LOG 102 Principles of Logistics II

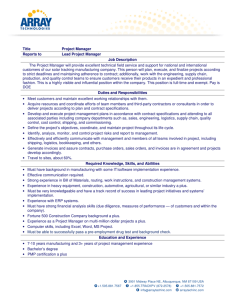

advertisement

LOG 102 Principles of Logistics II Global Logistics Definitions International Logistics International Logistics is the process of planning, implementing, and controlling the flow and storage of goods, services, and related information from a point of origin to a point of consumption located in a different country. -ORInternational logistics is the design and management of a system that controls the forward and reverse flow of materials, services, and information into, through, and out of the international corporation. International Logistics • Through the implementation of international logistics, the firm can implement cost-saving programs such as just-in-time (JIT), electronic data interchange (EDI), and early supplier involvement (ESI). • The two phases of the movement of materials include: – materials management, or the timely movement of materials, parts, and supplies. – physical distribution, or the movement of the firm’s physical product to its customers. Historical Development The Early “Slow” Days The Move Towards Speed Emphasis on Customer Satisfaction Strategic Advantage Historical Development The Early “Slow” Days The first international logisticians were traders on the Silk Road, a welltraveled trade route, in use for over 3,000 years, stretching from Europe to Asia and passing through the Middle East. Early modern logisticians were concerned primarily with ensuring goods arrived at their destination in good condition and at the lowest possible cost. Following World War II, logistics began to incorporate the techniques used by the military. Logistics began to refer to not just the movement of goods but also to sales, the procurement of supplies, and the management of supplier and customer relationships. Historical Development The Move Toward Speed The introduction of containers (or “boxes”) in the late 1950s, and their eventual widespread adoption, made shipping much more efficient as well as cheaper and faster. In the 1970s, new companies, like FedEx and DHL, introduced time-defined air shipping services, and gained a large market share in domestic shipments. In the 1980s, international air shipments grew as costs came down and the number of destinations increased. Air transport became cost-competitive with ocean transport for many products. Historical Development The Emphasis on Customer Satisfaction The very high interest rates of the 1980s led companies to reduce inventory levels. New inventory management techniques were created to reduce inventory costs. Those techniques included: • • • • Just-in-time (JIT) Materials Requirement Planning (MRP) Manufacturing Resources Planning (MRP II) Distribution Resources Planning (DRP) Since these techniques relied on rapid and reliable deliveries, logistics firms provided reduced shipping times and time-defined deliveries. Historical Development Just-In-Time Just-in-time manufacturing is a process that plans for parts to arrive on the assembly line just before they are needed. The goal of this technique is to reduce or eliminate the need for inventory. It now includes the delivery of parts to the assembly plant just before they are needed, and the delivery of finished goods just as the retail store is running out. JIT has become part of standard operations management practices in most manufacturing facilities. JIT involves a risk if the supply chain is disrupted as production may have to shut down due to lack of materials. Historical Development Computer-Based Tools Materials Requirement Planning (MRP) and Manufacturing Resources Planning (MRP II) are tools that allow manufacturing firms to determine what to produce (or order from suppliers), and in which quantity, in function of their sales forecasts and pending customer orders. Distribution Resources Planning (DRP) is a tool that allows a retail firm to determine what to order from its suppliers, in which quantity, and when, in function of what it sells to retail customers. These tools are dependent on the reliable, efficient delivery of relatively small shipments. Historical Development Strategic Advantage International Logistics management has become a strategic advantage for the firms that are capable of: • Containing the costs of shipping, in view of increased fuel costs • Providing “visibility” in the supply chain, or the ability to determine where a particular shipment is located, at any time • Providing reliable, dependable deliveries • Ensuring the security of the goods while they are in transit • Engaging in sustainable practices The International Supply Chain Suppliers Domestic/Import Sourcing Order Processing Corporation Inbound Materials Throughflow Order Processing Supplier-Firm Interface Transportation Storage Transportation Storage Physical Materials Distribution Management Management Inventory Management Storage Customers Outbound Materials Domestic/Expor Distribution Order Processing Order Placement Transportation Transportation Costumer-Firm Interface Customer Service Physical Distribution Management Inventory Management Inventory Management Forward and Reverse Flow of Information, Products, and Funds 12 Elements of International Logistics • The environment in which international logisticians operate is quite different from the domestic environment. • The decisions regarding international transportation are much more complicated than domestic transportation. • The number of intermediaries involved is greater. • The inherent risks and hazards of international transportation are much more significant. • International insurance is much more complex. • International means of payment are more complicated. • Terms of trade are more complicated. • The crossing of borders represents specific challenges. Globalization and international transport • Example: You want to buy a car “made in Japan”. • Today: is its transport from Japan to Izmir more or less expensive than 20 years ago? Globalization and international transport • Less expensive • BUT: You pay MORE for “transport” then 20 years ago. Why? International Inventory Issues • Inventories tie up a major portion of corporate funds, therefore proper inventory policies should be a major concern to the international logistician. • Just-in-time inventory policies minimize the volume of inventory by making it available only when needed. • The purpose of establishing inventory systems are: – to maintain product movement in the delivery pipeline – to have a cushion to absorb demand fluctuations 16 International Packaging Issues • Packaging is instrumental in getting the merchandise to the destination in a safe, presentable condition. • Because of the added stress of international shipping, packaging that is adequate for domestic shipping may be inadequate for international shipping. • Packaging considerations that should be taken into account are environmental conditions and weight. • One solution to the packaging problem has been the development of inter-modal containers. • Cost attention must be paid to international packaging. 17 Storage Facilities • A stationary period is involved when merchandise becomes inventory stored in warehouses. • The location decision addresses how many distribution centers to have and where to locate them. • Storage facilities abroad can differ in availability and quality. • The logistician should analyze international product sales and then rank order products according to warehousing needs. 18 Special Trade Zones • Foreign trade zones are areas where foreign goods may be held or processed and then re-exported without incurring duties. • Trade zones can be useful as transshipment points to reduce logistics cost and redesign marketing approaches. • Governments and firms benefit from foreign trade zones. 19 Centralized Logistics Management • In international logistics, the existence of a headquarters staff that retains decision-making power over logistics is important. • To avoid internal problems, both headquarters staff and local management should report to one person. • This individual can contribute an objective view when inevitable conflicts arise in international logistics coordination. 20 Decentralized Logistics Management • When a firm serves many diverse international markets, total centralization might leave the firm unresponsive to local adaptation needs. • If each subsidiary is made a profit center in itself, each one carries the full responsibility for its performance. • Once products are within a specific market, increased input from local logistics operations should be expected and encouraged. 21 Outsourcing Logistics Services • The systematic outsourcing of logistics capabilities is a third option. • By collaborating with transportation firms, private warehouses, or other specialists, corporate resources can be concentrated on the firm’s core product. • One-stop logistics allows shippers to buy all the transportation modes and functional services from a single carrier. 22 The Supply Chain and the Internet • Because of the internet, firms are able to conduct many more global comparisons among suppliers and select from a wider variety of choices. • When customers have the ability to access a company through the internet, the company must be prepared for 24-hour order-taking and customer service. • For all countries, but particularly in developing nations, the issue of universal access to the internet is crucial. 23