Course Project Process - Hong Kong University of Science and

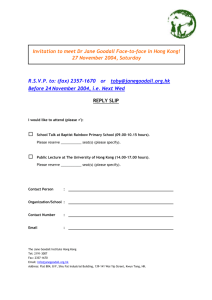

advertisement

Coventor Tutorial Bi-Stable Mechanical Beam Simulation -Remote Desktop Connection -Material definition -Fabrication (Process flow design) -Layout (Structure design) -Device fabrication (Meshing and Naming Entities) -Analyzer setting (Boundary conditions) -Simulation (Finite State Analysis) -Viewing result Hong Kong University of Science and Technology Kyoto University Remote Desktop Connection 5 IP addresses for the course ELEC5010: tmp234.ece.ust.hk tmp235.ece.ust.hk tmp236.ece.ust.hk tmp237.ece.ust.hk tmp238.ece.ust.hk Login: .\elec5010 Password: 5010user Two students share one virtual computer, it is important to log off to release computer for your partner. Hong Kong University of Science and Technology Kyoto University Coventor Tutorial Bi-Stable Mechanical Beam Simulation -Remote Desktop Connection -Material definition -Fabrication (Process flow design) -Layout (Structure design) -Device fabrication (Meshing and Naming Entities) -Analyzer setting (Boundary conditions) -Simulation (Finite State Analysis) -Viewing result Hong Kong University of Science and Technology Kyoto University Material Definition For detailed information on Material Definition, please refer to the Section 2.3 of the manual “Designer” ! ! ! 2.After opening a project, you will have models here 1.Create a project first or open your unfinished projects 3. Press this button Hong Kong University of Science and Technology Kyoto University Material Definition 1.Choose MPD materials database 2.Set the all parameters of Silicon_100 Hong Kong University of Science and Technology Kyoto University Coventor Tutorial Bi-Stable Mechanical Beam Simulation -Remote Desktop Connection -Material definition -Fabrication (Process flow design) -Layout (Structure design) -Device fabrication (Meshing and Naming Entities) -Analyzer setting (Boundary conditions) -Simulation (Finite State Analysis) -Viewing result Hong Kong University of Science and Technology Kyoto University Create Substrate 1.Create a new process and define the substrate For detailed information on editing process, please refer to the Section 2.4 of the manual “Designer” ! ! ! Hong Kong University of Science and Technology 2.Define thickness and material Kyoto University Oxide Formation 1.Double click 3.Layer Name 2.Thickness Hong Kong University of Science and Technology Kyoto University Si Formation Only this Si layer for simulation: Accurate “Thickness”!! Si layer for layout: Accurate “Layer Name”!! Hong Kong University of Science and Technology Kyoto University Si Patterning Hong Kong University of Science and Technology Kyoto University Metal Formation Metal layer for layout: Accurate “Layer Name”!! Hong Kong University of Science and Technology Kyoto University Metal Patterning Hong Kong University of Science and Technology Kyoto University Coventor Tutorial Bi-Stable Mechanical Beam Simulation -Remote Desktop Connection -Material definition -Fabrication (Process flow design) -Layout (Structure design) -Device fabrication (Meshing and Naming Entities) -Analyzer setting (Boundary conditions) -Simulation (Finite State Analysis) -Viewing result Hong Kong University of Science and Technology Kyoto University Create Layout 1.After saving the process file, we will create a new layout and check the layer names just defined For detailed information on editing layout, please refer to the Section 2.5 & 3.2.1 of the manual “Designer”! ! ! Hong Kong University of Science and Technology Kyoto University 2.Standard drawing Edit Your Layout 1.Choose the layer you will draw 3.Other functions For detailed information on editing layout, please refer to the Section 2.5 & 3 of the manual Hong Kong University of Science Kyoto University “Designer” ! ! and ! Technology Edit Your Layout How to draw a curving beam The important thing is the equation Also the rectangle Hong Kong University of Science and Technology Kyoto University Edit Your Layout For Bended beam: The beam and anchor should be merged. How? Select beam and anchor and then using “boolean>Or” for merge. Hong Kong University of Science and Technology Otherwise, solid model can’t be built!! ERROR Kyoto University Edit Your Layout For insert other cell’s graphs and define Cell. Otherwise, solid model can’t be built!! ERROR Hong Kong University of Science and Technology Kyoto University Finish Layout 1. Just draw the structures of two layers: SILICON!! METAL!! 2.You can hide the layer with turn off the light ahead layer name 3. Save the two layers layout and separate different parts in your structure as different cells. Hong Kong University of Science and Technology Kyoto University Flat Hierarchy This is for the final output!! (Don’t care it in the simulation) Before exporting the layout, find your final structure cell and flatten. Then…. For detailed information on editing layout, please refer to the Section 2.5.7 of the manual “Designer” ! ! ! Hong Kong University of Science and Technology Kyoto University Gds Out Chose a file to output the layout. For detailed information on editing layout, please refer to the Section 2.6.6 of the manual “Designer” ! ! ! Hong Kong University of Science and Technology Kyoto University Coventor Tutorial Bi-Stable Mechanical Beam Simulation -Remote Desktop Connection -Material definition -Fabrication (Process flow design) -Layout (Structure design) -Device fabrication (Meshing and Naming Entities) -Analyzer setting (Boundary conditions) -Simulation (Finite State Analysis) -Viewing result Hong Kong University of Science and Technology Kyoto University Initial Solid Model 2.Since only SILICON layer is simulated, other can be hided. (RightClick) 1.Select a top cell to build the solid model For detailed information on solid model, please refer to the Section 4.5 of the manual “Designer” ! ! ! Hong Kong University of Science and Technology Kyoto University Partition Partition the Si into several parts. (Partition the beam (moved parts) from the anchor (fixed parts) . 1.Ctrl choose 3 points 2.Add a plane 3.Ctrl select the plane and layer which will be parted 4.Partition Hong Kong University of Science and Technology Kyoto University Partition (After) After partition, one Silicon bulk is cut into many parts. After partition, the plane can be hided. Finally, the one Silicon bulk will be cut into many Layer3. After several times of partition, the beams will be completely separated from the anchor. Hong Kong University of Science and Technology Kyoto University Add Layer to Mesh Model Select ALL Silicon parts and add them to Mesh Model For detailed information on solid model, please refer to the Section 4.7 of the manual “Designer” ! ! ! Hong Kong University of Science and Technology Kyoto University Add Layer to Mesh Model ALL Silicon parts move into Mesh Model For detailed information on Mesh model, please refer to the Section 4.7 of the manual “Designer” ! ! ! Hong Kong University of Science and Technology Kyoto University Meshing Settings Smaller element size means more accurate simulation . Please try from larger size as saving simulation time at the beginning. Hong Kong University of Science and Technology Kyoto University Generate Meshing Select ALL Silicon parts and Generate Mesh. Hong Kong University of Science and Technology Kyoto University Finish Meshing Hong Kong University of Science and Technology Kyoto University Naming Entities Name the top faces which will be used as electrodes “Potential” will be applied on these faces. Hong Kong University of Science and Technology Kyoto University Naming Entities Name all the bottom faces which connects substrate Anchors “Fixall” and “Temperature” will be applied on these faces. Hong Kong University of Science and Technology Kyoto University Naming Entities Name the front faces or other needed faces of the actuator, amplifier or bistable beam on the side faces! “Pressure” or “Displacement” will be applied on these faces For detailed information on Mesh model, please refer to the Section 4.6 of the manual “Designer” ! ! ! Hong Kong University of Science and Technology Kyoto University Coventor Tutorial Bi-Stable Mechanical Beam Simulation -Remote Desktop Connection -Material definition -Fabrication (Process flow design) -Layout (Structure design) -Device fabrication (Meshing and Naming Entities) -Analyzer setting (Boundary conditions) -Simulation (Finite State Analysis) -Viewing result Hong Kong University of Science and Technology Kyoto University Solver Setting After saving the mesh model, we will have it here. Hong Kong University of Science and Technology Kyoto University Solver Setting Which be talked in the slide page 40 Hong Kong University of Science and Technology Kyoto University Surface Boundary conditions Example: apply voltage to actuator to analysis the temperature, displacement, stress and so on. 1. Fixall for anchor 2. Set the temperate of all anchor as room temperature (300K). The units is “K”. 3. Apply voltage to electrodes. The units is “voltage”. For detailed information on setting boundary conditions, please refer to the Section 3.5.3 of the manual “analyzer_standard” ! ! ! Hong Kong University of Science and Technology Kyoto University Surface Boundary conditions For other simulations: 1. “Fixall” and “Temperature” are always applied on anchor faces. 2. “Potential” can be applied on electrode faces. 3. “Pressure” or “Displacement” can be applied on side faces Hong Kong University of Science and Technology Kyoto University SBCs for Bistable Beam For detailed information on Simulation methodology of Bistable Beam, please refer to the “Tutorial on simiulation of bistable beam” ! ! ! Apply one Displacement to get one Force Hong Kong University of Science and Technology Kyoto University Displacement-Force Simulation • For simulation, one can not solve an arbitrary displacement directly, according to my experience. Instead, one need to increase the displacement bit by bit from zero, and telling Coventor to start the analysis from the result of the previous one. • In this manner, the simulation will not fail easily, because defining the displacement resolves the large nonlinearity of buckling. Hong Kong University of Science and Technology Kyoto University One or Multi Point Simulation 1. Correspond the displacement to a variable, “mechBC1”, based on “MemMech” Solver. 4. Set the value 3. Set the Trajectory 6. Run here for simulating one value 2. Start to set Variable 3. Correspond the “mechBC1” to a Trajectory 5. Run here for simulating a series of values Hong Kong University of Science and Technology Kyoto University Contact Boundary Conditions Plan: ACT CON Plan: AMP CON2 Plan: BEAM CON Plan: AMP CON1 Hong Kong University of Science and Technology If you want to use the actuator to push the amplifier, or use the amplifier to push the beam you need to define the Planes of actuator, amplifier and beam as contact planes. Otherwise, they actuator will move across the amplifier, or the amplifier will move across the beam rather than push it. Kyoto University Coventor Tutorial Bi-Stable Mechanical Beam Simulation -Remote Desktop Connection -Material definition -Fabrication (Process flow design) -Layout (Structure design) -Device fabrication (Meshing and Naming Entities) -Analyzer setting (Boundary conditions) -Simulation (Finite State Analysis) -Viewing result Hong Kong University of Science and Technology Kyoto University Simulation After simulation, no matter success or not, you view the results or debug the errors. Hong Kong University of Science and Technology Kyoto University View Resluts By click the displacement, you can switch to other parameters. For detailed information on Visualizer, please refer to the Section 9 of the manual “analyzer_standard” ! ! ! Hong Kong University of Science and Technology Kyoto University 3D Result Viewing For detailed information on Visualizer, please refer to the Section 9 & 9.1 of the manual “analyzer_standard” ! ! ! Hong Kong University of Science and Technology Kyoto University Simulation Result of the Displace-Fore of Bistable Beam Checking the displacement deformation using Geometry Scaling Hong Kong University of Science and Technology Kyoto University Simulation Result of the Displace-Fore of Bistable Beam Checking the Force Value using Table – rxnForces. Sign of rxnForces changes from + to – or – to +, indicating two stable states. Hong Kong University of Science and Technology Kyoto University Last year’s Design Hong Kong University of Science and Technology Kyoto University