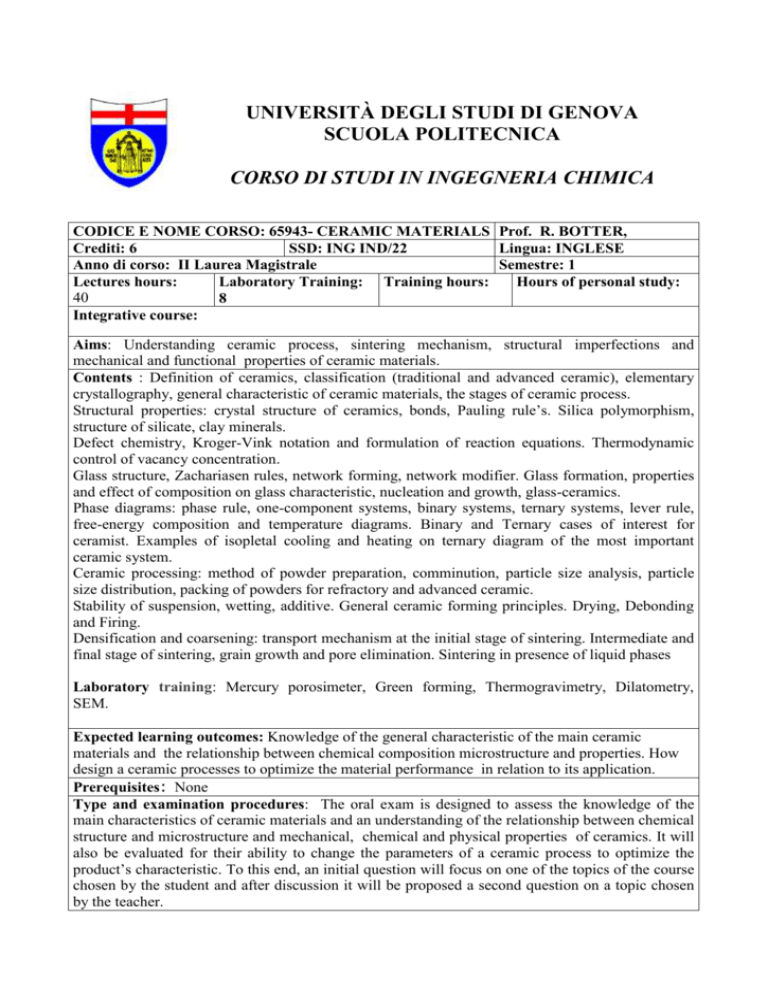

università degli studi di genova scuola politecnica corso di studi in

advertisement

UNIVERSITÀ DEGLI STUDI DI GENOVA SCUOLA POLITECNICA CORSO DI STUDI IN INGEGNERIA CHIMICA CODICE E NOME CORSO: 65943- CERAMIC MATERIALS Prof. R. BOTTER, Crediti: 6 SSD: ING IND/22 Lingua: INGLESE Anno di corso: II Laurea Magistrale Semestre: 1 Lectures hours: Laboratory Training: Training hours: Hours of personal study: 40 8 Integrative course: Aims: Understanding ceramic process, sintering mechanism, structural imperfections and mechanical and functional properties of ceramic materials. Contents : Definition of ceramics, classification (traditional and advanced ceramic), elementary crystallography, general characteristic of ceramic materials, the stages of ceramic process. Structural properties: crystal structure of ceramics, bonds, Pauling rule’s. Silica polymorphism, structure of silicate, clay minerals. Defect chemistry, Kroger-Vink notation and formulation of reaction equations. Thermodynamic control of vacancy concentration. Glass structure, Zachariasen rules, network forming, network modifier. Glass formation, properties and effect of composition on glass characteristic, nucleation and growth, glass-ceramics. Phase diagrams: phase rule, one-component systems, binary systems, ternary systems, lever rule, free-energy composition and temperature diagrams. Binary and Ternary cases of interest for ceramist. Examples of isopletal cooling and heating on ternary diagram of the most important ceramic system. Ceramic processing: method of powder preparation, comminution, particle size analysis, particle size distribution, packing of powders for refractory and advanced ceramic. Stability of suspension, wetting, additive. General ceramic forming principles. Drying, Debonding and Firing. Densification and coarsening: transport mechanism at the initial stage of sintering. Intermediate and final stage of sintering, grain growth and pore elimination. Sintering in presence of liquid phases Laboratory training: Mercury porosimeter, Green forming, Thermogravimetry, Dilatometry, SEM. Expected learning outcomes: Knowledge of the general characteristic of the main ceramic materials and the relationship between chemical composition microstructure and properties. How design a ceramic processes to optimize the material performance in relation to its application. Prerequisites: None Type and examination procedures: The oral exam is designed to assess the knowledge of the main characteristics of ceramic materials and an understanding of the relationship between chemical structure and microstructure and mechanical, chemical and physical properties of ceramics. It will also be evaluated for their ability to change the parameters of a ceramic process to optimize the product’s characteristic. To this end, an initial question will focus on one of the topics of the course chosen by the student and after discussion it will be proposed a second question on a topic chosen by the teacher. Addresses and office hours professor:: Every week at the request of the student appointment Textbooks: Slides available on AulaWeb. Introduction to Ceramics, 2nd Ed. –1976. Kingery, Bowen, Uhlmann Physical Ceramics: Principles for Ceramic Science and Engineering 1996. Kingery et al. Principles of Ceramics Processing, 1995. J.S Reed Dati statistici relativi alle votazioni d’esame conseguite dagli studenti: