Feasibility of Non-Contact Ultrasound Generation using Implanted

advertisement

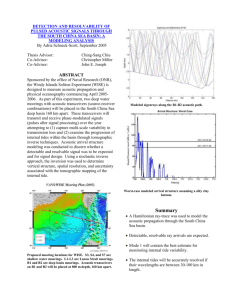

Feasibility of Non-Contact Ultrasound Generation using Implanted Metallic Surfaces as Electromagnetic Acoustic Transducers By: Yarub Alazzawi, Chunqui Qian, and Shantanu Chakrabartty alazzawi, shantanu@wustl.edu Abstract—In this paper we investigate the feasibility of using an in-vivo metallic implant like a stent for generation of acoustic waves which can then be used for imaging areas inside or near the surface of the implant. The proposed method relies on time-varying eddy-current loops that are excited on the metallic surface of the stent using an external RF coil. In this paper we have designed a phantom set up to characterize the acoustic wave generation process and we demonstrate that the acoustic waves can be measured, imaged and harvested remotely using a piezoelectric probe. Stents are routinely used in the surgical treatment of vascular stenosis where the metallic mesh in the stent provides mechanical support to the tissue walls and to facilitate the flow of vital fluids like blood or bile (as shown in Fig.1). Post-surgery, the implanted stents are routinely monitored for occlusions which could potentially lead to restenosis and hence require surgical intervention. A popular method for post-operative imaging of stents include x-ray which do not provide insight to the mechanics or growth of occlusions and the procedure neither provides any information regarding the fluid-flow through the stent. Direct magnetic resonance imaging (MRI) of stents are limited by the generation of eddy-currents which shield the spin signals emanating from within the stent. Fig. 1. Application of metallic stents and technologies used for monitoring stent potency [source: google images] In this paper, we explore an alternate approach where the metallic surface of the stent could be used for in-vivo generation of acoustic waves, which can then be used for characterizing stent potency. Objective ►In-vivo metallic implant to generate acoustic waves. ►Non-contact imaging areas inside or near the implant. ►Remotely harvest acoustic waves. At the core of the proposed technique is the use of electromagnetic acoustic transducers (EMAT) which have been routinely used for non-destructive evaluation (NDE) of conductive structures like aircraft skins and metallic pipes. The principle of EMAT is shown in Fig. 2 where an RF coil generates a time-varying electromagnetic (EM) field. When a metallic structure is exposed to this field, eddy-current loops are generated on the surface of the structure. The direction of the current is such that it opposes the change in the EM field and the result is loss of energy due to Joule heating. However, when the structure is simultaneously subjected to a constant magnetic field, the eddy-current loops experience a Lorentzian force that mechanically excite the metallic structure. The result is the generation of pressure waves, and the frequency of the acoustic wave is determined by the frequency of the EM field and by the mechanical properties of the structure. Fig. 2. Operational principle of EMAT Experimental Setup • In this paper we have designed a phantom set up, as shown in Fig. 3, to characterize the acoustic wave generation process and we demonstrate that the acoustic waves can be measured, imaged and harvested remotely using a piezoelectric probe. Fig.3 (a)Schematic of the phantom experimental setup; (b)Photograph of the experimental setup Experimental Setup ►Water tank to emulate in-vivo conditions ►Aluminum strip suspended in water to emulate metallic substrate ►1.7 T permanent magnet suspended above water tank using a pulley ►RF coil (coated copper wires) connected to (10V, 500mA) HP function generator ►Piezoelectric probe attached to the bottom of the water tank and connected to the oscilloscope to measure the acoustic signal generated by EMAT Amplitude of Acoustic Wave Real part of the amplitude of the acoustic wave: 𝐵𝑚 𝐵0 𝜁= × 2𝜋 𝜇0 𝑑0 𝑉𝑠 Parameter 1 𝜔02 𝛿 2 1+ 2𝑉𝑠2 Description 𝐵𝑚 RF electromagnetic field 𝐵0 Static magnetic field 𝜇0 Permeability of the vacuum 𝑑0 Bulk density of the metal 𝑉𝑠 Acoustic wave velocity 𝛿 Skin depth Fig. 4 Amplitude of the acoustic wave generated using EMAT for different metals Measurement Results 0 mm implanting depth (the aluminum substrate was freely floating on the water surface.) ►Variable magnet height (d) ►20 mm water depth ►5 mm RF-coil height Fig. 5 shows the result of the experiment and clearly shows an inverse relationship between the recorded signal and distance (d). This can be attributed to the EM losses inside water which results in smaller magnitude of eddy-current loops. Fig. 5 Measured signal power when the height of the magnet is varied and the implantation depth is set to 0mm. Measurement Results 3 mm implanting depth ►Variable magnet height (d) ►20 mm water depth ►5 mm RF-coil height The power received by the piezoelectric probe is lower for the case when the aluminum substrate was immersed in the water, as shown in Fig. 6. Fig. 6. Measured signal power when the height of the magnet is varied and the implantation depth is set to 3mm. Measurement Results 0 mm implanting depth ►Variable RF analog signal frequency(Hz) ►20 mm water depth ►5 mm RF-coil height ►10 mm distance between the RF coil and the Magnet Fig. 7 clearly shows the existence multiple system poles which leads to different frequency windows where the EMAT method is more effective. These system poles and frequency windows are determined by several mechanical and electrical factors. Fig. 7 System frequency response measured using the EMAT setup The important point is that for both the experiments, the probe was able to harvest more than 100nW of power (when accounting for coupling losses) even when it was placed 2cm away from the surface of the aluminum plate. Thus, the proposed method could in principle be used for designing an in-vivo acoustic beacon or an ultrasonic telemetry system that is powered remotely using the EMAT technique. Conclusions & Future Work Conclusions ►Feasibility of non-contact ultrasound generation using in-vivo EMAT based approach ►Possibility of non-contact imaging and energy harvesting ►Electrical and mechanical factors affect the process efficiency. Future work ►Optimizing EMAT technique for in-vivo studies using multi-physics modeling and analysis of EM and acoustic phenomena in biological tissue References • [1] S. Bhatia, “Biomaterials for clinical applications,” New York Dordrecht Heidelberg London, USA, February 2010. • [2] S. Ohnoa, T. Harimotob, M. Hirosued, M. Miyaie, K. Hattorib, M. Kurodab, S. Kanazawaf, K. Inamuraa, and H. Katob, “Visualization of stent lumen in mr imaging: Relationship with stent design and rf direction,” vol. 66, pp. 203–211, December 2011. • [3] D. S. Goldsmith, “Integrated system for the ballistic and nonballistic infixion and retrieval of implants with or without drug targeting,” June 2014. • [4] J. Garca-Martn, J. Gmez-Gil, and E. Vzquez-Snchez, “Non-destructive techniques based on eddy current testing,” February 2011. • [5] O. Nebi and V. Fireeanu, “Finite element analysis of an eddy current heater for wind or water kinetic energy conversion into heat,” International Conference on Renewable Energies and Power Quality, March 2010. • [6] I. Gerothanassis, “Methods of avoiding the effects of acoustic ringing in pulsed fourier transform nuclear magnetic resonance spectroscopy,” vol. 19, ELSEVER Journal on Progress in Nuclear Magnetic Resonance Spectroscopy, 1987. • [7] B. Fang, T. Feng, M. Zhang, and S. Chakrabartty, “Feasibility of b-mode diagnostic ultrasound energy transfer and telemetry to a cm2 sized deeptissue implant,” IEEE Symposium on Circuits and Systems (ISCAS 2015), Lisbon, Portugal, 2015.