Emulsions

advertisement

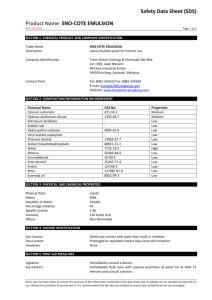

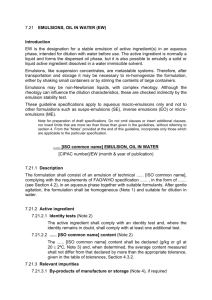

Emulsions Alfred Martin Lecturer: Dr. Majid R. Feddah Introduction Emulsion consists of two immiscible liquids one of which is uniformly dispersed throughout the other as droplets of diameter greater than 0.1µm. To prepare a stable emulsion a third phase, an emulsifying agent, is required. Emulsions is a useful way to present oils and fats in a palatable form. Emulsions for external use are known as a lotion. 2 Oil in Water or Water in Oil Oil Water Water in Oil Oil in Water 3 Emulsion Types Oil in Water, (O/W) the oil phase distributed as globules in the aqueous phase (continuous phase). Water in oil, (W/O) the water is distributed through out the oil phase (continuous phase). Pharmaceutical emulsion usually O/W emulsion. 4 Determining the type of emulsion 1. Water soluble dye to be dusted on the surface of the emulsion: O/W the dye will be dissolve the color & diffuse through the system. W/O, the dye will stay on as clumps on the tope of the emulsion. 2. Dilution of the emulsion with water, if the emulsion mixed freely with water, thus it is O/W. 5 Types of emulsion continue… 3. Electrical current test: Electrodes connected to the external electric source and immersed in the emulsion, if the external phase is water a current will pass through the emulsion. 4. Staining tests Filter paper soaked in cobalt chloride solution and allowed to dry The filter paper will turns from blue to pink on exposure to stable O/W emulsion. 6 Pharmaceutical Applications 1. Convenient of orally water insoluble liquids, when the dispersed phase has unpleasant taste. 2. Increase the absorption (some ingredients such as vitamins are absorbed completely when emulsified with emulsifying agent). 3. For patients how can’t getting medicine and nutrition's orally. (I.V Emulsion) 4. In many cosmetics preparations (dermatological products, lotions and creams) because the ability for spreading is high over the skin. 7 5. In diagnostic agents in x-ray examination. 6. In aerosols preparation for producing foams. 7. To prepare stable and homogeneous mixtures of two immiscible liquids. 8. It permits the administration of a liquid drug in a form of globules. 9. Reduce the droplet size of the oil, make it more readily absorbed. 10. If the active ingredients irritating the skin, are less irritant when used as internal phase. 8 Methods of Emulsion Preparation 1. 2. Emulsion may be prepared in different methods depends on: The nature of emulsion component. Available emulsion equipments. In small scale a mortar and pestle, a mechanical blender, a homogenizer. In large scale, large tanks, and high speed mixer homogenizer may be used to prepare an emulsion 9 In small scale 1. Continental or dry gum method. 2. English or wet gum method. 3. Bottle method. 10 Continental Dry Gum Method The method is also referred to as the 4-2-1 (Oil-Water-Gum). In this method: 1. The acacia or O/W emulsifier is triturated with the oil in a dry wedgewood or porcelain mortar, until mixed. A rough surface should be used, for good grinding to reduce the globules size. 2. Then the two parts of water are added all at once. 3. The mixture triturated immediately, rapidly and continuously until the primary emulsion is formed. creamy white and produces a crackling sound. 11 Continental method continued. 4. Other liquid ingredients that are soluble in the external phase may then be added. 5. Solid substances such as preservatives, stabilizers colorants, and any flavoring material usually dissolved in a water then added to an emulsion. 6. Any substances that may interfere with the stability of emulsion may added at the end. 12 English or Wet Gum method 1. 2. 3. 4. 5. The same proportion of water, gum and oil is used. Triturating of acacia with water in a mortar. The oil then is added slowly in portions. The mixture is triturated to emulsify the oil. The mixture is thoroughly mixed for several minutes to insure uniformity of the emulsion. Other substances may be added. 13 Bottle Method 1. 2. 3. 4. 5. It is used for volatile oils or oleaginous substances of low viscosity. The powder acacia is placed in a dry bottle. Two parts of oil then added. The bottle is then shaken in a caped container. A water is then added in portions. When a primary emulsion is formed the other ingredients is added. It is not suitable for viscous oils. 14 Auxiliary Methods To increase the quality of emulsion prepared by any of the pervious methods: The emulsion is passed through a hand homogenizer. The emulsion is forced to pass through a very small orifice which reduces the globules of the internal phase to a bout 5 µm. 15 In situ Soap method The two types of soaps are developed by this method: 1. Calcium soap. 2. Soft soap Calcium Soap: It is W/O emulsion contain vegetable oils (Oleic acid in combination with lime water (calcium hydroxide solution, USP). • Prepared by mixing equal volumes of oil and the lime water. • The emulsifying agent is the calcium salt of the free fatty acid which is formed from the combination of the two entities. This formula is ideal where occlusion and skin softening are desired. 16 Ideal Emulsion Ideal Emulsion 1. 2. 3. 4. 5. 6. Colorless Odorless. Tasteless. Non-toxic. Non irritant. Able to produce stable emulsions at low concentration. 18 Theories of Emulsification 1 No universal theory of emulsification. Because emulsion can be prepared using several different types of emulsifying agent, each of which depends for its action on a different principles to achieve a stable products. Any theory to be acceptable should explain the followings: 1. The stability of the product. 2. The type of emulsion formed. 19 2 What happened when two immiscible liquids are agitated together? Failure the two liquids to remain mixed, because : The cohesive force between the molecules of each separate liquid is greater than the adhesive force between the two liquids. The increase in the surface energy makes the system thermodynamically unstable, Hence the droplets have a tendency to coalesce. 3 To prevent coalescence: Introduce third material (Emulsifying agent), which form a film around the dispersed globules and prevent them from come to each other and form big one (globules). Types of emulsifying agents 21 Types of Emulsifying Agents 4 1. Surface active agents: Adsorbed at oil/water interfaces to form monomolecular films - reduce interfacial tension. 2. Hydrophilic Colloids: Form multi-molecular film around the dispersed droplets of oil in water (O/W) emulsion. 3. Finely divided solid particles: Adsorbed at the interface between two immiscible liquid phases and form a film of particles around the dispersed globules. 22 Summary All of them form a film around the globules, either mono, or multi layer, or particulate. Table 18-1 page 488. Classification of Dispersed Systems Class Range of particle size Characteristics of the system Examples Molecular Dispersion Less than 1.0nm (mµ) Invisible in SEM, pass through ultra filters Oxygen molecules, ordinary ions, Glucose Colloidal Dispersion 1.0nm to 0.5µm Could be detected under SEM Colloidal silver solution Coarse Dispersion Greater than 0.5µm (µ) Visible under microscope, not pass through normal filter Ref. Martin chapter 15, colloids 24 5 1. Surfactant: Monomolecular Adsorption: Surface active agents, reduce the interfacial tension because of their absorption at the oil water interface to form monomolecular layer films. . The film should be: 1. Flexible, to reform rapidly in case of broken or disturbed. 2. The presence of surface charge, cause repulsion and enhance stability of the emulsion. 3. Combination of more then one emulsifier are used in the preparation of emulsion. 25 Recommendations Atlas of surfactants, recommends that: The hydrophilic Tween be combined with a lipophilic Span, varying the proportion so as to produce the desired O/W or W/O emulsion. Tween 40 (polyoxyethylene sorbitan monopalmitate) and Span 80 for stabilization of emulsion. Mix of different emulsifying agents produce stable emulsion such as , (sodium stearate, cholesterol, sodium lauryl sulfate, glyceryl monostearate, tragacanth and span). 7 The type of emulsion produced, depends on the properties of emulsifying agent used. This characteristics is called Hydrophile-Lipophyl balance and referred to as (HLB). It is the polar, and non-polar nature of the emulsifier. Example: Sodium stearate C17H35COONa ─ The non-polar hydrophobic C17H35 go to oil. is the lipophilic ─Polar group hydrophilic ─ COONa go to water. The balance between the lipophilic and the hydrophilic will determine the type of emulsion formed 27 HLB The exam of the med HLB 9 Whether a surfactant is an Emulsifier. Wetting agent. Detergent. Solubilizing agent. It will be predicted from a knowledge of (HLB). Each emulsifying agent is assigned an HLB value. 30 HLB continued 10 The usual range of HLB is between 1 to 20. Material that are highly polar or hydrophilic have higher number of HLB than materials less polar lipophilic low number of HLB. Materials having an: HLB value (3-6) are lipophilic & produce W/O. HLB value (9-12) are hydrophilic and produce O/W. 31 Rule of Bancroft 11 The type of emulsion is a function of the relative solubility of the surfactant, the phase in which it is more soluble being the continuous phase. Emulsifying agent with a high HLB is soluble in water and results in the formation of an (O/W) emulsion. The reverse situation is true with surfactant of low HLB, which tend to form (water in oil) emulsions. 12 HLB Values of emulsifying agents Emulsifying agent HLB value Acacia 8.0 Sorbitan monolaurate 8.6 Sorbitan monostearate 4.7 Polysorbate 20 16.7 Polysorbate 60 14.9 Polysorbate 80 15.0 Sodium lauryl sulphate 40.0 Sodium oleate 18.0 Tragacanth 13.2 Triethanolamine oleate 12 33 13 II. Multi-molecular Adsorption & film formation Its hydrated lipophilic colloids, they considered as surface active agents because they appear at the oil water interface. They differed from the surfactants in: 1. They do not cause an sufficient lowering of the interfacial tension. 2. They form multi-layer rather a monolayer film at the interface. 34 14 The action as emulsifying agents is due to the multilayer formation around the droplets, so, strong film which resist coalescence. Another effect promoting stability is the significant increase in the viscosity of the dispersion medium. These emulsifying agents are hydrophilic, and they tend to promote the formation of O/W emulsions. 35 III. Solid Particle Adsorption 15 Those solids particles are wetted by both oil and water, so they can act as emulsifying agents. They presents water and oil interface, where they produce a film around the dispersed droplets. By this way it prevent coalescence. Powders which are wetted mainly by: • Water form O/W emulsion. • Oil they form W/O emulsion. 36 Physical Stability of Emulsions 16 Finished product and stability: 1. Absence of coalescence of the internal phase. 2. Absence of the creaming. 3. Maintenance of elegance with respect to appearance, Odor, Color, and other physical properties. 4. Agglomeration of the internal phase and separation from the product. 37 17 Physical stability continued Creaming, resulting from flocculation and concentration of the globules of the internal phase. Is not considered as a mark of instability. Creaming results from flocculation, which, represent potential steps toward complete coalescence of the internal phase. In pharmaceutical dosage forms creaming is results in lack of uniformity of drug distribution. 38 Phase Inversion 18 It is the change of emulsion type from W/O to O/W or vice versa. It is considered as emulsion instability. An oil in water emulsion stabilized with sodium stearate can be inverted to the water in oil by adding calcium chloride to form calcium stearate. Inversion occur by alteration in phase volume ratio. 39 Classification of the emulsion instability 1. 2. 3. 4. Flocculation and creaming. Coalescence and breaking. Miscellaneous physical and chemical changes. Phase inversion. Instability of Emulsion 19 41 Creaming and Stokes Law 20 If the dispersed phase is less dense than the continuous phase (the case in O/W) emulsion, the velocity of sedimentation become negative, that results in upward creaming. If the dispersed phase is heavier than the contiguous phase (the case in W/O) emulsion, the globules will settle in the bottom of the container (creaming in the downward direction). 42 Factors reducing creaming in emulsion 21 Viscosity: Increasing the viscosity of the external phase, by adding thickening agents such as Methylcellulose, Tragacanth, or Sodium alginate. Globules size: Reduction in the globules size by homogenization to reach below 2 to 5 µm. 43 Coalescence and Breaking 22 Creaming is a reversible process. It can re-dispersed by mixing and homogenization, as the oil globules are still surrounded by the protective film of the emulsifying agent. Breaking is irreversible. In this case the film surrounded the globules are destroyed and the oil tend to coalesces 44 Coalescence and Breaking 23 Reduction in the globules size does not necessarily lead to increased the stability of the emulsion. Optimum degree of dispersion for each particular system exists for maximum stability. Viscosity alone does not produce stable emulsion, however viscous emulsion are more stable than mobile ones. The phase volume ratio, the volume of oil and the volume of water in the emulsion, the best is 50 parts of water:50 parts of oil. 45 24 Cracking: Is the coalescence of dispersed globules (internal phase) and separation of the disperse phase as a separate layer. (It is irreversible process and re-dispersion cannot be achieved by shaking). 46 Electrolytes 25 Emulsion can be stabilized by electrostatic repulsion between the droplets, by increasing their zeta potential. Lecithin is used to stabilize emulsion. Lecithin produces very stable emulsion of triglyceride acids in water for intravenous administration. The stability of these emulsion some times is poor because in clinical practice they are mixed with electrolytes, amino acids, and other compounds for parenteral nutrition. The addition of positively charged species such as sodium and calcium ions or cationic amino acids, reduces the zeta potential and may cause flocculation. Heparin, an anticoagulant, is a negatively charged polyelectrolyte that causes rapid flocculation in emulsions containing calcium and lecithin. Emulsifier The most important factors in stabilization of an emulsion is the physical properties of emulsifier film at the interface. To be effective, an emulsifier film must be: 1. 2. 3. 4. Tough (strong). Elastic Should form rapidly during emulsification. Form a film around the globules and protect the globules from re aggregation during manufacturing the film, then slowly increases the film strength over a period of days or weeks. 26 Evaluation of Stability 1. 27 Size frequency analysis form time to time as the product ages. Microscopic observation of separated internal phase. The particle diameters are measured, and a size frequency distribution of particles ranging from 0-0.9, 1-1.9 etc. 2. Accelerating the separation process, which normally takes place under stress conditions. i. These methods employ freezing, thaw-freezing cycles, and centrifugation. ii. Electrical conductivity changes, during short heating cooling heating cycles. The stability index indicates the relative change in conductivity between two cycles. The smaller the conductivity, the greater is the stability of the emulsion. 29 Source of contamination in emulsions Contamination may be introduced from a variety of sources including: Natural emulsifying agents, for example, starch, acacia gum etc, . 1. 2. 3. 4. 5. Water, if not properly stored. Carelessly cleaned equipment. Poor closures on containers. Environment where the emulsion prepared. Container and closures systems. 51 Preservation of Emulsion 30 Is it necessary to achieve sterile condition in an emulsion? What about emulsion for parenteral use? Different components of emulsion: Water, Oil, emulsifying agents, color, odor, and microbial contaminations. Bacteria degrade nonionic & anionic emulsifying agents, (glycerin, and vegetable gums) which, presents as thickeners in the formula, resulting consequence deterioration of the emulsion 52 Preservation of Emulsion - 2 31 The main problem is to get adequate concentration of preservative in the system. Factors should be considered to achieve this: Emulsion is an heterogeneous system, hence partitioning of the preservative is occurs between water and oil phase. Bacteria grow at the aqueous phase, and the preservative partitioned to the oil phase, hence the concentration of the preservative in aqueous phase in not enough to prevent bacterial growth. 53 Preservation of Emulsion - 3 32 The phase volume ratio is significant in this regards. The preservative must be in an un-ionized state to penetrate the bacteria membrane. The preservative must not be bound to other ingredients in the emulsion since the complex form (preservative-X) are ineffective as preservatives. 54 Preservatives used in Emulsions-4 Benzoic acid: (0.1% ) at pH below 5. 2. Esters of parahydroxybenzoic acid such as methyl paraben (0.01 – 0.3%). 1. 33 3. Chloroform Water (0.25% V/V). 4. Chlorocresol (0.05 - 0.2%). 5. Phenoxyethanol (0.5 - 1.0%). 6. Quaternary ammonium compounds (cetramide). 7. Organic mercurial compounds such as phenylmercuric nitrate and acetate (0.002 -0.01%). 55 Rheologic properties of Emulsion The flow properties of emulsion is important according to the type of use: 1. In dermatological preparations: Spreadability is essential. 2. In case parenteral preparations: Flow of emulsion through needles is important. 3. The removal of emulsion from bottle and tubes 56 4. The behavior of an emulsion in the various operations employed in the large-scale preparations. 5. Most emulsion exhibit Non-Newtonian flow. 57 Emulsifying agents These agents helps in the production of stable dispersion by reducing interfacial tension and then maintaining the separation of the droplets by forming a barrier at the oil water interface. Effective emulsifying agents are surface-active agents, these have hydrophilic groups which are oriented towards the water, and lipophilic nonpolar toward the oil. extra 58 Oil Water Extra 59 Extra 60 W/O/W Oil in water Extra 61 Emulsifying agents Emulsion type determine by the solubility of the emulsifying agent, if the emulsifying agent is more soluble in water, i.e. hydrophilic then water will by the continuous phase and O/W emulsion will formed, If the emulsifying agent is more soluble in oil, i.e. hydrophobic then oil will by the continuous phase and W/O emulsion will formed, If some material is added which alters the solubility of the emulsifying agent, this balance may be altered and the emulsion may change type. 62 Naturally Occurring Emulsifying Agents These agents come from animal or vegetable sources., the quality is vary and are susceptible to microbial contamination. 1. Polysaccharides: - Acacia the best emulsifying agent 4 extemporaneously prepared oral emulsions (it form a thick film at the oil-water interface) to prevent the coalescence. - Tragacanth is used to increase the viscosity of an emulsion and prevent creaming. - Other polysaccharides, such as Starch, Pectin and Carrageenan, are used to stabilize an emulsion. Extra 63 Semi-Synthetic polysaccharides Low viscosity grades of: Methylcellulose and Carboxymethylcellulose will be form oil in water emulsion (O/W). Sterol-containing substances: These agents act as water in oil (W/O) emulsifying agents. (Beeswax, wool fat and wool alcohols). Extra 64 Surfactants Those agents contain hydrophilic and lipophilic regions in the molecule. Classification according to their ionic characteristics: 1. Anionic. 2. Cationic, 3. Non-ionic 4. Ampholytic. Anionic Surfactants: Its organic salts which in water have surface active anion. They must be in ionized form to be effective. Emulsion made with ionic surfactant are stable at alkaline pH. Extra 65 Example 1. Sodium Stearate. (o/w) 2. Calcium oleate (w/o). 3. Triethanolamine (TEA) oleate (o/w). 4. Sodium lauryl sulphate. (o/w) 66 Cationic Surfactant These are quaternary ammonium compounds, which, have surface active cation. They are used in the preparation of O/W emulsion for external used and must be in ionized form to be effective. Emulsion formed by cationic surfactant are stable at acidic pH. The cationic surfactant have antimicrobial activity. Example: Cetrimide and Benzalkonium chloride 67 Non-Ionic Surfactant Non-ionic these are synthetic materials and make up the largest groups of surfactants. They are used to produce either (O/W) or (W/O) emulsion for both external and internal use. Type of emulsion formed is depends on the balance of hydrophilic and lipophilic groups which is given by Hypophil Liphophyl Balance 68 Factors affecting the flow properties 1. Viscosity related properties of dispersed phase. The phase volume ratio. particle size distribution. The viscosity of the internal phase. When volume concentration of the dispersed phase is low, the system is Newtonian, as the volume concentration increased, the system become more resistant to flow and exhibits pseudo plastic flow, and at very high concentration plastic flow occur. When the volume conc. Approaches 0.74, inversion may occur. 69 By increasing the concentration of the dispersed phase Newtonian Plastic Pseudo plastic phase inversion. Reduction in the particle size increases the viscosity, the wider the distribution, the lower the viscosity when compared to system having a similar mean particle size but narrower distribution. 70 2. The emulsifying agent. The type of emulsifying agent used will affect the particle flocculation and interparticle attraction and this will affect flow. The greater the concentration of the emulsifying agent the higher will be the viscosity of the product. The physical properties of the film and its electric properties are also significant. 71 Antioxidant Some oils are liable to degradation by oxidation and therefore antioxidant may be added to the formulation. Antioxidants used in oral emulsions which are odorless and tasteless include ascorbic acid, citric acid, sodium metabisulphite and sodium sulphite. 72 Evaluation of Stability 73 Preservation of emulsion 74 Microemulsions Clear, transparent solution, but unlike micellar solubilized systems, microemulsions may not be thermodynamically stable. Its between stable solubilized solutions and ordinary emulsions, which are relatively unstable. Microemulsion contain droplets of oil in a water phase or droplets of water in oil with diameters of about 10 to 200 nm, and the volume fraction of the dispersed phase varies from 0.2 to 0.8 75 A third phase is used for emulsification of the system such as surfactant and co-surfactant . The micro-emulsion is studied as drug delivery system for the following reasons: To increase bioavailability of the drug poorly soluble in water by incorporation of the drug into the internal phase. Micro-emulsion have also been considered as topical drug delivery systems. 76 Micro-emulsion continued Hydrophilic surfactants may be used to produce transparent o/w emulsion of many oils including flavor oils and vitamin oils such as A, D and E. Surfactant in the HLB range of 15 to 18 have been used in preparation of such emulsions. Surfactants commonly used in the preparation of such oral liquid formulations are: Polysorbate 60 Polysorbate 80 77 Advantages of microemulsion 1. Rapid and efficient oral absorption of drug compared to solid dosage form. 2. Enhance trans-dermal drug delivery through increased drug diffusion into the skin. 3. Potential application of microemulsion in the development of artificial red blood cells and in the targeting of cytotoxic drugs to cancer cells. 78 Stability of emulsions In general the emulsions considered as unstable systems. 1. The internal phase tends to form aggregates of globules. 2. Large globules or aggregates rise to the top or fall to the bottom of the emulsion, to form a concentrated layer of internal phase called “Creaming”. 3. Emulsions may affected by microbial contaminations, and growth and by other chemical and physical changes. 79 Creaming is a reversible process. According to stokes’ equation, the rate of separation of the dispersed phase of an emulsion is related to: dx d 2 (ρ i ρ e )g dt 18η 1. 2. 3. The particles size of the dispersed phase. The differences in the density between the phases. The viscosity of the external phases. 80 Rate of separation increased by: 1. Increasing particle size. 2. Increasing the differences in density between the internal and the external phase dispersed. 3. Decreased by increasing the viscosity of the vehicle. 81 Another destruction occur in the emulsions is the coalescence of the globules of the internal phase and the separation of that phase into a layer. • This called “breaking” of the emulsion, and the emulsion described as being cracked or broken. • Care should be taken to protect emulsion from the external environment conditions cold and heat, freezing and thawing. • Emulsions are transported to different countries with different climate conditions so stability should cover these variations. 82 Stability of emulsions If the emulsion is light sensitive, a special container, may be used. For emulsions susceptible to oxidative decomposition, antioxidants may be included in the formulation. Methylparaben and propylparaben are frequently employed to serve this function. Alcohol in the amount of 12-15% based on the external phase volume is frequently added to orally used o/w emulsions fro preservation. 83 Examples of oral emulsions 1. Mineral oil emulsion: Mineral oil Acacia Syrup Vanillin Alcohol Purified water (qs) Prepared by dry gum method. 2. Simethicone Emulsion 3. Caster oil emulsion 500ml 125g 100ml 40mg 60ml 1000ml 84 Gels and Magmas Semi-rigid systems in which the movement of the dispersing medium is restricted by an interlacing threedimensional network in the system. A high degree of physical or chemical cross-linking may be involved. Some gels are clear in appearance other are turbid. The ingredients used may not be molecularly dispersed (soluble or not soluble). Two types of gels: 1. Single phase gels (the macromolecules are distributed throughout the liquid in such a way no boundaries exist between them and the liquid. 2. Two phase system or magma or milk The gel mass consists of floccules of small distinct particles 85 Colloidal dispersions “Sol” is a term to describe a dispersion of solid in either a liquid, a solid or a gaseous dispersion medium. A prefix such as hydro- for water. Alco- for alcohol. Aerosol to describe a dispersion of a solid or a liquid in a gaseous phase. 86 Colloidal dispersion there is no exact point of the particle size to be considered as a colloidal dispersion. In general solids in a range between (1nm to 0.5μm) called colloidal dispersion. Colloidal particles > than atoms, ions or molecules. The difference between the true solution and the colloidal dispersion is: 1. The particle size in the colloidal dispersion is larger. 2. The optical properties of the two systems, the solution do not scatter light and therefore clear, but colloidal dispersions scatter light thus appear turbid. 87 1. 2. 3. The nature of the dispersing phase with respect to the disperse phase (medium) is important. The attraction or lack of attraction between the disperse phase and the dispersion medium affects the ease of preparation of colloidal dispersion and the properties of the dispersion. Terms used to describe the degree of attraction: Lyophilic solvent loving Lyophobic solvent hating Amphiphilic this colloidal dispersion is formed by association of molecules that exhibit both lyophilic and lyophobic properties. 88 Lyophilic colloid (solvent loving) Large organic molecules, these substances dispersed readily upon addition to the dispersion medium to form colloidal dispersions. By increasing the disperse phase the viscosity increase. And may turned to semisolid or solid dispersion, termed a gel. Temperature can affect the gel to be turned to solution. Agitation also do the same and this phenomenon called thixotrophy. 89 Lyophobic colloids (solvent hating) Composed of inorganic particles. When added to the dispersing phase, there is little interaction between the two phases. It needs some procedure to make them to interact with the dispersion medium. Their addition to the dispersion medium does not affect the viscosity of the vehicle. 90 Most of the pharmaceutical preparations of colloidal desperation and gels are aqueous preparations. There is no general method for preparation of colloidal dispersion, but according to the means of best suited to the individual preparation. Some material termed “Natural colloids” because they are self-dispersing upon addition to the dispersing medium. Such as Acacia. Others require fine pulverization of coarse particles to colloidal size by colloidal mill or micropulverizer, and prepared under highly controlled condition. This called Artificial colloids. 91 Amphiphilic Amphiphilic colloids form dispersions in both aqueous and non-aqueous media. Depending upon their individual character and the nature of the dispersion medium. They generally increase the viscosity of the dispersion medium with an increase in concentration. 92 Terminology related to gels A number of terms are used to describe some of the properties of gels: Imbibitions. Taking up of certain amount of water without a measurable increase in volume. Swelling. Taking up water with an increase in volume. Only the liquids that solvate the gel can cause swelling. Syneresis. The shrinking of gel due to the great interaction between dispersed phase while standing. This is considered as instability (aqueous and non-aqueous gels). 93 Thixotropy: Is a reversible gel-sol formation with no change in volume or temperature a type of nonNewtonian flow. Xerogel: Xerogel is formed when the liquid is removed from a gel and only the framework remain. Examples: gelatin sheets, tragacanth ribbons and acacia tears. 94 Classification and Types of Gels Class Description Examples Inorganic Two phase systems Organic gel One phase system Hydrogel Contain water Silica, bentonite, sodium alginate, methylcellulose, alumina Organogels Hydrocarbon type Petrolatum, Mineral oil, Polyethylene gel (Plastibase) Hydrogels Organic hydrogels (Natural and synthetic gums Pectin paste, tragacanth jelly (Methylcellulose, sodium carboxymethylcellulose. 95 Aluminum hydroxide gel and bentonite magma Carbomer and tragacanth Preparation of Magmas and Gels Precipitating the disperse phase, to achieve fine degree of subdivision of the particles and a gelatinous character to those particles. The desired gelatinous precipitate results from the high attraction of inorganic agents with water. As the microcrystalline particles of the precipitate develop, they strongly attract water to yield gelatinous particles, which combine to form the desired gelatinous precipitate. 96 Theses preparations remain uniform on standing with little settling of the disperse phase. Because of the high degree of attraction between the disperse phase and the aqueous medium in both magmas and gels. Other magmas and gels may be prepared by the direct hydration in water of the inorganic chemical, the hydrated form constituting the disperse phase. In addition to the water vehicle, other agents as propylene glycol, propylgallate and hydroxypropylcellulose may be used to enhance gel formation 97 Examples of Gelling Agents Acacia, bentonite, carbomer, carboxymethylcellulose, sodium, cetostearyl alcohol, colloidal silicon dioxide, ethylcellulose, gelatin, magnesium aluminum silicate, maltodextrin, methylcellulose, polyvinyl alcohol, povidone, propylene carbonate, tragacanth, and xanthan gum. 98 Carbomer (Carbopol) It is a resin, used in a variety of pharmaceutical dosage systems including controlled release tablets, oral suspensions and topical gels. It is a high molecular weight. They are fluffy, white, dry powders with large bulk densities. The pH of 0.5 to 1% aqueous dispersions are (2.7 to 3.5) and (2.5 to 3) respectively. There are many carbomer resins, with viscosity ranges from 0 to 80,000 cps. Carbomer 910, 934, 934p, 940, and 1342 are official in the USP. 99 Carbomer continued Carbomer 934 are highly effective in thick formulation such as viscous gels. It can be used as suspending and emulsifying in both oral and topical formulation, the 934 polymer is also used to provide sustained release properties in both the stomach and intestinal tract for commercial products. The addition of alcohol decrease its viscosity and clarity, so the increase in the concentrations are required. The maximum viscosity and clarity occur at pH7. 100 Carboxymethylcellulose Carboxymethylcellulose can be used in concentration of 4 to 6% of the medium viscosity grade to produce gels. Glycerin may be added to prevent drying. Precipitation can occur at pH of less than 2. It is most stable at pH level between 2 and 10. It is incompatible with ethanol. 101 Colloidal silicon dioxide For preparation of transparent gels. Adsorbs large quantities of water without liquefying. The viscosity is largely independent of temperature. Change in pH may affect the viscosity. It is most effective at pH value 7.5 102 Gelatin Prepared from gelatin by dispersing the gelatin in hot water followed by cooling. Magnesium aluminum silicate, veegum It form film at concentration of about 10% from (Thixotropic gels). The material is inert and has few incompatibilities but is best used above pH 3.5. 103 Methylcellulose It is long chain substituted cellulose that can be used to form gels in concentrations up to 5% Methylcellulose hydrates slowly in hot water, the powder is dispersed with high shear in about 1/3 of the required amount of water at 80 to 90ºC 104 Examples of Magmas and Gels Bentonite Magma, NF Prepared by mixing 5% bentonite, and colloidal hydrated aluminum silicate, in purified water. 1. By adding the bentonite directly to the purified water in a blender while running. 2. Or by sprinkling the bentonite, in portion, on hot purified water. By this method the mixture allowed to stand for 24 hours for complete hydration before stirring. 105 The bentonite is swells twelve times its volume upon addition to water. Bentonite after standing, it sets to a gel. And by agitation the solution form return. This phenomenon is termed thixotropy. It is alkaline pH, Bentonite magma is used as: 1. Suspending agent . 2. Used in extemporaneous preparations. 106 Aluminum Hydroxide gel 1. 2. Aluminum hydroxide gel USP, Aqueous suspension of gelatinous precipitate of Insoluble aluminum hydroxide. and the hydrated aluminum oxide (eq to 4% aluminum oxide). Preparation: By chemical reaction, the aluminum source of the reaction is aluminum chloride, which yield aluminum oxide and aluminum hydroxide precipitate. Glycerin, Sorbitol, Sucrose, Saccharin and Antimicrobial agents. Peppermint may added to the formula as falvorant agent. 107 It is a white, viscous suspension. It is effective in neutralizing the gastric Hcl. The dose 10 ml three to four times daily. Because it possesses a trivalent cation, aluminum hydroxide has the capability to interfere with the bioavailability of tetracycline. Decreasing the bioavailability of other drugs by adsorption onto the gel. So care should be taken to ensure the proper dose to given to the patient. 108 Milk of Magnesia, USP This preparation contains between 7 -8.5% of magnesium hydroxide. Prepared by a reaction between sodium hydroxide and magnesium sulfate. The preparation has a pH of 10. Used as acid neutralizer. Side effects the development of diarrhea. Thus the problem of diarrhea from magnesium hydroxide and the constipating effect from of aluminum hydroxide, these two drugs are combined in an antacid preparation. 109 Lubricating Jelly Formula Methylcellulose, 4000 cps. Carbopol 934 Propylene glycol Methylparaben Sodium hydroxide, qs ad Purified water 0.8% 0.24% 16.7% 0.015% pH 7 100 % 110 Preparation 1. 2. 3. 4. 5. 6. Disperse the methylcellulose in 40 ml of hot water. Chill overnight in a refrigerator to effect solution. Disperse the Carbopol 934 in 20 ml of water. Adjust pH to 7. Dissolve Methylparaben in propylene glycol. Mix the methylcellulose, Carbopol and propylene glycol fractions with care to avoid incorporation of air. Uses: To assist in medical procedures, to aid in inserting of various devices and drugs, including catheters and suppositories, and as a vehicles for some drug products. 111 Methods of preparation There are two possible methods, with the dry gum method being the most popular: Dry gum method of preparation. Look on page 132 Wet gum method of preparation. Look on page 132. 112 Pharmaceutical application of Emulsions Oral, rectal, and topical administration of oils and oil-soluble drugs. To enhance palatability of oils when given orally by disguising taste and oiliness. They can increase absorption of oils and oil soluble drugs through intestinal walls. Intramuscular injections of some water-soluble vaccines to provide slow release. 113 Parenteral nutrition formulated as emulsion. Sterile oil-in water emulsions are used to deliver oily nutrients intravenously to patients, using non-toxic emulsifying agents, such as lecithin. Examples cod liver oil emulsion, liquid paraffin oral emulsion and castor oil emulsion. Examples of emulsions for external use are Turpentine Liniment BP and oily calamine lotion BP. 114 Emulsions types Oil in water (O/W). Water in Oil (W/O). Multiple emulsion Water in oil and all in water (W/O/W). For delay-action of drug delivery systems. If the emulsion is for oral or i.v administration it will always be oil-in water. Oil in water and all in oil (O/W/O). 115 Emulsion for External use: The therapeutic use, texture and patient acceptability will be taken place into account. Oil in water emulsion are less greasy, easily washed from the skin and more cosmetically acceptable than water in oil. They have an occlusive effect, which hydrates upper layers of skin called an emollients. Water in oil emulsions rub in more easily. 116 Identification of emulsion type Miscibility tests. Conductivity measurements. Staining tests. Dye tests. 117 Formulation of Emulsions An ideal emulsion has globules of disperse phase that retain their initial character, that is the mean size does not change and the globules remain evenly distributed. The formulation of emulsions involves the prevention of coalescence of the disperse phase and reducing creaming. 118 What causes emulsions to crack or cream? Incorporation of excess disperse phase as discussed above. Globule size. Stable emulsions require a maximal no of small sized (1-3µm) diameter globules, and as few as larger(15-20µm) diameter globules. Storage temperature. Potential for globule coalescence. Increasing the viscosity of the continuous phase will reduce the potential for globule coalescence as this reduces the movement of globules. Changes which affect the interfacial film formed by the emulsifying agent. These changes may be chemical, physical or biological effects: Microbiological contamination may destroy the emulsifying agent. Addition of a common solvent. Addition of an emulsifying agent. Addition of a common solvent. Addition of an emulsifying agent of opposite type, for instance cationic to anionic. 119 Dispensing emulsions Emulsions can be prepared in small scale using mortar and pestle. Electric mixers can also be used. Incorporation of excess air may be a problem. All equipment must be clean and dry. All oil-soluble and water soluble components of the emulsion are separately dissolved in the appropriate phase. A suitable emulsifying agent must then be chosen. 120 Quantities for primary emulsions Type of oil Examples Fixed Oil water Gum Almond, arachis, cod liver oil, 4 castor 2 1 Mineral (Hydrocarbon) Liquid paraffin 3 2 1 Volatile Turpentine, cinnamon, peppermint 2 2 1 Oleo-resin Male fern extract 1 2 1 121 122 123 124 125 126 Theories of Emulsification Surface-tension theory. Oriented-wedge theory. Block Plastic or interfacial film theory. 127 1. Surface tension theory All liquids have a tendency to assume a shape having the least amount of surface area exposed. For a drop of a liquid, it is a spherical shape. In the spherical drop of liquid there are internal forces which promote the association of the molecules to resist the distortion of the drop into a less spherical form. 128 Theory continued If two or more drops of the same liquid come into contact with one another, the tendency is for them to join or to coalesce, making one large drop having less surface area. This tendency of liquids may be measured quantitatively, and when the surrounding of the liquid is air, it is referred to as Liquid’s surface tension. 129 When a liquid is in contact with a second liquid in which it is insoluble and immiscible, the force causing each liquid to resist breaking up into smaller particles is called interfacial tension. Substances that can promote the lowering of this resistance to break up and encourage a liquid to be reduced to smaller drops or particles. These substances is called Surface Active Agent. 130 Thus surface active agent facilitate the breaking up of large globules into smaller ones. Which then have lesser tendency to form coalesce. 131 2. Oriented-wedge theory Assume monomolecular layers of emulsifying agent curved around a droplet of the internal phase of the emulsion. Certain emulsifying agents orient themselves about and within a liquid in a manner reflective of their solubility in the particular liquid. In a system containing two immiscible liquids, presumably the emulsifying agent would be preferentially soluble in one of the phases and would be embedded more deeply and strongly in that phase then the other. 132 Oil Water 133 This theory based on: emulsifying agent have a hydrophilic or water loving portion and a hydrophobic or oil loving portion. The molecules will position themselves into each phase. Depending on the shape and size of the molecules, their solubility characteristics and their orientation, the wedge-shape arrangement envisioned for the molecules will cause the surrounding of either oil globules or water globules. 134 Wedge theory continued Emulsifying agent having greater hydrophilic character than hydrophobic character will promote an oil-in-water emulsion. Emulsifying agent having a greater hydrophobic character than hydrophilic character will promote an water-in oil emulsion. 135 The plastic or interfacial film theory places the emulsifying agent at the interface between the oil and water, surrounding the droplets of the internal phase as a thin layer of film adsorbed on the surface of the drops. The film prevents the contact and coalescing of the dispersed phase. The formation of an oil-in-water or water-in-oil emulsion is dependent upon the degree of solubility of the agent in the two phases. 136 Preparation of emulsions emulsifying agent. 1. 2. 3. 4. 5. Selection of emulsifier Must be compatible with the other formulative ingredients, and must not interfere with the stability or efficacy of the therapeutic effect. Must be stable. Non-toxic in the concentration used. Little odor, taste or color. The compatibility of the emulsifying agent to promote emulsification and to maintain the stability of the emulsion of the intended shelf life. 137 Type of emulsifiers 1. Carbohydrate materials: Acacia, Tragacanth, Agar, Chondrus, and Pectin. Formed oil in water emulsion 2. Protein substances. Gelatin, Eggyolk, and Casein. Form oil in water emulsion 3. High molecular weight alcohols Stearyl alcohol, cetyl alcohol, and glyceryl monostearyl alcohol. Used as thekining agent and stabilizers for oil in water emulsions. 138 4. Wetting agents. May be anionic, cationic or nonionic, these agent contain both hydrophilic and lipophilic groups. The lipophilic group account for it’s activity: In anionic agents, lipophilic portion is negatively charged. In cationic it is positively charged. Non ionic show no tendency to ionize. Some of them form oil in water, others form water in oil emulsions. Non ionic surfactant are effective over pH (3 to 10). Cationic surfactant are effective over pH range (3 to 7). Anionic surfactants require a pH of greater than (8). 139 5. Finely divided solids Colloidal clays including bentonite, magnesium hydroxide, and aluminum hydroxide. These agents form oil in water emulsions. The relative volume of internal and external phases of an emulsion is important, regardless of the type of emulsifier used. As the internal concentration of an emulsion increased there is an increase in the viscosity of the emulsion to a certain point after which the viscosity decrease sharply. At this point the emulsion undergo inversion. 140 The HLB System In general each emulsifying agent has a hydrophilic and lipophilic portion with one or the other being more or less predominant and described the type of emulsion. Emulsifying agents are categorized on the basis of their chemical make-up as to their hydrophile-lipophile balance. Each emulsifying agent is assigned an HLB value. 141 HLB continued The usual range of HLB is between 1 to 20. Material that are highly polar or hydrophilic have higher number of HLB than materials less polar and more lipophilic. Those materials having an HLB value (3-6) are lipophilic and produce W/O emulsion. Those materials having an HLB value (8-18) are hydrophilic and produce O/W emulsion. See table 13. 2 for examples 142 Methods of Emulsion Preparation 1. 2. Emulsion may be prepared in different methods depends on: The nature of emulsion component. Available emulsion equipments. In small scale a mortar and pestle Wedgewood, a mechanical blender, a homogenizer. In large scale, large tanks, and high speed mixer homogenizer may be used to prepare an emulsion 143 Micro-emulsions Thermodynamically stable. Optically transparent. Isotropic mixtures of a biphasic oil-water system stabilized with surfactants. The diameter of droplets is microemulsion may be in the range of (100Å to 1000Å). W/O and O/W may be formed with carefully selected surfactant. The type of emulsion produced depends on the oil and surfactants used 144 145