Petroleum Engineering 405 Drilling Engineering

advertisement

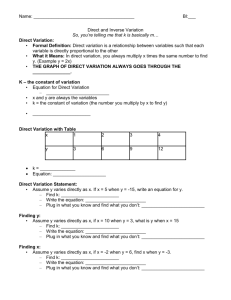

PETE 411 Well Drilling Lesson 31 Plugback Cementing 1 Plugback Cementing Case I: Case II: Equal Height Spacers Case III: Spacer Ahead of Cmt. (only) Case IV: Two Unequal Spacers Mixtures and Solutions No Spacer 2 Read: Applied Drilling Engineering Ch. 3. Cementing HW #16 Due November 22, 2002 3 Balanced Cement Plug Fig. 3.11- Placement technique used for setting cement plug. 4 Cementing (Open-Hole Plugging) 1. Plug-back for abandonment 2. Plug-back for fishing or hole deviation Open-hole plugging is usually performed with “slick” drillpipe or tubing. In some cases, reciprocating scratchers may be run to enchance cement bonding. 5 Types of Balanced Plugs Case I: No water or other fluid of different density from that in the hole is run ahead or behind the cement slurry. Case II: Water or other fluid of different density from that hole is run ahead and behind cement slurry. The volume of fluid ahead and behind slurry is calculated so that height in casing is same as height inside the string. 6 Displacement Case III: Water or other fluid of different density from that in the hole is run ahead of cement slurry and hole fluid only is used as displacing fluid. Case IV: Water or other fluid of different density from that in the hole is run ahead and behind cement slurry. In this case, the heights of fluid in annulus and drill string are not equal. 7 T C Case I ft 3 C annular capacity, ft ft 3 T drill pipe capacity, ft Height of plug with pipe in place Height of plug after pulling pipe 8 Case I T C ft 3 C annular capacity, ft ft 3 T drill pipe capacity, ft V volume of slurry, ft 3 H height of cement plug wit h pipe in place H Final Height V H*C H*T H(C T) V H CT 9 Example Balanced Plug - Case I Set a balanced cmt. plug from 8,500-9,000 ft, with no fluid spacers. 1. Open hole diameter = 10 3/4” 2. Assume no washout 3. Use 5”, 19.50 #/ft DP, open ended 4. Use class H cement, 15.6 #/gal 10 Example - Case I (a) Calculate volume of cement slurry required: 2 2 10.75 2 V DH L ft (500 ft) 4 4 12 315.15 ft 3 DH L of slurry required 11 Example - Case I (b) Calculate actual height of plug when DP is in place at 9,000 ft. If C annular capacity in ft / ft 3 T drillpipe capacity in ft / ft 3 then V (C T)H V H CT T C = Height of Plug, with Pipe in place 12 Example - Case I (b) cont’d In this case, 10.75 2 5 2 2 ft * 1 ft/ft C 4 144 0.49394 ft / ft 3 T 0.0997 ft 3 / ft ( Halliburton Book ) 13 Example - Case I (b) cont’d 3 V 315.15 ft H 3 C T (0.49394 0.0997) ft / ft H 530.9 ft height of plug, with pipe in place 14 Example - Case I (c) Determine the quantity of mud displacement inside the DP that will ensure a balanced plug. Balance requires that the pressures be equal inside the DP and in the annulus, at 9,000’. PD PA ΔP CD PMD PCA PMA 0.052(ρ MD )h MD 0.052(ρ MA )h MA hMD = hMA PD PA 15 Example - Case I height of mud inside drillpipe height of mud in annulus height of mud inside drillpipe 9,000 - 530.9 8,469.1 ft 16 Example - Case I Volume of mud displacement (behind the cement slurry) 3 = 8,469 ft * 0.0997 ft /ft bbl 844.4 ft * 3 5.61 ft 3 VDispl = 150.4 bbl (of mud) 17 Example - Case I Also required: 3 Class H cement req’d 315.15 ft 3 1.18 ft / sk 267.1 sks Mix water req’d 267.1 sks * 5.2 gal/sk 42 gal/bbl Water Re quired 33.1 bbl 18 hWD = hWA Case II VWD VWA T C T VWD VWA C mud water cement water mud hW Height of plug with pipe in place Height of plug after pulling pipe 19 Example, Balanced Plug - Case II Set a balanced plug, 500 ft high, with its bottom at 9,000 ft. Use water spacers of equal height inside DP and in annulus. Volume of annular water spacer = 10 bbl Open hole diameter = 10 3/4”. No washouts 5” DP, 19.50 #/ft, open ended. Use class H cement, 15.6 #/gal 20 Example - Case II (a) & (b) From previous example: V 315.15 ft 3 , vol. of cement slurry C 0.49394 ft 3 / ft , annular capacity T 0.0997 ft 3 / ft , drillpipe capacity H V 530.9 ft, height of plug CT with drillpipe in place 21 Example - Case II (c) Calculate height (length) of water spacer in DP: In annulus, 3 h WA ft 10 bbl * 5.61 VWA bbl 3 C 0.49394 ft / ft 113.6 ft h WD 113.6 ft 22 Example - Case II (d) Volume of water spacer inside DP V W,DP T Vol. of spacer in annulus * C 0.0997 ft 3 / ft 10 bbls * 3 0.49394 ft / ft V W,DP = 2.02 bbls … for spacers of equal height 23 Example - Case II (e) A balanced plug requires that PD PA PCD PWD PMD PCA PWA PMA PD PA mud in drillpipe must extend to the surface. 24 Example - Case II (e) cont’d Height of mud in drillpipe 9,000 - hCD hWD 9,000 530.9 113.6 8,355.5 ft 25 Example - Case II Volume of mud required to displace cement and spacers ft 3 8,355.5 ft * 0.0997 ft 3 = 833.0 ft VDispl = 148.5 bbls 26 Check 148.5 bbls 2.02 bbls 150.5 bbls answer to previous problem - Case I OK. 27 Pumping Sequence: 1. Water spacer for annulus: 10 bbls 2. Cement Slurry for Plug: 315.15 ft 56.2 bbls 3 3. Water spacer behind cement: 2.0 bbls 28 Pumping Sequence 4. Mud displacement behind second water spacer: 148.5 bbls Total fluid pumped = 10 + 56.2 + 2 + 148.5 = 216.7 bbls (at 10 bbl/min this would require ~22 min) 29 Case III Hole fluid density > density of water Hydrostatic heads in DS and annulus must balance at top of cement slurry with DS in hole. hW Height of plug with pipe in place Height of plug after pulling pipe PA PD 0 PCA PW A PMA PCD PW D PMD 30 Case IV - General Case Hole fluid density is greater than water density. Hydrostatic heads in DS and annulus must balance at top of cement slurry with DS in hole. PA PD PCA PW A PMA PCD PW D PMD 31 Procedure in setting balanced plug 1. Run drillpipe in to depth where plug is to be set; in this case 9,000 ft. (open ended). 2. Circulate and condition mud one complete circulation to make sure system is balanced. 3. Pump spacers and cement per calculations and displace w/proper amount of fluid 32 Procedure in setting balanced plug 4. Stop pumps; break connection at surface. A. If standing full, plug is balanced. B. If flowing back, a mistake in calculations has been made. Stab inside BOP, or have a slug of heavy mud ready to pump. 33 Procedure in setting balanced plug 5. Once the end of the drillpipe clears the plug, there is a good chance the pipe will pull wet. This is because pressures have gone back into a completely balanced mud system. 6. If pulling wet, slug pipe and pull out of hole. 34 Procedure in setting balanced plug 7. Even if plug is severely out-of-balance, never try to reverse cement out of hole. 8. Tag plug with DP at end of 8 hours. If too high, plug may have to be drilled out and another plug spotted. If too low, spot another plug to required height with DP just above top of first plug. 35 Calculations to Design a Balanced Open Hole Cement Plug 1. Calculate cu. ft. of slurry required for plug in open hole. π 2 V1 d L ft 3 4 or, use Halliburto n tables. 2. Multiply this volume by excess factor (50% excess factor = 1.50) V2 V1 * factor , ft 3 36 Calculations for balanced plug - HINT When dealing with a washed-out hole, where an excess factor is required, it is usually easier to calculate a new, effective hole size, and use that instead of the excess factor. V2 V1 * 1.5 If 50% excess is required π 2 π 2 d2 d1 * 1.5 4 4 d2 d1 1.5 1.225 d1 Use d2 for calculations This is the effective dia. 37 Calculations for balanced plug 3. Find height (h, ft) cement will occupy when drillpipe is at bottom of plug during pumping: V H TC h V2 Volinside DP Volannulus (based on d2 ) 3 ft ft 3 ft 38 Calculations for balanced plug - cont’d 4. Find height (ft) water spacer ahead of cement will occupy in annulus. Use d2 to calculate this (to account for the excess factor). 5. Find height (ft) water spacer behind cement will occupy in DP. Do not use excess factor. 6. Pressures must balance at bottom of plug PDP Pann 39 Calculations for balanced plug - cont’d 7. Pann Δ Pcmt Δ Pspacer Δ Pannulusmud PDP Δ Pcmt Δ Pspacer Δ PDP mud Solve for Δ PDP mud 8. Convert this PDP mud to feet inside DP. 40 Calculations for balanced plug - cont’d 9. Convert this footage to bbls inside DP for proper displacement. 10. To find sks cmt required, divide volume, V2, by yield/sk. This yield, Ysk, may be in the Halliburton tables (or may not…). Number of sx req’d, V2 N Ysk 41 Calculations for balanced plug - cont’d 11. If yield not shown, calculate from 1 v1 formula for mixtures. Solve for VW in this formula. Add the V’s for yield. 12. Total mix water will be VW / sk times number of sacks. VW total = (VW / sk) * N 42