National Environmental Laboratory Accreditation Conference

Preparing for Accreditation

Jerry L. Parr

Catalyst Information Resources, L.L.C.

TNRCC Trade Fair

May 7, 2002

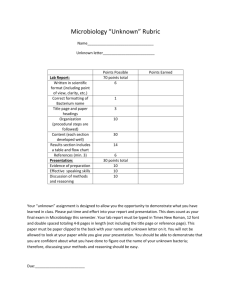

NELAC Accreditation:

Start to Finish

1. Deciding to apply

2. Understanding the requirements

3. Getting ready

4. Accreditation process

Key Documents

NELAC Standards

Assessor Training Manual

National Standards for Water PT

NELAC PT Tables

State Requirements

State Fields of Testing

STEP 1: Deciding to Apply

Your state’s requirements

Improve data quality

Customer expectations

Marketing advantage

NELAC Improves Data Quality

Implementation of a Quality System

Improved documentation

Standardized policies and procedures

Ethics program

Improved technical procedures

Customer Expectations

EPA

SDWA

OSWER

OIG

DOD

Industry

Marketing Considerations

Recognized standard of excellence

Use of logo

Reciprocity = geographic expansion

The Application

20 detailed items

Certificate of compliance

Fields of testing

Quality manual

Fee

State options

Required Elements in

Application

Legal name of lab

Address

Owner (and address)

Location

Name and phone of TD, QAO, contact

Hours of operation

Primary AA

Fields of testing

Methods employed

(with analytes)

Lab type

Certificate of Compliance

Attest to compliance to NELAC standards

Signed by Technical Director & QA

Director

Fields of Testing

Area:

Chemistry, Microbiology, WET, Radiochemistry, Field

Activities

Program

SDWA, CWA, RCRA, CAA (TSCA, FIFRA, CERCLA)

Changes to be made in 2002

Method/Analyte

Change to technology?

Include analyte group?

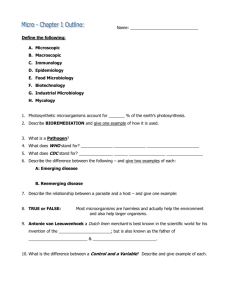

STEP 2 - Understanding the Requirements

Proficiency Testing

Quality System

Personnel Qualifications

PT Program Review

Two PT samples per year per field of testing where available

Purchase from any approved supplier

Uniform acceptance criteria

Pass 2 out of last 3

NELAC QUALITY SYSTEM

Elements documented in quality manual

Policies and objectives and commitment to accepted laboratory practices and quality of testing services

Annual internal audit and management review

NELAC Quality Manual

Policies and operational procedures established to meet NELAC standard.

Probably most significant up-front investment

Must address all QS elements

Template available from

Catalyst

Elements of a Quality System

Personnel

Physical facilities

Equipment and reference materials

Measurement traceability and calibration

Test methods and SOPs

Method verification (Appendix C)

Elements of a Quality System (2)

Sample handling

Records and storage of records

Laboratory report format and content

Subcontracting

Complaint procedures

Essential QC Procedures (Appendix D)

Chemical, WET, Micro, Radiochemistry, Air

Sample Handling

Sample tracking

Sample acceptance

Sample receipt

Sample storage

Legal chain of custody

Sample disposal

Calibration

Traceability of calibration

Reference standards

General requirements

Analytical support equipment

Instrument calibration

QA/QC

Document control

Acceptable permitting departures from documented policies, procedures, & specifications

Corrective action

Complaint handling

Preventive action

Internal audits

Developing acceptance criteria when no method or regulatory requirement exists

Data Review and Reporting

Data review

Reporting analytical results

Electronic reporting

Record retention

Records transfer

Data integrity

Data security

Test Methods

May be copies of published methods

Must address 23 elements

Essential Quality Control

Required activities, acceptance criteria and corrective action for:

D.1 Chemistry

D.2 WET Testing

D.3 Microbiology

D.4 Radiochemistry

D.5 Air

Chemistry QC

Method Blanks

LCS

MS

Surrogates

Detection Limits

Selectivity

Major revision in 2001 Standards

Detection Limit

Determination

Appropriate (e.g., MDL)

Limited exceptions (e.g., temperature)

Each Matrix (see Glossary)

Link to Quantitation Limit

Redo if “significant change”

Link to instrument calibration

Demonstration of Capability

All methods

4 replicates at 10 X DL

Compare X and s to acceptance criteria

Limited exceptions

“Work cell” provision

Certification statement

Exception in 2001 standards for methods in use before July 1999

Analyst Proficiency

One of the following at least once per year:

Single blind

DOC

PT sample

4 LCS

Sample analyzed by another

STEP 2 - Understanding the Requirements

Proficiency Testing

Quality System

Personnel Qualifications

Technical Director

Full time employee

Oversee all lab operations

QA/QC

Data being generated

Sufficient qualified personnel

“One or more” may be appointed

TD for Chemical Analysis

Bachelor’s degree in chemical, environmental, biological sciences, physical sciences, or engineering

24 college semester credit hours in chemistry

2 years of experience in environmental analysis

Master’s or Ph.D. may be substituted for

1 year experience

TD for Inorganic Analysis

(non metals)

Associate’s degree in chemical, physical or environmental sciences or

2 years college education and

16 semester credit hours in chemistry

2 years of experience

TD for Microbiology

Bachelor’s degree in microbiology, biology, chemistry, environmental sciences, physical sciences, or engineering

16 semester credit hours in general microbiology and biology

2 years of experience

Master’s or Ph.D. may be substituted for 1 year experience

Exception for Microbiology

Associate’s degree in science (or 2 years college) with 4 hours in general microbiology and 1 year experience in environmental analysis

Limited to fecal coliform, total coliform,

& standard plate count

Grandfather Clause

Does not meet educational requirements

Is the TD on date laboratory “applies” or

“becomes subject to” NELAC standards

AND has been TD for one year ( new for

2001 )

Can be TD at any other comparable laboratory

Limited to first year of program

Exceptions

Full-time employee:

Of drinking water or sewage treatment facility with valid treatment plant operator’s certificate appropriate for that facility is approved to serve as director of accredited lab devoted to samples taken within facility

Of industrial waste treatment facility with 1 year supervised experience is approved as director of accredited lab devoted to samples taken within facility

Quality Assurance Officer

May be TD or deputy TD if limited staff

Responsible for quality system management & implementation

Focal point for QA/QC

Documented training and/or experience in QA/QC

Knowledge of the test methods

Arrange for or conduct internal audits annually

Notify lab management of deficiencies in quality system & ensure corrective action

No educational or experience requirements

STEP 3 - Getting Ready

Organizational Decisions

Technical Director

Quality Assurance Officer

Data Generation

PT Sample Data

Method Performance Data

Documentation

Quality Manual

SOPs

Administrative Information

Organizational Options

Multiple TD(s), QAO

Singe TD, QAO

TD = QAO

Quality Assurance Officer

Title is optional

Direct access to management

May be technical director

Specific job functions

Recommendations for

TD/QAO

Have TD and QAO as 2 positions, if organization will allow

Have single TD, if qualifications allow

Have deputy TDs for contingency/growth

Consider grandfather clause

Summary of Data Needed

2 PT samples results

Detection limits

Demonstration of capability (not required for methods already in use, but a good idea)

Administrative Information

Laboratory organization

Personnel training

Equipment & reference materials

Standards & reagents

Other

Laboratory Organization

Organization chart

Identification of major units

Lines of responsibility

Personnel Records

Job descriptions

Documentation of education/technical background

Documentation for each employee relating to quality manual

Training records

Analyst proficiency

Equipment & Reference

Materials

Name of equipment

Manufacturer & serial number

Date received/placed into serviced

Current location

Condition when received

Copy of manufacturer’s instructions

Dates of calibration

Details of maintenance

History

Calibration certifications

Standards and Reagents

Certificate of analysis

Date of receipt

Manufacturer/vendor

Storage conditions

Expiration dates

Other information (e.g., sample disposal records)

STEP 4: The Assessment

Process

Understand the

Assessment Process

Assessors (i.e. auditors)

Frequency

Pre-Assessment

On-site Assessment (i.e. the Audit)

Assessment Report

Corrective Action

Closure

Steps to Take

Review assessor training manual

Review checklist

Internal/contractor review

Preliminary record submittal

SOPs

Data package

Other information

Review due process rules

Your Rights Before the On-Site

Checklist(s)

Confidentiality notice

Conflict of interest form

Assessor credentials

Mutually agreeable date

Award of Accreditation

Certificate

Signed by AA, effective dates, NELAC logo

Includes fields of testing

Must be posted

Staying Accredited

Compliance with Chapter 5

PTs (twice a year)

On-site (every 2 years)

Notification of key changes (< 30 days)

Ownership

Location

Key personnel

Instrumentation

Other Important

Information

EH&S not included

Use of logo

No supplemental requirements

Mobile laboratories

Record retention: 5 years

SUMMARY

Know the standards

Decide to apply

Get ready

Collect information

Plan for the On–Site

Stay accredited!

NELAC

Accredited!

HELP?

NELAC Website www.epa.gov/ttn/nelac

EPA QA Documents www.epa.gov/quality

QAMS 005 (print only)

QA/G-5

QA/R-5

EPA SOP Guidance

OW Streamlining Appendix F (3/28/97 FR)

QA/G-6

Catalyst www.catalystinforesources.com

Template Quality Manual

SOP Guidance

Many other related documents

Jerry L. Parr

Catalyst Information Resources, L.L.C.

The Information Resource for Environmental Professionals

817-598-1155 catalyst@eazy.net

www.CatalystInfoResources.com