 240 8 240 8 240 Transparency Customer Approval Total 20 20 100 10 7 200 140 8 9 160 180 7 8 140 160 Score Score Weighted Value FR-4 PCB Weighted Concept Scoring Material Selection FR-2 PCB 610 880 840 7 Analysis of Scoring We assigned acrylic the lowest score in the bonding category because it doesn’t bond to itself. Since it is clear, it received high marks in the transparency category. It is easy to cut and form, so we assigned it an 8 out of 10. Since the customer offered no opinion on its use, we assigned it 7 out of 10. Both FR-2 and FR-4 can bond to themselves which is why they both received 10 out of 10s in that category. They are both easy to cut and form so they both received 8 out of 10 in that category. FR-2 is more transparent than FR-4, though both are transparent enough for the needs of the channel. Since the professors we are working preferred FR2 over FR-4, we gave FR-2 a 9 out of 10 and FR-4 an 8 out of 10. Result We see that our best option is FR-2 PCB. This is quite easy to obtain and can be cut using both the milling machine and the laser cutter. FR-4 is not too far behind and is also a reasonable option. It is only inferior to FR-2 in the less critical areas. However, it cannot be cut with the laser cutter because the glass fibers in it reflect the laser. The transparency difference is not too important either. Acrylic would have ideal transparency but the fact that it doesn’t bond to itself totally removes it from the realm of possibilities in our design. Leakage Prevention Design Concept Definitions Multilayer Board – Multilayer boards allow for a lot of flexibility in design. However, we do not have the necessary equipment to make these boards so we would have to send our designs to an outside company which adds time and cost. Adhesive Method – A variety of adhesives could be used to help in the binding process and to reduce leakage. These would be complicated to use because they may fill the channel or get into other undesired areas. Pressure and Heat Method – This is by far the cheapest and easiest method. We have all that we need in our lab to bind using this technique. However, it is also the least reliable one. This is a fairly typical trade-off situation. 8 Concept Evaluation Cost – The cost of our system must be low, but none of these methods would be particularly expensive so it remains a fairly low priority. Reliability – The method must do a very good job of avoiding leakage. Leaking will become an even bigger factor when our system is pressurized. Complexity – The easier the method, the faster we can get it done and move on to testing and fine-tuning the device. Since we will likely be repeating the process a lot, it is a very good thing to be able to do it quickly. Concept Scoring Matrix Weighing Factors – The single most important factor in this case is reliability. The device has to be leak proof. For this reason, we assign a weight of 40 to that factor. While complexity is not as critical as reliability, it will affect several aspects of our project. If the leakage prevention is something that we can do quickly and simply without the use of many machines, we will save a lot of time in the long run. Because of how much it affects our overall project, we assign complexity with a weight of 40 also. Finally, we give a value of 20 to cost. It is always a good thing to minimize cost so it definitely has its place as a factor. However, none of the methods we would use as leakage prevention will ever be very costly so it is reasonable to not make it as important as the other factors. 10 200 5 100 1 20 Reliability 40 8 320 5 200 5 200 Complexity Total 40 100 2 80 6 240 10 400 600 540 Weighted 20 Score Cost Score Weighted Weighted Value Pressure & Heat Method Score Concept Scoring Switch Selection Adhesive Method Weighted Multilayer Board 620 9 Analysis of Scoring A multilayer board would be reliable because the additional layers would prevent the liquid from leaking. Thus we assigned it an 8 out of 10. Since the multilayer board would have to be fabricated, this would add to the time and complexity of the project. Hence, we assigned it a low complexity score. Adhesive methods would also be inexpensive, but since they would be more expensive than the multilayer board due to additional materials, we assigned the cost of this method 5 out of 10. We presume that the adhesive method would be reliable enough for our needs, though not as reliable as a multilayer board. Hence this was also assigned 5 out of 10. Since we could add the adhesive within our own shops, this method is less complex than the multilayer board method. Hence we assigned this a 6 out of 10. We assume that the pressure and heat is as reliable as the adhesive method because heat and pressure should keep the board sealed together as well as with an adhesive. Thus we assigned this a 5 out of 10. Since heat and pressure require no extra materials, we assigned this a 10 out of 10 for complexity. Result The heat and pressure method seems to be the best from the matrix. This is definitely convenient for us. Although the multilayer board comes quite close numerically, the added time it would take to send the design out and have the board fabricated is too much to be worthwhile. Signal Path Geometry There are several ways to implement our chip. All we need to meet our specifications is for the channel to run parallel to the waveguide for two centimeters and for the two ends of the copper waveguide to meet the edge of the board at some point. Two alternate geometries are shown below. An additional one (not pictured) would include vias and imply pass the copper to the other side of the board at the point where they 10 bend in the first picture. Concept Definitions 90 degree angle – The 90 degree angles in the copper lines were our initial design idea. The channel and reservoirs are very easy to mill and everything fits well on the chip. Using Vias – Vias are a good option for leakage problems because they eliminate the need for the copper traces to pass under the channel wall, thus creating holes. However, they are significantly more complicated to mill. Straight Traces – Another idea is to bend the channel instead and keep the copper traces straight. This may improve the functionality of our waveguide and also makes our system slightly easier to model. Concept Evaluation Reliability – In general this means how reliable the chip will be if we use this method. This includes how well it deals with leaking problems and how well the waveguide will work in the given geometry. Complexity – How complicated it is to actually fabricate. Customer Approval – Obviously, the geometry again needs to be approved by our customer. They may for example prefer the SMA connectors in a specific location on the chip. Concept Scoring Matrix 11 Weighing Factors – Some of our factors in this analysis are the same as those we used in our earlier concept selections and will be weighed similarly for the same reasons. Reliability is our number one factor; if the chip does not work, there is no point considering other factors at all. We give reliability a weight of 45 and place it as the most important factor. Next, we have complexity. For the same reason as in our leakage prevention discussion, complexity is quite important. It is not part of the definition of the concept we are working on but it will greatly affect the time and effort put into the project. Complexity is assigned a weight of 35. Finally, we again have customer approval. As we have said before, we are not allowed to proceed without customer approval but feel it is easy to obtain provided we have a good understanding of why we selected the given method. A value of 20 seems reasonable for our customer approval weight. 45 5 140 8 360 8 360 Complexity Customer Approval Total 35 20 100 8 8 240 160 6 7 210 140 10 8 300 160 665 710 Weighted Reliability Score Score Using Straight Traces Weighted Using Vias Score Weighted Value Weighted Concept Scoring Signal Path Selection Keeping 90 degree turn angles in copper 820 Analysis of Scoring Since we are not confident in the success of a waveguide with 90 degree bends, we assigned the first option a 5 out of 10. We have already demonstrated that it is easy to fabricate, so we assigned it an 8 out of 10. We assume that as long as it works properly, the customer will be satisfied so we assigned the customer approval an 8 out of 10. We expect that vias will be reliable since will prevent leakage by eliminating the need for copper traces to pass under the channel wall. Thus we assigned vias an 8 out of 10 for reliability. They are difficult to fabricate and would likely be sent elsewhere for fabrication, so we assigned them a 6 out of 10 for complexity. Again, as long as the device works properly, the customer will be satisfied so we assigned customer approval a 7 out of 10 (a bit lower due to the increased complexity in the finished product). 12 Since we anticipate that the waveguide will work better when it is completely straight, we assigned the reliability of straight traces an 8 out of 10. They are the simplest to both fabricate and model so we assigned them a 10 out of 10 for complexity. As before, we assigned customer approval an 8 out of 10. Result Straight traces are our best option. It turns out to be almost equally as reliable as both other geometries but is simpler to fabricate and convenient for the user. This is the least critical of our concept selections and could be modified if the modification led to an improvement in another area. For example, if another geometry ended up severely affecting leakage. Conclusion We have chosen to implement our system using FR-2 PCB material. We will bind it using the heat and pressure method and will adopt a geometry that uses straight copper traces on a single side of the board. The reasons for these decisions are clearly outlined in this document. This design is still very flexible and as outlined above, many of the concepts can be changed with only minor effects on the overall final system. The object of this document is not to outline the only good way to design a microfluidics impedance spectroscopy system as there are many ways to do so. It is simply to provide a solid background and reasoning for the option we have chosen to follow. If changes are to be made in the design later on in the design process, this document will be a good resource in order to evaluate the pros and cons of such a decision. It contains all the critical information needed to assess the trade-offs of making important adjustments.