Statistical Data Analysis: Primer

advertisement

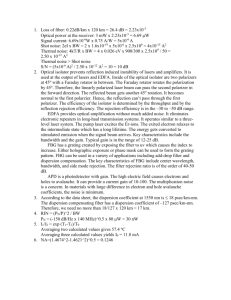

Stat 470-18 • Today: Start Chapter 10 Additional Homework Question A wood products company wishes to investigate the affect of several factors on the thickness swell of a manufactured wood product. The goal of the experiment is to minimize the swelling after the wood has bee saturated with th water. The manufacturing process has 2 steps. First, pieces of wood and additives are combined to form a batch. Next, the batch is split into several sub-batches and processed into s sheet or plank of wood. It is possible to make between 2 and 4 sub-batches per batch (it is the experimenter's choice). A designed experiment is to be run to investigate the impact of factors at both stages. The factors in the first stage are A,B,C,D,E. The second stage factors are labeled p, q and r. Due to operational restrictions, the experiment is run by first fixing 5 factors affecting the batch and then creating a batch of raw materials. Next the mixture is separated into sub-batches, keeping the first stage factors fixed. Thus a split-plot design results. a. b. c. d. e. f. g. h. i. Construct a 2(5+3)-(2+1) 32-run fractional factorial split-plot design. Find the defining contrast sub-group of the design. Write out the 32 treatments to be run and identify which trials are performed in the same sub-plot. Which effects are assessed using the WP error, and which effects are assessed using the SP error? Construct a 2(5+3)-(1+2) 32-run fractional factorial split-plot design. Find the defining contrast sub-group of the design. Which effects are assessed using the WP error, and which effects are assessed using the SP error? Which design has less aberration? If the mixing stage is the most expensive part of the experiment, which design is cheaper to run? Why? Chapter 10: Robust Parameter Design • Robust parameter design is an experimentation technique which aims to reduce system variation and also optimize the mean system response • Idea is to use control factors to make the system robust to the influences of noise factors Example: Leaf Spring Experiment (p. 438) • Experiment was conducted to investigate the impact of a heat treatment process on truck leaf springs where the target height of the springs is 8 inches • Experiment considered 5 factors, each at 2 levels: – B: High heat treatment – C: Heating time – D: Transfer time – E: Hold down time – Q: Quench oil temperature • In regular production Q is not controllable, but can be in the experiment Example: Leaf Spring Experiment (p. 438) • 25-1 fractional factorial design was performed: I=BCDE • Experiment has 3 replicates Control Factors B C D E -1 -1 -1 -1 +1 -1 -1 +1 -1 +1 -1 +1 +1 +1 -1 -1 -1 -1 +1 +1 +1 -1 +1 -1 -1 +1 +1 -1 +1 +1 +1 +1 Q Level 7.78 8.15 7.50 7.59 7.94 7.69 7.56 7.56 -1 7.78 8.18 7.56 7.56 8.00 8.09 7.62 7.81 7.81 7.88 7.50 7.75 7.88 8.06 7.44 7.69 7.50 7.88 7.50 7.63 7.32 7.56 7.18 7.81 +1 7.25 7.88 7.56 7.75 7.44 7.69 7.18 7.50 7.12 7.44 7.50 7.56 7.44 7.62 7.25 7.59 Noise Factors • Noise factors are factors that impact the system response, but in practice are not controllable • Examples include environmental factors, differing user conditions, variation in process parameter settings, … • Example: refrigerators are manufactured so that the interior temperature remains close to some target • Section 10.3 discusses different types of noise factors…please read Variance Reduction Via Parameter Design • Let x denote the control factor settings and z denote the noise factor settings • Relationship between the system response and the factors: y = f(x,z) • If noise factors impact the response, then variation in the levels of z will transmit this variance to the response, y • If some noise and control factors interact, can potentially adjust levels of control factors to dampen impact of noise factor variation Variance Reduction Via Parameter Design • Suppose there is one noise factor and two control factors y x1 x2 z z • What is variance of y in practice? • What does this imply? Cross Array Strategy • We will consider two types of design/analysis techniques for robust parameter design • The first one uses location-dispersion modeling (e.g., have a model for the mean response and another for the variance) similar to the epitaxial layer growth experiment in Chapter 3 • The design strategy for this technique is based on a cross array Cross Array Strategy • Consider the leaf spring example • We can view this experiment as the combination of two separate experimental designs – Control array: design for the control factors – Noise array: design for the noise factors • Cross array: design consisting of all level combinations between the control array and the noise array • If there are N1 runs in the control array and N2 trials in the noise array, then the cross array has N1 N2 trials Cross Array Strategy • Design for control factors: • Design for noise factors: Cross Array Strategy • The responses are modeled using the location-dispersion approach • The models include ONLY the control factors 2 • At each control factor setting, yi and ln( si ) are used as measures of location and dispersion • Factors that impact the mean are called location factors and those that impact the variance are dispersion factors • Location factors that are not dispersion factors are called adjustment factors Example: Leaf Spring Control Factors B C D E -1 +1 -1 +1 -1 +1 -1 +1 +1 +1 -1 -1 +1 +1 -1 -1 +1 +1 +1 +1 -1 -1 -1 -1 -1 +1 +1 -1 +1 -1 -1 +1 yi lnsi2 7.540 7.902 7.520 7.640 7.670 7.785 7.372 7.660 -2.4075 -2.6488 -6.9486 -4.8384 -2.3987 -2.9392 -3.2697 -4.0582 Example: Leaf Spring Effect B C D E BC=DE BD=CE BE=CD Estimate (Location) 0.22125 0.17625 0.02875 0.10375 0.01725 0.01975 -0.03525 Estimate (Dispersion) 0.1350 2.1802 -1.0444 -0.6499 -0.5259 0.7995 1.1852 -1.0 -0.5 0. DisperonEfcts 0.5 1.0 1.5 2.0 0. 0.5 LocatinEfes 0.1 0.15 0.2 Example: Leaf Spring -1 .0 -0 .5 0 .0 0 .5 1 .0 Qu a n ti l e s of -1 .0 -0 .5 0 .0 0 .5 1 .0 S ta n d a rd No rm Qu a n ti l e s of Example: Leaf Spring • Location Model: yˆ 7.6360 0.1106 xB 0.0881xC 0.0519 xE • Dispersion Model: zˆ 3.6886 1.0901xC • Level settings: Two-Step Optimization Procedures • Nominal the best problem: – Select the levels of the dispersion factors to minimize the dispersion – The select the levels of the adjustment factors to move the process on target • Larger (Smaller) the better problem: – Select levels of location factors to optimize process mean – Select levels of dispersion factors that are not location factors to minimize dispersion • Leaf Spring Example was a nominal the best problem Response Modeling • There may be several noise factors and control factors in the experiment • The cross array approach identifies control factors to help adjust the dispersion and location models, but does not identify which noise factors interact with which control factors • Cannot deduce the relationships between control and noise factors • The response model approach explicitly model both control and noise factors in a single model (called the response model) Response Modeling • Steps: – Model response, y, as a function of both noise and control factors (I.e., compute regression model with main effects and interactions of both types of factors) – To adjust variance: • make control by noise interaction plots for the significant control by noise interactions. The control factor setting that results in the flattest relationship gives the most robust setting. • construct the variance model, and choose control factor settings that minimize the variance Example: Leaf Spring Experiment (p. 438) • 25-1 fractional factorial design was performed: I=BCDE • Experiment has 3 replicates Control Factors B C D E -1 -1 -1 -1 +1 -1 -1 +1 -1 +1 -1 +1 +1 +1 -1 -1 -1 -1 +1 +1 +1 -1 +1 -1 -1 +1 +1 -1 +1 +1 +1 +1 Q Level 7.78 8.15 7.50 7.59 7.94 7.69 7.56 7.56 -1 7.78 8.18 7.56 7.56 8.00 8.09 7.62 7.81 7.81 7.88 7.50 7.75 7.88 8.06 7.44 7.69 7.50 7.88 7.50 7.63 7.32 7.56 7.18 7.81 +1 7.25 7.88 7.56 7.75 7.44 7.69 7.18 7.50 7.12 7.44 7.50 7.56 7.44 7.62 7.25 7.59 Example: Leaf Spring Experiment (p. 438) • 25-1 fractional factorial design was performed: I=BCDE B -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 -1 1 C -1 -1 1 1 -1 -1 1 1 -1 -1 1 1 -1 -1 1 1 D -1 -1 -1 -1 1 1 1 1 -1 -1 -1 -1 1 1 1 1 E -1 1 1 -1 1 -1 -1 1 -1 1 1 -1 1 -1 -1 1 Q -1 -1 -1 -1 -1 -1 -1 -1 1 1 1 1 1 1 1 1 Y 7.79 8.07 7.52 7.63 7.94 7.95 7.54 7.69 7.29 7.73 7.52 7.65 7.40 7.62 7.20 7.63 Example: Leaf Spring Experiment (p. 438) Effect B C D E Q BC=DE BD=CE BE=CD BQ CQ DQ EQ BCQ=DEQ BDQ=CEQ BEQ=CDQ Estimate 0.221 -0.176 -0.029 0.104 -0.260 -0.017 -0.020 -0.035 0.085 0.165 -0.054 0.027 -0.010 0.040 -0.047 E f e c t s i m a -0.2 -0.1 0. 0.1 0.2 Example: Leaf Spring Experiment (p. 438) -1 0 1 Qu a n ti l e s of Example: Leaf Spring Experiment (p. 438) • Response Model: Example: Leaf Spring Experiment (p. 438) m e a n o f Y 7.5 7.6 7. 7.8 7.9 C -1 1 -1 1 Q Example: Leaf Spring Experiment (p. 438) • Variance Model: