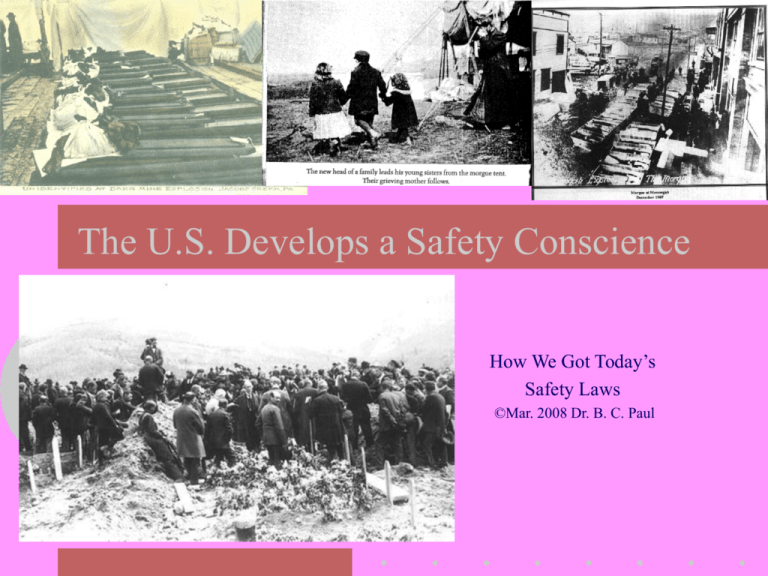

The Problem of Mine Safety

advertisement

The U.S. Develops a Safety Conscience How We Got Today’s Safety Laws ©Mar. 2008 Dr. B. C. Paul An Industrial Revolution • Period of 1870 to 1910 saw an undeveloped rural economy become a great world economic engine • Fueled by – Investment • New home grown investor industrialist class – Endless supply of cheap labor - from immigration – Coal Growth of Coal As an Energy Source Coal as a Percentage of American Energy Consumption, 1850-1900 Source: Sam H. Schurr and Bruce C. Netschert, Energy in the American Economy, 1850-1975 (Baltimore: Johns Hopkins Press, 1960), 36-37. Consequences • Fabric of Tradition was Torn • New Politics of Power • Coal to fuel the industrial revolution purchased with blood 4000 140 120 100 80 60 40 20 0 3000 2000 1000 3 18 0s 4 18 0s 5 18 0s 6 18 0s 7 18 0s 8 18 0s 9 19 0s 00 s 0 18 Number Killed US Coal Mine Deaths Decade # Killed # Explosions Not So Flattering Headlines • U.S. had the highest accident rate in the world – Not just coal – whole industrial machine • Only advanced nation on earth without any form of worker compensation or liability • If there was regulation it wasn’t working Profile of an Industry • Class Distinction in Practitioners – Miners were considered a skilled class • Could cut with picks or other tools • Broke coal usually with explosives – Laborer class hand loaded into cars often pulled out by mules • Early miners were skilled owners who hired laborers to work with them at small mines – Owners and laborers worked together A Rent in the Fabric of Society • 1890’s - Increasing demand challenges of going back into the earth created a need for capital and a new class that controlled capital – The Coal Barons – The people who did the work no longer controlled the facilities of Production How Did We Mine at the Turn of the Century Mining was conventional – a block of coal at the face was undercut (originally laying on your side and cutting With a pick) Drill and Blast the coal into the undercut Then load with shovels into cars to haul out Sometimes they would try to skip the undercut and blow the coal out – called shooting off the solid Turn of the Century Ventilation • Could no longer rely on natural ventilation pressure • Would build an upcast shaft to the surface with a vertical funnel on top – Then light a fire in at the bottom of the shaft • Induced a draft like a chimney – If you were really sophisticated you would use a furnace at the bottom Wasn’t That Dangerous? • Oh Ya! • Avondale Pennsylvania Sept 6, 1869 – Fire at the bottom of the Man Shaft set the shaft timbers on fire – The timbers burned and the shaft collapsed – 110 miners suffocated – One of the worst disasters up to that time A Single Entry Ventilation System Note there are no overcasts and air circulates From one face area to the next Doors were used as regulators to determine How much air was on a section The cuts were often near dead air spaces Sometimes they would run an air hose from A compressor to push air to the face The Rise of Mechanization (and the coal barons) • Late 1880s and decade of 1890s was an era of mechanization Mechanization of Ohio Coal 26% by 1896 49% by 1900 20000000 15000000 Mechanized 10000000 Manual 5000000 19 00 18 98 18 96 18 94 18 92 18 90 0 18 88 Annual Tons 25000000 What Was Mechanized Mechanical Picks began To be used for undercutting coal Mining cycle was conventional – Step #1 Undercut the Coal Start of Chain Cutters Drilling Saw Mechanization Step #2 drill holes in to the undercut coal Unbelievable Step #3 Charge the Holes – black powder And dynamite How is this for a flame Safety lamp Yes it is a oil lamp on The miners hat! – some people used candles Isn’t Having People With Candles on their heads loading Power Dangerous? • Oh Ya! – Winter Quarters Mine Utah – May 1, 1900 – A Miner with his cap lamp lit up the main powder storage area • The explosion stirred up coal dust and spread through the mine • 200 to 350 killed • What about these folks walking into methane filled dead-end entries – Ok we kind of loose count of how many on that one After Shooting Coal Was Loaded By Hand This job was done by unskilled labor teams – Sometimes Father and Son Laborers Were Paid by Production and tagged their cars of coal In some mines the Professional miners under-cut Left loader teams to shoot And load their own coal Don’t upset the professional Miners or the boss or you Might not get a good cut. Not the best way to make The laborers concerned about Safety. Mining Under the New Capitalist Class • Deeper Mining Needed Pumps for drainage and equipment for ventilation – Beyond the means of the artisan peasant • Capital class hired miners and laborers at given rates per ton of coal produced – Piece work system – Owners/Artisans and Laborers no longer worked together • Monopoly on opportunity – Best opportunities for wealth were in mine work and one group generally controlled everything The Mining Town • Remote locations required infrastructure – Coal Barons often built towns – homes – stores • • • • • • • Residents worked in company mines Lived in Company Housing Shopped at Company Stores Received care from company doctors Often Used Company Script (money) Saved or took loans from company People in power owned everything the workers needed for life The Capitalist and Government • New Investor Class felt they were chosen – By God – Or by superior natural selection • It was the responsibility to lead the people – Wealth and Pride linked • Those who came to power either were or had to be backed by the investor class – Result was that those who controlled the economic engines and those who governed were the same It’s the Economy Stupid • 1992 remark as Clinton defeated Bush Sr. • The industrial engines powered the goods of everyday living – Promised to raise the wellbeing of the people – Or at least those who ran the government • No one wanted to shut-off the economic engines – Those engines ran on cheap coal and cheap labor – A lack of will to control safety Barriers to Safety • No One Can Say No! – Government is charged with protecting the people but • What happens when those who govern own the means of production? – Who watches the watchers? • Believe that economic growth will best serve the people – you mustn’t tamper with the economic engines • Pride – Wealth and Power of Rulers also fueled by the economic engines – The People Have No Organization and only the voice those in power allow them More Barriers • Growth Pressures – Almost need time to pause – look around and think – Get the timing right is hard • When growth is hot hard to look around • When growth is slow often looking to cut – safety doesn’t at first glance produce coal – Workers themselves were linked directly to production • Your skills will save you • It can’t happen to me • Huge crews of cheap disposable labor running around underground – Dispersed locations hard to supervise if you wanted to The State of Regulation • U.S. Government was a Federal System – Different powers were delegated to different levels of government – State (Provincial) Governments had responsibility for welfare of the people • Federal Government did not regulate mining safety except in the territories that didn’t have State governments • Regulation was basically at the blessing of the owner class and what was needed for strong social values of the time. – Had some child labor laws – usually for those under 10 to 12 – Whole States had about 6 mine inspectors • • • • Could go around and report on conditions or make suggestions Their power was their personal influence Some had limited closure power (BUT NO ONE WANTS TO TURN OFF THE ENGINE) What Did the Laws Do • States such as Pennsylvania had qualification laws – Mine manager and foreman had to meet certain state training standards to get certification papers • Powder handling was still pretty much unregulated – Child Labor laws – early work only looked at gainfully employed above 10 years – Ventilation – usually required some type of ventilation support • Fans were only State Inspector recommendations • Funnels and draft furnaces at shaft bottoms were very acceptable and dominated even into early 20th Century