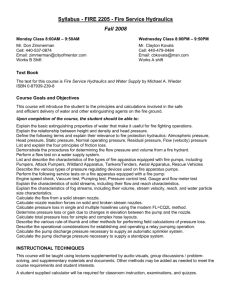

Pumping Apparatus Driver/Operator

advertisement

Pumping Apparatus Driver/Operator — Lesson 11 Pumping Apparatus Driver/Operator Handbook, 2nd Edition Chapter 11 — Operating Fire Pumps Learning Objectives 1. Answer questions about making the pump operational. 2. Engage and disengage a power take-off (PTO) or front-mount pump during pumpand-roll operation. 3. Engage and disengage a power take-off (PTO) or front-mount pump during stationary operation. (Continued) Pumping Apparatus Driver/Operator 11–1 Learning Objectives 4. Engage and disengage a midship pump. 5. Engage and disengage an auxiliary engine driven fire pump. 6. Complete statements about operating from the water tank. 7. Operate from the apparatus water tank. (Continued) Pumping Apparatus Driver/Operator 11–2 Learning Objectives 8. Make the transition from the apparatus water tank to an external water supply. 9. Answer questions about operating from a pressurized water supply source. 10. Operate from a pressurized water source. 11. Select facts about choosing a hydrant. Pumping Apparatus Driver/Operator 11–3 (Continued) Learning Objectives 12. Describe both a forward lay and a reverse lay. 13. Answer questions about forward and reverse lays. 14. List the preliminary checks that should be made after making hydrant connections but before opening the hydrant. (Continued) Pumping Apparatus Driver/Operator 11–4 Learning Objectives 15. Answer questions about putting the pump in service. 16. List methods for preventing pump overheating. 17. Complete statements about determining how much additional water a hydrant can supply. (Continued) Pumping Apparatus Driver/Operator 11–5 Learning Objectives 18. Calculate how much additional water a hydrant can supply. 19. List the steps for shutting down the hydrant operation. 20. Answer questions about operating from a static water supply source. (Continued) Pumping Apparatus Driver/Operator 11–6 Learning Objectives 21. List indications that a pump is cavitating. 22. Select facts about selecting the drafting site. 23. Select facts about connecting to the pump. 24. Answer questions about priming the pump and beginning operation. (Continued) Pumping Apparatus Driver/Operator 11–7 Learning Objectives 25. List common causes of inability to prime the pump. 26. List the categories of problems that can occur while operating from draft. 27. Operate from a static water source. 28. Select facts about supporting automatic sprinkler systems. (Continued) Pumping Apparatus Driver/Operator 11–8 Learning Objectives 29. Support a sprinkler system. 30. Select facts about supporting standpipe systems. 31. List factors that determine pump discharge pressure when supporting standpipe FDCs. (Continued) Pumping Apparatus Driver/Operator 11–9 Learning Objectives 32. Explain techniques for overcoming various standpipe impairments. 33. Support a standpipe system. 34. Troubleshoot pumping operations. Pumping Apparatus Driver/Operator 11–10 Making the Fire Pump Operational • Is also referred to as “putting the pump into gear” • Begins after the apparatus has been properly positioned and the parking brake has been set (Continued) Pumping Apparatus Driver/Operator 11–11 Making the Fire Pump Operational • After properly positioning the apparatus and setting the parking brake, on the majority of apparatus, the remainder of the procedure for making the fire pump operational takes place before the driver/operator exits the cab. (Continued) Pumping Apparatus Driver/Operator 11–12 Making the Fire Pump Operational • Once the driver/operator exits the cab, in all cases except when the apparatus is used for pump-and-roll operations, the next step should be to chock the apparatus wheels. (Continued) Pumping Apparatus Driver/Operator 11–13 Making the Fire Pump Operational • IFSTA recommends that the apparatus wheels be chocked every time the apparatus is stopped with the engine running and the driver/operator exits the cab. Pumping Apparatus Driver/Operator 11–14 Operating from the Water Tank • Most driver/operators operate solely from the onboard water tank at the vast majority of incidents. • In some circumstances, the fire attack begins with the water tank and may then make the transition to an external supply source. (Continued) Pumping Apparatus Driver/Operator 11–15 Operating from the Water Tank • The pump operator must be able to make the transition from the apparatus tank to an incoming water supply smoothly, with no disruption of the fireground operation. Pumping Apparatus Driver/Operator 11–16 Operating from a Pressurized Water Supply Source • Two basic pressurized water supply sources used to supply a fire pump – Hydrant – A supply hose from another fire pump Pumping Apparatus Driver/Operator 11–17 Negative Pump Pressure (Vacuum) • Water enters the pump under pressure. • As the discharge pressure or volume from the fire pump increases, the incoming pressure from the supply source may drop due to friction loss in the water system. • If the discharge pressure is increased too much, the intake pressure from the supply source may be reduced below 0 psi (0 kPa). Pumping Apparatus Driver/Operator 11–18 Dangers of Operating at Negative Pressure from a Fire Hydrant • Increases the possibility of damage to the fire pump due to cavitation • Can cause damage to the pump and water system due to water hammer if the flow is stopped suddenly • May damage water heaters or other domestic appliances on a municipal water supply system Pumping Apparatus Driver/Operator 11–19 Dangers of Operating at Negative Pressure from Another Pumper • Can cause supply hose to collapse, resulting in interruption of water supply • Can damage the pump through cavitation Pumping Apparatus Driver/Operator 11–20 Choosing a Hydrant • A thorough knowledge of the water system is required. • The hydrants are located on large water mains that are interconnected in a grid pattern. • The worst are those located on “dead-end mains.” (Continued) Pumping Apparatus Driver/Operator 11–21 Choosing a Hydrant • Single mains that supply small amounts of water do not have sufficient flow to prevent them from becoming clogged with sediment and encrustation. • Fire departments should have access to water department records that indicate the reliability of all hydrants in their jurisdiction. (Continued) Pumping Apparatus Driver/Operator 11–22 Choosing a Hydrant • Apparatus may be equipped with map books with hydrant information and locations. • Fire hydrants may be color coded to indicate the flow that can be expected. • Once a hydrant is selected, the pumper should be hooked to it as quickly as possible, using a forward or reverse lay. Pumping Apparatus Driver/Operator 11–23 Forward Lay • Stop at the hydrant, drop the end of one or more supply lines at the hydrant, and proceed to the fire location. (Continued) Pumping Apparatus Driver/Operator 11–24 Forward Lay • Problems – The distance from the hydrant to the fire and the length of hose carried on the engine. If the first-arriving engine runs out of hose, it may be necessary to bring in more hose or have the next-arriving company set up a relay pumping operation. (Continued) Pumping Apparatus Driver/Operator 11–25 Forward Lay • May use a four-way hydrant valve – Allows the original supply line to be immediately charged with hydrant pressure – Has second discharge outlet that allows second pumper to connect to hydrant without interrupting flow to original supply line – Allows the pumper connecting to the valve to boost pressure in the original supply line (Continued) Pumping Apparatus Driver/Operator 11–26 Forward Lay (Continued) Pumping Apparatus Driver/Operator 11–27 Forward Lay • Gate valves should be attached to unused hydrant discharges when using dry-barrel hydrants. • When using 2½- or 3-inch (65 mm or 77 mm) hoselines to supply the pumper off hydrant pressure, it is recommended that the lines be no longer than 300 feet (90 m) Pumping Apparatus Driver/Operator 11–28 Reverse Lay • Lays hose from the fire to the water source • Is used when a pumper must first go to the fire location for size-up • Is the most expedient way to lay hose if the apparatus must stay at the water source (Continued) Pumping Apparatus Driver/Operator 11–29 Reverse Lay (Continued) Pumping Apparatus Driver/Operator 11–30 Reverse Lay • Requires that, if threaded couplings are used, hose beds should be loaded so that the first coupling to come off is male • Is standard for setting up a relay pumping operation when using smaller diameter hose as a supply line (Continued) Pumping Apparatus Driver/Operator 11–31 Reverse Lay • Disadvantages – Essential fire fighting equipment must be removed and placed at the fire location before the pumper can proceed to the water source, causing delays – Pumper may not carry enough hose to reach from the fire to the nearest water source (Continued) Pumping Apparatus Driver/Operator 11–32 Reverse Lay • Does not require a four-way hydrant valve, although one can be used • May be used when the first pumper arrives at a fire and must work alone for an extended period of time Pumping Apparatus Driver/Operator 11–33 After Making Hydrant Connections but Before Opening the Hydrant • Check that: – The tank–to-pump valve must be closed if the intake is not equipped with a shutoff valve – A dry barrel hydrant must be opened all the way (Continued) Pumping Apparatus Driver/Operator 11–34 After Making Hydrant Connections but Before Opening the Hydrant • After the pump is full of water and the pressure in the system has stabilized with no water flowing, a reading of the pressure on the master intake gauge indicates the static pressure in the water supply system. (Continued) Pumping Apparatus Driver/Operator 11–35 After Making Hydrant Connections but Before Opening the Hydrant • It may be desirable for the pump operator to record or remember the static pressure before the operation begins. • Some departments use a grease pencil to mark the static pressure on the intake gauge. Pumping Apparatus Driver/Operator 11–36 Putting the Pump in Service • Do not engage the pump drive system before leaving the cab if there will be an extended period of time where water is introduced into the pump. • On a two-stage pump, set the transfer valve to the proper position before increasing the throttle to build discharge pressure. • Open discharge valves slowly. Pumping Apparatus Driver/Operator 11–37 Preventing Pump Overheating • Pull some of the booster line off the reel and securely tie off the nozzle to a solid object. Open the valve that supplies the booster reel, and discharge water in a direction that will not harm people or damage property. (Continued) Pumping Apparatus Driver/Operator 11–38 Preventing Pump Overheating • Open a discharge drain valve. – Designed to discharge water in a manner that will not harm people or damage property – May have threaded outlets that allow hose to be connected and routed to a safe discharge point – If so, discharge water away from the apparatus so that it does not become stuck in the mud (or frozen in ice) that could be created by discharging water directly beneath it (Continued) Pumping Apparatus Driver/Operator 11–39 Preventing Pump Overheating • Partially open the tank fill valve or pump-totank line. • Use a bypass or circulator valve if the apparatus is so equipped. Pumping Apparatus Driver/Operator 11–40 Determining How Much Additional Water a Hydrant Can Supply • When a pumper is connected to a hydrant and is not discharging water, the pressure shown on the intake gauge is static pressure. • When the pumper is discharging water, the intake gauge reading is the residual pressure. • The difference between these two pressures is used to determine how much more water the hydrant can supply. Pumping Apparatus Driver/Operator 11–41 Percentage Method • Calculate the drop in pressure as a percentage, using the following formula: Percent drop = (Static – Residual)(100) Static (Continued) Pumping Apparatus Driver/Operator 11–42 Percentage Method • 10% or less – May add 3 lines with same flow as the line being used • 11 to 15% – May add 2 lines with same flow as the line being used • 16 to 25% – May add 1 line with same flow as the line being used • Over 25% – More water may be available, but not as much as is flowing through the line being used Pumping Apparatus Driver/Operator 11–43 First-Digit Method • Find the difference in psi between the static and residual pressures. • Multiply the first digit of the static pressure by 1, 2, or 3 to determine how many additional lines of equal flow may be added. (Continued) Pumping Apparatus Driver/Operator 11–44 First-Digit Method • If psi drop is equal to or less than the first digit of the static pressure multiplied by: – one (1), three additional lines of equal flow may be added – two (2), two additional lines of equal flow may be added – three (3), one additional line of equal flow may be added Pumping Apparatus Driver/Operator 11–45 Squaring the Lines Method • Note the static pressure on the water system before any pump discharges are open. • Figure a relatively close figure of the volume of water that is initially being flowed by the pumper. • Square the number of lines currently flowing and multiply by the original pressure drop. Pumping Apparatus Driver/Operator 11–46 Shutting Down the Hydrant Operation 1. Gradually slow the engine rpm to idle to reduce the discharge pressure. 2. Take the pressure control device out of service if in use. 3. Slowly and smoothly close the discharge valves. 4. Place the drive transmission in neutral, and disengage the pump control device. Pumping Apparatus Driver/Operator 11–47 Operating from a Static Water Supply Source • In most cases, pumpers will be pumping water from a static water supply that will be located at a lower level than the fire pump. • Because one drop of water will not stick to another, it is not possible to pull water into the pump from a lower level. (Continued) Pumping Apparatus Driver/Operator 11–48 Operating from a Static Water Supply Source • To pump from a lower level, a pressure differential (partial vacuum) must be created by evacuating some of the air inside the fire pump. • To accomplish this, an airtight, noncollapsible waterway (hard intake hose) is needed between the pump and the body of water to be used. (Continued) Pumping Apparatus Driver/Operator 11–49 Operating from a Static Water Supply Source • The amount of friction loss in the hard intake hose is dependent upon the diameter and length of the hose. • The total pressure available to overcome all these pressure losses is limited to the atmospheric pressure at sea level – 14.7 psi or 100 kPa. (Continued) Pumping Apparatus Driver/Operator 11–50 Operating from a Static Water Supply Source • Atmospheric pressure decreases 0.5 psi (3.5 kPa) for each 1,000 feet (305 m) of elevation gain. • Increasing the height of the lift decreases total pump capacity. (Continued) Pumping Apparatus Driver/Operator 11–51 Operating from a Static Water Supply Source • The maximum amount of vacuum that most pumps develop is around 22 inches (560 mm) or mercury. A reading anywhere near this is a warning that the pump is getting close to the limit of its ability. Pumping Apparatus Driver/Operator 11–52 Cavitation • Is the condition where water is being discharged from the pump faster than it is coming in • Results if an attempt is made to increase the discharge from the pump beyond the point of maximum vacuum on the intake • Can damage the pump Pumping Apparatus Driver/Operator 11–53 Indications of Cavitation • Hose streams will pulsate, and the pressure gauge on the pump will fluctuate • A popping or sputtering may be heard as the water leaves the nozzle • The pump will be noisy, sounding like gravel is passing through it • A lack of reaction on the pressure gauge to changes in the setting of the throttle Pumping Apparatus Driver/Operator 11–54 Selecting a Drafting Site • If a draft is being established to supply water tenders for a shuttle operation, there may be several choices. • The choice is dictated by: – Amount of water (the most important factor) – Type of water – Accessibility of water Pumping Apparatus Driver/Operator 11–55 Amount of Water Available • If using a traditional strainer, there should be a minimum of 2 feet (0.6 m) all around the strainer (Continued) Pumping Apparatus Driver/Operator 11–56 Amount of Water Available • If using a traditional strainer, a whirlpool can form if there are not 2 feet (0.6 m) above the strainer. – Place a wooden board, capped plastic bottle, or beach ball above strainer to prevent whirlpool. Pumping Apparatus Driver/Operator 11–57 (Continued) Amount of Water Available • Drafting from a swiftly moving shallow stream – A dam can be constructed, – The bottom can be dug out to form a pool, – Or a combination of both (Continued) Pumping Apparatus Driver/Operator 11–58 Amount of Water Available • Drafting from a swiftly moving shallow stream – A “floating” strainer can be used – the end of intake hose floats on surface, and water is drawn into intake hose through holes on bottom of strainer (Continued) Pumping Apparatus Driver/Operator 11–59 Amount of Water Available • Drafting from a portable water tank or swimming pool – A low-level strainer may be used, which sits directly on the bottom of the tank or pool and allows the water to be drafted down to a depth of about 2 inches (50 mm) (Continued) Pumping Apparatus Driver/Operator 11–60 Amount of Water Available • Drafting from the ocean – What may be an acceptable drafting location at one time of the day may not be usable when the tide goes out • Temperature of water – Water below 35ºF (2ºC) or above 90ºF (32ºC) may adversely impact the pump’s ability to reach capacity Pumping Apparatus Driver/Operator 11–61 Type of Water Available • Any type of water can be used; however: – Untreated water can be harmful – Salt water and caustic chemicals can cause corrosion of the pump – Foreign materials and debris can clog the strainer • The most common type of contamination, and the most damaging, is dirty or sandy water. Pumping Apparatus Driver/Operator 11–62 Accessibility of Water • A maximum atmospheric pressure of 14.7 psi (100 kPa) is available when drafting. This pressure has to overcome elevation pressure and friction loss. • As the amount of lift increases: – Elevation pressure increases – Less friction loss can be overcome – Capacity of the pump is decreased (Continued) Pumping Apparatus Driver/Operator 11–63 Accessibility of Water • All fire pumps are rated to pump their • • • • • capacity at 10 feet (3 m) of lift. Less lift, higher capacity; greater lift, the capacity decreases. Stability of ground Time of year Convenience of connecting hoselines Safety of the operator Pumping Apparatus Driver/Operator 11–64 Connecting to the Pump • The apparatus may be able to park directly at the drafting location, or may have to temporarily park short. • Once the hard intake hose and strainer are connected to the apparatus, they can be put into the desired position and the apparatus can then ease slowly into the final drafting spot. (Continued) Pumping Apparatus Driver/Operator 11–65 Connecting to the Pump • Before connecting sections of hard intake hose, check that the gaskets are in place and that couplings are free of dirt or gravel. • The strainer and hard intake hose must be coupled and made airtight. (Continued) Pumping Apparatus Driver/Operator 11–66 Connecting to the Pump • It is usually easiest to connect the hose to the intake fittings by first putting the strainer in the water and then pulling the apparatus into position. • Improper positioning of the hard intake hose can result in the formation of an air pocket that can prevent effective drafting. (Continued) Pumping Apparatus Driver/Operator 11–67 Connecting to the Pump • If a barrel strainer is used, the rope that was tied to it can be used to suspend the strainer above the bottom by tying it to the pumper or to a tree or other fixed object. (Continued) Pumping Apparatus Driver/Operator 11–68 Connecting to the Pump • If the bottom slopes away steeply from the edge, it may be possible to put a roof ladder in the water and rest the intake hose on it. Pumping Apparatus Driver/Operator 11–69 Priming the Pump and Beginning Operation • Starts the draft operation • Transfer valve on two-stage pumps must be in the PARALLEL (VOLUME) position • All drains and valves must be closed • All unused openings must be capped to make the pump airtight before beginning Pumping Apparatus Driver/Operator 11–70 (Continued) Priming the Pump and Beginning Operation • On a positive displacement pump that is driven by the transfer case, the engine rpm should be set according to manufacturer’s instructions. • Most priming pumps are intended to work best between 1,000 and 1,200 rpm. (Continued) Pumping Apparatus Driver/Operator 11–71 Priming the Pump and Beginning Operation • When operating the primer control, the vacuum reading on the master intake gauge should read 1 inch (25 mm) for each 1 foot (0.3 m) of lift. • Priming should not be stopped until all air has been removed and primer is discharging a steady stream of water. (Continued) Pumping Apparatus Driver/Operator 11–72 Priming the Pump and Beginning Operation • The entire action typically requires 10 to 15 seconds, but should not take more than 30 seconds. • If a prime has not been achieved in 30 seconds, stop priming and find out what the problem is. (Continued) Pumping Apparatus Driver/Operator 11–73 Priming the Pump and Beginning Operation • Causes of inability to prime: – An air leak that prevents the primer from developing enough vacuum to successfully draft water – Insufficient fluid in the priming reservoir – Engine speed (rpm) is too slow – Lift is too high – A high point in the hard intake hose is creating an air pocket (Continued) Pumping Apparatus Driver/Operator 11–74 Priming the Pump and Beginning Operation • After successful priming, slowly increase throttle before opening any discharges. The pressure should be between 50 and 100 psi (350 kPa and 700 kPa). (Continued) Pumping Apparatus Driver/Operator 11–75 Priming the Pump and Beginning Operation • Open discharge valves slowly while observing discharge pressure. – If pressure falls below 50 psi (350 kPa), pause to allow it to stabilize. – If pressure continues to drop, momentarily operate primer to eliminate air in the pump and restore pressure to original value. (Continued) Pumping Apparatus Driver/Operator 11–76 Priming the Pump and Beginning Operation • Constant movement of water through the pump prevents overheating and maintains a vacuum. Pumping Apparatus Driver/Operator 11–77 Operating the Pump from Draft • Is the most demanding type of operation • Demands careful monitoring of gauges associated with the engine as well as those associated with the pump; any deviation from normal engine temperature is a signal that another pumper should be used Pumping Apparatus Driver/Operator 11–78 Problems that Can Occur While Operating from Draft • Air leak on the intake side of the pump • Whirlpool allowing air to enter the pump • Air leakage due to defective packing in the pump Pumping Apparatus Driver/Operator 11–79 Shutting Down the Operation • Slowly decrease the engine speed to idle • Take the pump out of gear • Allow the pump to drain • Operate the primer until primer oil or fluid comes out of the discharge from the priming pump Pumping Apparatus Driver/Operator 11–80 Supporting Automatic Sprinkler Systems • Because fires rarely cause all the sprinklers in a building to open, the water supply for sprinkler systems is designed to supply only a fraction of the total number of sprinklers installed on the system. (Continued) Pumping Apparatus Driver/Operator 11–81 Supporting Automatic Sprinkler Systems • Upon arrival, supply the fire department connection (FDC) immediately. – A siamese with at least two 2 ½-inch (65 mm) female connections, or – One large diameter sexless connection connected to a clappered inlet (Continued) Pumping Apparatus Driver/Operator 11–82 Supporting Automatic Sprinkler Systems • If any indication of actual fire – A minimum of two 2 ½-inch (65 mm) hoselines should be connected to the FDC – Supply lines should be laid to the hydrant and connections made • Rule of thumb: One 1,000 gpm (4 000 L/min) rated pumper should supply the FDC for every 50 sprinklers estimated to be flowing. (Continued) Pumping Apparatus Driver/Operator 11–83 Supporting Automatic Sprinkler Systems CAUTION! When interior crews are operating hoselines from a combination sprinkler/standpipe system with sprinklers flowing, the pressure supplied to the FDC should be based on the safe operating pressure for the hose crews. (Continued) Pumping Apparatus Driver/Operator 11–84 Supporting Automatic Sprinkler Systems • Interior attack crews should locate fire and determine if charging sprinkler system is necessary. If so, driver/operator should slowly develop pressure needed to supply system. • Recommended pressures may be: – Listed on a plate at the FDC – Listed in pre-incident plans – Rule of thumb: 150 psi (1 050 kPa) (Continued) Pumping Apparatus Driver/Operator 11–85 Supporting Automatic Sprinkler Systems • When possible, a firefighter should immediately check the control valves to ensure that they are open. • If a fixed fire pump on the property supplies the sprinkler system, the firefighter should also ensure that the pump is running. Pumping Apparatus Driver/Operator 11–86 Standpipe Systems • Are used to speed fire attack in multistory or single-story buildings with large floor areas • Include 2½- or 1½-inch (65 mm or 38 mm) connections on each floor (Continued) Pumping Apparatus Driver/Operator 11–87 Standpipe Systems Note: Fire personnel should not use house or standpipe lines unless a hose-testing program is implemented. (Continued) Pumping Apparatus Driver/Operator 11–88 Standpipe Systems • May be wet or dry – Wet: Contain water under pressure – Dry: Must be supplied with water from the FDC outside the building Note: Standpipe FDCs should be clearly marked to prevent confusion between sprinkler and standpipe connections. (Continued) Pumping Apparatus Driver/Operator 11–89 Standpipe Systems • Pump discharge pressure depends on: – Pressure loss (25 psi [150 kPa]) in the standpipe – Friction loss in the hose from the pumper to the FDC – Friction loss in the hose on the fire floor – Nozzle pressure for type of nozzle used – Elevation pressure due to the height of the building (Continued) Pumping Apparatus Driver/Operator 11–90 Standpipe Systems • When calculating discharge pressure, add 5 psi (35 kPa) to nozzle pressure for each floor above standpipe connection that will have operating fire streams in addition to losses already mentioned. (Continued) Pumping Apparatus Driver/Operator 11–91 Standpipe Systems • Pump discharge pressure calculations are too lengthy to make at scene • Fire department should have a planned pump discharge pressure or develop a rule of thumb for each building in the area. (Continued) Pumping Apparatus Driver/Operator 11–92 Standpipe Systems • If system is equipped with pressure-reducing valves, elevation pressure must be based on total height of standpipe or zone being used. • Vandals may open hose valves in dry standpipes and leave them open. Teams may have to go up or down the stairwell and close the open valves. Pumping Apparatus Driver/Operator 11–93 Overcoming Standpipe Impairments • FDC has a frozen swivel — A double male can be used with a double female • FDC is unusable because of vandalism — The standpipe riser can be charged at the first-floor level by attaching a double female to a hose valve at the first-floor level (Continued) Pumping Apparatus Driver/Operator 11–94 Overcoming Standpipe Impairments • An individual hose valve on an upper floor is found inoperative — A valve on the next floor down can be used • Single-riser building where standpipe is totally unserviceable – Hoist a line up the outside of the building – Use a standpipe in an adjacent building – Lay supply hose up the interior stairwell Pumping Apparatus Driver/Operator 11–95 Summary • Driver/Operators must: – Know how to operate fire pumps under a variety of conditions – Be able to engage the pump, to make it operational, and troubleshoot any problems that may develop. (Continued) Pumping Apparatus Driver/Operator 11–96 Summary • Driver/Operators must: – Choose the best available water source – onboard water tank, pressurized source, or static source – and provide this water to the pump – Operate the pump to safely and effectively supply water to attack lines and support automatic sprinkler systems and standpipes in buildings so equipped Pumping Apparatus Driver/Operator 11–97 Discussion Questions 1. What are the two basic pressurized water supply sources used to supply a fire pump? 2. What are some of the dangers of operating at a vacuum from a pressurized water source? 3. Describe both a forward lay and a reverse lay. (Continued) Pumping Apparatus Driver/Operator 11–98 Discussion Questions 4. What checks should be made after making hydrant connections but before opening the hydrant? 5. Name methods for preventing the pump from overheating. 6. Discuss the three methods for determining how much more water a hydrant can supply. (Continued) Pumping Apparatus Driver/Operator 11–99 Discussion Questions 7. Name the steps for shutting down a hydrant operation. 8. Name some indications that the pump is cavitating. 9. What three things dictate the selection of a drafting site? 10. Name some common causes of an inability to prime the pump. Pumping Apparatus Driver/Operator 11–100