What factors need to be considered for spacecraft structure design?

advertisement

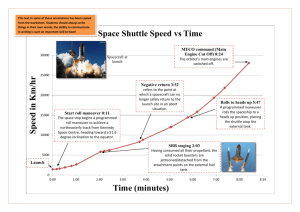

衛星結構設計 祝飛鴻 10/26/2006 1 2 Pre-Class Assignment: 1. What are the main functions of spacecraft structure? 2. What factors need to be considered for spacecraft structure design? 3. What factors need to be considered on material selection for space application? 4. What are the required major tasks for spacecraft structure design? 5. How to verify spacecraft structure design? 3 What are the main functions of spacecraft structure? Carry Loads - provide support all other subsystems and attach the spacecraft to launch vehicle. Maintain geometry – alignment, thermal stability, mass center, etc. Provide radiation shielding ARGO Satellite - The first Taiwan designed satellite 4 What factors need to be considered for spacecraft structure design? Size Weight Field-of-view Interference Alignment Loads ARGO Satellite - The first Taiwan designed satellite 5 Falcon-1 Envelope Size: Fit into the fairing of candidate launch vehicle. Provide adequate space for component mounting. 30 cm 132 cm 13mm clearance 123 cm 11mm clearance 135 cm 6 Weight: Not to exceed lift-off weight of the selected launch vehicle. 7 Field-of-view (FOV): Define by other subsystems, e.g. attitude control sensors, payload instruments, antenna subsystem, etc. MSI FOV= 6 ° 110 ° 65 ° 65 ° 110 ° X Band Antenna FOV Star Camera FOV= 6.7° on short axis 9.2° on long axis 8 Interference: With the launch vehicle fairing. Between components for physical contact Falcon-1Envelope and assembly. GPS Ant. 8.6mm clearance Solar Panel 19mm clearance Section Y=1219 X-Band Ant 15.5mm clearance 9 Alignment: Define by other subsystems, e.g. attitude control sensors, payload instrument, etc. On ground alignment. On-orbit thermal & hydroscopic distortion. Requirement Star Camera Orientation ± 0.5 (TBR) Thruster Orientation ±1.5 (TBR) X-antenna Orientation ±5 (TBR) S-antenna Orientation ±5 (TBR) 10 Loads: Environmental loads for structure design. Not-to-exceed loads for components and payloads. 11 What factors need to be considered on material selection for space application? Strength-to-weight ratio Durability Thermal stability Thermal conductivity Outgassing Cost Lead time Manufacture 12 Commonly used material: Metals – Aluminum, Titanium, Magnesium, Beryllium Composites Ceramics Polymers Semiconductors Adhesives Lubricants Paints Coating 13 Material Selection Material Density 3 (Kg/m ) Young’s Module E (Gpa) Yield Strength S (Mpa) E/ S/ CTE (m/m K) Aluminum 7075 T6 2700 71 503 26 186.3 23.4 Magnesium AZ31B 1700 45 220 26 129.4 26 Titanium Ti-6Al-4V 4400 110 825 25 187.5 9 Beryllium S 65 A Fiber Composite - Kevlar - Graphite 2000 304 207 152 103.5 11.5 1380 1640 76 220 1240 760 55 134 898.5 463.4 -4 -11.7 14 What are the required major tasks for spacecraft structure design? Configuration design Environmental loads Structure analysis 15 Configuration Design To accommodate all the components in a limited space while satisfying its functional requirements, every spacecraft will end up with a unique configuration. 16 Configuration Design - ARGO 17 Configuration Design Structure Configuration Hardware List Mechanical Layout Hardware Size FOV Requirements Orientation Requirements Structure Analysis Environmental Loads 18 Environmental Loads To successfully deliver the spacecraft into the orbit, the launcher has to go through several stages of state changes from lift-off to separation. Each stage is called a “flight event” and those events critical to the spacecraft design is called “critical flight events”. 19 Environmental Loads Each flight event will introduce loads into the spacecraft. Major types of loads include: Transient dynamic loads caused by the changes of acceleration state of the launcher, i.e. F = ma. F will be generated if a or m is introduced. Random vibration loads caused by the launcher engine and aero-induced vibration transmitted through the spacecraft mechanical interface. Acoustic loads generated from noise in the fairing of the launcher, e.g. at lift-off and during transonic flight. Shock loads induced from the separation device. 20 Environmental Loads The above mentioned launcher induced loads are typically defined in the launch vehicle user’s manual. However, these loads are specified at the spacecraft interface except for acoustic environment. The loads to be used for the spacecraft structure design has to be derived. For picosat design, if P-POD is used, please refer to “The PPOD Payload Planner’s Guide” Revision C – June 5, 2000 for definition of launch loads. 21 Dynamic Coupling Among all the launch loads, the derivation of transient dynamic loads is most involved and typically is the dominate load for spacecraft primary structure design. To understand the derivation of transient dynamic loads, the concept of “dynamic coupling” needs to be explained. Based on the basic vibration theory, the natural frequency of a mass spring system can be expressed as: 1 f = ------ K/M 2 Where f = natural frequency (Hz: cycle/second) M = mass of the system K = spring constant of the system 22 Dynamic Coupling Based on the above equation, a spring-mass system with K1 = 654,000 lb/in and weight W1= 4,000 lbs will have f1 = 40Hz (verify it!). Assume a second system has f2 = 75Hz. (if this system has 30 lbs weight, what should be the value of K2?) The forced response of these two systems subjected to 1g sinusoidal force base a W excitation with 3% damping ratio will have 16.7g response at their natural K frequency, i.e. For system 1: 16.7g at 40Hz For system 2: 16.7g at 75Hz 1g (Please refer to any vibration text book for derivation of results) 23 Dynamic Coupling Suppose we stack these two system together, the response of the system can be derived as: 39.8Hz 75.4Hz a1 16.6g 0.4g a2 23.1g 6.4g a1 W2 K2 a2 W1 where 39.8Hz and 75.4Hz are the natural frequencies of the combined system. (Please refer to advanced vibration text book K1 1g for derivation of results) 24 Dynamic Coupling Now, let’s change the second system to have natural frequency of 40Hz, then the responses will be: 38.3Hz 41.8Hz a1 9.9g 9.2g a2 99.2g 83.4g a1 W2 K2 a2 W1 where 38.3Hz and 41.8Hz are the natural frequencies of the combined system. K1 1g 25 Dynamic Coupling It can be seen that by changing the natural frequency of the second system to be identical to the first system, the maximum response of the second a1 W2 system will increase from 23.2g to 99.2g. K2 This phenomenon is called “dynamic coupling”. The more closer natural frequencies of the two systems, the a2 W1 K1 higher response the system will get. 1g 26 Dynamic Coupling Now you can think the first system as a launcher and the second system as a spacecraft. To minimize response of the spacecraft, the spacecraft W2 a1 should be designed to avoid dynamic coupling with the launcher, i.e. designed K2 above the launch vehicle minimum a2 W1 frequency requirement. K1 Obviously the launcher and spacecraft are more complicated than the two degrees 1g of freedom system. Coupled loads analysis (CLA) is required to obtain the responses. 27 Coupled Loads Analysis The natural frequencies of a spacecraft can be predicted by mathematical model, e.g. finite element model. This model will be delivered to the launcher supplier for coupling with the launch vehicle model. Dynamic analysis can be performed using this combined model and critical responses of the spacecraft can be derived for the spacecraft structure design. Spacecraft Model Launch Vehicle Model Combined Model Dynamic Analysis Spacecraft Responses Forcing Functions of Critical Flight Events 28 Structure Analysis Once the mechanical layout is completed, the structural analysis can be started. Major items include: Mass property analysis Structure member and load path Material selection Dynamic and Stress analysis 29 Mass Property Analysis One of the important factors associated with the mechanical layout is the mass property analysis, i.e. weight and moment of inertia (MOI) of the spacecraft. Mass property of a spacecraft can be W1 calculated based on the mass property Y of each individual elements e.g. X components, structure, hardness, etc. W2 D1 The main purpose of mass property analysis is to assure the design satisfies D2 the weight and CG offset constraints from the selected launcher. Total Weight ? MOI about Z axis ? 30 Falcon-1 Launcher Lateral CG centerline offset (in) 2.5 2.0 1.5 1.0 0.5 0.0 0 200 400 600 800 1000 Spacecraft Weight (lb) 1200 1400 31 Structure Member and Load Path The spacecraft is supported by the launcher interface therefore all the loads acting on the spacecraft has to properly transmitted through the internal structure elements to the interface. This load path needs to be checked before spending extensive time on structural analysis. No matter how complex the structure is, it is always made of basic elements, i.e. bar, beam, plate, shell, etc. 32 Structure Member and Load Path Components => Supporting Plate => Beam => Supporting Points Beam Plate 33 Dynamic & Stress Analysis Finite element analysis is the most popular and accurate method to determine the natural frequencies and internal member stresses of a spacecraft. This analysis requires construction of a finite element model. 34 Dynamic & Stress Analysis Once the environmental loads, configuration and mass distribution have been determined, analysis can be performed to determine sizing of the structure members. Major analysis required for spacecraft structure design include dynamic (stiffness) and stress (strength) analysis. Major goal of the dynamic analysis is to determine natural frequencies of the spacecraft in order to avoid dynamic coupling between the structure elements and with the launch vehicle. 35 Dynamic & Stress Analysis Purpose of the stress analysis is to determine the Margin of Safety (M. S.) of structure elements: Allowable Stress or Loads -1 0 M. S. = Max. Stress or Loads x Factor of Safety Allowable stresses or loads depends on the material used and can be obtained from handbooks, calculations, or test data. Maximum stress or loads can be derived from the structure analysis. Factor of Safety is a factor to cover uncertainty of the analysis. Typically 1.25 is used for yield stress and 1.4 for ultimate stress. 36 Dynamic & Stress Analysis Construction finite element model of a spacecraft is not an easy task. Local models, e.g. panel and beam models, can be used to determine a first approximation sizing of the structure members. close form solution (Simply supported plate with uniform loading) Finite element solution (Simply supported plate with concentrated mass) reaction force close form solution (beam with concentrated force) 37 Dynamic & Stress Analysis Structure Configuration Mechanical Layout Preliminary Analysis/Design Material Selection Quasi-Static Loads Load Path Check Approximation Sizing Preliminary CLA Detailed Analysis/Design Finite Element Model Final CLA Design Verification 38 How to verify spacecraft structure design? Mechanical Layout – Assembly and integration Mass Property – Mass property measurement Quasi-static Loads – Static load test Transient Dynamic Loads – Sine vibration test Random Vibration Loads – Random vibration test Acoustic Loads – Acoustic test Shock Loads – Shock test On-orbit loads – Thermal vacuum test 39 Homework Problem Describe future technology trend for spacecraft structure design: Technology Goals Applications 40 What you have learned is: 41 Reference Spacecraft Systems Engineering, 2nd edition, Chapter 9, Edited by Peter Fortescue and John Stark, Wiley Publishers, 1995. 42