MGT314-M2

advertisement

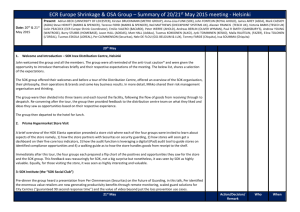

MGT 314 | M2 Set1 | C 5, 6, 12, 13 » Read the question at least twice to understand it and answer accordingly (objectively). » Keep the readings (textbook, lectures) in mind and/or provide details including any assumption(s). » Select the best. Use the blank-side if you need additional space and make sure your reference it. » If a question asks for explanation, include an example. A fill-in the blank (FB) can include more than one word. Describe in case you understand the topic but do not remember the exact word. If a question calls for a list, you do not need to describe. Fill in your NSU ID (on the bottom). Answer all MCs, TFs, FBs, SQs,and any 2 DQs. 13 x2 + 11 x2 + 14 x3 + 12 x4 + 2 x10 = 158 MC 1. Efficiency, in capacity terms, is the ratio of: Actual output to effective capacity Units produced to labor hours used Effective capacity to actual output Design capacity to effective capacity Design capacity to actual capacity All of these Some of these None of these MC 2. Given the following information: Effective capacity = 45 units per day; Design capacity = 60 units per day; Actual output = 30 units per day, what is the utilization? MC 3. The maximum output rate or service capacity an operation, process or facility is designed for is the 25% 33.3% 50% All of these Some of these Effective capacity Efficiency peak All of these 75% None of these Theoretical throughput Design capacity Some of these None of these MC 4. The system that has the highest equipment flexibility is a job shop a batch system repetitive production continuous processing All of these Some of these None of these MC 5. An operations strategy for process selection should recognize that: process selection is easily changed engineering is solely responsible for choosing what process is best there is little need to manage technology managers need not have technical skills All of these Some of these None of these MC 6. Which one of the following is generally regarded as an advantage of product layouts? Material handling costs per unit are low. Labor costs are low per unit. The system is fairly flexible to changes in volume of output. unit costs may be lower than with other processes There is high utilization of labor and equipment All of these Some of these None of these MC 7. In a product layout, the process of deciding how to assign tasks to work stations is referred to as: process balancing line balancing All of these MC 8. An automated car wash has three stations; wash which takes 0.6 minutes, rinse at 1.1 minutes and dry at 0.7 minutes. The maximum cycle time in minutes is: MC 9. What items do average consumers typically buy on an ROP basis? 0.6 0.7 1.4 1.6 1.7 3.2 All of these Some of these 2.4 3.4 None of these magazines & newspapers gas (for car) computer software All of these Some of these kacchi biryani gift items None of these Ayn | Spring 2012 NSU ID Page 1 of 5 task allocation station balancing scheduling Some of these None of these Page 1 of 5 MGT 314 | M2 Set1 | C 5, 6, 12, 13 MC 10. Which one of the following is a requirement for effective inventory management? A system to keep track of inventory on hand A classification system for inventory items Reasonable estimates of holding and shortage costs All of these Some of these None of these MC 11. In the basic EOQ model, if annual demand is increased by 50%, the effect on the EOQ is: It is four times its previous amount It is half its previous amount It increases by about 50 percent It is about 70 percent of its previous amount It doubles Some of these None of these MC 12. Which one of the following is not a basic option for altering capacity? Hire and fire workers Use overtime Use subcontracting Use backorders All of these Some of these None of these MC 13. One option for altering the availability of capacity is: overtime pricing promotion All of these Some of these TF- 1. Increased capacity can be expected by increasing productivity and quality. TF- 2. Increasing capacity in the operation following a bottleneck operation will improve the output of the process. TF- 3. Understanding our needs, including what kind, how much, and when is key to doing effective capacity planning. TF- 4. Flexible manufacturing systems can handle a large variety of similar products. TF- 5. Process layouts usually require less-skilled workers than product layouts. TF- 6. Cycle time is the average amount of clock time required to produce one unit of output. TF- 7. Reorder point models are primarily used for dependent demand items. TF- 8. Space considerations are not included in any of the economic ordering models. TF- 9. An assembly line may have workstations in parallel but will always have workstations in series. TF- 10. Disaggregating an aggregate plan involves creating a master schedule for production of the end items included in the aggregate plan. TF- 11. Company policy and costs have little or no impact on aggregate planning. backorders None of these True True False False True False True True True False False False True True True False False False True False True False For starting a new pastry at Shumi's Bakery, the fixed Cost is 200,000 taka. Revenue per pastry is 40 taka and the variable cost per unit is 22 taka. FB 1. How many of these pastries must the bakery sell for breaking even? FB 2. What would be the total cost? FB 3. One drawback of ____ layout is that equipment utilization rates are lower than in a process layout. Ayn | Spring 2012 NSU ID Page 2 of 5 Page 2 of 5 MGT 314 | M2 FB 4. Set1 | C 5, 6, 12, 13 Aggregate planning is ____-range planning . Item Usage Unit Cost 4021 50 1400 9402 300 12 4066 40 700 6500 150 20 9280 10 1020 4050 80 140 6850 2000 15 3010 400 20 4400 7000 5 FB 5. FB 6. Classification Lower Limits and Fill in the table above with the ABC classification Period Forecast 1 2 3 4 5 6 7 8 9 190 230 270 280 210 170 160 260 180 Total # Employees Regular output Inventory Beginning Inventory Ending Inventory Average Backlog Cost- Regular Output Cost- Inventory Cost- Backorder FB 7. Assuming an employee can produce 5 tables a day, use the forecast of tables to determine the number of employees using a level approach/strategy and the regular output. (fill inside the table) FB 8. Determine the inventory levels and backlog (if any) assuming an initial inventory of zero FB 9. Determine the costs assuming regular output cost is 50 taka per unit, inventory carrying cost is 50 taka per unit and backorder cost is 50 taka per unit. Ayn | Spring 2012 NSU ID Page 3 of 5 Page 3 of 5 MGT 314 | M2 Set1 | C 5, 6, 12, 13 Station: 1 2 3 4 5 6 Task Time Idle Time Percentage Idle Time Efficiency FB 10. Using the diagram above, allocate work to the different workstations assuming minimum cycle time FB 11. Determine the “Task time” and Idle time FB 12. Calculate percent idle time and efficiency In a reorder point model, the daily demand rate is normally distributed with a mean of 70 units and a standard deviation of 10 units. The lead time is 9 days, and the lead time service level (LTSL) is 90%. FB 13. What are approximate values for Safety Stock? FB 14. What are approximate values for Reorder Point? SQ- 1. List two reasons “why capacity decisions are strategic”? SQ- 2. List two determinants of effective capacity. SQ- 3. Define break-even point Ayn | Spring 2012 NSU ID Page 4 of 5 Page 4 of 5 MGT 314 | M2 Set1 | C 5, 6, 12, 13 SQ- 4. List two of the four process types SQ- 5. Define a manufacturing cell () SQ- 6. List three of the different kinds of inventories manufacturing firms carry SQ- 7. List three demand options in aggregate planning. SQ- 8. List three capacity options in aggregate planning. SQ- 9. Define “rough-cut capacity planning”. SQ- 10. List three inputs of master production scheduling SQ- 11. Explain the “frozen” scheduling phase. SQ- 12. For a particular product, if Annual Demand is 10,000 units with an ordering cost is 500 taka per order and an annual carrying cost is 40 taka per unit. The working days are 360 per year. What would be the EOQ DQ- 1. DQ- 2. DQ- 3. DQ- 4. Explain what a bottleneck operation is and how that can affect operations. Draw a U-shaped line and explain the layout using five advantages. Explain with a diagram how closeness ratings are used in a process layout. Compare and contrast the fixed order interval model and the ROP model. Answer your DQs on the left side of the page. Ayn | Spring 2012 NSU ID Page 5 of 5 Page 5 of 5