OP8

advertisement

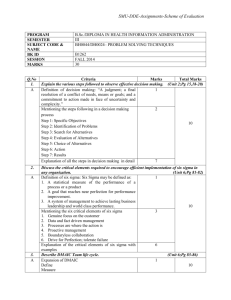

Operations 8 473.31 Fall 2015 Bruce Duggan Providence University College Summary The definition of quality has been expanded to include organizationwide quality issues such as the quality of the work environment for employees. DMAIC, the acronym for Define, Measure, Analyze, Improve, and Control, is fundamental to the approach companies use to guide improvement projects. Six sigma processes are designed to produce very few defects. Statistical process control techniques include control charts and acceptance sampling, which ensure that processes are operating as they are designed to operate. 6-20 Know The Answers To These Questions 1. What does the “total” in total quality management (TQM) mean? 2. How is quality measured? What are the “dimensions” of quality? 3. How can two companies spend the amount on quality, but one have far superior quality? 4. What is the difference between ISO 9000, ISO 14000, and ISO 26000? 5. Does Six Sigma’s DMAIC methodology stand for “Dumb Managers Always Ignore Customers”? 6. How can we calculate if our process is capable of meeting external specifications? 7. How does a control chart help you know when to stop a process and investigate it? 8. Can acceptance sampling be used on raw materials sent from a supplier? 6-21 Total Quality Management Total Quality Management is defined as “managing the entire organization so that it excels on all dimensions of products and services that are important to the customer.” Quality Gurus Compared 8-4 Quality Specifications Design quality: • Inherent value of the product in the marketplace. Conformance quality: • Degree to which the product or service design specifications are met. 8-5 Quality Specifications Quality Specifications Cost of Quality • appraisal costs • prevention costs • internal failure costs • external failure costs ISO 9000 Series of standards agreed upon by the International Organization for Standardization (ISO). The idea behind the standards is that defects can be prevented through the planning and application of “best practices” at every stage in the business. A prerequisite for global competition? ISO 9000 directs you to "document what you do and then do as you documented." Recognition for Good Quality Canada Award for Excellence (CAE) • An award established on behalf of the Canadian government given annually to companies that excel in organization wide quality. Malcolm Baldrige National Quality Award • An award established by the U.S. Department of Commerce given annually to companies that excel in quality. Recognition for Good Quality 8-11 Six Sigma Quality Six Sigma refers to a statistical term to describe the quality goal of no more than four defects out of every million units. Seeks to reduce variation in the processes that lead to product defects The name, “six sigma” refers to the variation that exists within plus or minus three standard deviations of the process outputs Six Sigma Quality Six Sigma allows managers to readily describe process performance using a common metric: Defects Per Million Opportunities (DPMO) DPMO Numberof defects Numberof opportunit ies x No.of units for error per unit x 1,000,000 Six Sigma Quality: DMAIC Cycle Overall focus of the methodology is to understand and achieve what the customer wants. A 6-sigma program seeks to reduce the variation in the processes that lead to these defects. DMAIC: • Define • Measure • Analyze • Improve, and • Control 8-14 Six Sigma Quality: DMAIC Cycle 1. Define (D) Customers and their priorities 2. Measure (M) Process and its performance 3. Analyze (A) Causes of defects 4. Improve (I) Remove causes of defects 5. Control (C) Maintain quality Analytical Tools for Six Sigma Define Analytical Tools for Six Sigma Measure Analytical Tools for Six Sigma Analyze Analytical Tools for Six Sigma Improve Analytical Tools for Six Sigma Control Analytical Tools for Six Sigma Failure Mode and Effect Analysis (FMEA) is a structured approach to identify, estimate, prioritize, and evaluate risk of possible failures at each stage in the process. Design of Experiments (DOE) a statistical test to determine cause-andeffect relationships between process variables and output. Statistical Quality Control The quantitative aspects of quality management. Processes usually exhibit some variation in their output. Some variation can be controlled and others are inherent in the process. Statistical Quality Control Assignable variation is caused by factors that can be clearly identified and possibly managed. • Example: o A poorly trained employee that creates variation in finished product output. Common variation is inherent in the production process • Example: o A molding process that always leaves “burrs” or flaws on a molded item. Statistical Quality Control Statistical Quality Control 8-25 Process Capability Process limits Specification limits How do the limits relate to one another? Process Capability Process Capability 8-28 Process Capability Index, Cpk Capability Index shows how well parts being produced fit into design limit specifications. As a production process produces items small shifts in equipment or systems can cause differences in production performance from differing samples. C pk X LTL UTL - X = min or 3 3 Shifts in Process Mean 8-29 Statistical Process Control (SPC) Techniques for testing a random sample of output from a process to determine whether the process is producing items within a preselected range. Types of Statistical Sampling Attribute (go or no-go information) • Defectives refers to the acceptability of product across a range of characteristics. • Defects refers to the number of defects per unit which may be higher than the number of defectives. • p-chart application Variable (continuous) • Usually measured by the mean and the standard deviation. • X-bar and R chart applications 8-31 Control Limits We establish the Upper Control Limits (UCL) and the Lower Control Limits (LCL) with plus or minus 3 standard deviations from some x-bar or mean value. Based on this we can expect 99.7% of our sample observations to fall within these limits. 99.7% LCL UCL x Statistical Process Control (SPC) Using p Charts [8.4] [8.5] [8.6] [8.7] p Total number of defects from all samples Number of samples Sample Size sp p 1 p n UCL p zs p LCL p zs p Using p Charts Using X-bar and R Charts Using X-bar and R Charts Using X-bar and R Charts Using X-bar and R Charts Statistical Sampling for Quality Control Acceptance Sampling is performed on goods that already exist to determine what percentage of product conforms to specifications. Statistical Process Control is sampling to determine if the process is within acceptable limits. Acceptance Sampling purposes • the purpose of a sampling plan is to test the lot to either : o determine quality level o ensure that the quality is what it is supposed to be Acceptance Sampling advantages • economy • less handling damage • fewer inspectors • upgrading of the inspection job • applicability to destructive testing • entire lot rejection (motivation for improvement) Acceptance Sampling disadvantages • risks of accepting “bad” lots and rejecting “good” lots • added planning and documentation • sample provides less information than 100-percent inspection Acceptance Sampling Single Sampling Plan • a simple goal: • determine 1. how many units, n, to sample from a lot, and 2. the maximum number of defective items, c, that can be found in the sample before the lot is rejected. Risk Acceptable Quality Level (AQL) • maximum acceptable percentage of defectives defined by producer the α • the Producer’s risk • the probability of rejecting a good lot Lot Tolerance Percent Defective (LTPD) • percentage of defectives that defines consumer’s rejection point the • the Consumer’s risk • the probability of accepting a bad lot Operating Characteristic Curve (OCC) The OCC brings the concepts of producer’s risk, consumer’s risk, sample size, and maximum defects allowed together. The shape or slope of the curve is dependent on a particular combination of the four parameters. Operating Characteristic Curve Example: • The vendor produces circuit boards to parameters of: o AQL = 0.02 o LTPD = 0.08 o 5% risk of having lots of this level or fewer defectives rejected o acceptance of poor-quality lots no more than 10% • What values of n and c should be selected to determine the quality of this lot? Example: Operating Characteristic Curve Example: Operating Characteristic Curve Now given the information below, compute the sample size in units to generate your sampling plan. c = 4, from Table n (AQL) = 1.970, from Table n = 98.5, round up to 99 Therefore, the appropriate sampling plan is c = 4, n = 99. Operating Characteristic Curve (OCC) End of Chapter 8 Ken Hin •7 • 12 • 11 • 13 • 14 • 14 Suggest you work o 8 & 9 together for practice.