Boeing Corporate PPT Template

advertisement

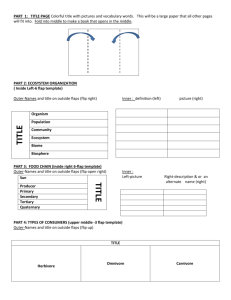

Project Management Techniques Steve Snelling 747 Industrial Engineering Boeing Commercial Airplanes stephen.r.snelling@boeing.com My Background • B.S. Industrial Engineering degree from Virginia Tech Co-Op student (7 work quarters) & (Reynolds Aluminum Co. – Richmond, Virginia) • Worked 5 years as an Area Industrial Engineer (Reynolds Aluminum Co. – Listerhill, Alabama) • Worked 10 years as a Management Consultant (A.T. Kearney Inc. & Arthur Young Intl. – Chicago, San Francisco & Vancouver - worked in 22 states & Canada) • Worked last 21 years as an IE - Process Improvement Engineer (Boeing - Everett site: 747, 767, 777, & 787 airplanes – currently on 747-8 program, some projects coaching & mentoring) • Volunteer activities with IIE (nationally & locally) & PSEC (Puget Sound Engineering Council) 2 Presentation Outline • Pictures of Boeing products & 747 Freighter Assembly • Types & Structure of IE Projects • Five Project Stages • Some Project Dangers • Project Management Tips • An Example Project • Q&A 3 Commercial Airplanes 4 Military 5 Space 6 Commercial Airplanes - Military Aircraft & Missiles - Space & Communications - Air Traffic Management - Boeing Capital Corporation - Shared Services Group - Phantom Works 7 747 Final Assembly at Everett, Washington 8 747 Freighter 9 747 Freighter 10 Industries of IE Projects • • • • • • • • • • • Aluminum & Steel Materials Testing Ceramics Electronics Assembly Aerospace & Airplanes Plastics & forming Shipbuilding Entertainment Military Construction Applied Research • • • • • • • • • • Forestry & Logging Mining Healthcare Banking State & Federal Government Transportation Oil & Gas Utilities Insurance Consulting 11 Types of IE Projects Process improvement Problem resolution Elimination of rework Cost analysis Facility layout Equipment justification Stand alone benchmarking Systems integration 12 Project Management Industrial Engineering Functional Work Areas Production Control Factory Operations Quality - Project Planning - Project Scheduling - Projects Coaching - Risk Assessment Material - Product Mix Analysis - Forecasting - Production Scheduling - Lean Manufacturing - Systems Integration - Chronic Rework - Supplier Quality Product Engineering Costing Facilities - Supplier On-Site Visits - Supply Chain Management - Parts Storage & Movement - Layout Design - Process Flow Analysis - Integrated Product Teams - Product Development - Product Costing - Comparison of Alternatives - Cost & Savings Estimating Training Safety Tooling Transportation - Safety Investigations - Ergonomic Evaluations - Machine Capacity - Tool Usage - Tool Certifications - Logistics Planning - Material Handling - Alternative Methods - Training Presentations - Course Scheduling 13 Logical Progression of a Project Objectives Initial Findings Areas of Detail Cost Analysis of Alternatives Recommendations Summary Report & Presentation Implementation Plan 14 1 Start-up Activities Five Project Stages 2 Process Documentation & Measurement 3 Develop & Evaluate Solutions 4 Conclusions & Recommendations 5 Implementation Follow-up 15 3/16/2016 1 Start-up Activities Five Project Stages Project Profile & Schedule, Feasibility Examination 2 Process Documentation & Measurement Historical Data, Observations, Flow Diagrams, Cause/Effect, Benchmarking 3 Develop & Evaluate Solutions Legend: Outputs from each stage Preliminary Solutions, Evaluation of Findings 4 Conclusions & Recommendations 5 Implementation Final Presentation New Plan Follow-up 16 3/16/2016 Five Project Stages 1. Project Start-up Activities – – – – – Project is authorized and assigned Initial meetings with the project’s customer Project Team is formed Initial understanding about project A feasibility study may be required before proceeding too far – Project Profile is prepared & reviewed with the project’s customer – Project Schedule is prepared & reviewed with the project’s customer 17 Five Project Stages (continued) 2. Process Documentation & Measurement – Process flow charts are prepared, if applicable – Historical data is obtained & analyzed – New data is obtained & analyzed (e.g. Time Studies, direct observations) – Direct observations of current conditions – Digital pictures of current conditions – Interviewing for Information – Cause and effect diagrams, etc. – Possible Benchmarking tours 18 Five Project Stages (continued) 3. Develop & Evaluate Solutions – Solutions are listed and organized – Additional benchmarking, if needed – Simulations (mathematical or using simulation software) are performed, if applicable – Evaluation criteria are determined and utilized – All viable solutions are evaluated 19 Five Project Stages (continued) 4. Prepare Conclusions & Recommendations – Conclusions are documented and investigated – Final recommendations are documented – Final presentations are prepared, reviewed & given 20 Five Project Stages (continued) 5. Implementation & Follow-up – Implementation items are planned and assisted – Follow-up is done as necessary – A large scale implementation may become a new project 21 Some Project Dangers Vague commitment from customer Poor project description Undefined or unclear objective Unrealistic scope Unrealistic deliverables Poorly defined tasks Too tight a schedule Multiple customers not in agreement No safety margin for late tasks Key team members not available 22 Some Project Dangers (continued) Poor communication with customer Poor data storage & sharing of files Late outside data sources Sub standard quality of data being used Bad team dynamics Non action-oriented report (or final presentation) Overlap with other project teams Legal issues 23 Project Management Tips Project Profile & Scope • Develop a good Project Profile with a descriptive objective • Develop a realistic project Scope (the project’s “boundaries”) • Develop a logical Statement of Work / Schedule • Limit the simultaneous work you show in your project Schedule, if a small Team • Show the entire project in the Project Schedule to complete all Deliverables • Continually compare new action items against the original Scope & Deliverables • Keep track of the Estimated Completion Date (ECD) - adjust to complete on time, if possible 24 Project Profile Project Profile Project #: PE- 0410 Assignment Title: Customers: Analyst: Steve Snelling 747 T.O.C./Critical Chain Pilot Area Final Assembly General Supervisor A/C Bay Supervisor Date Assigned: 4/1/2004 ECD: 12/10/2004 Description: To determine if a pilot area for T.O.C. (Critical Chain) is viable for an area in FBJ systems. Then set up and run the pilot area for several airplanes. Scope: FBJ Air Conditioning Installation area (~110 jobs). Expected Benefits: Determine potential savings by using alternate scheduling methods. Determine if feasible. If there are measurable savings by this approach. Statement of Work: Develop a project plan and schedule Learn from F-22 usage and 777 S&I pilot area Define the true Critical Chain (note: differs from the Critical Path, and also more detailed than current P-nets), including revised job times and buffers Investigate software options Get IE Resource Commitment Prepare report on turning on the pilot Decide to go or no-go Start up the pilot area Deliverables: Detailed precedence networks Calculated (or estimated Project Buffer and Feeder Buffers) A detailed Critical Chain network that represents the entire pilot area (all skills) Sample management reports & tracking charts A recommendation to proceed or not to proceed with turning on the pilot A recommendation after running the pilot, to expand or not to expand it to other systems areas in Final Assembly Schedule: 25 (see attached MS Project schedule) 3/16/2016 Project Management Tips Project Schedule • I suggest taking an outline approach to building your project Schedule • Most big & complex projects can be broken down into phases or smaller projects • Make the project Schedule only as detailed and complex as the project requires • The Schedule needs to be a useful and dynamic tool, and not a static one-time-use document • Any Scheduling software cannot take the place of logical steps and good task time estimates 26 Project Schedule 27 3/16/2016 Project Management Tips (continued) Project Phases • Consider breaking larger projects into several phases • Work on project phases sequentially as smaller projects, if enough resources are available • Break out portions of the project, if necessary, due to delays in the project customer’s decision making • Implementation and significant follow-up activity is commonly viewed as a separate phase of the project 28 Project Management Tips (continued) Getting Help • Look for ways of partnering with other individuals or groups on projects • At Boeing, MR&D (now M&PT) has a variety of experts on call & may be able to purchase some inexpensive items for testing • Also at Boeing, other groups of “Subject Experts” bring additional needed expertise – (e.g. Tool Engineering, Quality Engineering, Design Engineering, etc.) • Most IE projects are collaborative – How well you coordinate with other groups is critical to a project’s success 29 Project Management Tips (continued) Project Communication • Use a variety of medium to communicate with your Team – (meetings, e-mail, digital pictures, file servers, white board discussions, Web Ex, etc.) • Ask for reviews during the project – Don’t wait for everyone to chase you down to find out how it is going • Regularly communicate with your project’s customer – The more frequent - the less “forced” the final presentation will seem • A positive & team-focused “Attitude” is critical to today’s project communications – A “bad attitude” is rarely tolerated for long 30 Project Management Tips (continued) Data Analysis & Measurement • Understand what data is needed, then develop your collection plan – (both historical & new data) • Use data to verify and help investigate findings • Utilize good statistical analysis skills, and check all calculations • Link data to actual observations, when possible • Set up lab tests and mathematical models • Constantly do “reality checks” with your subject experts 31 Project Management Tips (continued) Benchmarking • Benchmarking is mainly on-site tours of other similar facilities for best practice comparisons • Do the main benchmarking only after you fully understand your current process – If done too early, you are not ready – If done too late, the benchmarking can’t properly influence the solution development • Utilize “white board” discussions (that are later typed up) to reach consensus with your Team • Try to include your project’s customer on some of the benchmarking tours 32 Project Management Tips (continued) Solutions & Evaluations • Write down alternative solutions throughout the project – Plan to research and investigate them • Be creative and comprehensive when developing initial solutions ideas • Develop an evaluation approach – (The criteria you want to use to determine which solutions are best) • Rank the most likely solutions – (The ranking may be based on cost, schedule, or risk factors) • Bring the project’s customer in on the selection process and to offer real applications information – (A “reality check”) 33 Project Management Tips (continued) Cost & Savings Estimates • Cost & Savings estimates are built up from a good detailed outline • Get a good Unit Cost estimate for anything very expensive or with a large number of occurrences (biggest impact items) • Get the owning organizations to confirm your Costs & Savings estimates • List one-time Costs & Savings separately from recurring Costs & Savings 34 Cost & Savings Estimates Initial Costs Initial Savings Recurring Costs Recurring Savings 35 Project Management Tips (continued) Conclusions & Recommendations • Research & investigate the most likely conclusions with the entire Team • Review the possible conclusions ongoing with your project’s customer • Take the best of the ideas and form a logical recommendation • Assess the Recommendations by cost & risk when presented • Time phase the recommendations, if needed 36 Project Management Tips (continued) Presentations & Reports • Review all final presentations (and final reports) prior to being given to the project’s customer • Make sure all files (hard copies & electronic) are organized and stored properly at the conclusion of the assignment • Make sure Implementation Plans are well organized and doable (Implementation may take much longer then the Analysis) 37 Some Summary Comments Recognize when to use Project Management techniques on your IE assignments Form a good Team, with the needed Subject Experts Develop a good Plan, then work your Plan to a successful conclusion, with your Team Utilize good daily management and time management techniques Monitor progress (overall & to the assigned tasks) and make adjustments as required Keep your customer informed throughout the project Learn from your own project management experiences (both the good and the bad) 38 A Sample Project Flap Damage Reduction 39 Flap Damage Reduction • The 747 Trailing Edge Inboard and Outboard Flaps were consistently being damaged (dents, scratches, punctures, etc.) • This caused major disruption to the shop & increased cost to the company • IE used a project approach to analyze the entire flap build-up & installation sequence • Developed improvement options working with the crew and tested & implemented them 40 3/16/2016 Four Square Chart (Flap Damage Reduction) Pictures Goals - Reduce the amount of defects and damage related to Flaps - Minimize disruption to the shop and to the supplier - Improve customer satisfaction Problem The 747 Trailing Edge Inboard and Outboard Flaps were consistently being damaged, causing major disruption to the shop floor and our suppliers, while increasing cost to the company. Schedule Measure July Define June Improve January Analyze November Control February Implementation April Project Profile (Flap Damage project) 42 Project Schedule (Flap Damage project) 43 Process Flow Chart (Flap Damage project) FLAPS ARRIVE IN TRUCKS. FLAPS ARE TAKEN OUT OF TRUCKS. Inboards THEY ARE VERIFIED FOR DAMAGE AND THE RAIL SHIPMENT PACKING SLIP IS FILLED. Outboards THEY ARE DRAGGED OUT AND STAGED AT 40-55 YARD. YELLOW TAG IS PLACED (WAITING FOR QA). QA VERIFIES THE FLAP AND PLACE TAG FOR READY TO MOVE. FLAPS ARE TRANSPORTED TO FLAP BUILD UP. FINISH 44 Pareto Chart [Control Surface] Pareto Chart of TYPE OF DEFECT 70 Count 50 80 40 60 30 40 20 20 10 0 TYPE OF DEFECT Count Percent Cum % Percent 100 60 nt ch e at D r Sc t ks in a ar P lM o To ip er ge l ate ge ge h h u u u C o tp Ot Ga Go u /G t N n n e De ok Br 37 9 5 3 2 2 1 1 1 3 57.8 14.1 7.8 4.7 3.1 3.1 1.6 1.6 1.6 4.7 57.8 71.9 79.7 84.4 87.5 90.6 92.2 93.8 95.3 100.0 • 72% of defects are due to dents and scratches (2 of 10 defect categories, 20%) 0 45 Defect Locator (‘Measles’) Chart [Control Surface] 2 DENTS INBD AFT DENT AND GAUGE WS 807 PAINT DENT WS 469.82 WS 500 SCRATCH AND DENT 10" 10" 6" 4'-9" 5 9" 6 1'-9" 2 6" 1'-3" 1'-8" 3 8" 1 7 4 WBL 128.4575 WBL 445 WBL 140 OUTBD FORE DENT AND CRACKED WBL 822 WS 834.5 5" 3'-4" 2 DENTS 26 2" CHIPPED WS 1196 25 25 WBL 583 WBL 515 46 Cause & Effect Diagram (Flap Damage project) 47 5-Whys Analysis Problem 1 Why 2 Why 3 Why 4 Why Schedule incorrect IE error PRE not installed in time Tired and lack of focus 5 Why 6 Why (Flap Damage project) 7 Why Flap damage disruption Working too fast, busy schedule, overtime -Ineffective use of PREs Not enough resources Mechanic forgot New mechanics Awareness Ineffective use of PRE PRE doesn’t cover where the damage is ocurring Three main causes: Small PRE Insufficient work instructions PRE not installed correctly Mechanic error Lack of experience PRE does not work Cannot withstand surface loads PRE material not adequate -Dropping tools and screws IP not clear Lack of training Aft/Mid Inboard Flap Damage near SOB Wrong screws Pushing screws from inside the A/P Mechanic error Dropping tools & screws Joins Process No space to put the tools Very small platform Lack of good access to the area -Walking on flaps Kitting process? (different screws’ sizes mixed) Screws’ difference very small for mechanics to distinguished Can’t have a bigger platform because interfere with flaps Joins & flaps overlap for 1 day Scheduling Lack of training Joins jobs behind schedule New mechanics Using different platform Landing gears installed (day 5) Joins jobs behind schedule Can’t use tiger lift Flaps are in the middle Joins & flaps overlap for 1 day Seal jobs & CIC Scheduling Awareness Walking on the flaps SOB Panel Scheduling Deep Root Causes: -Schedule overlap of jobs -PRE doesn’t cover proper areas -Side of Body Panel PRE is insufficient 48 48 Description of Solutions & Impacts to Process Solutions 1. New Hinged PRE Impacts to Process PRE will cover entire flap and is robust enough to prevent heavy damage. It is lightweight, durable, easy to install, and will stay on flap through build sequence. 2. Laser Measurement Device Device will enable Functional Test to take measurements without walking on flaps 3. Carriage Panel Screw Relocation Supplier to relocate placement of screws on flap carriage panels to areas with less risk to process Turn Buckle PRE Improve process and protect area on flap that is volatile and susceptible to damage through use of PRE 4. Awareness Presentation To be presented to shop crews to point out the fragile nature of the flaps, the costs to the company due to damage, the amount of disruption it causes, and best practices if working near the area. 6. Wing Boots and Containment Trays Reinstate and make available for use. Put processes in place to make items easy to obtain, apparent, and mandatory. Boots provide clean surfaces. Trays used to place tools in one area and not laying around on flap. 7. Caution Notes on IPs 5. Place important notes on relevant IPs that warn mechanics 49 about fragility of flaps and to use PREs 1. New Hinged PRE • Will replace the current acrylic PRE (PRotective Equipment) which is small (doesn’t cover entire flap), has a slick surface, and is removed when inconvenient or during flap tests. • The New Hinged PRE will be made of a new material, covers all three flap sections, and hinges at each section so that it will not have to be removed during flap test. • PRE is robust enough to prevent heavy damage. It is lightweight, durable, easy to install, and will stay on flap through build sequence. 50 2. Laser Measurement Device • Concept is for the mechanic to use any such laser instrument to measure the gaps on the flaps without walking on the flaps themselves. • Exact device specifications still in work. • Use of scissor lift will also be necessary. Improve use of MIT. Panel to be measured Current tool Speed brake Flap 51 3. Carriage Panel Screw Relocation • Supplier to relocate placement of screws on flap carriage panels to areas with less risk to process. • Eliminates current process risks of hitting the fore flap with a tool during screw removal. Leave it as is Install Screw here Do not install Screw here Install Screw here Do not install Screw here 52 4. Turn Buckle PRE • Use Elephant Hide on flap in between turn buckle in case tool slips away from mechanic when tightening. • Other materials that are as thin as Elephant Hide but more rigid are being investigated and could be used in the future. • Improve process and protect area on flap that is volatile and susceptible to damage through use of PRE. PRE Implemented 53 5. Awareness Presentation & Tipsheet • Make Flap Damage Prevention Presentation and Tipsheet required training for all 747 mechanics. • Describes the vulnerability of flaps to damage, description of the consequences of damage to company including total costs and disruption caused to manufacturing, explanation of the proper procedures when working on or around flaps, and repercussions of not following established procedures. • Should be presented to crews at least once per year Awareness and education will prevent damage across the entire flap 54 6. Wing Boots & Containment Trays • Reinstate and make available for use. • Wing Boots should be placed over the mechanic's shoes every time they step on the flap to protect from debris that gets caught on the sole. • Containment Trays should be used as a central storage to place tools in one area and not laying around on flap. • Each mechanic who walks on the flap should have one. Put processes in place to make items easy to obtain, apparent, and mandatory. Wing Boots required on upper wing surface 55 7. Caution Notes on IPs • Place important notes on relevant IPs that warn mechanics about fragility of flaps, to contact appropriate personnel before accessing flaps, and to use PREs. • Increases awareness and serves as reminder. • Currently, only affected seal jobs have notes on them but IPs from other areas will also have notes. 56 Any Project Management Questions? stephen.r.snelling@boeing.com 57 3/16/2016