The Science and Engineering of Materials, 4th ed Donald R

advertisement

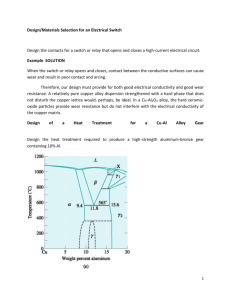

The Science and Engineering of Materials, 4th ed Donald R. Askeland – Pradeep P. Phulé Chapter 13 – Nonferrous Alloys 1 1 Objectives of Chapter 13 Explore the properties and applications of Cu, Al, and Ti alloys in load-bearing applications. 2 2 Chapter Outline 13.1 13.2 13.3 13.4 13.5 13.6 Aluminum Alloys Magnesium and Beryllium Alloys Copper Alloys Nickel and Cobalt Alloys Titanium Alloys Refractory and Precious Metals 3 3 4 4 Section 13.1 Aluminum Alloys Hall-Heroult process - An electrolytic process by which aluminum is extracted from its ore. Temper designation - A shorthand notation using letters and numbers to describe the processing of an alloy. H tempers refer to cold-worked alloys; T tempers refer to age-hardening treatments. 5 5 ©2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning ™ is a trademark used herein under license. Figure 13.1 Production of aluminum in an electrolytic cell. 6 6 7 7 8 8 9 9 10 10 Figure 13.2 (a) FeAl3 inclusions in annealed 1100 aluminum ( 350). (b) Mg2Si precipitates in annealed 5457 aluminum alloy ( 75). (From ASM Handbook, Vol. 7, (1972), ASM International, Materials Park, OH 44073.) 11 11 ©2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning ™ is a trademark used herein under license. Figure 13.3 Portion of the aluminum-magnesium phase diagram. 12 12 Figure 13.4 (a) Sand-cast 443 aluminum alloy containing coarse silicon and inclusions. (b) Permanent-mold 443 alloy containing fine dendrite cells and fine silicon due to faster cooling. (c) Die-cast 443 alloy with a still finer microstructure ( 350). (From ASM Handbook, Vol. 7, (1972), ASM International, Materials Park, OH 44073.) 13 13 Example 13.1 Strength-to-Weight Ratio in Design A steel cable 0.5 in. in diameter has a yield strength of 70,000 psi. The density of steel is about 7.87 g/cm3. Based on the data in Table 13-5, determine (a) the maximum load that the steel cable can support, (b) the diameter of a cold-worked aluminum-manganese alloy (3004-H 18) required to support the same load as the steel, and (c) the weight per foot of the steel cable versus the aluminum alloy cable. 14 14 15 15 Example 13.1 SOLUTION a. Load = F = σy A = 70.000 (π/4) (0.5 in.)2 = 13,744 lb b. The yield strength of the aluminum alloy is 36,000 psi. Thus: A = (π/4)d2 = F/σy = 13,744/36,000 = 0.38 in.2 d = 0.697 in. Density of steel = ρ = 7.87 g/cm3 = 0.284 lb/in.3 Density of aluminum = ρ = 2.70 g/cm3 = 0.097 lb/in3 c. Weight of steel = Alρ = (π/4)(0.5in)2(12)(0284) = 0.669 lb/ft Weight of aluminum = Alρ = (π/4)(0.697)2 (2) (12) (0.097) = 0.444 lb/ft Although the yield strength of the aluminum is lower than that of the steel and the cable must be larger in diameter, the aluminum cable weighs only about half as much as the steel cable. When comparing materials, a proper factor-ofsafety should also be included during design. 16 16 Example 13.2 Design of an Aluminum Recycling Process Design a method for recycling aluminum alloys used for beverage cans. Example 13.2 SOLUTION One approach to recycling the cans is to separate the two alloys from the cans. The cans are shredded, then heated to remove the lacquer that helps protect the cans during use. We could then further shred the material at a temperature where the 5182 alloy begins to melt. The small pieces of 5182 can therefore be separated by passing the material through a screen. The two separated alloys can then be melted, cast, and rolled into new can stock. An alternative method would be to simply remelt the cans. Once the cans have been remelted, we could bubble chlorine gas through the liquid alloy. The chlorine reacts selectively with the magnesium, removing it as a chloride. The remaining liquid can then be adjusted to the proper composition and be recycled as 3004 alloy. 17 17 Example 13.3 Design/Materials Selection for a Cryogenic Tank Design the material to be used to contain liquid hydrogen fuel for the space shuttle. Example 13.3 SOLUTION Liquid hydrogen is stored below 253oC; therefore, our tank must have good cryogenic properties. Lightweight aluminum would appear to be a good choice. Aluminum does not show a ductile to brittle transition. Because of its good ductility, we expect aluminum to also have good fracture toughness, particularly when the alloy is in the annealed condition. One of the most common cryogenic aluminum alloys is 5083-O. Aluminum-lithium alloys are also being considered for low-temperature applications to take advantage of their even lower density. 18 18 Example 13.4 Design of a Casting Process for Wheels Design a casting process to produce automotive wheels having reduced weight and consistent and uniform properties. Example 13.4 SOLUTION Thixocasting process in which the material is stirred during solidification, producing a partly liquid, partly solid structure that behaves as a solid when no external force is applied, yet flows as a liquid under pressure. We would select an alloy with a widefreezing range so that a significant portion of the solidification process occurs by the growth of dendrites. A hypoeutectic aluminum-silicon alloy might be appropriate. In the thixocasting process, the dendrites are broken up by stirring during solidification. The billet is later reheated to cause melting of just the eutectic portion of the alloy, and it is then forced into the mold in its semi-solid condition at a temperature below the liquidus temperature. 19 19 Section 13.2 Magnesium and Beryllium Alloys Magnesium alloys are used in aerospace applications, high-speed machinery, and transportation and materials handling equipment. Instrument grade beryllium is used in inertial guidance systems where the elastic deformation must be minimal; structural grades are used in aerospace applications; and nuclear applications take advantage of the transparency of beryllium to electromagnetic radiation. Beryllium is expensive, brittle, reactive, and toxic. 20 20 ©2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning™ is a trademark used herein under license. Figure 13.5 The magnesium-aluminum phase diagram. 21 21 22 22 Section 13.3 Copper Alloys Blister copper - An impure form of copper obtained during the copper refining process. Applications for copper-based alloys include electrical components (such as wire), pumps, valves, and plumbing parts, where these properties are used to advantage. Brass - A group of copper-based alloys, normally containing zinc as the major alloying element. Bronze - Generally, copper alloys containing tin, can contain other elements. 23 23 24 24 ©2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning ™ is a trademark used herein under license. Figure 13.6 Binary phase diagrams for the (a) copper-zinc, (b) copper-tin, (c) copperaluminum, and (d) copperberyllium systems. 25 25 Example 13.5 Design/Materials Selection for an Electrical Switch Design the contacts for a switch or relay that opens and closes a high-current electrical circuit. Example 13.5 SOLUTION When the switch or relay opens and closes, contact between the conductive surfaces can cause wear and result in poor contact and arcing. Therefore, our design must provide for both good electrical conductivity and good wear resistance. A relatively pure copper alloy dispersion strengthened with a hard phase that does not disturb the copper lattice would, perhaps, be ideal. In a Cu-Al2O3 alloy, the hard ceramic-oxide particles provide wear resistance but do not interfere with the electrical conductivity of the copper matrix. 26 26 Example 13.6 Design of a Heat Treatment for a Cu-Al Alloy Gear Design the heat treatment required to produce a high-strength aluminum-bronze gear containing 10% Al. Figure 13.6 Binary phase diagrams for the (c) copper-aluminum 27 27 Example 13.6 SOLUTION 1. Heat the alloy to 950oC and hold to produce 100% β. 2. Quench the alloy to room temperature to cause β to transform to martensite, β´, which is supersaturated in copper. 3. Temper below 565oC; a temperature of 400oC might be suitable. During tempering, the martensite transforms to α and γ2. The amount of the γ2 that forms at 400oC is: 4. Cool rapidly to room temperature so that the equilibrium γ does not form. 28 28 Section 13.4 Nickel and Cobalt Alloys Nickel and cobalt alloys are used for corrosion protection and for high-temperature resistance, taking advantage of their high melting points and high strengths. Superalloys - A group of nickel, iron-nickel, and cobaltbased alloys that have exceptional heat resistance, creep resistance, and corrosion resistance. 29 29 30 30 ©2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning ™ is a trademark used herein under license. Figure 13.7 The effect of temperature on the tensile strength of several nickelbased alloys. 31 31 Figure 13.8 (a) Microstructure of a superalloy, with carbides at the grain boundaries and γ΄ precipitates in the matrix ( 15,000). (b) Microstructure of a superalloy aged at two temperatures, producing both large and small cubical γ΄ precipitates ( 10,000). (ASM Handbook, Vol. 9, Metallography and Microstructure (1985), ASM International, Materials Park, OH 44073.) 32 32 Example 13.7 Design/Materials Selection for a High-Performance Jet Engine Turbine Blade Design a nickel-based superalloy for producing turbine blades for a gas turbine aircraft engine that will have a particularly long creep-rupture time at temperatures approaching 1100oC. 33 33 ©2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning ™ is a trademark used herein under license. Figure 13.9 (a) A turbine blade designed for active cooling by a gas. (b) The high-temperature capability of superalloys has increased with improvements in manufacturing methods (for Example 13.7). 34 34 Example 13.7 SOLUTION First, we need a very stable microstructure. Addition of aluminum or titanium permits the precipitation of up to 60 vol% of the γ´ phase during heat treatment and may permit the alloy to operate at temperatures approaching 0.85 times the absolute melting temperature. Second, we might produce a directionally solidified or even single-crystal turbine blade (Chapter 8). In directional solidification, only columnar grains. We would then heat treat the casting to assure that the carbides and γ´ precipitate with the correct size and distribution. Finally, the blade might contain small cooling channels along its length. Air for combustion in the engine can pass through these channels, providing active cooling to the blade, before reacting with fuel in the combustion chamber. 35 35 Section 13.5 Titanium Alloys Titanium’s excellent corrosion resistance provides applications in chemical processing equipment, marine components, and biomedical implants such as hip prostheses. Titanium is an important aerospace material, finding applications as airframe and jet engine components. Titanium alloys are considered biocompatible (i.e., they are not rejected by the body). By developing porous coatings of bone-like ceramic compositions known as hydroxyapatite, it may be possible to make titanium implants bioactive (i.e., the natural bone can grow into the hydroxyapatite coating). 36 36 ©2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning ™ is a trademark used herein under license. Figure 13.10 Portions of the phase diagrams for (a) titanium-tin, (b) titaniumaluminum, (c) titaniummolybdenum, and (d) titaniummanganese. 37 37 38 38 ©2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning ™ is a trademark used herein under license. Figure 13.11 The effect of temperature on the yield strength of selected titanium alloys. 39 39 Figure 13.12 (a) Annealing and (b) microstructure of rapidly cooled alpha titanium ( 100). Both the grain boundary precipitate and the Widmanstätten plates are alpha. (From ASM Handbook, Vol. 7, (1972), ASM International, Materials Park, OH 44073.) 40 40 Figure 13.13 Annealing of an alpha-beta titanium alloy. (a) Annealing is done just below the α–β transformation temperature, (b) slow cooling gives equiaxed α grains ( 250), and (c) rapid cooling yields acicular α grains ( 2500). (From Metals Handbook, Vol. 7, (1972), ASM International, Materials Park, OH 44073.) 41 41 Figure 13.14 (a) Heat treatment and (b) microstructure of the alpha-beta titanium alloys. The structure contains primary α (large white grains) and a dark β matrix with needles of α formed during aging (250). (From ASM Handbook, Vol. 7, (1972), ASM International, Materials Park, OH 44073.) 42 42 Example 13.8 Design of a Heat Exchanger Design a 5-ft-diameter, 30-ft-long heat exchanger for the petrochemical industry (Figure 13.15). ©2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning ™ is a trademark used herein under license. Figure 13.15 Sketch of a heat exchanger using titanium tubes (for Example 13.8). 43 43 Example 13.8 SOLUTION Provided that the maximum operating temperature is below 535oC so that the oxide film is stable, titanium might be a good choice to provide corrosion resistance at elevated temperatures. A commercially pure titanium provides the best corrosion resistance. Pure titanium also provides superior forming and welding characteristics and would, therefore, be our most logical selection. If pure titanium does not provide sufficient strength, an alternative is an alpha titanium alloy, still providing good corrosion resistance, forming characteristics, and weldability but also somewhat improved strength. 44 44 Example 13.9 Design of a Connecting Rod Design a high-performance connecting rod for the engine of a racing automobile (Figure 13.16). Figure 13.16 Sketch of connecting rod (for Example 13.9). 45 45 Example 13.9 SOLUTION To achieve high strengths, we might consider an alphabeta titanium alloy. Because of its availability, the Ti-6% Al-4% V alloy is a good choice. The alloy is heated to about 1065oC, which is in the all-β portion of the phase diagram. When the heat treatment is performed in the all-β region, the tempered martensite has an acicular structure, which reduces the rate of growth of any fatigue cracks that might develop. 46 46 Example 13.10 Materials for Hip Prosthesis What type of a material would you choose for an implant to be used for a total hip replacement implant? Example 13.10 SOLUTION We need to consider the following factors: biocompatibility, corrosion resistance, high-fracture toughness, excellent fatigue life, and wear resistance. These requirements suggest 316 stainless steel or Ti6% Al-4% V. Titanium is bio-compatible and would be a better choice. Perhaps a composite material in which the stem is made from a Ti-6% Al-4% V alloy and a head that is made from a wear-resistant, corrosion resistant, and fractured tough ceramic, such as alumina, may be an answer. Another option is to coat the implant with a material like porous hydroxyapatite to encourage bone growth. 47 47 Section 13.6 Refractory and Precious Metals Refractory metals – These include tungsten, molybdenum, tantalum, and niobium (or columbium), have exceptionally high-melting temperatures (above 1925oC) and, consequently, have the potential for hightemperature service. Applications of Refractory metals include filaments for light bulbs, rocket nozzles, nuclear power generators, tantalum- and niobium-based electronic capacitors, and chemical processing equipment. Precious Metals - These include gold, silver, palladium, platinum, and rhodium.From an engineering viewpoint, these materials resist corrosion and make very good conductors of electricity. 48 48 49 49