- Paradigm Shift International

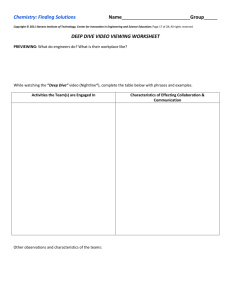

advertisement

ES/SDOE 678 Reconfigurable Agile Systems and Enterprises Fundamentals of Analysis, Synthesis, and Performance Session 2: Problem Space and Solution Space School of Systems and Enterprises Stevens Institute of Technology, USA rick.dove@stevens.edu, attributed copies permitted 2:1 Guest Speaker: Andreas Raptopoulos Also see: http://matternet.us File5.2 Drones for good Video: http://poptech.org/people/andreas_raptopoulos Poptech 2012, Camden, Maine, 18-20 October Andreas Raptopoulos is the founder and CEO of Matternet, building a network of unmanned aerial vehicles (UAVs) to transport medicine and goods in places with poor road infrastructure. Matternet's "drones for good" use small, electric UAVs to transport packages weighing up to 2 kilos and containing items like vaccines, medicines or blood samples, over distances of 10 kilometers at a time. By creating a new paradigm for transportation that leapfrogs roads, Matternet is helping to revolutionize transportation in both the developed and developing world. Matternet Inc. is a startup based in Palo Alto, California. The Matternet: A Flying Autonomous Delivery System For The Developing World Where Matternet is going, it doesn’t need roads. But the people there need food and medicine. And these drones can bring it to them. www.fastcoexist.com/1678463/the-matternet-a-flying-autonomous-delivery-system-for-the-developing-world The Matternet is being developed in three stages. In the first stage, the Matternet team anticipates carrying loads of one to two kilograms. The team's prototype (pictured above) can already do this, but its autonomous capabilities have not yet been tested. During the second stage, the autonomous vehicles will carry 200 kilograms, and automated solar-powered recharging stations will be installed on the ground. In the third stage, the vehicles will be able to carry up to 1,000 kilograms--so they will be able to transport both goods and people. The prototype AAVs are quadcopters that have a range of 10 kilometers, but the technology may change as the project advances. rick.dove@stevens.edu, attributed copies permitted 2:2 How Does It Get Built? http://feedproxy.google.com/~r/typepad/rzYD/~3/e4j-9ASyHY4/how-to-roll-out-dronenet-1.html The Internet rolled out by using the common global network as a starting point. It then piggybacked on public infrastructure to connect people up. Each new connection increased the value of the network. Dronet, in contrast, will emerge from peer to peer (p2p) connections as well as a few local hub and spoke delivery networks. Let me walk you through it... I set up a landing pad. You set up a landing pad. We have a delivery network with a little effort on software and routes (take off, 300 ft straight up, GPS point to point, hover over target, landing provides a beacon for landing precisely). It solves our problem. We don't go to the FAA or any government agency for permission. Then, someone develops a on-line system for registering landing pad locations and capabilities. I register my landing pad in that system. With the next iteration of the system, I actively connect my landing pad to the system via a wireless hookup. At that point, the status and capabilities of the pad are part of a global network that is forming. Soon, there are a dozen pads in my area within hoping distance. I note that a couple are at homes of friends and a local makerspace. We start to regularly deliver stuff via our network. To solve our problems, we see advances in the following areas: • Drones begin to connect to the emerging online system. They do this through wireless connections via landing pads and cell phone networks. They report status -- location to speed to altitude to power level. • Drones get new capabilities. Rapid swap batteries and wireless recharging capabilities. • Drone payloads get modularized. Standard packaging metrics and weights. • Dronet gets more detailed and real-time in its coverage of landing pad and drone activity. • People write apps that allow people to coordinate drone flights and performance metrics. Small companies and coops (like the micro ISPs that we saw in the mid 90's) that provide drone landing pads and drone connectivity emerge everywhere simultaneously. They offer drone pick ups and move quickly to adopt new standards as they emerge. Soon thereafter, controls engineers jump in with a drone routing protocol based on some earlier work for a different purpose. That bare bones protocol serves as a way to route drones from point to point and across multiple hops based on real-time status data. The Dronet coops and companies begin to peer with each other, and work on establishing multi-hop systems. The local networks that grow the fastest are the ones that make easy for people to buy a pad and connect to the emerging network. rick.dove@stevens.edu, attributed copies permitted 2:3 Drone Net References An internet of airborne things. The Economist, Technology Quarterly: Q4 2012. www.economist.com/news/technology-quarterly/21567193-networking-enthusiasts-dream-building-drone-powered-internet-carry-objects An Open Drone Network vs. Closed Logistics Network. John Robb Blog, 3Jan2013 http://feedproxy.google.com/~r/typepad/rzYD/~3/mxLvBfCUJ8M/an-open-drone-network-vs-closed-logistics-networks.html What a Dronet (a more compressed spelling) Can Leverage. John Robb Blog, 3Jan2013 http://feedproxy.google.com/~r/typepad/rzYD/~3/-JajzPnlw8c/what-a-dronet-a-more-compressed-spelling-can-leverage-.html DRONET How to Build It. John Robb Blog, 4Jan2013 http://feedproxy.google.com/~r/typepad/rzYD/~3/S8WrTS4h2c4/dronenet-how-to-build-it.htm l How to Roll Out Dronet. John Robb Blog, 6Jan2013 http://feedproxy.google.com/~r/typepad/rzYD/~3/e4j-9ASyHY4/how-to-roll-out-dronenet-1.html rick.dove@stevens.edu, attributed copies permitted 2:4 Amazon unveils futuristic plan: Delivery by drone http://www.cbsnews.com/news/amazon-unveils-futuristic-plan-delivery-by-drone/ Amazon's secret R&D project aimed at delivering packages to your doorstep by "octocopter" mini-drones with a mere 30-minute delivery time Amazon CEO Jeff Bezos had a big surprise for correspondent Charlie Rose this week. After their 60 Minutes interview, Bezos walked Rose into a mystery room at the Amazon offices and revealed a secret R&D project: “Octocopter” drones that will fly packages directly to your doorstep in 30 minutes. It’s an audacious plan that Bezos says requires more safety testing and FAA approvals, but he estimates that delivery-by-drone, called Amazon “Prime Air,” will be available to customers in as soon as 4-5 years. The story had been in the works for months before the Amazon representatives started hinting that a new project might be revealed to 60 Minutes. “I only knew that there was a surprise coming. I had no idea what it was,” says 60 Minutes producer Draggan Mihailovich. “They kept saying over and over again, ‘Whatever you think it is, it isn't.’” Mihailovich grew skeptical when the Amazon PR team began to hype their surprise behind the scenes. “How great can this be?” he thought. When Rose, Mihailovich, and Sommer finally saw the drones, they were perplexed. Then Bezos played a Prime Air demo video for the 60 Minutes team that showed how his octocopters will pick up packages in small yellow buckets at Amazon’s fulfillment centers and whiz through the air to deliver items to individual customers 30 minutes after they hit the “buy” button online at Amazon.com. rick.dove@stevens.edu, attributed copies permitted 2:5 December 02, 2013 DHL Tests Drug-Delivery http://news.dice.com/2013/12/10/amazon-lags-uav-race-as-dhl-tests-drug-delivery-drone/ Dec 10, 2013, Kevin Fogerty: Amazon is apparently not alone in its desire to use miniature drones to deliver packages. On the morning of Monday, Dec. 9, employees at the Bonn, Germany headquarters of package-delivery giant DHL challenged Amazon’s dominance of the skies by having medicine delivered from a local pharmacy via a mustard-yellow package-carrying helicopter the Germans dubbed “Paketkopter.” The quad-rotored mini-drone – painted with the carrier’s logo on its trademark background of mustard-yellow – flew a box of medicines from a launching point near the pharmacy, above traffic and across the Rhine River to DHL’s headquarters just over a kilometer away. It made the flight in about two minutes, was unloaded quickly and returned to the launch team near the pharmacy. It made the trip a total of five times Monday but will keep flying all week (Here’s the video). This first phase of DHL’s experiment with drone delivery is more than a one-time demonstration; the company is considering a same-day delivery service that would small, time-sensitive packages of up to 6.6 pounds, but has no immediate plans to put it into effect, according to a DHL spokesperson quoted in The Wall Street Journal. Amazon has owned total mindshare of the still-imaginary drone-based package delivery market since CEO Jeff Bezos gushed about his plans for Amazon PrimeAir during a TV interview last week. The plan generated immediate controversy due to the negative image of drones following heavy use for surveillance and targeted anti-personnel strikes by the U.S. military in Afghanistan and Iraq. Within the United States, the FAA, FTC and a host of consumer-protection groups objected to the possibility that thousands of autonomous drones would be hovering over U.S. cities, potentially invading the privacy and endangering the lives of those who might run afoul of either cameras or rotors. Autonomous drones are virtually banned in the U.S. due to FAA concerns they would interfere with airline traffic. In Germany, drones can’t take off or land in populated areas, have to be remote controlled rather than fly on their own using GPS, and can’t fly higher than 50 feet above the ground – meaning any battle for package-carrier air superiority will be fought out in easy view of potential customers and victims. DHL may eventually offer drone deliveries, but is using the special pharmacy deliveries to employees as a pilot test, according to Deutsche Post spokeswoman Dunja Kuhlmann. Bezos predicted Amazon could be flying packages within four or five years. No actual Amazon drones have yet made an appearance, giving DHL a lead in the market simply by having a working drone and processes in place to order and deliver products using it, even while downplaying the whole idea. “Our plans are in the early stages and there are a number of scenarios we’re evaluating, including delivering medicine that’s needed quickly, or to hard-to-reach places,” Kuhlmann told the Journal. U.S.-based delivery service United Parcel Service (UPS) is also considering deliveries via drone, which it revealed a day after Bezos’ revelation about Amazon PrimeAir. Though the company offered no details, or even much confirmation, a spokesperson made a point of saying UPS “invests more in technology than any other company in the delivery business, and we’re always planning for the future,” according to a Dec. 3 Engadget story, which also pointed out UPS already offers edgy services, including 3D printing from some of its retail locations. rick.dove@stevens.edu, attributed copies permitted 2:6 File 1.25 DHL drone will make deliveries to German island starting 26-Sep-2014 Regular 7.5 mile delivery to island. 2.6 pounds www.theverge.com/2014/9/24/6838443/dhl-drone-making-deliveries-to-german-island-juist DHL will use drones to deliver medical supplies to a small German island. The company's quad-rotor "parcelcopter" will transport packages to the island of Juist, home to between 1,500 and 1,700 people, and DHL claims this marks the first unmanned drone delivery service to launch in Europe. Flights will occur daily through October; Reuters says the drone will make trips when ferries and flights — the typical methods of traveling to Juist — aren't running. DHL will be keeping tabs on the parcelcopter's travels, but the drone will operate entirely on autopilot for the actual fights, which should take between 15 and 30 minutes in each direction. DHL's drone can't fly over any houses, which should avoid complaints from Juist's privacy-minded inhabitants. And if the test program goes well, DHL says it could use the parcelcopter to make urgent deliveries to other areas that are "geographically difficult to access," though it's not committing to any grand plans on the same level as Amazon's. see: https://www.facebook.com/Dronenet rick.dove@stevens.edu, attributed copies permitted 2:7 Robots in Google Car deliver a doorstep package? 4-Dec-2013. Google Puts Money on Robots, Using the Man Behind Android www.nytimes.com/2013/12/04/technology/google-puts-money-on-robots-using-the-man-behind-android.html If Amazon can imagine delivering books by drones, is it too much to think that Google might be planning to one day have one of the robots hop off an automated Google Car and race to your doorstep to deliver a package? Google executives acknowledge that robotic vision is a “moonshot.” But it appears to be more realistic than Amazon’s proposed drone delivery service, which Jeff Bezos, Amazon’s chief executive, revealed in a television interview the evening before one of the biggest online shopping days of the year. While Google has not detailed its long-term robotics plans, Mr. Rubin said that there were both manufacturing and logistics markets that were not being served by today’s robotic technologies, and that they were clear opportunities. This is not the first time that Google has strayed beyond the typical confines of a tech company. It has already shaken up the world’s automobile companies with its robot car project. Google has not yet publicly stated whether it intends to sell its own vehicles or become a supplier to other manufacturers. Speculation about Google’s intentions has stretched from fleets of robotic taxis moving people in urban areas to automated delivery systems. Andy Rubin is the engineer heading Google’s robotics effort. He is the man who built the Android software for smartphones. Drone Net: Class 1 Agile System. Google: Class 2 Agile System rick.dove@stevens.edu, attributed copies permitted 2:8 Human Truck Driver, Robot Doorstep Delivery http://spectrum.ieee.org/automaton/robotics/aerial-robots/amp-electric-truck-delivery-drones/ Evan Ackerman, 24 Feb 2015 IEEE Spectrum Amp Holdings is a company that’s making a hybrid electric delivery truck that costs delivery companies 30 cents per mile to operate, as opposed to the dollar per mile that diesel trucks cost. That sounds like it’s a thing that’s worth buying all by itself, but Amp also wants to integrate a delivery drone (called a HorseFly) into each truck to make short deliveries semi-autonomously. So, is using a truck as a base the way to make delivery drones work? Amp’s HorseFly drone system has two primary differentiators to other drone delivery concepts. First, it plans to use the trucks as mobile launch and recharging bases to bring the drones (and packages) closer to their destinations, allowing each drone to carry significantly more over a shorter distance, up to 20 pounds (9 kilograms). Second, Amp says that they’re going to deal with the biggest issue—the last few dozen meters or so—by letting remote human pilots take over for the final portion of the flight. According to Amp, this system would be safer and more efficient than Amazon’s proposed autonomous warehouse-based drones. … [much more said] … I’m going to end this curmugeonly drone delivery article the same way I end all of my curmogeonly drone delivery articles: I would absolutely love to be proven wrong. There are drone delivery scenarios that make sense, and work. What we need are more of those—more real and practical solutions—and less hype. See: http://spectrum.ieee.org/automaton/robotics/aerial-robots/when-drone-delivery-makes-sense rick.dove@stevens.edu, attributed copies permitted 2:9 Reality Just drive the package to the address. That “last mile” of robotic delivery to the doorstep is neither cost effective nor necessary. The $70 Egg Tray and the Last Inch of Convenience 01Dec2013. John Robb. www.homefreeamerica.us/the-70-egg-tray-and-the-last-inch-of-convenience We’re on the brink of an explosion in home automation. All of the technologies that make it possible are moving forward at light speed now. How will it arrive? It won’t be: automation that solves the last inch of convenience. For example, here’s a smart egg tray built by the company Quirky. This egg tray actively measures the weight of each egg it holds, to find rotten eggs. When it finds a rotten egg, it sends an alert to your iPhone. The big problem with this is conceptual. It’s a product that automates convenience. The problem is that we are already very comfortable and the extra inch of convenience it offers the buyer is so small, it’s not worth even a dollar or two more than a standard egg tray. Quirky isn’t alone in that. The same conceptual problem is true with nearly every other form of home automation I’ve reviewed recently. We don’t have a problem with convenience. rick.dove@stevens.edu, attributed copies permitted 2:10 Increasing Gap Between Need and Capability situation complexity cut-over capability complexity requirements requirements develop established established for gen n+1 for gen n+2 system generation n over designed initially system generation n+1 never quite good enough sys gen n+2 effectiveness gap ROI failure Time rick.dove@stevens.edu, attributed copies permitted 2:11 Defining Agility and Migration Using the term as intended in the 1991 OSD funded Lehigh study and subsequent research: Agility is effective response under conditions of uncertainty There are at least three components to agility: situational awareness, decisive choice making and the ability to respond The latter aspect is what we deal with here Migration is the crossing of a change in basic infrastructure, be it technical, organizational or strategic. rick.dove@stevens.edu, attributed copies permitted 2:12 Contemporary Context Next-generation challenges are demanding new architectures… Force Transformation is the U.S. military’s response to next-generation warfare Service Oriented Architectures is Enterprise response to next-generation competition Significant in both is the objective of a change that enables future change Instead of perpetuating the scrap and replace cycle, an architecture is envisioned that facilitates migration through successive next generations rick.dove@stevens.edu, attributed copies permitted 2:13 Objective: System X-Ray Vision (the underlying architecture) http://awespendo.us/animemangacomics/kermit-at-the-doctor/ rick.dove@stevens.edu, attributed copies permitted 2:14 “On How Agile Systems Gracefully Migrate Across Next-Generation Life Cycle Boundaries” www.parshift.com/Files/PsiDocs/Pap080614GloGift08-LifeCycleMigration.pdf Case: Home Entertainment Technology Migration agile architecture pattern: drag-and-drop, plug-and-play Encapsulated Modules amplifiers speakers signal tuners playback units video displays content sources (tape, CD, DVD) ) (TV, computer) Drag-and-Drop Reusable Components (TIVO,P2P) rick.dove@stevens.edu, attributed copies permitted 2:15 “On How Agile Systems Gracefully Migrate Across Next-Generation Life Cycle Boundaries” www.parshift.com/Files/PsiDocs/Pap080614GloGift08-LifeCycleMigration.pdf Case: Home Entertainment Technology Migration agile architecture pattern: drag-and-drop, plug-and-play Encapsulated Modules amplifiers speakers signal tuners playback units video displays content sources (tape, CD, DVD) ) (TV, computer) Drag-and-Drop Reusable Components (TIVO,P2P) Examples of Typical Reconfigurable/Scalable System Configurations Audio tape Video media rick.dove@stevens.edu, attributed copies permitted Net in/out 2:16 “On How Agile Systems Gracefully Migrate Across Next-Generation Life Cycle Boundaries” www.parshift.com/Files/PsiDocs/Pap080614GloGift08-LifeCycleMigration.pdf Case: Home Entertainment Technology Migration agile architecture pattern: drag-and-drop, plug-and-play Encapsulated Modules amplifiers speakers signal tuners playback units video displays content sources (tape, CD, DVD) ) (TV, computer) Drag-and-Drop Reusable Components (TIVO,P2P) Examples of Typical Reconfigurable/Scalable System Configurations Audio tape Video media Net in/out Video/Surround Digital/Internet ‘40s/’50s ‘90s rick.dove@stevens.edu, attributed copies permitted Plug-and-Play Evolving Passive Infrastructure Rules/Standards/Principles ‘00s 2:17 “On How Agile Systems Gracefully Migrate Across Next-Generation Life Cycle Boundaries” www.parshift.com/Files/PsiDocs/Pap080614GloGift08-LifeCycleMigration.pdf Case: Home Entertainment Technology Migration agile architecture pattern: drag-and-drop, plug-and-play Encapsulated Modules amplifiers speakers signal tuners playback units video displays content sources (tape, CD, DVD) ) Assembly (TV, computer) Drag-and-Drop Reusable Components (TIVO,P2P) Plug-and-Play Evolving Active Infrastructure Responsible-Parties User/Owner Examples of Typical Reconfigurable/Scalable System Configurations Audio tape Video media Net in/out Video/Surround Digital/Internet ‘40s/’50s ‘90s rick.dove@stevens.edu, attributed copies permitted Plug-and-Play Evolving Passive Infrastructure Rules/Standards/Principles ‘00s 2:18 “On How Agile Systems Gracefully Migrate Across Next-Generation Life Cycle Boundaries” www.parshift.com/Files/PsiDocs/Pap080614GloGift08-LifeCycleMigration.pdf Case: Home Entertainment Technology Migration agile architecture pattern: drag-and-drop, plug-and-play Encapsulated Modules amplifiers speakers signal tuners playback units video displays content sources (tape, CD, DVD) ) Readiness Stores Assembly User/Owner (TV, computer) Drag-and-Drop Reusable Components (TIVO,P2P) Plug-and-Play Evolving Active Infrastructure Responsible-Parties Examples of Typical Reconfigurable/Scalable System Configurations Audio tape Video media Net in/out Video/Surround Digital/Internet ‘40s/’50s ‘90s rick.dove@stevens.edu, attributed copies permitted Plug-and-Play Evolving Passive Infrastructure Rules/Standards/Principles ‘00s 2:19 “On How Agile Systems Gracefully Migrate Across Next-Generation Life Cycle Boundaries” www.parshift.com/Files/PsiDocs/Pap080614GloGift08-LifeCycleMigration.pdf Case: Home Entertainment Technology Migration agile architecture pattern: drag-and-drop, plug-and-play Encapsulated Modules amplifiers speakers signal tuners playback units video displays content sources (tape, CD, DVD) ) Module Evolution Mfgrs Readiness Stores Assembly User/Owner (TV, computer) Drag-and-Drop Reusable Components (TIVO,P2P) Plug-and-Play Evolving Active Infrastructure Responsible-Parties Examples of Typical Reconfigurable/Scalable System Configurations Audio tape Video media Net in/out Video/Surround Digital/Internet ‘40s/’50s ‘90s rick.dove@stevens.edu, attributed copies permitted Plug-and-Play Evolving Passive Infrastructure Rules/Standards/Principles ‘00s 2:20 “On How Agile Systems Gracefully Migrate Across Next-Generation Life Cycle Boundaries” www.parshift.com/Files/PsiDocs/Pap080614GloGift08-LifeCycleMigration.pdf Case: Home Entertainment Technology Migration agile architecture pattern: drag-and-drop, plug-and-play Encapsulated Modules amplifiers speakers signal tuners playback units video displays content sources (tape, CD, DVD) ) Module Evolution Mfgrs Readiness Stores Assembly Infrastructure Evolution User/Owner (TV, computer) Drag-and-Drop Reusable Components (TIVO,P2P) Plug-and-Play Evolving Active Infrastructure Responsible-Parties Industry Assocs Examples of Typical Reconfigurable/Scalable System Configurations Audio tape Video media Net in/out Video/Surround Digital/Internet ‘40s/’50s ‘90s rick.dove@stevens.edu, attributed copies permitted Plug-and-Play Evolving Passive Infrastructure Rules/Standards/Principles ‘00s 2:21 (Dove 2009) On How Agile Systems Gracefully Migrate Across Next-Generation Life Cycle Boundaries Crossing Next-Generation Life Cycle Boundaries for Internet Protocol Migration Modules Integrity Management routers switches DNS Servers Component evolution: Vendor Community Component readiness: Vendor Community System assembly: Subnet Owners Infrastructure evolution: filters appliances end points, (eg IDS, Firewall) (eg, xml) NICs, NOMs Int. Eng. Task Force Active Infrastructure Passive IPv4 era NCP era IPv6 era NCP Wire standards TCP/IPv4 Wireless stds Rules/Standards rough operational start… ’70s ’80s/’90s rick.dove@stevens.edu, attributed copies permitted Optical stds IPv6 ’00/’10s 2:22 Fundamental Concept Reusable modules Reconfigurable in a Scalable architecture (RRS) agile architecture pattern: drag-and-drop, plug-and-play Encapsulated Modules type C type B type A Module Evolution Who? Readiness Who? Assembly Infrastructure Evolution Who? type D ....... type n Drag-and-Drop Reusable Components Plug-and-Play Evolving Active Infrastructure Responsible-Parties Who? Examples of Typical Reconfigurable/Scalable System Configurations Type 1 Type 2 Type 3 Generation 2 Generation 3 Plug-and-Play Evolving Passive Infrastructure Rules/Standards/Principles Type 1-2-3 examples depict a range of different system-assembly possibilities rick.dove@stevens.edu, attributed copies permitted 2:23 Who/What is Accountable Sustainability & Effectiveness The “active” parts of the infrastructure Module Mix Evolution: • Who (or what process) is responsible for ensuring that existing modules are upgraded, new modules are added, and inadequate modules are removed, in time to satisfy response needs? Module Readiness : • Who (or what process) is responsible for ensuring that sufficient modules are ready for deployment at unpredictable times? System Assembly/Reconfiguration: • Who (or what process) assembles new system configurations when new situations require something different in capability? Infrastructure Evolution: • Who (or what process) is responsible for evolving the passive and active infrastructures as new rules and standards become appropriate to enable next generation capability. The “passive” parts of the infrastructure are the interoperability standards rick.dove@stevens.edu, attributed copies permitted 2:24 System X-Ray Vision The bones are depicted in the Agile Architecture Pattern. All truly agile systems have the same basic structure and strategy. Knowing this will change the way you “see” and evaluate a system. http://awespendo.us/animemangacomics/kermit-at-the-doctor/ rick.dove@stevens.edu, attributed copies permitted 2:25 Football Agile Architecture Pattern (AAP) Drag-and-drop modules in a plug-and-play infrastructure Details in www.parshift.com/s/140630IS14-AgileSystemsEngineering-Part1&2.pdf Modules Defense Players Coaches Module mix evolution Special Teams Scouts Medics/Therapists TT--T ZZZ---ZZZ S---S M---M Coaches, Owner, Scouts Trainers, Coaches, Medics System assembly QB, Def/Off Coaches Infrastructure evolution NFL and Owner O O O O O O Tak Grd Ctr Grd Tak Tnd Infrastructure O Wide Rec O QB O F/R Bk O H/R Bk O Wide Rec C Passive X X X X X X X OLB End Tak MLB Tak End OLB X CB X CB X Saf X Saf C Offensive Down Sockets Signals Security Safety Service Plays Trainers Module readiness Active Game Plans OOO---OOO XXX---XXX C--CC Integrity Management Offense Players Defensive Down Z Z Z Z Z Z Z End Ubk Ubk Ctr Ubk Ubk End Z Z Wng Wng Z Pro Z C Pnt Special Teams Punt Positions Play Book, QB Calls Covert Communications Protective Equipment NFL Rules, Team Culture Rules/Standards rick.dove@stevens.edu, attributed copies permitted 2:26 Here’s a Box of Bones rick.dove@stevens.edu, attributed copies permitted 2:27 Agile Architecture Pattern (AAP) Notional Concept: System Response-Construction Kit Details in www.parshift.com/s/140630IS14-AgileSystemsEngineering-Part1&2.pdf Modules/Components Integrity Management Module mix evolution Gears/Pulleys Motors Wheels Structural Material Product System Eng. Module readiness Retail Distribution Process System assembly Owner/Builder Infrastructure evolution Tools Joiners, Axles, Small Parts Product Manager Active Infrastructure Passive Helicopter Plane Sockets Signals Security Safety Service Rules/Standards Parts Interconnect Standards Stability, eventually radio control (None) Harm-Proofing Standards Process Rules & ConOps Mobile Radar Radio Control rick.dove@stevens.edu, attributed copies permitted 2:28 Straws and Connectors Bendables Design the Architecture of Your Construction Set Marble Run Snap Blocks Log Builder Tinker Toy Woodbuilders Lego Bristle Blocks Erector Set Construction (response) architecture different from system functional architecture. Response architecture is a domain-focused engineering architecture rick.dove@stevens.edu, attributed copies permitted 2:29 Perceived Effectiveness 100% Relating Agile Development to Agile Operations www.parshift.com/Files/PsiDocs/Pap080404Cser2008DevOpsMigration.pdf In-agile system Development Operation Development Time Delivery Agile system would continue ROI, but does age, and can suffer strategy-lapse integrity failure life-cycle end Agile Systems Gracefully Migrate Across Next-Generation Boundaries www.parshift.com/Files/PsiDocs/Pap080614GloGift08-LifeCycleMigration.pdf Module Mix Modifications Perceived Effectiveness 100% Infrastructure Migration agile system Development Gen 1 Operation Time Delivery rick.dove@stevens.edu, attributed copies permitted Gen 2 Operation 2:30 In-Class Tool Applications Class Warm-ups Team Trials Team Project Unit 2 AAP Analysis: Case ConOps: Objectives Unit 3 RS Analysis: Case Reactive/Proactive Unit 4 Unit 5 RS Analysis RRS Analysis: Case Unit 6 Unit 7 Unit 8 RS Analysis Framework/Modules RRS Analysis Reality Factors: Case RRS + Integrity Reality + Activities Integrity Closure Unit 9 Unit 10 rick.dove@stevens.edu, attributed copies permitted 2:31 Three Nested Agile Systems NFL Team Augment? Correct? Game • Teams Encapsulated • Conferences Modules • Divisions • Offensive players • Defensive players • Sp Teams players • Player lineup • Referees • Plays • Schedules Passive • Contracts Infrastructure • Salary cap • Play book • Code of conduct • Uniform • Rules • Game plan • League • Gen mgr • Coaching staff • League • Scouts • Medical staff • Owners • Owners • Head coach • Owner • Rules committee Module Evolution Module Readiness System Assembly Infrastructure • Owners Evolution Composite from multiple classes rick.dove@stevens.edu, attributed copies permitted 2:32 Last Planner Agile Project Management IS13 Presentation Case Study www.parshift.com/s/130624Last Planner.pdf Active management of the anticipated schedule and work flow to ensure there is always a buffer of “quality” jobs ready to work on and matched with resources. production master Components units sched Integrity Management CPM tasks activity definitions Task elements: Project Manager Task readiness: Supes/Foremen/Expediters Task assembly: tools materials Key Practices: Rules 1-2-3 and •Lookahead •Make ready •Learn & Correct Supes/Foreman Infrastructure evolution: equipment Last Planner Process Manager week week week week week week Active 6 5 4 3 2 1 Infrastructure Passive Task Lookahead Window Sockets Signals Security Safety Service Standards Task Backlog Buffer Work Task Task Soundness/Sequence/Size Task Definitions Physical Site Security Construction Safety Standards/Regs Master Sched, Learning, R1-2-3 MS Learning Agile architecture Pattern based on: (Ballard 1997) Lookahead Planning: the Missing Link in Production Control (Ballard 1998) Shielding Production: an Essential Step in Production Control (Ballard 1999) Improving Work Flow Reliability (Ballard 2000) The Last Planner System of Production Control-PhD Thesis rick.dove@stevens.edu, attributed copies permitted Change 2:33 Problem Space and Solution Space Agile Architecture Pattern as framework 4 response effectiveness metrics 8 reactive and proactive response domains 10 response enabling design principles 3 design quality principles Strategy activity diagrams Systems operational and integrity management Closure matrix rick.dove@stevens.edu, attributed copies permitted 2:34 Basic Definitions System A group of modules Stereo System of Components sharing a common interaction framework Company of Divisions and serving a common purpose. Framework Chain of Suppliers A set of standards constraining and enabling the interactions of compatible system modules. Practice of Procedures Module A separable system sub-unit Cell of Workstations with a self-contained capability/purpose/identity, Team of People and capable of interaction with other modules. The reconfigurability of component systems is familiar to us from the ease with which we can add, change, or upgrade units in our home stereo and entertainment centers, even when different brand names are involved. We call any organization of common-purpose interacting modules a “system”: an entertainment center of components, a team of people, a cell of workstations, a network of controllers, a chain of suppliers, a corporation of functional departments, even a contract of clauses. rick.dove@stevens.edu, attributed copies permitted 2:35 Modular – But Not Agile Art: KPMG rick.dove@stevens.edu, attributed copies permitted 2:36 Cluster Machine Depiction of Precision 5000 Family from Applied Materials Inc. Reusable Material interfaces, transfer robots, process modules, utility bases, docking modules, and user controls are independent units. Common human, mechanical, electrical, gas, and hydraulic framework. A growing variety of processing modules may be mixed or matched within a cluster. Reconfigurable Wafer path determined in real-time by availability of appropriate process modules. New process modules may be added when new capability is required, and not before. Clusters may begin as 4 sequential processes and evolve to a single 4-unit process as product demand grows. Process-specific control is contained within the process module, traveling with it when redeployed. User control modules are custom configurable for proprietary processing. Scalable Within a cluster 1 to 4 process modules may be installed. Clusters may be interconnected into larger superclusters using docking modules in place of process modules. Clusters and super-clusters can be interconnected without limit. Material Interface Module Robotic Transfer Arm Variety of Process Modules Common Utility Base Customizable User Control Response Ability Test & Introduce new process modules incrementally. Custom process individual wafers and prototype runs. Repair/replace faulty module while cluster operates. Add modules and machine clusters as/when needed. Reconfigure clusters and redeploy process modules as product-line demand cycle changes. Create super-clusters as contaminant sensitivity requires. rick.dove@stevens.edu, attributed copies permitted 2:37 Scalable Machine Clusters Clean-Environment Inter-Cluster Transport Bay Interface Module Process Module Docking Module Transfer Module Using standardized docking modules to replace a process module allows multiple cluster machines to be assembled into larger, constant vacuum, clusters. This has particular value when a process sequence is sensitive to contamination, which is most likely to occur when wafers make the transition between the vacuum environment of the cluster machines and the atmospheric pressure of the inter-cluster transport bay. Process modules may be mixed or matched within a cluster. rick.dove@stevens.edu, attributed copies permitted 2:38 Production Cell Reusable Machines, work setting stations, pallet changers, fixtures are all standard, independent units. Common human, mechanical, electrical, and coolant framework. Machines do not require excavated pits or special foundations, and are relatively light and easy to move from one cell to another. Reconfigurable Cell control dynamically changes work routing as machines are removed or added, on the fly. Autonomous part machining, non-sequential. Machines and material scheduled by cell control software in real time per current cell status. Part programs downloaded when needed. Machine’s history stays with its controller. Machines ask for appropriate work when ready. Scalable Cell may have any number of machines and up to four work setting stations. Cells may have multiple unit instances in operation. Machines capable of duplicate work functionality. Utility services and vehicle tracks can be extended without restrictions imposed by the cell or its units. A1 A3 A5 A7 A2 A4 A6 A8 WSS WSS Concept Based on LeBlond Makino A55 Cells at Kelsey-Hayes Response Ability Install and set up a new cell in 4-8 weeks. Reconfigure a cell for entirely new part in 1-4 weeks. Duplicate cell functionality in another cell in 1-2 days. Add/calibrate machine in 1-2 days while cell operates. Remove or service machine without cell disruption. JIT part program download. Insert prototypes seamlessly. rick.dove@stevens.edu, attributed copies permitted 2:39 Production Cells in a Reconfigurable Environment Cell 1 A6 Cell 2 A5 A4 A3 A2 A1 LeBlond Makino A55s Cell 3 B6 B5 B4 B3 B2 C3 Work Setup Stations B1 C2 C1 WSS WSS WSS WSS WSS WSS WSS WSS WSS WSS WSS WSS D2 D1 E2 E1 D4 D3 E4 E6 Cell 4 AGV (This central AGV line not actually present in Kelsey Hayse plants) F2 F1 E3 F4 F3 E5 F6 F5 Cell 5 Cell 6 These horizontal machining centers do not require that pits be dug underneath the machines for delivery of cooling fluids and removal of scrap, or that special rigid foundations be constructed, so they are readily movable. A cell can increase or decrease its machining capacity in the space of a day. This is facilitated by a plant infrastructure that provides common utility, coolant, mechanical, and human interfaces that provide a framework for reconfiguring modules easily. rick.dove@stevens.edu, attributed copies permitted 2:40 Configurable Resources Reusable Design Individual in/outsource resources are configured on a bid-per-order basis. .. Order fulfillment configurations are bid . and assembled by Hong Kong group. Common network interface at each Design resource provides enterprise integration and real-time management. Can be relocated as resources come and go. Insource Network-accessible production data can Outsource be downloaded to multiple locations Reconfigurable Common resource interface and realtime order process status enables midorder reconfiguration of prod. chain. Insource and outsource resources are interchangeable for equivalent processing technology. Scalable No limits on the number or mix of insource and outsource resources. Hong Kong management group qualifies new and existing resources as needed to maintain sufficient resource pool. Wafer Process Test and Sort .. . .. . Wafer Process Test and Sort Design Wafer Process Test and Sort Dice Lead and Package .. . .. . .. . .. . .. . Design Wafer Process Test and Sort Dice Lead and Package Modeled After LSI Logic (1998) A Semiconductor Foundry Loosely coupled resources bid for order-fulfillment role on a per-order basis. Response Ability Production chain assembled, scheduled, working within 24 hours. Resources added any time for extra capacity or quicker fulfillment. Real-time status & issue-resolution for quick problem correction. Net-wide data enables coordinated system-wide order changes. LSI had practices to nurture and manage a loosely coupled mixture of in- and outsources as a coherent entity. The management operational center was in Hong Kong, which built and maintained the pool of outsources, and configured all resources for specific customer orders. Resources bid on jobs - with price and schedule. A production resource path was then assembled from the best bids. Insources were not given preferred status. rick.dove@stevens.edu, attributed copies permitted 2:41 Reusable Modules Reconfigurable within a Scalable Framework Applied’s Machines Components Physics Units Robotic Transfer User Controls Framework Standardized Utility Base Kelsey-Hayes’ Cells Components Machines Setup Stations Pallet Changers LSI’s Production Chains Components In-side Resources Out-side Resources Partner Interfaces Resource Management Activities Module Mgmnt Framework Mgmnt Inventory Mgmnt Response Mgmnt Framework Framework AGV Network Grid Enterprise Network Cell Layout Standards Qualification Standards Common Machines Module Pool Framework High Concept: Agility is Deployed as an Assembly-Line Process www.parshift.com/Essays/essay005.htm rick.dove@stevens.edu, attributed copies permitted 2:42 Agile Data-Center Location, Capability, Capacity Drag and Drop Modules Type A Seattle Type A Type B Type B Type B Type B Denver New Orleans Type C Type C (Classified) Type B New York Air standards Water stds Power stds Network stds Plug and Play Infrastructure Following SUN’s Black Box…Rackable’s Concentro – A modern data center that breaks records for density and energy efficiency, problems that keep CIOs up at night: running out of floor space and operating budget (sky-high power bills to run all the gear AND cool it). Rather than spend three years building massive new buildings and hiring armies of techies to buy, install and operate gear from scads of different tech suppliers, companies (or Universities, or Army divisions) could simply roll a Concentro into the parking lot. And when the innards become obsolete, it could literally be driven to a recycling center and dis-assembled for parts. [Edited excerpt: “Rackable Goes Mobile. Does Two Make a Trend?” Peter Burrows, Business Week, March 26, 2007] rick.dove@stevens.edu, attributed copies permitted 2:43 Frameworks/Infrastructures: Three construction system types Chaordic1 Ordered Lego Lego Lego Model Lego Glue Chaotic Lego Erector Set 1 Dee Hock (Visa Corp) coined the word chaord for organisms, organizations, and systems which harmoniously exhibit characteristics of both order and chaos. rick.dove@stevens.edu, attributed copies permitted 2:44 Response Able System Principles – RRS Evolving Infrastructure Standards Reusable Facilitated Interfacing (Pluggable) Scalable Encapsulated Modules Redundancy and Diversity Elastic Capacity Facilitated Reuse Reconfigurable Peer-Peer Interaction Distributed Control and Information Deferred Commitment Self-Organization rick.dove@stevens.edu, attributed copies permitted 2:45 8 Response-Requirement Domains for Response Situation Analysis (RSA) General Characteristic Change Domain Improvement Migration Modification (of Capability) Reactive Correction Variation Proactive Innovative/Composable Creates Opportunity Takes Preemptive Initiative Proactive Proficiency Proactive Creation (and Elimination) Innovative (Composable) Agile Fragile Resilient Reactive Proficiency Reactive Expansion (of Capacity) Reconfiguration rick.dove@stevens.edu, attributed copies permitted Resilient Seizes Opportunity Copes with Adverse Events 2:46 Change Metrics Time Cost $ $ $ $ Elapsed Time $ Time Cost Total Cost $ Activity Based Change-Costing Bad 100% Quality Scope 0% Latitude OK Stretch Good Range Mission Boundary OK Stretch On-Time, On-Budget, On-Spec Response Process Quality Sufficient Economic Range? Predictability Scope rick.dove@stevens.edu, attributed copies permitted 2:47 Concepts That Enable Agility 678 Focus Agility consists of practices and processes for Knowledge Management to have awareness Value Propositioning to select actions System Response Architecture Change Management Change Proficiency to take action molded by language of with Reusable Reconfigurable principles of Modularity Facilitated Reuse Plug Compatibility principles of Flat Interaction Scalable principles of Evolving Framework Deferred Commitment Self Organization Distributed Cont & Info Response Ability to enable change with Redundancy & Diversity Elastic Capacity Change Metrics with domains of Time ProActive Change with domains of Creation Cost Improvement Quality Scope rick.dove@stevens.edu, attributed copies permitted Migration ReActive Change with domains of Correction Variation Expansion Modification Reconfiguration 2:48 Porter on Strategy "What is Strategy?", Michael Porter, Harvard Business Review, Nov-Dec '96 All differences in cost or price derive from hundreds of activities required to create, produce, sell, and deliver. Activities are the basic units of competitive advantage. Overall advantage or disadvantage results from all of a company’s activities, not only a few. Strategic positioning means performing different activities from rivals’ or performing similar activities in different ways. rick.dove@stevens.edu, attributed copies permitted 2:49 Southwest Airlines (Concept of Operations) Strategic Objectives Key Activities No meals Limited Passenger Service No baggage transfers No seat assignments Frequent, Reliable Departures High employee pay Flexible union contract 15 minute gate turnaround Lean, Highly Productive Ground and Gate Crews High employee stock ownership Limited use of travel agents No connections with other airlines Standard 737 fleet Automatic ticketing machines Short Haul Point-to-Point Mid-sized Cities Secondary Airports Very Low Ticket Prices High Aircraft Utilization rick.dove@stevens.edu, attributed copies permitted "Southwest the low-fare airline" 2:50 Semiconductor Foundry Cultural Engineering Mgmnt “Strategy” strength comes from activity interaction Lines show synergistic dependencies IT Infrastruct. Mgmnt IT Adaptation Mgmnt Service Interaction Mgmnt Strategy Devel'ment Mgmnt Talent Relationship Mgmnt Customer Satisfaction Mgmnt Strategy Delivery Mgmnt Leadership Service Agile Systems Mgmnt Customer Compatible Transparent Process Devel'ment Mgmnt Production Mastery Mgmnt Mix and Capacity Mgmnt Security Evolution Mgmnt - Strategic Objectives - Agile Activities – Initial - Agile Activities - Later Best Value Trustworthy Reliable Strategic Activity ConOps Web Inspired by Porter’s Activity Web Emphasizes Process Activity and Response Objectives rick.dove@stevens.edu, attributed copies permitted 2:51 Closure Matrix – Where Deep Design Begins Details: http://www.parshift.com/Essays/essay039.htm (Case: An Insight Development System) Reactive Proactive Issues (Requirements) Evolving Infrastructure Redundancy & Diversity Elastic Capacity Self Organization Distributed Control & Info Deferred Commitment Peer-Peer interaction Facilitated Re-Use 1 2 3 4 5 6 7 Facilitated Interfacing Establish personal values Analyze external case for ideas Analyze local case for principles Design a business practice Package as response ability models Rotate student / mentor roles Review and select for quality Encapsulated Modules Activities (Functions) RRS Principles Principle-Based Activities, and Issues Served Capturing hidden tacit knowledge Creating student interest and value Improving knowledge accuracy Improving knowledge effectiveness Migrating the knowledge focus Accommodating different student types Injecting fresh outside knowledge Finding and fixing incorrect knowledge Excising poor value knowledge Allowing flexible student schedules Accommodating any size group Reinterpret rules for new applications 3567 35 356 57 3 37 124 1 1 1 12 124 3 37 367 6 1245 45 245 45 247 27 4 2 (all) 25 6 26 26 26 367 7 7 3 2357 7 7 3 34 34 2345 2345 23457 27 6 124 6 1 4 7 247 347 2 12345 6 2 3 6 3 2 34 1 1 3 5 37 7 2 4 47 17 2 3 3 7 23 35 257 1 34 234 2 rick.dove@stevens.edu, attributed copies permitted 3 3 12 2 5 3 2 357 25 34 234 23457 2:52 Project Management A Product Management Innovative Agile Strategy Management A Innovative Agile B Fragile C B Fragile C Innovative Resilient Agile B C Resilient Fragile Resilient Comparing Companies A, B, C. A Assessment/Evaluation 4 Response Proficiency Maturity Model Reactive 3 Stages 2 1 0 0 1 2 Proactive 3 4 Metric Focus Working Knowledge Competitive Development Proactive Reactive 0 Accidental Pass/Fail Examples Lucky None 1 Repeatable Time Concepts Creation Correction 2 Defined Cost Metrics Improvement Variation 3 Managed Quality Rules Migration 4 Mastered Scope Principles Modification Reconfig'tion Expansion Maturity has been observed to progress sequentially rick.dove@stevens.edu, attributed copies permitted 2:53 BREAK rick.dove@stevens.edu, attributed copies permitted 2:54 Classic Case On-Demand Response GM after-market auto-body production. High variety – small lot. ~500 different metal body assemblies 250 units average production lot size 230 average pieces per hour 28 minute average die change $30 fender world market price Agile AUTOnomy Skateboard Architecture Case: GM+ Art: Boris Artzybasheff www.animationarchive.org/bio/2006/01/artzybasheff-boris.html interchangeable bodies, drive-by-wire, plug-and-play Fenders, Hoods, Lids, Sides, Doors Operations include: Press: die change, stamp Assembly: bend/form, weld, glue Maybe a hundred new assemblies per year rick.dove@stevens.edu, attributed copies permitted 2:55 JIT Assembly Systems (part 1 of 2) (t = time of change, c = cost of change, p = predictability of change, s = scope of change) Key Proactive Issues Key Reactive Issues Components Creation Weld Tips Roller Tables • Designing short-run assembly lines for new parts that come with long-run tooling [t] Improvement • Productivity of limited space while increasing part variety [s] Racks Hemmers Standing Platforms Controllers Production Team Members (PTMs) *Ctrl* Programs **** Mastic Tables ••• Variation Systems Integrity Management Module Evolution: Component team Module Readiness: Component team Assembly: Production teams Infrastructure Evolution: Configuration team P41 Deck Lid System • High part production variety [s] • Time available for new line design [t] • New parts to accommodate with the JIT system [s] * * Expansion • Production of non-GM parts with non-GM tooling [ps] Modification • Absorb employees from closed GM plants with different union work rules into cross-trained Production Team Member positions [ts] • Union refusals to accommodate necessary work rule changes [cs] Assem Areas System Examples Migration Correction • Absorb growing part variety [s] • Absorb growing inventory of tooling [s] • Area B A47 Fender System • Area A (Old-Form Agile Architecture Pattern) rick.dove@stevens.edu, attributed copies permitted Reconfiguration • Short-run assembly line construction/tear-down [t] 2:56 JIT Assembly Systems (part 2 of 2) Facilitated Interfacing (Pluggable) Everything carry/roll/fork portable, common piping/wiring, quick disconnect fittings, no integrated controllers, standard controller interface/programs. Unit Redundancy and Diversity 8 identical controllers, cross-trained production team, diversity in roller/mastic tables, weld guns, standing platforms, racks, weld tips, and assembly areas. Facilitated Reuse • Management and Union manage PTM cross-training • Component team manages all other components • Production teams manage system configurations Scalable Evolving Infrastructure Standards The framework configuration team eventually decided to strip un-used legacy items from hemmers, and to add TDA lifters to Area A utility grid. Reusable Encapsulated Modules • Hemmers • Racks • PTMs • Areas • Roller tables • Weld tips • Racks • Mastic tables • Controllers • Programs Elastic Capacity Frequently used components are pooled locally, with separate warehousing available for unlimited inventory growth and rarely used components. Reconfigurable Peer-Peer Interaction • PTMs free to make real time process changes • Communication encouraged among tradesmen, engineers, supervisors, and customers Distributed Control and Information • PTMs make real time decisions on process configuration improvements and changes. • Operation sequence sheet attached to hemmer Deferred Commitment • Assembly lines configured just-in-time for production • New-part acquisition/transfer team is not designated until a transfer opportunity requires an action. Self-Organization People take initiative in solving problems and making operating improvements – because risk is encouraged and failure expected/accepted. rick.dove@stevens.edu, attributed copies permitted 2:57 Class 1 Agile Systems are Reconfigurable Useful Metaphors: Plug-and-Play – Drag-and-Drop some we will look at Reconfigurable Machine Clusters Adaptable Production Cells Configurable Resources On-Demand Assembly Lines Data-Centers Anywhere Anytime Anykind Agile (Software) Development Processes … and many others rick.dove@stevens.edu, attributed copies permitted 2:58 Class Drag-and-Drop 1: Drag-and-Drop What Does Dragon Drop Mean? Case: Agile Aircraft Installation In real Realtime: Time: Something is available to drag and drop. Something accepts the things that are dropped. Somebody does the dragging and dropping and connecting. In all Some time: Other Time: Somebody maintains and improves the draggable things. Somebody maintains and improves the drag-and-drop capability Somebody maintains and improves the accepting infrastructure. rick.dove@stevens.edu, attributed copies permitted 2:59 We discussed the yellow boxes. All lectures will show what has been discussed like this. "When I am working on a problem, I never think about beauty, but when I have finished, if the solution is not Quality beautiful, Evaluation I know it is wrong." -- R. Buckminster Fuller RAP Tools & Process Projected Operational Story Closure Matrix Design Reality Factors Identified “Quality is practical, and factories and airlines and hospital labs must be practical. ConOps But it is also moral and aesthetic. Objectives And it is also perceptual and subjective.” & Activities -- Tom Peters rick.dove@stevens.edu, attributed copies permitted Architectural Concept & Integrity Response Situation Analysis RRS Principles Synthesis 2:60 In-Class Tool Applications Class Warm-ups Team Trials Team Project Unit 2 AAP Analysis: Case ConOps: Objectives Unit 3 RS Analysis: Case Reactive/Proactive Unit 4 Unit 5 RS Analysis RRS Analysis: Case Unit 6 Unit 7 Unit 8 RS Analysis Framework/Modules RRS Analysis Reality Factors: Case RRS + Integrity Reality + Activities Integrity Closure Unit 9 Unit 10 rick.dove@stevens.edu, attributed copies permitted 2:61 Task - Form into project teams Prepare 1-2 slides for brief out - Name your team - Name your work file: Ex-teamname.ppt - Write a descriptive statement of your agile-system project (uncertain environment, effective response) -List strategic “response” objectives/values - Have an initial title slide with team name and team-member names listed. EXERCISE • The project MUST engage everyone's passion. • Make sure the whole group is in favor of the choice, you will live with it through all sessions. • You must see that this system is non-trivial, has a future, and is the subject of further development, improvement, or increased understanding. • Give time and care to producing your system statement, as though your boss’s bosses would be interested and intrigued, not only by your choice, but also by your statement. rick.dove@stevens.edu, attributed copies permitted 2:62 Team: Sky Riders System: Airborne Reconnaissance Sensor Testbed (ARST) Strategic Values/Objectives • Rapid Configurability • Multiple Simultaneous Sensor Tests • Full Airborne Sensor Test • Risk Reduction • High Utilization • Inexpensive • High Availability Descriptive Statement The ARST is an airborne platform designed to provide the ability for reconnaissance sensor system developers to test their products in a realistic environment. Sensors may be rapidly installed onto the ARST for either standalone testing or side-by-side comparisons with legacy sensors. The ARST can also serve as a research and development platform to develop future sensor technologies. Note: This is an example of form, with no endorsement of content Team members: John Miller, Rita Kitridge, Jack Stack, Janice Goodrich. rick.dove@stevens.edu, attributed copies permitted 2:63 Team: __________________________ System: __________________________ Strategic Values/Objectives •? •? •? •? •? •? Descriptive Statement ? Team members: ?????. rick.dove@stevens.edu, attributed copies permitted 2:64 Guest Speaker: Joe Justice Part1 File63 Part2 File53 Using Agile, Lean and Scrum - The Team Wikispeed Process Team WIKISPEED uses methods developed by the fastestmoving software companies. In fact, in many ways we have more in common with Google or Twitter than with GM or Toyota. Manufacturing and old-thought software teams gather requirements, design the solution, build the solution, test the solution, then deliver the solution. In existing automotive companies, the design portion of that process alone takes three to twelve years, and then the vehicle design is built for five to fourteen years. This means it is possible to buy a brand new car from a dealer and that car represents the engineering team's understanding of what the customer might have wanted Seattle 16-18 May 2011 twenty-four years ago! The closing keynote Team WIKISPEED follows the model of Agile software teams, of the 2011 Global compressing the entire development cycle into one-week Scrum Gathering "sprints." We iterate the entire car every seven days, meaning brought together by the Scrum Alliance. that every seven days we reevaluate each part of the car and Joe talks about reinvent the highest-priority aspects, instead of waiting ten to managing a twenty-four years to upgrade. This process enables a collaborative multicompletely different pace of development. national team using agile, lean, and Our process: Before Tomorrow Class Starts scrum, and how that allowed them to do revolutionary work like build a 100 mpg car in 3 months Video: www.parshift.com/s/JusticeJoe-VideoFileAccess.html 91 mins rick.dove@stevens.edu, attributed copies permitted 2:65