Industry: Part I

advertisement

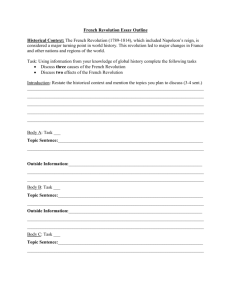

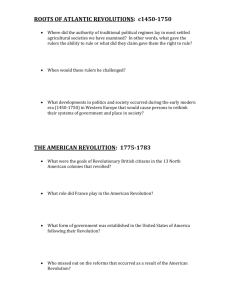

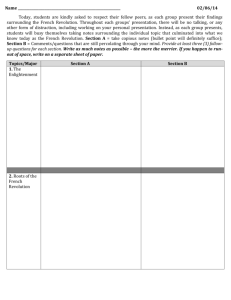

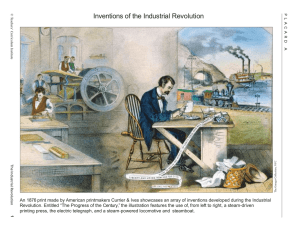

Industry: Part I APHG Copeland Key Question: Where did the Industrial Revolution begin, and How did it Diffuse? Industrial Revolution: a series of inventions that brought new uses to known energy sources, new machines to improve efficiencies and enable other new inventions. eg. steam engine iron smelting water pump Beginning of Industrial Revolution • When and where did the industrial revolution begin? – In Great Britain in the mid to late 1700s • Why Great Britain? – – – – Flow of capital Second agricultural revolution Mercantilism and cottage industries Resources: coal, iron ore, and water power (lumber supply limited due to use in urban settings) The Industrial Revolution • European domestic markets were growing, and a labor force was lacking in England • The steam-driven engine made up for the lack of available labor Flow of Capital into Europe, 1775 Needed flow of capital in order to fuel the industrial revolution. The Industrial Revolution • Freed from charcoal use, iron smelters could be concentrated near British coal fields • Transportation and communications were affected Textiles Production: Liverpool and Manchester Iron Production: Birmingham Coal Mining: Newcastle The Industrial Revolution • The first steam-powered ocean-going vessel emerged • England held a monopoly over products in world demand and the skills to make machines to manufacture them Ironbridge, England World’s first bridge made entirely of cast iron, constructed in late 1700s. Iron Ore to Steel Diffusion to Mainland Europe In early 1800s, innovations diffused into mainland Europe. Location criteria: proximity to coal fields connection via water to a port flow of capital Later Diffusion In late 1800s, innovations diffused to some regions without coal. Location criteria: access to railroad flow of capital Diffusion of Industrial Revolution Examine the map of diffusion of the Industrial Revolution into Europe and determine what other characteristics (aside from presence of coal) were necessary for industrialization to take hold in these regions. Key Question: How do Location Theories explain Industrial Location? The Paris Basin is the Industrial base of France. Rouen (pictured here) is at the head of navigation point on the Seine River. Location Theory • Location Theory – predicting where business will or should be located. Considers: - Variable costs vs. Fixed costs (List) - Profit maximization (Revenue>Costs) - Friction of distance (time & cost increase due to increasing distance) - Transportation Factors of Industrial Location Raw Materials • Very few industries use raw materials • Most manufacturing is based on the further processing and shaping of materials already treated in some fashion • Transportation costs affect industry location Power Supply (Energy) • Power supplies that are immobile or of low transferability may attract activities dependent on them • Current technology made less important • Industries requiring large amounts of energy still situated near the power source Labor • Spatial variable affecting location decisions and industrial development • 3 major traditional considerations – price, skill, and amount • Labor Flexibility: highly educated workers able to apply themselves to a wide variety of tasks and functions Market • Goods are produced to supply a market demand • Size, nature, and distribution or markets is important in industrial location decisions • Ubiquitous industries (necessities) Transportation • Unifying thread of all factors of industrial location • Modern industry is immediately tied to transportation • Use many different forms of transportation modes locate at break-of-bulk points (seaports, airports). If a manufacturer uses multiple b-o-b points, what does this do to the price of the product for the consumer? Alfred Weber • Created the classical model of industrial location theory in 1909 (Industrial Triangle) Least-Cost Theory • Explains the optimum location of a manufacturing establishment in terms of minimizing three basic expenses – Transportation cost, labor, agglomeration Least Cost Theory 1) Transportation: the site chosen must entail the lowest possible cost of A) moving raw materials to the factory B) finished products to the market. This, according to Weber, is the most important. C) Is the item bulk-gaining or bulk-reducing? Least Cost Theory 2) Labor: higher labor costs reduce profits, so a factory might do better farther from raw materials and markets if cheap labor is available -ex: China – today Least Cost Theory 3) Agglomeration: when a large number of enterprises cluster in the same area, they can provide assistance to each other through shared talents, services, and facilities Ex. manufacturing plants need office furniture, strip malls, light industrial parks (consumer goods), heavy industrial parks (capital goods) 5 Controlling Assumptions 1. Area is uniform physically, culturally, and technologically (isotropic, plain) 2. Manufacturing involves a single product to be shipped to a single market whose location is known 3. Inputs involve raw materials from more than one known source location 5 Controlling Assumptions 4. Labor is infinitely available but immobile in location 5. Transportation routes connect origin and destination by the shortest path and directly reflect the weight of the items shipped and distance moved Other Location Models Hotelling’s Model Location of an industry cannot be understood without reference to other industries of the same kind. Theory: Locational interdependence: indicates that locational decisions are not made independently but are influenced by the actions of others. Other Location Models Losch’s Model Manufacturing plants choose locations where they can maximize profit. Theory: Zone of Profitability