How RFID Works - Alpha Systems

advertisement

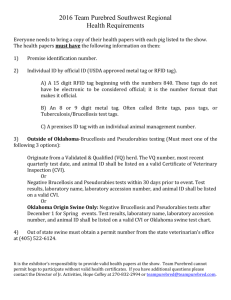

RFID Robert Cook Alpha Systems Agenda • How RFID Works? • Tags • RFID Standards • Interrogators • The “truth” about RFID today • Myth vs. Reality • RFID Implementation Considerations Theory of Operation Antenna Reader / Interrogator Existing Data Collection System Tag How RFID Works Asset Contains an RF Tag/Label Instead of (or in conjunction with) a Bar Code Label Interrogator “Scans” the Tag for Information Using RFID. The Differences: a) Interrogator May Read any field or memory location b) May select a group of tags based on field values c) Write New or Additional Information to Tag (depending on privileges or process requirements) RFID Tag Chip Insert Tag One Small number Application Specific Multiple Tag Antenna Shapes and Encapsulations Cover Several Frequencies and Application Environments Not All Tags Are The Same Three Basic Types: • Active Tags • • • • Passive Backscatter • • • • Battery powered memory, radio & circuitry High Read Range (300 feet) $$$ Reader powered Shorter Read Range (4 inches - 18 feet) $ Semi-passive • • • Reader activates tag, but battery powers memory and circuitry Medium Read Range (10 - 50 feet) $$ Frequencies RFID: Item Management & Toll Roads RFID: Access Control Animal ID RFID: Smart Cards RFID: Item Management Microwave EAS Low Freq. EAS Data Modem 10 kHz Mid. Freq. EAS Radio Toys 100 kHz AM 1 MHz CB 10 MHz Data Terminal Cell Phone TV Garage FM Door 100 MHz 1000 MHz 2.45 GHz 300 GHz Best bet… Concentrate on your business requirements Let requirements dictate frequency Active Tags Have Their Place Advantages: • Long Range Monitoring (15 – 300 ft.) • Can afford • • • • • $25 - $50 per tag reusable / life of asset Need to monitor events (temp, shock, etc.) Desire instant inventory Desire location look-up capability Active Tags - Disadvantages • Power Management of Tag Battery • • Only some assets can afford to be tagged • • • • • Blink Rate vs. Battery Life Tag Size is an issue Tag Cost is an issue The Operational Environment is an issue (heat, cold) Proprietary Air Interfaces and Data Structures Lack of International Regulatory Acceptance Passive Backscatter – Our Focus • • • • Low Cost Good Read Range Good Read Rate Standards RFID Communication Methods RFID Frequencies 125 KHz - 13.56 MHz • • • • Electromagnetic or Inductive Coupling Close Proximity Slower Data Rates Ferrous Metal Affects Inductive Coupling RFID Frequencies 400 MHz – 6800 MHz • • • • Propagating Electromagnetic Waves Longer Range High Data Rate Absorption Affects Propagation 125 – 134 kHz RFID Lower Frequency Tags are typically identified by their larger sized or long looping antennas. This increases tag thickness and cost. 125 – 134 kHz RFID Advantages • Uses normal CMOS processing — basic and ubiquitous • Relative freedom from regulatory limitations • Well suited for applications requiring reading small amounts of data at slow speeds and minimal distances • Penetrates materials well (water, tissue, wood, aluminum) 125 – 134 kHz RFID Disadvantages: • Does not penetrate or transmit around all metals (iron, steel) • Handles only small amounts of data • Slow read speeds • Larger Antennas -- compared to higher frequencies • Minimal Range • Tag construction is: • • • thicker (than 13.56 MHz) more expensive (than 13.56 MHz) more complex (requires more turns of the induction coil) 13.56 MHz RFID 13.56 MHz RFID 13.56 MHz RFID Advantages • Uses normal CMOS processing--basic and ubiquitous • Well suited for applications requiring reading small amounts of data and minimal distances • Penetrates water/tissue well • Simpler antenna design (fewer turns of the coil); lower costs to build • Higher data rate (than 125 kHz--but slower than higher MHz systems) • Thinner tag construction (than 125 kHz) • Popular Smart Card frequency 13.56 MHz RFID Disadvantages • Government regulated frequency (U.S. versus Europe) • Does not penetrate or transmit around metals (unless very thick) • Large Antennas (compared to higher frequencies) • Larger tag size than higher frequencies • Tag construction: requires more than one surface to complete a circuit • Reading Range of ≈ 0.7 m 868-950 MHz UHF RFID 4” x 4” 868-950 MHz UHF RFID Advantages • Effective around metals (if tuned) • Best available frequency for distances of >1m • Tag size smaller than 13.56 MHz • Smaller antennas • Range: licensed to 20-40' with reasonable sized tag (stamp to eraser size) • Good non-line-of-sight communication (except for "lossy" materials) • High data rate; Large amounts of Data • Controlled read zone (through antenna directionality) 868-950 MHz UHF RFID Disadvantages • Does not penetrate water/tissue • Regulatory issues (differences in frequency, channels, power, and duty cycle) • • • • Radio Region 1 Europe - 869 MHz, 250 KHz Bandwidth, 0.5W ERP, 10% Duty Cycle Radio Region 2 – Americas – (902-928 MHz, 4W EIRP, 100% Duty Cycle Radio Region 3 – Asia – Emerging Standards Summary – Requires Frequency Agile Chip Capable of Operating 0.5 W to 4 W - Varying Duty Cycles and Output Power 2.45 GHz Tags 915 MHz Tags / Inserts Reusable Plastic Container Tag Label Inserts Generic Plastic Container Tag Windshield Sticker Tag Wooden Pallet with RFID Plastic Leader Boards Plastic Leader Board Tags 2.45 GHz Advantages • Tag size smaller than inductive or UHF (1"x 1/4") • Range: greater range than inductive w/o battery • More bandwidth than UHF (more frequencies to hop) • Smaller antennas than UHF or inductive • High data rate 2.45 GHz Advantages (cont.) • Good non-line-of-sight communication • Can store large amounts of Data • Controlled read zone (through antenna directionality) • Effective around metals with tuning/design adaptations 2.45 GHz Disadvantages • More susceptible to electronic noise than UHF • Shared spectrum with other technologies-microwave ovens, RLANS, TV devices, etc. • Requires non-interfering, "good neighbor" tactics • Competitive requirement: single chip--highly technical; limited number of vendors • Regulatory approvals still "in process" RFID Frequency Differences (Passive Tags Only) Tuning for Metal Tuned Free Space De-tuned Distance from Metal Metal Ground Plane If properly tuned to the environment, a reflective metal ground plane can increase the tag’s read range. Dealing with Liquids Free Space De-tuned De-tuned Distance from Liquid Liquid Medium Close proximity to liquids will degrade a tag’s performance, as liquids absorb RF energy. Interoperability • • Standards Basic plus enhancements Standards • • Necessary prior to interoperability ISO 18000-6 • • Only recognized international standard for UHF passive RFID EPCglobal UHF Generation 2 • • • Not yet a standard Currently under review by HAG Ratification expected Sept. ‘04 EPCglobal UHF Generation 2 • • • • Crosses Class boundaries 96 bits + (or 256 bits and use what is needed) Separates the data and syntax from the carrier and silicon Enables low cost targets through streamlined, mass production Tag ICs and Memory Tag IC Memory size RF Interface Memory organization Notes Intermec Intellitag 1024 bits Philips UCODE HSL 2048 bits Philips UCODE EPC 1.19 96 + 256 = 352 bits ISO 18000-6B ISO 18000-6B ISO 18000-6B ISO 18000-6B ISO 18000-6B EPC Unique ID ensured Unique ID ensured Faster read rate to obtain EPC number Tag Memory Data • • Any data (i.e. GTIN, EAN-13, EPC) can be stored in upper memory of ISO 18000-6 tags Tags with UCODE EPC 1.19 permit storage of EPC data in lower memory (byte addresses 023). Examples of supported EPC tag data formats: • • • Serialized Global Trade Item Number (SGTIN) Serial Shipping Container Code (SSCC) Global Returnable Asset Identifier (GRAI) Tag Memory Organizations EPC Tag Data Standard Data header Company / item info. Serial number Partition value Filter value Tag memory byte addr. 0 1 2 3 4 5 6 7 8 9 Unique value from IC vendor 10 11 12 Hardware tag type 13 14 15 16 Software tag type ISO 18000-6B Tag Data Standard 17 18 19 20 21 22 23 EPC Global UHF Gen 2 - Timeline per Dicki Lulay, President EPC Global, April 30, 2004 • May 14, 2004 – End of comment period on protocol proposals • May 28, 2004 – Consensus decision, assuming no unresolved issues – only one protocol will be put forth. If no consensus, move to a technical “bake off.” • June 28 – End of technical “bake off” process (if necessary) to resolve consensus issues. The result is the “Last Call Working Draft”. • August 12 – Review of Last Call Working Draft, comment collection, and comment resolution with the Hardware Action Group (results in a Candidate Specification). • September 27 – Validation, Prototype and Test (results in a Proposed Specification). • October 5 – Technical and Business Specification Committee reviews (results in a Recommended Specification). • October 6 – Ratification by the EPCglobal Board of Governors. • EPC Global may submit ratified standard to ISO for their ratification EPC Network EPC The globally unique identifier that serves as a pointer for making enquiries about the item it identifies Reader The data capture device; portable or fixed (installed), connected to a Savant server or network. RFID Tags The carrier for the EPC that communicates with the readers Savant Servers which act as local repositories for EPCs and associated information, and which support middleware for serving PML queries. ONS Object Name Service; the distributed resource that “knows” where information about EPCs is held (just like DNS). PML Physical Markup Language; like XML, with XQL query structure to allow structured querying and reporting concerning EPCs. Why Intermec’s RFID? • ePC Global Class 1, Generation 2 (Now called UPC Gen 2) • Production by multiple world class vendors – Philips, Impinj, TI, BTG, EM Micro, SamSys, Sharp, ITC • ISO 18000-6 compliant – global use • Future proof investment protection • Meets ultimate goal for Wal-Mart, DoD, and others RFID Hardware Readers Antenna Bells & Whistles The Overhead Scanner Assets Tracked: • Oversized Items • Pallets • Plastic Containers Benefits: • Automated Delivery Notification • Inventory Management • Staging Operations • Improved Conveyance Usage Tracking Level(s) Forklift Mount Reader • Use Requirements: • Read Pallet Tags • Read Location Tags • Existing Application Support • In Lieu of Dock Door • Reader Requirements: • Standard Software • Cordless Antennas • Backup Scanner Support Portal Scanner Assets Tracked: • Pallets • Plastic Containers Benefits: • Automated Delivery Notification • Automated Shipment Notification • Prevents Mis-Shipments • Automated Bill of Lading • Improved Cross Dock / Dock Utilization Tracking Level(s) Metro AG Case & Pallet Dock Door Portal (Back Store – Rheinberg, Germany) RF Shielding - Mesh Screen Interrogator With Antennae Portal Status Lights Presence Detectors Conveyor Applications Assets Tracked: • Manufactured Items • Eaches Inside of Case • Cases Tracking Level(s) • Plastic Containers Benefits: • Eaches Verification w/o Opening Case • Lot tracking of Cases • Read/Write of data to Case, Eaches for regulatory, warranty, distribution purposes WIP Stretch Wrap Scanner Assets Tracked: • Cases of product on a Pallet • Eaches of product on a Pallet Benefits: • Eaches or Case Level Verification prior to shipping Tracking Level(s) Hand Held Mobile Batch Tracking Level(s) Wireless WIP Fixed Station Benefits: • Allows for exception processing • Rapid Searching / Inventorying • Rapid Pallet Build using bar-code and RFID Integrated Handheld Reader • Use Requirements: • Existing Applications • Extended Uses • Speech Recognition, VoIP, etc. • Reader Requirements: • Standard Software • Battery for 8 Hrs • Multiple Interfaces • WLAN, WWAN, etc. • Lightweight • Ergonomic Design Handheld Reader • Use Requirements: • Attach to Legacy Handhelds • Attach to PCs • Reader Requirements: • Self-Powered • Lightweight • Ergonomic Design Network Reader • Use Requirements: • Multiple Readers • Central Point of Control • Complex Processes • Sensors • Reader Requirements: • Processing Power • Power Over Ethernet • Wireless Capable • Multiple Antennas • Peripheral Capabilities Serial Reader • Use Requirements: • Simple Interface • PLC Interface • Sensors • Reader Requirements: • Simple Design • Low Cost • DC Power • Multiple Antennas • Peripheral Capabilities PC Card Reader • Use Requirements: • Simple Station • PCs • Tablets • Reader Requirements: • PCMCIA Interface • 100% Duty Cycle RFID Printer • Use Requirements: • Labeling • Existing Drivers • Applicators • Reader Requirements: • Standard Interface • High-Speed • Applicator Module Why Intermec’s RFID? • ePC Global Class 1, Generation 2 (Now called UPC Gen 2) • Production by multiple world class vendors – Philips, Impinj, TI, BTG, EM Micro, SamSys, Sharp, ITC • ISO 18000-6 compliant – global use • Future proof investment protection • Meets ultimate goal for Wal-Mart, DoD, and others Intermec RFID Applications Industrial Products Logistics/ Trans. Consumer Products Retail Homeland Security Field Service Tyco (Sensormatic) – Video rental and return, retail inventory management and item location Coalescent – High value military hardware Toyota – Automobile Tracking Ford Engine Plant (MI) – Engine Assembly Automotive Tire Tracking Security – ‘Nexus Program’ US-Canadian Border Excel/Cargill, Inc. – Beef processing Paramount Farms – Nut harvesting RFID Myths and Realities RFID Myths and Realities • Myth #1: RFID is a “talking” bar code • A bar code that broadcasts its serial number • More data than most bar codes – 128 bytes vs 1.1 bytes (approx) • Identify SKU plus unique serial number • Read/write – distributed database RFID Myths and Realities • Myth #2: You can read every RFID tag every time • Immutable laws of physics • Tag placement, contents, orientation, nulls • Good engineering and system design required • Procedures will have to be altered RFID Myths and Realities • Myth #3: You can take inventory with a push of a button • Technology does not exist today and, if it did, it would be cost prohibitive • Real time inventory by: • Tracking when it came in • Where it was placed • When it left • System design, new procedures and employee training is required Myth: RFID will replace Bar Code. Reality: RFID and Bar Code are expected to co-exist. • RFID costs more • RFID does not provide a positive ROI for every application. RFID may be an option for customers who have high profile item management problems that are not addressed with bar codes. Myth: “I just have a simple RFID application.” Reality: RFID is ALWAYS a complex installation. • Things that add to RFID complexity: • Read/Write range is not adjustable. • Read/Write range varies with environment. • Read/Write range is not visible (portable). • Tag orientation to reader. • Read and Write command structure. • Training and process changes. • Tag design requirements change with environment and substrate. RFID Considerations How am I reading the tag? • What type of system is required? • • • • • • • Fixed readers (portal, conveyor…etc.) Portable readers (forklift, handheld…etc.) What are the range requirements? What are the speed requirements? What frequency is best? What is the tag population? How much separation exists between tags? How much data do I need on the tag? • • • Do I require 64 bits? ….96 bits?…more? Do I want to add data through the lifecycle? Do I have access to a database? Why am I using RFID? • • • Is it required to meet a customer mandate? Will it provide a necessary functionality unavailable elsewhere? Will it provide improved efficiencies that lower my operating costs? An RFID tag will NEVER be cheaper than a barcode label!!! RFID ? • RFID typically used when…. • • • • Line of sight not possible Dirty environment( grease, paint) Orientation not known Many reads required at once • More efficient than scanning each box) • Addition of data required • Reusable container • High security – anti thief/counterfeit Any RFID Project Requires: • Process Changes / Requirements Defined • Needs Analysis / Site Surveys • Application Design • • • • • Tag Selection, Tag Attachment, Data Transactions Defined Timing and Physical Environment Defined Network and Data-Flow Defined Hardware and Software Interfaces Defined System Level Specifications • S/W, H/W, and Network Development • Installation, Test, and Integration into Existing Systems • Training, Support Educate and Set Appropriate Expectations • Capabilities of RFID • • • • Read and Write capability Extremely fast data collection Read/Write through many solids, non-Line of Sight. Very accurate, automatic data collection possible • Limitations of RFID • Does not interrogate through water/metal and RF reflective or absorbent surfaces • Read field can not be customized. • Global regulations and standards not fully adopted. • Investment Required • Est. at least $50 K of NRE through pilot • Human Resource/Contractors • Time Frame = 1-3 years on ave. Questions?