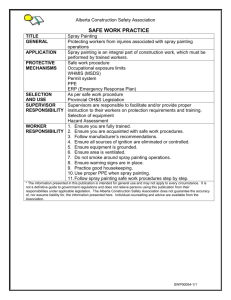

Testing of the pressure system

advertisement

1 SprAid Prototype Analysis and Potential Application for Superficial Wound Treatment (March 2015) Richard Patrican, Nathan Jordan, Andrew Cedeno Abstract — The SprAid prototype, is the installment of a medical device to include both a pressure and electrical system to theoretically accept different medicinal solutions including: wound dressings, antiseptic and hemostatic agents to hypothetically treat superficial wounds by the use of a pressure spray system. The designed prototype was implemented to ascertain whether or not medicinal solutions of the same viscosity could be added by an electrical system during a pressure differential change. The construction of such a system in its entirety in previous recorded studies has never been attempted due to the problem of viscosity levels and formulation of an electrical system to coordinate the release of fluid into a pressure differential chamber. The solution to the problem was to utilize medicinal solutions, of the same viscosity level incorporated into to the t-fitting of the pressure system driven by a custom motorized palate. The motorized palate would rotate the solution and the pressure system, utilizing a unique valve stem, incorporating an O-ring, would fill the chamber with pressure only when the system is activated by the user, thereby overcoming the pressure differential problem. The overall goal of the design, is to include the working parameters of both pressure and electrical system that can later be used in the process of human trials to determine whether or not the effect of the system improves the healing nature of superficial wounds. The results of the pressure system indicated in regards to spray diameter and pressure that, as the spray diameter decreased, it was proportional to the area of wound coverage provided by the particular pressure. The results in regards to spray diameter and distance illustrated an optimal use within the range of 8-14 inches in which a standard spray diameter was viewed. The electrical system configuration dealing with 2-4, produced the optimal results of degree rotation in which to move from one solution to the next. The guidance of these results, highlighted that the system could maintain a differential pressure change in the system along with rotate from one solution to the next. The impact of the research, could one day be translated, in the application of wound care in both a hospital and military basis to treat extensive superficial wounds to multiple patients when using the SprAid device. Index Terms—Electrical Spraying System, Mechanical Spray Gun, Spraying Apparatus I. INTRODUCTION In the field of health care, the aspect of wound care is an undeniable action induced or caused by unavoidable events that leads to resulting wounds to all individuals who come into contact with such events. The author (Fidler, 2002), states in reference to statistical matters concerning wound endeavors in the state of the U.S. that 37.6 million individuals are taken to the emergency room yearly due to injuries. The commonality of such results stated (Fidler, 2002) reveals that 4 out of 10 patients suffer wound related incidents and 22 percent are open-ended wounds inflicted to the patients in which 7 out of 10 patient’s required medicinal medications. Findings reported (Fidler, 2002) from the National Center for Health Statistics, state in the case of wound care, 29.6 percent required therapeutic treatment. For example, (Fidler, 2002) provides an account of 1997 in which children under the age of 5 and elderly residents showed that accidental falls were the leading cause of wound injuries. The notion of such a field that promises no span of pre-preventable protection can only be followed by a governing self-sustaining system to treat the wound injuries. Therefore, background information will be presented regarding the development and future use of spray on applicators such as wound dressings, antiseptic and hemostatic agents that can be utilized in any spray device to treat superficial wounds. Details will be presented regarding the product design and future outlook of the spray prototype, such as the SprAid. Parameters regarding methods and results will be analyzed and discussed regarding the outcome of all three tests for the both the pressure system and electrical system of the SprAid prototype. The novelty of wound dressings became apparent for their medicinal purposes during the Mesopotamian era around 2500 BCE. However, as the expenditure of technology grew and the innovation of multiple fields became understood such as engineering, biochemistry and organic chemistry, dressing applications highlighted these medicinal improvements. The authors (C, S, L, & D, 2012) and (Mogosanu & Grumezescu, 2014) illustrate a plethora of categorical dressings under investigation or in production commercially, including: natural polymers, glycolipids, proteoglycans, proteins and peptides, synthetic polymers and skin substitutes. But, in the aspect of standard treatment for superficial wounds, items such as gauzes and semipermeable films are more common to the average investor but not spray-on dressings. The apparent nature of these items provided by (C, S, L, & D, 2012), 2 elaborates in the sense both advantages and disadvantages of these exclusive items. In referring to gauzes, the author (C, S, L, & D, 2012), details the advantage as being: cheap, accessible, impregnable and physical debridement. However, in referring to the disadvantage one that still has provided problems since the 5th century BCE is the promiscuity of releasing fibers into the affected area, traumatic removal resulting in pain and further bleeding and lateral bacterial migration. Semipermeable films, commonly referred to as Band-Aids, where founded during the era of World War II under the direction of an employee working for Johnson and Johnson by the name of Earle Dickson. The heighten appeal of their functionality during the war was a direct correlation of their sterilization properties, maintaining a moist environment and minimizing the colonization of bacterial migration (C, S, L, & D, 2012). In regards to medicinal disadvantages of the BandAid, a slight risk in non-preventable maceration. However, in the respect of aerosolizing the wound aperture in treatment of superficial wounds, (C, S, L, & D, 2012), (Gerlach, Johnen, McCoy, Brautigam, Plettig, & Corcos, 2011) and (Camp, 2014) theorize the surface to wound ratio is greater, provides cosmetic advantages and delivers strong viability results. Spray on formulations noted by (C, S, L, & D, 2012), provide an applicable first aid response and reduces infection. However, though the spray applicator is a growing technology, cons prescribed by the author (C, S, L, & D, 2012) stipulate that possible haemolysing can occur. Therefore, the rational of choosing both growing and control dressings is dependent upon the particular case presented to the user. In which, the judgment of rational and logical understanding must be considered when addressing the health care of the wound site. However, this is the first step towards the advancements in improving the efficacy of the healing process in otherwise severe wounds. The secondary measure of treating the wound is no longer about simply covering the wound, but addressing the best way of how to clean the wound beyond the superficial injury using antiseptic agents. In the progression of treating minor wounds with conditional prep agents, author (Zinn, Jenkins, Swofford, Harrelson, & McCarter, 2010) provides relative evidence in choosing certain prep agents for conditional treatment. However, authors (Zinn, Jenkins, Swofford, Harrelson, & McCarter, 2010) and (Fidler, 2002) stress that when choosing agents: consideration of the patient allergies and skin conditions are recognized, area of treatment is acceptable for that particular agent, manufacture’s review and guidelines are followed for the uses of that agent and preference of the user or medical examiner are considered when choosing an appropriate prep agent for the onsite condition. In response to choosing a prep agent, authors (Zinn, Jenkins, Swofford, Harrelson, & McCarter, 2010) and (Fidler, 2002) highlight that the functionality is secondary to the prevalence of treating minor wound cases. Coordinated distinctions between authors (Zinn, Jenkins, Swofford, Harrelson, & McCarter, 2010) and (Fidler, 2002) enclose that prep agents must coordinate the following functionality: microorganism cell count is decreased from original status, efficient in addressing a plethora of microorganism cultures, fast response and rebound effect in preventing the re-synthesis or re-growth of microorganism sub-populations. In reference to the prep agents, author (Zinn, Jenkins, Swofford, Harrelson, & McCarter, 2010) provides an itemized list of the agents in regards to advantages and disadvantages they pose to the system layer of the body. In regards to the importance of prep agents, authors (Fidler, 2002) and (Zinn, Jenkins, Swofford, Harrelson, & McCarter, 2010) undergo logical reasoning that prep agents are justified in the matter of treating the affected area by: removing soil deposition or elemental components foreign to the layer of the skin, decreasing cell viability of foreign microorganisms and stalling the rebound and regrowth effect of microorganisms to the lining of the skin. For example, iodine base agents with alcohol as stated by (Zinn, Jenkins, Swofford, Harrelson, & McCarter, 2010) provides proficiency in its reactivity towards gram positive and gram negative bacteria, long duration effect, broad spectrum, and immediate germicidal reaction. However, as illustrated by both authors (Fidler, 2002) and (Zinn, Jenkins, Swofford, Harrelson, & McCarter, 2010) iodine base products with alcohol are considered to be highly flammable due to the catalyst of the alcohol present within the mixture, but can be avoided if precautionary steps are taken. In regards to chlorhexidine gluconate as stated by (Zinn, Jenkins, Swofford, Harrelson, & McCarter, 2010), the agent comes with considerable flaws in the case of a drying effect visible on the skin and adverse effects when applied to the eyes, ears, genitalia and mucous membranes. However, consistency exist between both authors (Fidler, 2002) and (Zinn, Jenkins, Swofford, Harrelson, & McCarter, 2010) in the fact that each of the following agents are FDA approved, but a frame of reference of which is preferred as a general control in treating wounds in hospital settings is still unclear. In looking at unpredictable variables, antiseptic agents have both positive and negative side effects that are detrimental to the repairing process of the skin, thus leaving the hospitals with an unclear decision of which antiseptic agents to use. In spite of this conundrum, antiseptic agents are still considered essential for wound care. In looking at the entire process of wound management after cleaning the wound, if the case is severe enough, where there is heavy bleeding involved, then a hemostatic agent becomes necessary. In the process of cultivating the healing cascade of minor wounds, the temperance of distinctive topical hemostatic agents can be applied to assist in the process of healing wounds. When referencing such agent’s author (Camp, 2014), breaks down topical agents into five categories: passive, active, flowables, fibrin sealants and adhesives. But, we will only focus on three of the topical agents including passive, active and fibrin sealants. Since, they are three of five agents that have been incorporated into spray applicator devices in order to treat bleeding cases. The process of treating superficial wounds, authors (Camp, 2014) and (Fidler, 2002) understand from a clinical standpoint that associations dealing with first response to a site of bleeding must first be handled mechanically by inducing pressure, sutures or thermal energy. In which case, the same concept applies when choosing an antiseptic or hemostatic, the right solution for the particularity of the incidence. In reference to three of the five hemostatic agents; passive, active and fibrin sealants provided by the 3 author (Camp, 2014) suggest that commercial applications can be used for cell spraying in treatment of superficial wounds. However, the indicative nature of these three categories, holds a distinctive chemical nature that possess both advantages and disadvantages when applied to the user. Passive agents explained by the author (Camp, 2014) provide certain effects that make it very distinctive to other hemostatic agents. The sense of passive agents is the ability for the conditional area to control minimal bleeding. However, noted by the author (Camp, 2014), agents classified under this category can work within two to three minutes, inexpensive, preparation technicalities are small and requirements for storage ascertains no special accommodations. The agent undergoes the ability of activation due to the presence of blood, however in the sense of a pro to the nature of the agent, disruption of the clotting cascade is not affected. In essence, passive agents can be constructed in the following composition as stated by (Camp, 2014): porcine gelatin, bovine collagen, oxidized regenerated cellulose, polysaccharide spheres and beeswax. In regards to the composition of these passive agents the author (Camp, 2014) highlights the advantages of these components, but provides also a commonality in risk to the usage of such components such as; prevention of any injection into the wound, risk of granuloma/abscess formation, swelling risk and increase infection risk. The advantages provided by (Camp, 2014) include; two to three minute functionality, no preparation needed and no human/animal source. Active agents implore a sense of continuity in the means of controlling blood flow in the same sense as the other agents, however stated by the author (Camp, 2014) they implore thrombin. The author (Camp, 2014) ties a direct correlation to the full functionality of active agents with that of thrombin. Active agents come within the following three formats: bovine thrombin, pooled human thrombin and recombinant thrombin. Statements stipulated by the author (Camp, 2014) assess that an increase in concentration of thrombin provides a higher yield effect to the process of hemostasis. Reasons behind the statement come from the logistic of biological understanding, assessed by the author (Camp, 2014), active agents are processed with the means of delivering high levels of thrombin. Thrombin in the essence of its inner-workings, converts fibrinogen to a fibrin clot which provides clotting aggregation and thrombus to develop at the site of injury. However, a disadvantage noted by the author (Camp, 2014) states that disruption to the thrombin concentration can be manipulated in the sense of denaturing the full effect of thrombin in the wound. The process of reducing the thrombin concentration thereby its functionality can occur in the following way as stated by (Camp, 2014): hemodiluation, absorptive sponges, wound irrigation and wiping or blotting of the wound. In terms of the application of the active agent to the wound area, the author (Camp, 2014) states that measures of spray applicators or direct application can be used to modulate the release of the active agent. Thereby providing the accessibility of different modes of delivery when confronted with different circumstances. Fibrin sealants, in the essence of hemostatic classification under topical, provide full functionality in the directive parameter stated by (Camp, 2014), in the condition of providing the stoppage of bleeding. The author (Camp, 2014) provides strict defining differences between the advantages and disadvantages of this hemostatic agent in controlling superficial wounds. Advantages, include the conclusive demeanor of the foundational makeup that encompass the inner workings of the agent in providing an accelerated level of fibrin clot due to increases in concentration of both fibrinogen and thrombin. The elevated response to levels in concentration provide the opportune creation of a clot due to accelerated responses of both thrombin and fibrinogen when applied to blood. Consequently, disadvantages stated by (Camp, 2014) reveal that the application of the agent to the patient is not suited to a general user with no foreknowledge of the material, but requires the services of a trained technician. Technicians within this endeavor provide basic strengths in the process of basic lab procedures which are conducted towards the effort of retrieving pooled plasma from the patient to reconstitute the product. The nature of the agent allows the ability of the user stated by (Camp, 2014) to deliver the agent via aerosol spray. The delivery of such a method provides an opportune relief in terms of high spray area ratio, mobile delivery of the agent and user friendly. It is this method of delivery that makes the hemostatic agent more accessible, however, the drawback is that the user needs certain training skills to use and administer the delivery system. It is in providing this training that is the unforeseeable element that prevents the research from stating that this delivery system can be introduced within the home. The application of these different solutions when used in a spray applicator device, have shown to have optimal results in enhancing wound recovery when dealing with superficial wounds. Though the applicator device regarding the SprAid prototype is being finalized regarding both the pressure and electrical system, in theory the solutions discussed can be used with the device to treat superficial wounds. Since each of the solutions possess the same viscosity level as that of water. However, the future outlook of the product will include the design and process of a working spray applicator prototype and not in the testing of the device in the effectiveness of enhancing or treating superficial wounds. The overall design of the SprAid prototype will have two working properties, a mechanical and electrical system. The mechanical system regarding the pressure system will be powered by a source, such as a CO2 tank, in which will be regulated by a CO2 regulator. The regulator will control the amount of CO 2 flowing into the pressure system. The horizontal portion of the L-shape pressure system will include the trigger lever connected to the valve stem, and the placement of the cartridges in the t-fitting of the spray head. By pushing back on the trigger lever, the compression spring will cause the valve stem to move back, thus allowing air to flow into the openings of the valve stem. Once the air rushes into the opening of the valve stem, the pressurized air will move down the tubing of the spray head and exit through the spray nozzle. However, once the trigger lever is released causing the compression spring to recoil back to its original position, the CO2 pressure will remain confided at a constant pressure. The electrical system of the device, will function in the vertical, rotational placement of the cartridges into the t-fitting of the spray head. The means in which to maintain the pressure 4 through the mechanism is still under construction. However, the process of rotation utilizing a micro-stepper motor has been finalized and tested. Once the process of both mechanical and electrical system are operational, a 3D printed cast will be printed and then placed on the device. The methods section will explain in detail, the setup of the pressure system and electrical system. In regards to the pressure system, the section will explain, how the pressure propagates through the system and remains constant when inactive. The section will provide details of the nozzle construction, along with the mechanism by which the fluid enters into the t-fitting of the spray system. Explanations will be provided regarding the testing procedure of the spray system. Following this, the electrical system in the section will explain what mechanisms of circuit operations may be used to allow the vertical rotation of the solutions into the t-fitting of the spray system. Results, regarding the pressure system will include results from two tests such as: spray diameter with variable pressure changes and spray diameter with variations in distances from target. The electrical system results, will include a total of eight configurations. In which the nature of the test will be to find the optimal configuration to achieve the optimal rotation value, in order to rotate from one solution to the next. II. METHODS Pressure System: In order to propel fluid, out of a spray nozzle, pressure must build up in the system and then be actuated by a user mechanically. As a source of pressure, a pressurized CO 2 tank is used to deliver 3000-4500 psi. In order to lower pressure, the system is regulated to 20-80 psi, which fits within the specifications determined by the Mechanical Engineers code for pressure piping as (ASME B31): 𝑃= 2𝑆(𝑇𝑚𝑖𝑛 − 𝐶) 𝐷𝑚𝑎𝑥 − 0.8(𝑇𝑚𝑖𝑛 − 𝐶) Where: P=Pressure allowed, psi. S=Maximum allowable stress in tension, psi. Tmin=Wall thickness (min), in. Dmax=Outside diameter (max), in. C=Constant (Due to coppers corrosion, the resistance factor can be set to 0). Once the pressure is reduced to an appropriate level, it’s contained within the elbow joint. With a release valve at the end of the system, it will allow the pressure to be sustained until it is actuated by the user. The valve is shown below: Figure 1: Top: In this state of the pressurized system, a pressure differential is being contained by a valve that needs to be actuated by the user. An O-ring seals off the CO2 gases from the system. Bottom: When the valve is opened, gas will flow to the rest of the system, through three 1/16” holes, which have been exposed to pressurized air. The valve facilitates the flow of pressure from one end to the other. By sliding the valve back, into the pressurized side of the copper tubing, CO2 flows into the valve and out through the spray nozzle of the device. Theoretically, medicinal fluids can be delivered to the patient for treatment of superficial wounds. When the user releases the valve spring, it causes a decompression to occur. The decompression factor blocks the flow of gas into the valve, thereby maintaining the pressure at a constant rate. Once this occurs, the pressure remains constant within the lower half of the system until the sliding of the valve stem occurs again. Nozzle: The nozzle of our system, was developed by drilling a 1/16” hole into a cap on the end of the pressurized system. In doing so, this allowed the gas to be perpetuated by the pressure differential created by the CO2 source. Muzzle velocity was calculated by using Bernoulli’s equation of: 1 𝑃 + 𝜌𝑉 2 = 𝑃0 2 in order for a gentle spray to be delivered. The fluid that is delivered to the system is introduced utilizing 3 different cartridges. Each cartridge contains different fluids that are located on the top of the spray gun and are electrically actuated by the user. The fluid is gravity fed into the t-fitting of the barrel based on gravitational forces. Upon this point, the fluid is stored in the barrel until the pressure differential is introduced into the system. Thus allowing the fluid to be ejected from the nozzle head. 5 Electrical system: In order to insert and differentiate between solutions added to the t-fitting of the spray gun, a motorized palate was developed to rotate the correct solution into place. In order to accomplish this, a full driven controller was created using two, 555 timing ICs for function generation, JK flip flops and XOR logic gates. By utilizing these features, it would allow the driving action of the motor, to control which fluid is selected. The results showed, that the system was able to operate under variable pressure changes that were introduced into the system. As well as, being able to expel the fluid out of the nozzle head. When the pressure gradient within the system increased, there is less variance in the diameter of the spray that is being delivered to the target site. However, further analysis revealed, that a decrease in the pressure, resulted in a decrease in the spray area as shown in figure 4. 5 4.5 4 Spray Diameter (Inches) Figure 2: The housing device for the cartridges are fed through the t-fitting and before exposure to the pressure differential can be stored within that area. When the pressure differential propagates through the lining of the t-fitting of where the fluid is stored, the fluid is ejected out of the nozzle head. 3.5 3 2.5 2 1.5 1 0.5 0 15 20 25 30 35 40 45 50 55 pressure (PSI) Testing of the pressure system: The pressure system was tested outdoors using a vice clamp, in order to hold the spray gun at a fixed position. By placing the spray gun in a fixed position, the user was able to measure different positions from the fixed position of the spray gun in order to test the device. An air compressor with a regulated pressure system was connected to the spray system of the device using a ½” adapter and a female push pen. A solution of dark blue food coloring mixed with water, was added to the t-fitting and then sprayed at a paper target from a set distance. In order to measure the effects of each pressure at variable distances, the target was moved from 8 inches to 20 inches in increments of 2. To measure the variance of each pressure, the target was placed 8 inches from the spray nozzle and 5 trials were run, at pressures ranging from 20-50 psi. The stained targets were then measured to include the diameter that covered at least 95% of the stain. When the target distances were adjusted, results highlighted a defining difference in the spray area when being applied to the target site. Between 8-14 inches, there was a standard spray diameter for pressures 20-50 psi. However, the results show that the spray diameter begins to tailor off at 20 inches and that pressures 30-50 psi become an ineffective spray size. At 20 psi, there was not enough pressure to produce an effective spray diameter at any length past 12 inches. 7 6 Diameter of spray (Inches) Figure 3: In the figure above, shows the wave driven controller for a stepper motor. Each coil represents a coil within the stepper motor. In order for it to move 1.8° it has to have this sequence of propagation from the controller circuit. Figure 4: In the figure above, shows that by decreasing the pressure, the spray diameter decreased. Meaning, when the spray diameter decreased, the diameter change was proportional to the area of wound coverage, covered with that particular pressure variable. An increase in diameter, resulted in a smaller variance between trials. As such, this will allow the spray gun to provide a consistent treatment size depending on the type and size of wound. 20 30 40 50 PSI PSI PSI PSI 5 4 3 2 1 III. RESULTS Pressure System: 0 8 10 12 14 16 Distance from nozzle (Inches) 18 20 Figure 5: In the figure above, depending on the target distance from the nozzle, its considered proportional to the spray area 6 delivered to the target site. Increase in pressure, will allow for a more distant spray. However, pressures above and below 20 psi will only cover up to 16 inches from the spray nozzle. Electrical system: The electrical system, was verified using an oscilloscope and visual observations of the stepper motor function. Eight different configurations were measured in this system and a variance of the correct measurement for optimal rotation was found to be 1.8°. The configurations are noted below: Configuration 1-4 Normal XOR logic gates • Configuration 1-Original circuit design • Configuration 2-Monostable capacitance was doubled • Configuration 3-Monostable capacitor was switched out • Configuration 4-Monostable capacitor was switched out Configuration 5-8 Modified XOR logic Driver • Configuration 5-Modified XOR driven logic, eliminated feedback • Configuration 6-Tripled monostable capacitance • Configuration 7- Doubled monostable capacitance • Configuration 8- Changed the capacitance from conf 5 Stepper Motor Function 120 IV. CONCLUSION The current SprAid prototype design contains two working parts. The first is a mechanical component capable of spraying solutions at regulated pressures between 20 and 50 psi. The second part is a motorized palate that can be activated to rotate three different solutions into the fluid housing of the spray gun where it can be stored until the solution is ready to be sprayed. The spray system can cover areas of up to 4.4 inches in diameter in one shot and spray from distances of up to 20 inches away. Presently, the electrical circuit uses stepper motors to rotate 90 degrees, which is optimal for employing a three-port manifold, which has a lever that has to be rotated 90 degrees to open and close to dispense fluid. However, the results from the electrical test showed that the electrical circuit could also be configured to rotate 60 degrees instead. This modification will allow us to employ the motorize palate to rotate a barrel 60 degrees to dispense one of three solutions at a time. Turning the barrel the right number of degrees prevents leakage of the fluid by feeding one of the solution directly into the pressurized system while keep the other two solutions locked into place. Integrating the mechanical and electrical components will enable the device the SprAid device to be able to dispense a variety of solutions with a viscosity near that of water at controlled pressures in one unified system. The system has potential use in medicine for treating superficial wounds since it has been shown that the delivery of sprayed solutions provides high spray area ratios, mobility, and convenience. 100 Degrees Rotation 80 V. REFERENCES [1] B. D. Fidler, "Wounds and bandages: old problems/new solutions," Drug Store News, pp. 37-43, 15 April 2002. 60 40 [2] D. C, K. S, S. L and S. D, "A history of materials and practices for wound management," Wound Practice and Research, vol. 20, no. 4, pp. 174-186, November 2012. 20 0 8 7 6 5 4 Configuration # 3 2 1 Figure 6: In the figure above, configurations 4-2 allowed for the proper rotation to be achieved by the system of 90°. The recorded variance was 1.8°, which was dependent on the tolerance levels of the capacitors used within that pulse generation. There was a large variance in the modified feedback loops, 5-8 which was dependent on the starting position of the control circuit. In regards to configuration 2-4, theoretically, the 90° rotation provides the optimal vertical rotation in order to lock the fluid cartridges, one by one, into the t-fitting of the pressure system. By locking into place, the fluid is gravity fed into the pressure system. Thereby, awaiting a pressure differential to occur to eject the fluid from the spray nozzle. Therefore, each 90° rotation of the stepper motor will switch from one solution to the next. [3] G. D. Mogosanu and A. M. Grumezescu, "Natural and synthetic polymers for wounds and burns dressing," International Journal of Pharmaceutics, vol. 463, no. 2, pp. 127-136, 25 March 2014. [4] J. C. Gerlach, C. Johnen, E. McCoy, K. Brautigam, J. Plettig and A. Corcos, "Autologous skin cell spray-transplantation for a deep dermal burn patient in an ambulant treatment room setting," Burns, vol. 37, no. 4, pp. e19e23, June 2011. [5] M. A. Camp, "Hemostatic Agents: A Guide to Safe Practice for Perioperative Nurses," AORN Journal, vol. 100, no. 2, pp. 131-147, August 2014. [6] J. Zinn, J. B. Jenkins, V. Swofford, B. Harrelson and S. McCarter, "Intraoperative Patient Skin Prep Agents: Is There a Difference?," AORN Journal, vol. 92, no. 6, pp. 662-674, December 2010. VI. ACKNOWLEDGMENTS 7 Yuntao Wu, PhD Professor of Microbiology & Infectious Diseases at George Mason University Ph.D., Queens University, Ontario Colin J. Reagle, PhD Assistant Professor of Mechanical Engineering at George Mason University Ph.D., Virginia Tech, VA