The policy applies to all ARS Corvallis Location employees who

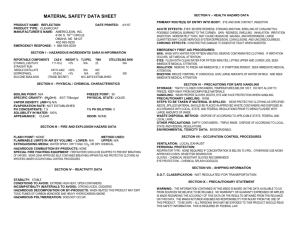

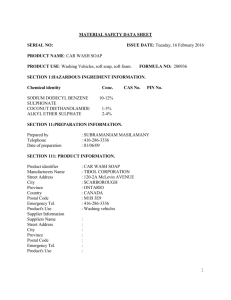

advertisement