IS485ConfigMMOrgStructures

advertisement

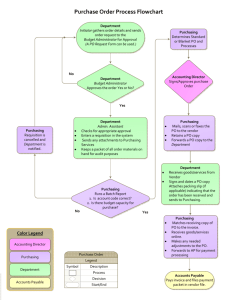

Configuring the MM Structures Review of the Procurement Process Internal Demand Purchase Requisition Purchase Order Vendor Goods Receipt Invoice Receipt Pay Invoice Materials Management (Functions) Purchasing activities Goods receipt Storing materials Issuing materials Materials Management (Integration) MM is integrated with FI Materials are described in MM Vendors are described in both MM and FI Materials Management (Valuation) SAP can value materials differently (called the valuation level At the company-code level, the same material has the same value across all plants At the plant-level, each plant maintains prices separately Note that the valuation level-is set once for the entire client and cannot be changed Materials Management (Valuation) Organizational Units A company code has one or more plants A plant has one or more storage locations A purchasing organization is responsible for purchasing goods for one or many plants A purchasing group is a group of buyers responsible for purchasing specific kinds of materials Organizational Unit (Plant) A plant is typically a physical place but does not have to be Typically a manufacturing facility, distribution center or other physical place where the company does business A plant applies to one and exactly one company code A plant is used to determine the shipping point for goods A plant can have several shipping points (loading docks) A shipping point can be assigned to several plants Organizational Unit (Plant) Plants are created (defined) from the IMG Plants have a factory calendar Once created, plants must be (assigned) to a company code Back to definement and assignment A plant belongs to exactly one company Organizational Unit (Plant Factory Calendar) SAP defines most country calendars 3 parts The factory calendar Holiday calendar Derived from public holidays Transaction code SCAL Organizational Unit (Plant) Remember a business area is a FI organizational unit used to categorize areas operations A single business area can be assigned to a plant A plant can be responsible for several sales organizations and distribution channels MRP is performed at the plant organizational level A Plant has its own material master records Organizational Unit (Storage Location) A storage location identifies where a material is stored It might be as simple as raw materials / work in progress / finished goods Or as complex as a unique bin at an Amazon.com Requires enabling the warehouse management subsystem Storage locations can be physical or logical Organizational Unit (Storage Location) Storage locations are created using the IMG A storage location applies to exactly one plant Organizational Unit (Purchasing Organization) Responsible for the procurement of materials and/or services A purchasing organization is assigned to one or more plants A purchasing organization has Its own vendor master data Its own pricing conditions Its own external purchasing documents Organizational Unit (Purchasing Organization) Purchasing organizations can be configured differently Centralized Distributed Hybrid Organizational Unit (Purchasing Organization) A purchasing organization is assigned to one or many plants Centralized Responsible for many plants Assigned to multiple plants possibly having different company codes Decentralized (Company-specific) Purchasing organization assigned directly to a company code Organizational Unit (Purchasing Organization) Plant-specific purchasing A purchasing organization is responsible for one and only one plant Again, purchasing organizations are created from the IMG They are then assigned