Chapter 2

advertisement

Product and Equipment

Analysis

Chapter 2

Data required for developing good

layouts

• Product Analysis

• Process Analysis

Input Data and Activities

• What data are critical to the facility plan?

• Muther categorizes the information as:

P – Product (what?)

Q – Quantity (how much?)

R – Routing (where?)

S – Support (with what?)

T – Timing (when?)

Product Analysis

•

•

•

•

•

Bill of Materials

Assembly Charts

Engineering Drawing

Operation Process Chart

Route Sheet

Input Data and Activities

• Tompkins, White, et. al., categorize it as:

Product Design – what is to be produced?

Process Design – how is it to be produced?

Schedule Design – when and how much?

Product

Facility

Process

Schedule

Product Design

• Based on

– Function

– Aesthetics

– Costs

– Materials

– Manufacturing Methods

Driven by market

demand

• Key point

– The product design MUST be finalized before

designing the facility. Otherwise a flexible

facility is needed.

Tools Used in Product Design

• Product/Part

Drawings

– 2-D, 3-D visualization

• Exploded Assembly Diagrams

Part drawing

Tools Used in Process Design

A partial list (dependent on product and service):

• Process Flowcharts and Process Maps

• Make vs. Buy

• Parts Lists

• Bill of Materials

• Route Sheets

• Assembly Charts

• Operations Process Charts

• Precedence Diagrams

Process Flowcharts

UPS

Active

Bins

Receiving

Reserve

Storage

Picking

Packing

Monogramming

Embroidering

Quality

Assurance

Back to

Vendor

Hemming

Gift

Boxing

Shipping

Parcel

Post

Next-Day

UPS

Process Maps

Customer

Waiter

Place order

Is order

complete?

Salad Chef

Dinner Chef

N

Y

Give soup or salad order to chef

Prepare soup or

salad order

Prepare dinner

order

Give dinner order to chef

Drink

Get drinks for customer

Eat salad or

soup

Deliver salad or soup order to customer

Eat dinner

Deliver dinner to customer

Receives check

Deliver check to customer

Gives payment

to waiter

Receive payment for meal

Cash or

Credit?

Credit

Cash

Collect change,

leave tip

Bring change to customer

Run credit card through

Fill in tip

amount

Return credit slip to customer

Collect tip

Give order

to waiter

Give order

to waiter

Make vs. Buy?

BUY

No

Can item be

purchased?

No

MAKE

Yes

Can we

make the

item?

No

BUY

Yes

Is it cheaper

for us to

make?

No

BUY

Yes

Is the capital

available?

Yes

MAKE

Parts List

• A listing of component parts.

PARTS LIST

Company: TW Inc.

Product: Air Flow Regulator

Part No.

1050

2200

3250

3251

3252

3253

3254

3255

4150

4250

Name

Pipe plug

Body

Seat Ring

O-Ring

Plunger

Spring

Plunger Housing

O-Ring

Plunger Retainer

Lock Nut

Prepared By: JSU

Date: 6/30/2003

Drwg. No.

4006

1003

1005

1007

1009

1011

4007

Qty/unit

1

1

1

1

1

1

1

1

1

1

Material

Steel

Aluminum

Stainless Steel

Rubber

Brass

Steel

Aluminum

Rubber

Aluminum

Aluminum

Size

0.5" x 1.00"

2.75" x 2.5" x 1.5"

2.97" x 0.87"

0.75" diam.

0.812" x 0.715"

1.4" x 0.225"

1.6" x 0.225"

0.925" diam.

0.42" x 1.2"

0.21" x 1.00"

Make/Buy

Buy

Make

Make

Buy

Make

Buy

Make

Buy

Make

Buy

Bill of Materials

• Many different types of “structured parts lists”

BILL OF MATERIALS

Company: TW Inc.

Product: Air Flow Regulator

Level

0

1

1

2

2

3

3

4

4

4

4

4

4

4

Part No.

0021

1050

6023

4250

6022

2200

6021

3250

3251

3252

3253

3254

3255

4150

Prepared By:

Date:

Name

Air Flow Regulator

Pipe plug

Main assembly

Lock Nut

Body Assembly

Body

Plunger Assembly

Seat ring

O-Ring

Plunger

Spring

Plunger Housing

O-ring

Plunger retainer

Drwg. No.

0999

4006

4007

1003

1005

1007

1009

1011

Qty/unit

1

1

1

1

1

1

1

1

1

1

1

1

1

1

JSU

6/30/2003

Make/Buy

Make

Buy

Make

Buy

Make

Make

Make

Make

Buy

Make

Buy

Make

Buy

Make

Bill of Materials

12

Computer Device

11

Keyboard Assembly (Purcha sed)

10

Color Video Display Device

8

Video Panel (Purch ased)

7

Circuit Board

9

Main CPU Unit

6

Power Supply Kit (Purc hased)

5

PC Board Assembly

3

Main PC Board (Purch ased)

4

Disk Drive Unit

2

Floppy Drive

1

Hard Drive

Company: ARC Inc.

Produce:

Air Flow Regulator

Oper.

No.

Operation

Description

0104

Shape, drill,

cut off

0204

Route Sheet

Part:

Plunger Housing

Prepared by:

JSU

Part No.

3254

Part No.

6/6/03

Machine

Type

Auto sc.

Machine

Tooling

Setup

(hr.)

Oper.

Time

(hr.)

Mtls.

Parts

Alum

1”x12’

.5 in dia coller, cir.

Form tool, .45”

diam center drill

5

0.0057

Machine Slot Chucker

and thread

0.045” slot saw,

turret slot

2.25

0.0067

0304

Drill 8 holes

Auto dr.

unit

0.078” diam twist

drill

1.25

0.0038

0404

Debur and

Blow out

Drill press

Deburring tool with 0.5

pilot

0.0031

SA 1

Enclose

Dennison

subassembly hydraulic

press

None

0.0100

0.25

Routing sheet

--PART NUMBER-- ---------DESCRIPTION---------DRAWING REVISION

H6709

HANDLE,DENSPLY PROBE

G

MASTER ROUTING LIST

ALT CODE

BUYER/PLANNER

DATE

6/25/92

B

239

--------STANDARD-------TIME

MOVE

OPER

WORK OPER SETUP

CREW

MACH --TOOLING REF-BASIS

TIME

-----EFFECTIVE---& ALT CENTER CODE CODE FACTOR GROUP

NUMBER

CDE/-QTY-DAYSFROM

TO

10

01226

1.0 01226 T9330

1000

.000

0/00/00 99/99/99

PARTIAL AHEAD QTY

----------ROUTING DESCRIPTIONS---------MAKE @ AUTO 804843P

C 804843P B

A A02247 A

15

02053

1.0 02053 T9712

1000

.000

0/00/00 99/99/99

PARTIAL AHEAD QTY

----------ROUTING DESCRIPTIONS---------DRILL & TAP 804843P1

B 804843P1 A

20

02053

1.0 02053 T9713

1000

.000

0/00/00 99/99/99

PARTIAL AHEAD QTY

----------ROUTING DESCRIPTIONS---------KNURL OD

30

03029

1.0

1000

.000

0/00/00 99/99/99

PARTIAL AHEAD QTY

----------ROUTING DESCRIPTIONS---------SCOTCHBRITE/BELT

40

03105

1.0 03105

1000

.000

0/00/00 99/99/99

PARTIAL AHEAD QTY

----------ROUTING DESCRIPTIONS---------PASSIVATE

50

03005

1.0

1000

.000

0/00/00 99/99/99

PARTIAL AHEAD QTY

----------ROUTING DESCRIPTIONS---------BUFF

60

03007

1.0 03007

1000

.000

0/00/00 99/99/99

PARTIAL AHEAD QTY

----------ROUTING DESCRIPTIONS---------GLASSBEAD KNURL/ SHIP

--SETUP-

-LABOR-

-MACHINE--

I/O

HOURS

HOURS

12.000

336.880

336.880

4

1.500

41.670

83.330

4

1.500

8.330

16.670

4

.000

33.330

33.330

4

.000

3.000

3.000

4

.000

54.170

54.170

4

.000

50.000

50.000

4

HOURS

2200

Assembly Chart

3254

Analog model of the assembly

3253

process.

3252

•

Circles denote components

SA-1

3251

•

Links denote

operations/subassemblies

•

•

A-1

Squares represent inspections

3250

3255

A-2

operation

4150

Begin with the original product

4250

and to trace the product

1050

disassembly back to its basic

components.

A-3

I-1

Pack

A-4

Assembly Charts

1

4

2

3

5

9

6

7

10

8

12

11

Symbols for 5 basic mfg activities

Symbol

Name

Operation

Inspection

Transportation

Storage

Delay

Operation process chart for 3.5 volt

halogen otoscope

TC

W

S

B

P

LHS

T

FB

LH

OL

LN

Dr

Mi

Dr

LR

PS

L

Th

Mi

Th

LA

Tu

Pl

LHA

LPA

BA

A1

A2

A3

HO

Found by superimposing

the route sheets and the

assembly chart, a chart

results that gives an

overview of the flow within

the facility.

Operations Process Chart

Volume Variety Charts

16000

120%

14000

100%

12000

80%

10000

60%

8000

6000

40%

4000

20%

2000

0

0%

C

F

G

J

K

A

Products

E

D

B

H

I

Percent

Percent

47%

67%

78%

88%

92%

95%

98%

99%

99%

100%

100%

Units/yr

Product Units/year

C

14000

F

6000

G

3250

J

3000

K

1120

A

1000

E

650

D

450

B

100

H

100

I

81

Volume Variety Chart

900

120%

800

100%

700

600

80%

500

60%

400

300

40%

200

20%

100

0

0%

P

F

C

J

G

O

K

A

Q

E

Products

D

B

H

N

I

L

M

Percent

Percent

13%

26%

36%

45%

53%

62%

69%

76%

83%

89%

93%

94%

96%

98%

99%

100%

100%

Units/Yr

Product Units/year

P

800

F

766

C

600

J

542

G

513

O

498

K

475

A

423

Q

418

E

322

D

234

B

100

H

100

N

100

I

81

L

52

M

16

Production Requirements –

Yield Loss

Pi

i

Oi

Pisi

Oi Pi Pi si

Oi Pi (1 si )

Pi – Production input to operation i

si – Fraction of Pi lost (scrap)

Oi – output of process i

Oi

Pi

(1 si )

Production Requirements –

Series Systems

P1

1

2

P1s1

P2s2

...

n

Pnsn

On

P1

(1 s1 )(1 s2 ) (1 sn )

On

Example

• 5 processes in series

• Need 2000 units out

Process

5

4

3

2

1

Loss

3%

2%

1%

2%

1%

Out

2000

2062

2104

2125

2169

In

2062

2104

2125

2169

2190

2000

P1

2190

(1 .01)(1 .02)(1 .01)(1 .02)(1 .03)

Production Requirements – Non Series

Part B

Part A

Work backward from

end of the line.

s1=1%

s2=2%

P5

O5

100,000

104,167 O4

1 s5

.96

P4

O4

104,167

105,219 O3 O2

1 s4

.99

P3

O3

105,219

107,366

1 s3

.98

P2

O2

105,219

107,366

1 s2

.98

P1

O1

107,366

108,451

1 s1

.99

1

2

M1

s3=2%

3

M2

s4=1%

4

M3

s5=4%

5

M4

M2

100,000 units

Simple equipment selection model

• P desired prod rate

• t time (in hours)

to process one part

•

m/c avail time

(in hours)

•

m/c efficiency

tP

NM

Simple equipment selection model

• Nol Number of good

units at output of

stage l

• Nil Number of units

reqd at input of stage

l

• Sl Scrap at stage l

Nol

Nil

1 Sl

Simple example

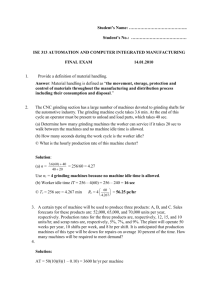

1. Consider a simple jobshop manufacturing system that makes three

major “Class A” products requiring five types of machines. The three

products include seven parts shown in Table 2.1. Table 2.1 also

shows the time standards in units per hour.

2. Assume we an hour has only 55 minutes of productive time and that

5 minutes are lost due to operator or machine unavailability and

machine downtime.

3. Dividing the value 55 by the values in Table 2.1, we get the as well

as time per unit.

4. Determine the quantities of machines of each type required to make

the standard time per unit.

5. Assuming 12000 “representative” parts are to be made and that only

440 minutes of productive time is available per shift, we can find that

we need 4.9 units of machine A, 5.85 units of machine B, and 4.3

units of machine C.

6. Rounding up these numbers gives us 5, 6, and 5 units of machine

types A, B, and C, respectively.

Table 2.1

Part

Machine

1

2

3

4

5

6

7

A

2000

-

1200

1500

-

2300

1200

B

1200

1800

1200

-

1600

2000

1000

C

-

-

1200

2000

1200

-

1400

Table 2.2

Part

Machine

1

2

3

4

5

A

0.0275

-

0.0459

0.0367

-

0.0239 0.0459

0.1799

B

0.0459 0.3056

0.0459

-

0.0344

0.0275 0.0550

0.2143

0.0459

0.0275

0.0459

C

-

-

6

-

7

0.0393

Total Time

0.1586

Calculating Equipment Requirements

How many pieces of equipment do we need?

Pi

Ti

Ci

Ei

Ri

Mj

xj

Production rate for operation i (pcs/period)

Time per piece for operation i (time/pc)

Time available to run operation i (time/period)

Efficiency of machine while running

Reliability of machine

Number of type j machines required

Set of operations run on machine j

pc time

period pc

PiTi

Mj

time

i X j Ci Ei Ri

period

Example

• Consider Machine 2

• x2={2,3}

Oper (i) Pi (pcs/yr) Ti (hr/pc) PiTi (hrs/yr) Ci (hrs/yr)

2

107,366

0.043

4616.7

2000

3

107,366

0.022

2362.1

2000

Ei

0.98

0.90

Ri

0.99

0.99

CiEiRi (hrs/yr)

1940.4

1782.0

M2=

• Do similar calculation for other machines

• Other factors to consider

– Number of shifts

– Setup times

– Customer lot sizes (smaller require more

setups)

– Layout type

– Maintenance activities

No. Mach.

2.38

1.33

3.70

Operator-Machine Charts

• Tool for showing activity of

both operator and machine

along a time line

• Also called “multiple activity

chart”

Example:

1 minute to load

1 minute to unload

6 minute run cycle

0.5 minute to inspect and pack

0.5 minute to travel to another

machine

ONE MACHINE

Time

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

6

6.5

7

7.5

8

Cycle Time

Oper Idle

Mach. Idle

Prod. Rate

Operator

M1

U1

UNLOAD

U1

UNLOAD

L1

LOAD

L1

LOAD

I&P

RUN

RUN

RUN

RUN

RUN

RUN

IDLE

RUN

RUN

RUN

RUN

RUN

RUN

8

5.5

0

0.125

min

min

min

pc/min

Operator Machine Charts

TWO MACHINES

Time

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

6

6.5

7

7.5

8

Cycle Time

Oper. Idle

Mach Idle

Prod Rate

Operator

M1

M2

U1

UNLOAD

RUN

U1

UNLOAD

RUN

L1

LOAD

RUN

L1

LOAD

RUN

I&P

RUN

RUN

T-2

RUN

RUN

U2

RUN

UNLOAD

U2

RUN

UNLOAD

L2

RUN

LOAD

L2

RUN

LOAD

I&P

RUN

RUN

T-1

RUN

RUN

RUN

RUN

RUN

RUN

IDLE

RUN

RUN

RUN

RUN

8

2

0

0.25

min

min

min

pc/min

THREE MACHINES

Time

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

6

6.5

7

7.5

8

8.5

9

Cycle Time

Oper. Idle

Mach Idle

Prod Rate

Operator

M1

M2

M2

U1

UNLOAD

RUN

RUN

U1

UNLOAD

RUN

RUN

L1

LOAD

RUN

RUN

L1

LOAD

RUN

RUN

I&P 1

RUN

IDLE

RUN

T-2

RUN

IDLE

RUN

U2

RUN

UNLOAD

RUN

U2

RUN

UNLOAD

RUN

L2

RUN

LOAD

RUN

L2

RUN

LOAD

RUN

I&P 2

RUN

RUN

IDLE

T-3

RUN

RUN

IDLE

U3

RUN

RUN

UNLOAD

U3

RUN

RUN

UNLOAD

L3

RUN

RUN

LOAD

L3

RUN

RUN

LOAD

I&P 3

IDLE

RUN

RUN

T-3

IDLE

RUN

RUN

9

0

1

0.333333

min

min

min

pc/min

Parameters for an LP equipment

selection model

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Oi

Operation type i, i=1,2,...,o

Mi

Production equipment type i, i=1,2,...,m

Pi

Part type i, i=1,2,...,p

MHi Material handling system type i, i=1,2,...,n

cij

cost of performing operation Oi on production equipment type Mj

hij

cost of handling part type Pi using material handling system type MHj

tij

time required to perform operation Oi on production equipment type Mj

sij

time required to transport part type Pi using material handling carrier

type MHj

τj

time available on production equipment type Mj

σj

time available on material handling carrier type MHj

NOi number of operations Oi to be performed

NPi number of units of part type Pi to be manufactured

Cj

cost of production equipment type Mj

Hj

cost of material handling system MHj

B

total budget available

Decision Variables for LP

equipment selection model

• xij number of operations Oi to be performed on

production equipment type Mj

• yij number of units of part type Pi to be

transported on material handling system type

MHj

• NMj number of units of production equipment

type Mj selected

• NMHj number of units of material handling

system type MHj selected

LP equipment selection model

• Min

o

p

m

n

m

n

c x h y C NM H NMH

i 1 j 1

• Subject to

ij ij

i 1 j 1

m

x

j 1

o

ij

NOi

t x

i 1

ij ij

n

y

ij

j 1

p

s

i 1

ij

ij

ij

j 1

i

i 1

i =1,2,...,o

j NM j

NPi

i

j =1,2,...,m

i =1,2,...,p

yij j NMH j

j =1,2,...,m

i

i

LP equipment selection model

(cont)

m

n

C NM H NMH

i 1

i

i

i 1

i

i

B

xij 0 and integer

i 1, 2,..., o; j 1, 2,..., m

yij 0 and integer

i 1, 2,..., o; j 1, 2,..., m

NMH j 0 and integer

NM j 0 and integer

j 1, 2,..., m

j 1, 2,..., m

Example

An automobile engine cylinder manufacturing company

that supplies high precision engines to a multinational

car manufacturer plans to manufacture several models

of cylinder.

For planning purposes, it uses the following pseudo

products - a standard engine cylinder, a high-technology

model, an engine cylinder for sports cars and a luxury

car cylinder.

The marketing department has demand forecast figures

which have been aggregated for the four pseudo

models. It has been determined that 2000, 1500, 1800

and 1000 units of the basic, high-tech, sports and luxury

models will be demanded during the next six months.

Example

The models require one or more of three operations, referred to as

O1, O2, and O3.

Three machine types and two material handling systems available

for performing the three operations and transporting the models.

These are denoted as M1, M2, M3 and MH1, MH2, respectively.

Each machine and handling system may be assumed to be

available for 90 percent of the time.

The cost of machines M1, M2, and M3 are $230,000; $250,000;

$310,000

The cost of material handling carriers MH1, MH2 are $90,000 and

$130,000

The available budget is $10,000,000.

The following two matrices show the cij's and hij's - that is, the cost of

performing operation Oi on production equipment type Mj and cost of

handling part type Pi using material handling system type MHj,

respectively.

Data for example

[cij]=

6

12

8

4

20

4

12

10

5

[hij]=

10

5

12

6

18

9

6

3

LP Model for example

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

MIN 90000 NMH1 + 130000 NMH2 + 230000 NM1 + 250000 NM2

+ 310000 NM3 + 6 X11 + 12 X12 + 8 X13 + 4 X21 + 5 X22

+ 4 X23 + 12 X31 + 5 X32 + 5 X33 + 10 Y11 + 5 Y12 + 12 Y21

+ 6 Y22 + 18 Y31 + 9 Y32 + 6 Y41 + 3 Y42

SUBJECT TO

C1) X11 + X12 + X13 >= 200

C2) X21 + X22 + X23 >= 200

C3) X31 + X32 + X33 >= 150

C4) - 300 NM1 + 1.67 X11 + 2.5 X21 + 0.83 X31 <= 0

C5) - 300 NM2 + 0.833 X12 + 2 X22 + 2 X32 <= 0

C6) - 300 NM3 + 1.25 X13 + 2.5 X23 + 2 X33 <= 0

C7) Y11 + Y12 >= 2000

C8) Y21 + Y22 >= 1500

C9) Y31 + Y32 >= 1800

C10) Y41 + Y42 >= 1000

C11) - 300 NMH1 + 0.1 Y11 + 0.0833 Y21 + 0.056 Y31 + 0.167 Y41 <= 0

C12) - 300 NMH2 + 0.2 Y12 + 0.167 Y22 + 0.11 Y32 + 0.33 Y42 <= 0

C13) 90000 NMH1 + 130000 NMH2 + 230000 NM1 + 250000 NM2

+ 310000 NM3 <= 1000000

END

GIN

5

LP Model Solution

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

VARIABLE

NMH1

NMH2

NM1

NM2

NM3

X11

X12

X13

X21

X22

X23

X31

X32

X33

Y11

Y12

Y21

Y22

Y31

Y32

Y41

Y42

VALUE

2.000000

.000000

2.000000

1.000000

.000000

200.000000

.000000

.000000

59.880245

140.119751

.000000

140.119751

9.880246

.000000

2000.000000

.000000

1500.000000

.000000

1800.000000

.000000

1000.000000

.000000

REDUCED COST

90000.000000

105454.546875

228562.875000

248353.593750

308353.593750

.000000

2.571524

.860030

.000000

.000000

1.744012

.000000

.000000

.000000

.000000

11.363637

.000000

7.663636

.000000

.000000

.000000

24.000002

Parameters for LP equipment

selection model

• rik number of times operation Oi is to be

performed on part type Pk

• cijk cost of performing operation Oi using

production equipment type Mj on part type Pk

• tijk time required to perform operation Oi using

production equipment type Mj on part type Pk

• xijk number of units of operation Oi performed

using production equipment type Mj on part type

Pk

• Cj purchase cost of production equipment type

Mj prorated over the planning period

LP equipment selection model

o

• Min

• Subject to

p

m

c

i 1 j 1 k 1

m

x

ijk

j 1

o

p

t

i 1 k 1

m

x C j NM j

ijk ijk

rik NPk

j 1

i =1,2,...,o; k =1,2,...,p

x j NM j

ijk ijk

xijk 0 and integer

j =1,2,...,m

i 1, 2,..., o; j 1, 2,..., m; k 1, 2,..., p

NM j 0 and integer

j 1, 2,..., m

Queuing Model

Manufacturing engineers at the Widget Manufacturing

Company recently convinced their manger to purchase a

more expensive, but flexible machine that can do

multiple operations simultaneously.

The rate at which parts arrived at the machine that was

replaced by the flexible machines follows a Poisson

process with a mean of 10 parts per hour.

The service rate of the flexible machine is 15 units parts

per hour compared with the 11 units per hour service

rate of the machine it replaced. (All service times follow

an exponential distribution.)

Queuing Model

The engineers and manager were convinced that the company

would have sufficient capacity to meet higher levels of demand, but

just after a two months of purchasing the machines it turned out that

the input queue to the flexible machine was excessively long and

part flow times at this station were so long, that the flexible machine

became a severe bottleneck.

The engineers noticed that more parts were routed through this

machine, and that the parts arrival rate to the flexible machines had

increased from 10 per hour to about 20 per hour, but were puzzled

why the part flow time at this station doubled from 30 minutes to one

hour and the work-n-process (WIP) inventory increased nearly

threefold from 5 o 14 when the arrival rte only increased 40%.

Use a queuing model to justify the results observed at Widget

Manufacturing Company.

M/M/1 Model Solution

Parameters

Arrival rate

Service Rate

Machine Utilization

WIP

Flow Time

Replaced Machine

10

12

Flexible Machine

14

15

0.83

0.93

5

14

0.5

1

Personnel requirements analysis

• n number of types of

operations

• Oi aggregate number of

operation type i required

on all the pseudo (or real)

products manufactured

per day

• Ti standard time

required for an average

operation Oi

• H total production time

available per day

• η assumed production

efficiency of the plant

n

Ti Oi

N

i 1 H

Queuing Model

The American Automobile Drivers’ Association (AADA) is the only

office serving customers in New York’s greater capital district area.

Ahead of the busy summer season, the office manager wants to hire

additional staff members to help provide these services to members

effectively - summer travel planning, membership renewal,

disbursing traveler’s checks, airline, hotel, and cruise booking, and

other travel related services.

It is anticipated that each customer typically requires 10 minutes of

service time and customers arrive at the rate of one customer every

three minutes.

The arrival process is Poisson and the service times are

exponentially distributed.

Determine how many staff members are required if the average

wages and benefits per staff member are $20 per hour and the

“cost” to AADA for every hour that a customer waits to be served is

$40.

M/M/m Model Solution

Number of staff members (m)

Arrival rate

4

20

Service Rate

6

0.83

Machine Utilization

Time in queue

Hourly Cost

0.1447

$195.74

5

20

6

20

6

0.67

6

0.56

0.0261

$120.85

0.0075

$126.01

Production space requirement

sheet

Departme

nt Name

Work

Center

Name

Work

Center

Code

Lengt

h

(feet)

Width

(feet)

Area

(feet2 )

Auxiliar

y Area

(feet 2)

Operato

r Space

(feet2 )

Materia

l Space

(feet 2)

SubTotal

(feet2 )

Allowanc

e (feet2)

Total

space per

machine

(feet2 )

Number

of

Machine

s

Total

Space

Machine

Type

(feet2 )

General

Machining

Vertical

Milling

1202

15

15

225

70

30

50

375

150%

565

2

1130

Planer

2005L

25

5

125

40

20

40

225

125%

290

1

290

Punch

Press

3058

10

10

100

30

20

20

170

140%

240

2

480

Injection

Molding

6078

20

10

200

60

50

100

410

150%

615

3

1845

NCMachine

9087

20

8

160

50

30

30

270

125%

340

2

680

Lathe

1212

15

8

120

40

20

30

210

150%

315

1

315

AutoChucker

2056

5

5

25

10

5

5

45

125%

60

1

60

Otoscope

Cell