Focus document - Boars heading for 2018

advertisement

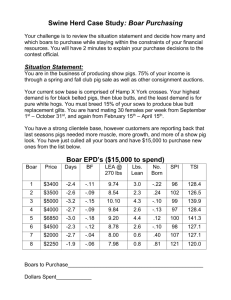

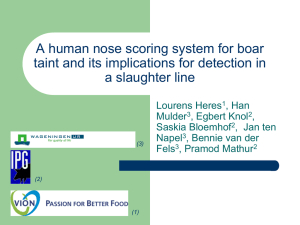

Focus document Press trip Boars heading for 2018 17th and 18th April 2013 Eindhoven, the Netherlands Contents Background What is boar taint? Detecting boar taint Preventing boar taint Challenges Presentations Welcome by Annechien ten Have Update and presentation of European and Dutch research: - An overview of recent international developments in production and consumption of meat from entire male pigs - Highlights of results of consumer acceptance studies - Economics of producing boars Gé Backus - Research on risk management and detection Coen van Wagenberg - Research on farm level management and animal behaviour Carola van der Peet Companies to visit Pig farm Polsdonk Background information about the farm and the breeding of boars, experiences and results. Albert Heijn Retail, location Eindhoven, information about their fresh meat department. VION Food Group Background information on VION in Helmond Information about the detection of boar meat in the slaughter line by the human nose. Research and development News Facts and figures Contact Background “Since boar meat is less tasty, the young boars which are intended for fattening are always castrated,” states an Encyclopaedia of 1954 emphatically. The castration of boars was so selfevident in the last century that we know relatively little about the unpalatable taste – referred to as boar taint. Since then the (non-anaesthetized) castration of boars has become regarded more and more as an infringement of the wellbeing of the animal and as socially unacceptable. It is also a task pig farmers find unpleasant. There are economic disadvantages too: castrated boars require relatively more feed and have a less favourable meat to fat ratio. It should be added that castrated boars (hogs) are less aggressive than non-castrated boars. This is an advantage for the pig farmer and for the welfare of animals housed in groups. There are many different views on the castration and non-castration of male pigs in European and international markets. Nonetheless, the European Commission and representatives of European farmers, the meat industry, retailers, scientists, veterinarians and animal welfare NGO’s have agreed to a plan to voluntarily end surgical castration of pigs in Europe by January 1st, 2018. A European approach is necessary to develop the tools to achieve these goals, to ensure that the costs are fairly shared and to ensure that the European market accepts meat of non-castrated male pigs. The main obstacle is that the meat of non-castrated boars is anything but popular in the international trade because of the fear of boar taint. What is boar taint? Boar taint is a penetrating unpleasant odour (and accompanying taste) in pork. If strong, it is associated with manure, urine and sweat. A person can only smell the odour when the meat is heated, i.e. in the pan. There is no problem with cold meat products. The majority of pig meat, however, is destined for the fresh meat market, i.e. for ‘the pan’. Boar taint is a gradual phenomenon and is dependent on the concentration and combination of certain substances in fat. The likelihood of boar taint in castrated and female pigs is very low. In older/heavier non-castrated male pigs the likelihood is considerably higher. Three compounds Three compounds are regarded as responsible for boar taint: androstenone, skatole and indole. Androstenone is a testicular steroid with a strong urine odour. This substance is important for creating the boar’s semen that begins approximately at 18 weeks and at a weight of 60 kilos. Skatole is a non-sex-specific substance which arises from the breakdown of certain amino-aids in the body. This substance is three times more concentrated in the fat of male pigs than in that of females. Castration reduces the concentration by a factor of one-and-a-half to two. The three substances explain only two thirds of the variation in boar taint. Most probably more substances play a role. Consumer acceptance Boar taint is literally a matter of taste. The problem concerns not just the concentration of the substances but also how consumers experience the odour and flavour associated with these substances. For example, a considerable proportion of consumers (30%) were found to be not at all sensitive to androstenone. Moreover, consumers in one country appear to have fewer problems with what we call boar taint, than consumers in other countries. That could be related to habituation, but also to the way pork is prepared. There is very little experience of non– acceptance by consumers because fresh pork is currently produced from castrated adult boars. The pork chain simply does not want to run the risk. The percentage of adult boars that actually have boar taint is not known. Estimates vary widely. Several research projects have been conducted to discover the extent to which consumers will accept meat from entire male pigs. The overall conclusion was that there was no clear preference among these consumers for meat from barrows (male pigs castrated before puberty) compared to that from boars that did pass the boar taint detection test at the slaughter line. Although consumers are not very consistent in their sensory evaluation of meat during successive tests with the same product, meat from boars with high levels of androstenone, skatole and indole is on average less preferred. Detecting Boar Taint To prevent pork that contains boar taint from being sold to consumers, boars with boar taint have to be detected at slaughter. After detection of such a boar, its meat is processed separately to prevent consumers from experiencing the unpleasant odour and taste. Many methods to detect boars with boar taint in the slaughterhouse have been developed or are in development. These can be divided into methods focusing on specific compounds and sensory methods assessing boar taint as a holistic concept. Specific compound To detect specific compounds of boar taint, mainly androstenone and skatole, several analytical and bio sensing methods are being used or are under development. Analytical methods focus on the quantitative measurement of compounds. A fat or meat sample is taken from each boar and this sample is chemically analysed for the presence of androstenone and/or skatole. If the level of androstenone and/or skatole exceeds a specified threshold, the boar has boar taint. Many methods have been developed or are in development, such as spectrophotometry, chemical sensor array technology, gas-sensor technology, gas-phase fingerprinting, massspectrometry, gas chromatography, Ion Molecule Reaction, and gas-phase Fourier transform infrared. Currently, only the spectrophotometric method is being applied at the slaughter line in Danish slaughter plants to detect skatole. Sample taking and preparation is of utmost importance for such methods to correctly measure compounds levels. Electrochemical biosensing methods and parasitoid bio-sensing methods using trained insects such as wasps to detect target compounds are currently only in the development phase. An important point of discussion is whether measuring only androstenone and/or skatole is sufficient for assessing boar taint. Practical experience has shown that this can result in substantial numbers of false negatives and/or false positives: boars falsely being associated with/without boar taint. Additionally, these methods often are not yet able to analyse the samples at the speed required by a commercial slaughter line and are often costly. Sensory methods Sensory methods use the human nose to assess the smell of a boar. Pieces of fat or meat of each boar are heated. The released vapours are smelled by trained assessors to assess the odour of the boar. If an assessor perceives an odour to be boar taint, the boar has boar taint. Several heating methods have been developed, for example heating fat or meat in a micro wave, with a soldering iron, and using a heated metal plate. This method works at commercial slaughter line speeds and has been implemented in several slaughter companies across Europe. The method relies on the training of assessors, on the consistency of an assessor over time and on consistency between assessors. Current research aims to improve such characteristics. Preventing boar taint To prevent boar taint, young male pigs in the majority of the EU countries are surgically castrated (with and without anaesthetics). No androstenone and less skatole are formed in castrated pigs. There are many ways to prevent or help to prevent boar taint, such as Castration without anaesthetic: In order to prevent boar taint, young male pigs in the majority of EU countries are surgically castrated. This affects some hundred million animals annually. Castration under anaesthetic: Castration causes demonstrably less pain and stress if an anaesthetic is used. Slaughtering young: in countries such as Great Britain and Ireland, male pigs are not castrated; they are slaughtered at a lower weight (up to a slaughter weight of 85 kg). Breeding: The level of androstenone and skatole has been found to be inheritable. This means that they can be bred for. ‘Genomic selection’ also offers that prospect, all the more so because a great deal is already known about the genome of the pig. Immuno neutralization: There is a vaccine in existence that (indirectly) strongly inhibits testicle growth and thus the production of androstenone. This method has long been used in Australia, for example, and has proved to be reliable. Management measures: A generous water supply, good hygiene and adjusted feed can contribute to a lower level of skatole. Sexing of semen: It is theoretically possible to select only female semen before fertilization. Research experiences do not lead one to suppose that such a method will be feasible for pigs in the short term. Detection on the slaughter line: Boar taint in the (heated) consumer product can also be avoided by detecting all the boars with boar taint in the slaughterhouse, and only using products from these boars for processed meat that is not to be heated. This would enable a ‘boar taint-free’ guarantee to be given for the remaining meat products. There are widely different views within European countries on alternatives for the castration of male pigs. Challenges Challenges to developing a market-based solution for producing and marketing entire male pigs are manifold. 1. Boar taint is literally a question of taste. The boar taint issue is thus primarily related to market acceptance. In order to avoid any negative consumer response, international market parties do not accept boar tainted meat products. 2. Preventive measures can reduce the prevalence of boar tainted meat. These are genetics, feed composition, mixing of animals and hygienic measures. Breeding for particular characteristics traditionally takes several years. Other preventive measures can be in effect almost immediately. 3. A safety net in the slaughter line is the necessary final check. Boar taint in the (heated) consumer product can be avoided by removing all the boars with boar taint in the abattoir (detection). A commonly accepted reference method in Europe is needed, as well as a harmonized protocol for the current human nose detection method. Moreover there is an urgent need for the development of novel on line methods. 4. Castrated male pigs are less active than boars. For the pig farmer and the welfare of animals housed in groups, that is an advantage. Farmers have to learn to identify and apply the do’s and don’ts of raising boars in order to prevent excessive aggressive behaviour. 5. Specific markets, like free range production or quality oriented production (Parma ham, organic meat, traditional high quality products, in Mediterranean countries) are a special issue. There is an urgent need to solve the problems of extensive free range product marketing of entire males. Speakers Mrs Annechien ten Have-Mellema Annechien ten Have-Mellema was chairman of the pig farming sector at LTO (Dutch farmers union) until 2013. LTO represents the interests of Dutch farmers and especially the interests of pig farmers in the Netherlands. She reviewed subjects such as animal health, animal wellbeing and the welfare of farmers. Mrs Mellema is also the Vice-Chairman of the Product Boards for Livestock, Meat and Eggs. These marketing boards are a platform for employees and employers in the Dutch cattle, meat and egg industry. Dr.ir Gé Backus Gé Backus is the director of Connecting Agri & Food. His expertise is in supply chain management and animal production and marketing systems. He has more than 30 years’ experience in sustainable animal production and marketing systems. Gé Backus has presented and/or conducted research in 23 countries. He has been project leader of a research project to identify and evaluate the perspectives of increasing supply and demand of healthy, environmentally friendly and fair trade food products in the Netherlands. This project was financed by the Dutch Ministry of Economic Affairs, Agriculture and Innovation. He is the programme leader of a five-year Dutch research project developing a solution for producing and marketing entire male pig meat acceptable to the international market. .His core competence is stakeholder management and managing multi-disciplinary projects. He was a partner in the PIGCAS project for DG SANCO (carried out in 2009). Ir. C.M.C. (Carola) van der Peet-Schwering Carola van der Peet-Schwering is a senior researcher in pig nutrition at Livestock Research at Wageningen University and Research Centre. The subject of het PhD in 2004 was “Long-term performance and behavior of sows fed high levels of non-starch polysaccharides”. Projects: - Boars: how to reduce sexual and aggressive behaviours in boars, how to feed boars, how to reduce boar taint; - Performance of growing and finishing pigs: optimizing technical and economic performance of growing and finishing pigs by feed composition, feeding system and quality of the weaned piglet; - Reducing the number of weaned piglets with clinical signs of Streptococcus suis by feeding and management; - Gilt rearing: how to raise gilts, so that they can maintain themselves in group housing during gestation. dr. C.P.A. (Coen) van Wagenberg Coen van Wagenberg is senior researcher food quality in supply chains. He studied operations research and has a PhD in food safety economics with a focus on incentives to control food safety. He specialises in quantitative research on cost-effective control of food quality and food safety aspects throughout food supply chains, especially pig and poultry chains. Since 2009 he is leader of the project "detection and consumer" of the Dutch program Stopping with castration. He is also involved in the DG Sanco project BoarCheck about boar taint detection systems in the EU. Companies that will be visited Zichtstalhoeve Polsdonk Polsdonken 1, NL – 5688 LE Oirschot Zichtstalhoeve Polsdonk is a pig farm run and owned by Mieke and Pieter Vlemminx, two ambitious entrepreneurs. Pieter Vlemminx took over the business from his parents. Their farm has a special pig house that is open to the public every day where people can come in freely and for free to see how a modern pig farm works. The pig house that is open to the public is completely isolated from the production farm. The pig farm has some 2,000 fatteners and 320 sows. Vlemminx has also been farming boars for the last two years. The Vlemminxes combine their pig farm with a B&B. Albert Heijn (AH) - Facts & Figures A leading, over a hundred year’s old (1887), Dutch supermarket chain. Part of Ahold holding. Number of shops: Number of employees: 850 (of which 227 in franchise) 110.000 (end 2012) In total 6 national and 4 regional distribution centers throughout The Netherlands, plus online /home deliveries/pickups in 3 cities. Various shop sizes and concepts. According to GFK research 85,6% of Dutch households visited a Albert Heijn store. Market share in the Netherlands of 33,7% (2012) Focus on sustainability. First retail chain offering meat out animal welfare productions chains. Since 2012 various concepts (1, 2 and 3 stars of Dierenbescherming (Dutch Society for the Prevention of Cruelty to Animals)) VION Food Group VION Food Group is a global food company and is active in the fields of high quality foodstuffs and ingredients for people and animals. VION Food Group is one of the larger food companies in the Netherlands and is represented all over the world. VION Food Group consists of VION Food and VION Ingredients. The inter-relationship between these two core activities results in knowledge building and knowledge sharing, and makes VION a valuable and distinctive partner. The Food and Ingredients activities provide added value throughout the chain. This is both in the interests of VION's customers and suppliers, and a response to consumer needs and requirements. VION Helmond VION Food Group has had a slaughter and processing facility with a surface area of some 14,000 m2 and 275 employees in Helmond, the Netherlands, since 1988. About 30,000 pigs are processed here every week (some 650 per hour). The company produces 530,000 kilos of products, such as meat, bones, fat, etc., every day. Production hours are from 6 am to 4.30 pm (in one shift). VION Helmond produces raw materials for bacon-producing companies, hams for the European market and parts for the British retail market. View of sustainability/animal welfare VION makes an active contribution to improving the level of animal welfare in the chains in which VION is active. This is expressed in such matters as giving attention to the quality and duration of the transport of animals, and animals being handled respectfully and professionally at the operational sites. VION attaches great value to good cooperation with the primary sector and this sector's licence to operate and development. VION has been working closely with livestock farmers, the meat processing industry, retail, food service and community organisations for years to ensure that animal wellbeing remains high on the agenda. The position of the primary sector A sustainable meat chain starts with a sustainable perspective for the suppliers in the primary sector. Factors such as economics, environment, and social acceptance of stock farming are crucial. Sustainable raw materials Efforts to improve the level of sustainability of the raw materials in the chains are still primarily focused on soy. Soy is an important ingredient for animal feed. VION has been represented for a number of years on some of the consultation bodies that work on more sustainable soy production. Public health As part of its quality systems, VION continuously assures the safety and quality of its products. Programmes permanently monitor all animal production flows in the home markets. Beter Leven quality mark Good Farming Star is the most recent pig farming concept of VION Food in the Netherlands. This form of pork production complies with the 1-star Beter Leven (Better Life) quality mark of the Dutch Society for Prevention of Cruelty to Animals. Good Farming Star enables market demand and developments in society to form the basis for the further development of the concept that focuses on animal welfare. Some 160 pig farmers participate in Good Farming Star. It is a concrete answer to society's demand for responsible and sustainable pork. One star under the Beter Leven quality mark Every pig is given more space than in traditional pig farming: 1 m2 instead of 0.8 m2. This gives the animals more room to display their natural behaviour than when the areas where they can lie down, eat and defecate are separated. The pigs are given toys. Pigs are intelligent animals and the toys they are given comply with three of five welfare needs that pigs have: they must stimulate the pigs to root around and bite in them, and they must be edible, degradable and something new. The piglets are not castrated. Two stars under the Beter Leven quality mark: free range Female pigs (sows) are allowed to go outside all year long, so that they can display their natural behaviours like rooting around and bathing in the mud. The fatteners are kept on straw in large groups, and have a covered outside pasture. Their tails are not docked nor are their teeth cut. The pigs are given straw and toys. Pigs are intelligent animals and the toys they are given comply with three of five welfare needs that pigs have: they must stimulate the pigs to root around and bite in them, and they must be edible, degradable and something new. The male piglets are not castrated. Three stars under the Beter Leven quality mark: organic Pigs are given twice as much room as pigs in the bio-industry. The sows have the possibility to go out into the field. The pigs are kept on straw in groups, and have a partly covered outside pasture of 1 m 2 per animal. Their tails are not docked. Research On the subject of castration of boars and boar taint, information can be found in the reports of various studies and published articles on the website www.boars2018.com. Studies of the human nose These reports involve some 1.3 million human nose scores (HNS) on the slaughter lines from October 2010 to December 2012. Furthermore, some 7,000 chemical sensory evaluations were performed as part of this project in recent years. News On the website www.boars2018.com we frequently publish news, blogs and articles on subjects related to ending the castration of male piglets in Europe. Every month we publish a newsletter. Facts and figures There are 11,027 million piglets and fatteners in the Netherlands. The number of non-castrated pigs is 2.8 million. Contact Postal Address Dutch Steering Group Stopping Castration P/a Product Board for livestock and meat Co-ordinator Market, Mr. B.van Dam P.O. Box 460 NL – 2700 AL Zoetermeer The Netherlands Email: info@boars2018.com By telephone Fenny Straat +31(0) 30 6932684 +31(0) 6 53304068