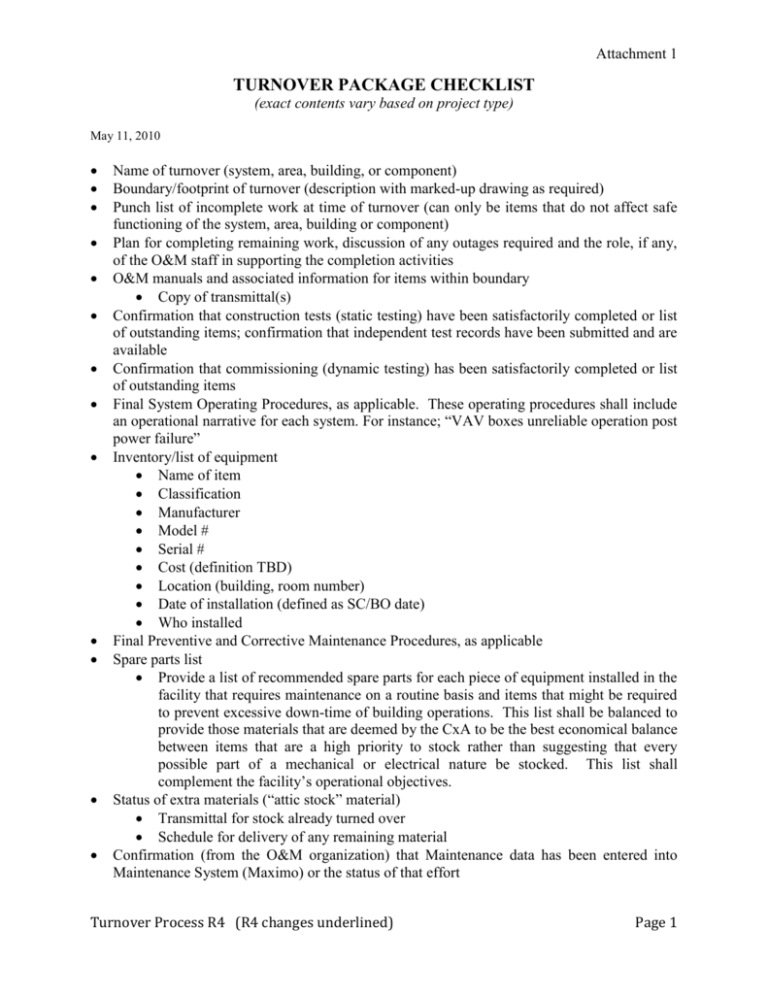

Attachment 1 – Turnover Package Checklist

advertisement

Attachment 1 TURNOVER PACKAGE CHECKLIST (exact contents vary based on project type) May 11, 2010 Name of turnover (system, area, building, or component) Boundary/footprint of turnover (description with marked-up drawing as required) Punch list of incomplete work at time of turnover (can only be items that do not affect safe functioning of the system, area, building or component) Plan for completing remaining work, discussion of any outages required and the role, if any, of the O&M staff in supporting the completion activities O&M manuals and associated information for items within boundary Copy of transmittal(s) Confirmation that construction tests (static testing) have been satisfactorily completed or list of outstanding items; confirmation that independent test records have been submitted and are available Confirmation that commissioning (dynamic testing) has been satisfactorily completed or list of outstanding items Final System Operating Procedures, as applicable. These operating procedures shall include an operational narrative for each system. For instance; “VAV boxes unreliable operation post power failure” Inventory/list of equipment Name of item Classification Manufacturer Model # Serial # Cost (definition TBD) Location (building, room number) Date of installation (defined as SC/BO date) Who installed Final Preventive and Corrective Maintenance Procedures, as applicable Spare parts list Provide a list of recommended spare parts for each piece of equipment installed in the facility that requires maintenance on a routine basis and items that might be required to prevent excessive down-time of building operations. This list shall be balanced to provide those materials that are deemed by the CxA to be the best economical balance between items that are a high priority to stock rather than suggesting that every possible part of a mechanical or electrical nature be stocked. This list shall complement the facility’s operational objectives. Status of extra materials (“attic stock” material) Transmittal for stock already turned over Schedule for delivery of any remaining material Confirmation (from the O&M organization) that Maintenance data has been entered into Maintenance System (Maximo) or the status of that effort Turnover Process R4 (R4 changes underlined) Page 1 May 11, 2010 Systems Control Center (SCC) Items “Points” and programs have been established on one of the existing front ends so that staff can actively monitor the new points. o Points are inputs/outputs such as temperature sensors, AHU status, etc. Appropriate alarms and trends have been established per the design documents for the various points. System Graphics have been provided as required by the design documents. Training has been provided to SCC staff regarding the new systems or points, especially focusing on any systems with unusual sequences of operation. Electronic versions of control drawings, including the sequences of operation, have been provided to the SCC Manager. MS Visio format is preferred but PDF is acceptable. Electronic versions of as-built drawings for base map updating (this will be a Final Completion item if they are not available at turnover). Training record (date, subject, list of attendees, signatures) HVAC Systems Control Plumbing Electrical Fire Alarm Sprinkler Systems Elevator Landscape Housekeeping Utilities Specialties Equipment Systems If videotaped, transmittal record for video Status of drawings/specifications reflecting as-built condition. Note: If the work has been modified from the approved construction documents, as-built information shall be supplied for any modifications that impact the operability or maintainability of the system, area, building or component. Copy of transmittal(s) Warranty information Duration Administration per attached copy of Directive 360F Contacts Start date Status of all warranty claims including those initiated by the UVa organization responsible for operation and maintenance of the asset. Substantial Completion items System performance verified Building Automation Systems head end programming complete May 11, 2010 Balance report submitted (provide date of final, accepted balance report) HECO-13.3b Checklist for Beneficial Occupancy, attached Contact list PM CAM Signature Date/Time of Turnover O&M representative’s signature acknowledging that the Turnover Package was delivered as shown.