Feedback Control Rou..

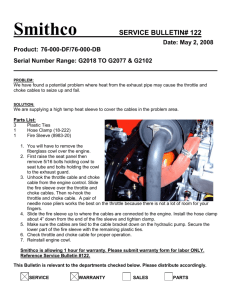

advertisement

Feedback Control Roundup • • • • Where is this class going? Why control? What is feedback? What are those block diagrams, and how do they relate to the equations? • How does PID work? • How do controllers go out of tune, how can I recognize them, and what do I do? Where is this class going? • Things I want you to learn – “Assume steady state” does not work in real life. – Engineering is a synthesis of what you have learned, not a collection of separate topics – How to analyze and describe a dynamic system – How to understand control systems: • Anything called a “regulator” – Trade-offs in control design – How to save the day when the irresponsible control engineer goes on vacation Where is this class going? • Content remaining – Control applications: feedforward, cascade, decoupling – Ways to analyze the effect of control on closed loop stability – Frequency domain analysis of dynamic systems – State space (very good for mechanical systems) Why control? • We use control to: – Keep a value close to its desired value: • • • • Room temperature, thermostat Car speed, cruise control Boiler drum level Boiler fire-side pressure – Trade off variation between controlled and manipulated variables • Torque and position or speed • Flow and level in a surge tank • Temperature and heat stresses induced by heat Where are we, as mechanical engineers, going to encounter control? • Any time something moves, that motion must be regulated. – Equipment: motors and guides – Fluids: flow rate, pressure and temperature • Control is implemented through mechanical equipment – Motors, valves, dampers – Limitations or faults in this equipment will affect control (and thus system) performance. What is Feedback? 1. 2. 3. 4. 5. 6. 7. The controlled variable is measured. It is then compared to a desired value, or setpoint. The difference between setpoint and measurement is called the error. The controller calculates a control output depending on the error. The control output is sent to some physical equipment, a valve or similar, to affect the process. This physical equipment is called the Final Control Element. The process responds to the change made by the final control element. or 1. The process response is measured Speed Error in km/h Desired speed in km/h + Cruise Control Desired Throttle Position Throttle Actuator Speed in km/h Speed Sensor Actual Throttle Position Engine, Transmission, Wheels Disturbances wind, slope, bad fuel Speed What are those block diagrams? • Block diagrams are a visual representation of the actual dynamic system and its governing equations. • Each line is a signal - something that varies over time, and can be measured or calculated. • Each block is a “functional element” - something that does something, and is governed by differential, integral or algebraic equations, and describable as a transfer function. Block Diagram Disturbances wind, slope, bad fuel Speed Error in km/h Desired speed in km/h + Cruise Control Desired Throttle Position Throttle Actuator Speed Sensor Speed in km/h Actual Throttle Position Engine, Transmission, Wheels Speed Standard Nomenclature • • • • • • • PV, or y : controlled variable SP or ysp : setpoint, desired value OP or u (text uses p): controller output e : error, ysp - y d or l : disturbance or load (wild) variable ym : measured value of y G : a transfer function – – – – – – • • • • Gp : process transfer function Gc : controller transfer function Gv : final control element (valve) transfer function Gm : measurement element transfer function Gd or GL : Disturbance (Load) transfer function Gcl : closed loop transfer function K : transfer function gain : time constant : time delay (dead time) : damping ratio (also called damping factor) Block Diagram Disturbances wind, slope, bad fuel d The purpose of the C.L.T.F. is to describe the entire system with a single transfer function that can be analyzed. Desired speed in km/h + ysp Speed Error in km/h - e Cruise Gc Control Desired Throttle Position u Throttle Gv Actuator ym Speed Gm Sensor Speed in km/h Actual Throttle Position Disturbance Gd or GL Process Engine, Transmission, Gp Wheels Speed y Block Diagram Disturbances wind, slope, bad fuel d Disturbance or GL ClosedGd Loop Process Desired speed in km/h + ysp Speed Error in km/h - e Disturbance Transfer Function Actual Desired Throttle Throttle Engine, Position Closed Loop Position Cruise Throttle Transmission, Gp Gc Setpoint Gv Control Actuator Wheels u Transfer Function ym Speed Gm Sensor Speed in km/h Closed Loop System Speed y Block Diagram y = Gd * d + Gp * Gv * u rules are applied around the block = •These Gd *block d +transfer Gp * Gv *function Gc *is e used •The •Each •Summers diagram (circle with is x inside) multiplied to figure add out byinputs, its theinput or, to if diagram: = get Gd *its dinput +output: Gpequations *isGv * Gc * directly. (ysp - ym) governing the marked with a - sign, that input is yd =+ Gd * Gv d +* Gp * (ysp Gv *- uGm * y) = Gd * Gp * Gc * subtracted u = Gc * e e * Gc * ysp - Gp * Gv * Gc * Gm * y = Gd * ud = + Gc Gp ** Gv e = ysp ym *=Gc Gm -* ym y y + Gp * eGv = ysp -* Gm ym * y = Gd * d + Gp * Gv * Gc * ysp y ( 1 + Gp * Gc* *yGm) = Gd * d + Gp * Gv * Gc * ysp ym* Gv = Gm y = (Gd/(1 + Gp Gv Gc Gm)) * d + ( Gp Gv Gv/(1 + Gp Gv Gc Gm)) * ysp Desired speed in km/h + ysp Speed Error in km/h - e Cruise Gc Control Desired Throttle Position u Throttle Gv Actuator ym Gm Speed in km/h Actual Throttle Position Disturbances wind, slope, bad fuel Engine, Transmission, Gp Wheels d Gd or GL Speed y Block Diagram Disturbances wind, slope, bad fuel d Desired speed in km/h + ysp Speed Error in km/h - e ClosedGd Loop Gd or GL Disturbance 1 + Gp Gv Gc Gm Transfer Function Actual Desired Throttle Throttle Engine, Position Closed Loop Position CruiseGp Gv Gc Throttle Transmission, Gp Gc Setpoint Gv Control Actuator Wheels 1 + Gp Gv u Gc Gm Transfer Function ym Gm Speed in km/h Closed Loop System Speed y How does PID work? • PID control acts on the error. • The control action is the sum of three terms: – Proportional: Kc * the error now – Integral: Kc/TauI * the integral of error since the controller was turned on – Derivative: Kc*TauD * the rate of change of the error now P animation QuickTime™ and a MPEG-4 Video decompressor are needed to see this picture. PI animation QuickTime™ and a MPEG-4 Video decompressor are needed to see this picture. Animation QuickTime™ and a MPEG-4 Video decompressor are needed to see this picture. Comparison Comments • P never reaches setpoint. • PID responds before PI does because of the Derivative term.