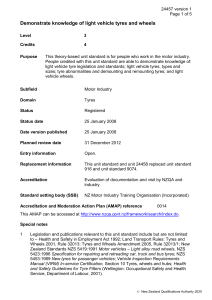

Document

advertisement

President’s Address Fellow ETDS, ITTAC & ATMA Members & Delegates We are meeting again after highly successful Seminar held on 5 th March 2014 at Gulmohar Hall, India Habitat Centre, which was attended by about 100 delegates coming from different areas, both from rubber industry & suppliers as well as academic institutions. Earlier ETDS organised Seminars in Kolkata & Chennai jointly with AIRIA – ER & SR respectively, meet at IIT Kharagpur, besides Seminar at Triangle Tire, Weihai, China. ETDS is growing slowly but steadily with respect to activities & Membership. All activities, lectures, seminar information & pictures are up-loaded in the Website which you may visit to see detail of ETDS. We dedicate this Seminar in memory of Mr. Dilkhush Seth, founder member & first Secretary General of ETDS & remember Mr. R.R.Pandit ,the veteran Rubber Technologist who passed away recently. May I request all to stand & pay homage by observing one mt. silence. Today’s Seminar subject is of high importance and of interest to all – tyre & non – tyre people which is sponsored by ITTAC. Special attraction of today’s event is the presence of well known Personality of Tyre companies who has honoured us by agreeing to deliver speeches and participate in Panel discussion. For years, the tyre industry had an image problem. Consumers viewed tires as a commodity, without realizing the amount of science & technology that went into manufacturing the product. Over time, the industry did its best to educate the buyers. They stressed what characteristics had to be fine-tuned to yield desired performance characteristics; how tyres can last much longer; and, most importantly, how the tyre was the most important component of a vehicle when it came to safety. It's clear, however, that improving the technology of a tyre is a never-ending project. Rolling resistance continues to be an area of focus with higher fuel economy standards on the horizon - improvement here isn't just a matter of usage of silica & silane coupling agent in the compound but involves strenuous research activity covering wide range of subjects. Fuel economy initiatives are only going to get stricter. The concept of green tyre has moved out of laboratories and reached production lines. Governments are mandating tougher regulations to promote energy-saving tyres. As 20-30 percent of fuel consumption and over 24 percent of CO 2 emissions are attributed of tyres, statutory labeling is being considered to rein in auto emissions. The future of 1|Page mobility will be driven by green concerns and manufactures are switching to new compounds Wheel / Tyre perhaps, has been the most influential and important invention in the history of the mankind. Just imagine a world without wheel. The modern tyre we take for granted in very different form when it all started. Vulcanisation of natural rubber invented by Charles Goodyear, (1839) & Charlies Macintosh invented water proofing of fabric. John Dunlop, a veterinarian from Belfast invented the first pneumatic tyre while trying to make his son’s bicycle more comfortable to ride on. In 1948 Michelin developed the first radial tyre and this became the most revolutionary development in the tyre industry as steel-belted radial tyres were used. The advantages of radial technology included longer life and increased for the vehicle. The Future of Tire Michelin starting production of Airless Tyres and are ready to launch Selfseal Tyres in 2015. Timberland introducing “Recyclable Tyres” – at the end to use as Shoe sole. European Union (EU) has introduced a series of regulations that will heavily influence the direction of the tire industry, with one key regulation being the standardized labeling system which will inform the customer on three key performance attributes: fuel efficiency, wet grip performance and exterior rolling noise. The usage of functionalized SSBR in tyres imparts high performance, low rolling resistance while at the same time maintaining the required wet grip properties. Functionalized SSBR decreases the hysteresis of the fillers (Carbon Black & Silica) in tyre compounds. This results in lower rolling resistance and provides improvements for abrasion performance through better linkage between filler and the polymers. We are yet to see anything as revolutionary as Radials or Tubeless. There have been concepts, with a major one being the Bridgestone Air Free, first announced in 2011. Obviously, success of ETDS activities depend on your active involvement and support to ETDS by becoming member. For any activity financial support is necessary. All these arrangement costs. There are many organisation who come forward to support such cause & sponsor the programme like today’s sponsor ITTAC. In past we had Ralson India, Renuka Export, Modinagar Rolls Ltd etc. as sponsor. I close with an appeal to all to become member of ETDS & support financially. Please remember “There is no free lunch in the World”. 2|Page