Risk Assessment: A Practical Guide to Assessing Operational Risk

advertisement

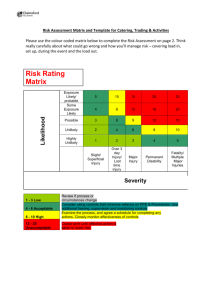

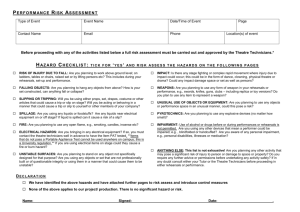

Risk Assessment What, Why, When and How UCM Fall Symposium and ASSE/AIHA/A&WMA PDC November 5, 2015 Bruce Lyon, CSP, PE, ARM, CHMM Hays Companies Risk Assessment Fundamentals What… Why… When… How… Objectives Hazards, Risks, and Risk Management Developing Trends, Standards, FSI & PtD Triggers for Assessing Risk Steps for Conducting Risk Assessments What is Risk Management? The coordinated activities of risk avoidance, control, and financing to a level that is considered acceptable. ‘Risk Assessment’ is the cornerstone of Risk Management. What is Risk? Hazards vs. Risks… Hazard • Source of harm. (Z690.1) Hazards vs. Risks… Exposure – • Contact with or proximity to a hazard, taking into account duration and intensity. (Z10) • Extent to which an organization or stakeholder is subject to an event. (Z690.1) Exposure includes frequency and duration of a hazard coming into contact with the population or assets at risk. Hazards vs. Risks… Risk • Effect of uncertainty on objectives. (Z690.1) • An estimate of the probability of a hazard-related incident or exposure occurring and the severity of harm or damage that could result. (Z590.3) Risk is the estimated severity of harm and likelihood of occurrence from the hazard. Definitions • Severity – Degree of harm. • Likelihood – Chance of something happening. • Operational Risk – Risks generated from the workplace including SH&E, liability, legal and information technology. • Acceptable Risk - The risk level that is considered by the organization to be acceptable in its current context. This level of risk is generally lowered as the organization matures and the control technologies improve. Definitions Risk Assessment • “A process that commences with hazard identification and analysis, through which the probable severity of harm or damage is established, followed by an estimate of the probability of the incident or exposure occurring, and concluding with a statement of risk.” (Z590.3) • “Overall process of risk identification, risk analysis and risk evaluation.” (Z690.1) Risk Assessment is a three step process that including identifying hazards, analyzing their risk, and evaluation the risk to determine if it requires additional control. The Risk Assessment Process Risk Analysis Hazard/Risk Identification Risk Evaluation Risk Assessment within the Risk Management Framework Why Assess Risk? Fatalities and Serious Incidents (FSI) Continue to Occur • • • While Incident Rates have decreased, Fatality Rates remain steady Major Disasters, Fires, Explosions, Chemical Releases FSIs in Construction, Petro-chemical, Transportation, Agribusiness among other industries Why Assess Risk? Why Assess Risk? The Rising Importance of Managing Risk Risk assessments required in: • many countries • branches of the military • NASA • Chemical operations – (OSHA Process Safety Management & EPA RMP) • Atomic energy field • Pharmaceuticals Global Trends ISO 31000 Risk Management Standards Key Standards • ISO 31000 - ANSI/ASSE Z690-2011 Risk Management Standards • ANSI/ASSE Z590.3-2011 Prevention through Design • ANSI B11.0-2015 Safety of Machinery • MIL-STD-882E-2012 The Purpose of Assessing Risk… to “provide evidence-based information and analysis to make informed decisions on how to treat particular risks and how to select between options.” ISO 31010/ANSI/ASSE Z690.3-2011 Risk Assessments required in Management Systems Standards Plan, Do, Check, Act “The effectiveness of an ORMS requires the continual identification, analysis and evaluation of risks to understand their magnitude of loss, and potential of occurring, as well as adequacy of existing control measures and needed improvements within the organization.” Operational Risk Management Systems • OSHA’s Voluntary Protection Program (VPP) • ANSI Z10-2012 • BS OHSAS 18001-2007 • International Labor Office ILO-OSH 2001 • ISO 14001-2004, Environmental management systems • ISO 45001- 2015-16, Occupational Health and Safety Management Systems The Rising Importance of Risk Assessment • Established February 2013 • Risk-based information, tools, and research for safety professionals • Risk Assessment Certificate Program http://www.oshrisk.org/ OSHA Recognizes Need for Risk-based Approach In a July 19, 2010 letter to the OSHA staff, Assistant Secretary David Michaels wrote: “Ensuring that American workplaces are safe will require a paradigm shift, with employers going beyond simply attempting to meet OSHA standards, to implementing riskbased workplace injury and illness prevention programs.” When should Risks be Assessed? Design of New Systems Redesign of Existing Systems Changes & Additions (MOC) Procurement High Risk Activities Non-routine Activities Serious Incidents (FSI) Upsets and Emergencies Third-party Interactions, Contractors, & Construction External Requirements When Assess Risks? Develop a Strategy for ‘when’, ‘where’, ‘who’ and ‘how’ risk assessments are to be performed Gain Management Commitment Involve Stakeholders Ensure Adequate Resources are Available Qualified Risk Assessors Document and Communicate Risk Establish Risk Criteria Monitor / Review Document Establish Context Risk Assessment Process Assemble Team Identify Hazards Treat Risks Evaluate Risks Analyze Risks Establish Risk Criteria and Matrix Define Risk Criteria & Levels Establish Risk Scoring System Select Risk Assessment Matrix Establishing the context (5.3) Risk assessment (5.4) Risk identification (5.4.2) Communication and consultation (5.2) Risk analysis (5.4.3) Risk evaluation (5.4.4) Risk treatment (5.5) Monitoring and review (5.6) Establish Risk Criteria and Matrix Establish a Risk Scoring System Qualitative, Semi-quantitative, or Quantitative Risk Factors in System • Severity, Likelihood, Control Effectiveness, Exposure, etc. Existing or Customized System • MIL-STD-882 • ANSI Z10 • ANSI Z590.3 PtD Establish Risk Criteria and Matrix Define Risk Criteria & Levels for the Organization • Severity • Likelihood • Action Levels • Acceptable Level Establish Risk Criteria and Matrix “A method to categorize combinations of probability of occurrence and severity of harm, thus establishing risk levels.” (Z590.3) Establish Risk Criteria and Matrix Risk Level Unacceptable High Moderate Low Risk Action Levels Action Immediate action required. Operation not permissible, except in rare and extra-ordinary circumstances. Remedial action is to be given high priority. Remedial action is to be taken at appropriate time. Remedial action is discretionary. Procedures are to be in place to ensure risk level is maintained. Establish Context Purpose and Scope Boundaries and Limitations Select Risk Assessment Method(s) Form a Team Context will Determine Size and Makeup Cross-functional Group Roles and Responsibilities Training in Method(s) Identify Hazards/Risks Find, Recognize and Record • Hazards • Causes and Sources • Events, Scenarios or Failure Modes • Existing Controls Establishing the context (5.3) Risk assessment (5.4) Risk identification (5.4.2) Communication and consultation (5.2) Risk analysis (5.4.3) Risk evaluation (5.4.4) Risk treatment (5.5) Monitoring and review (5.6) Identification Methods • • • • • • • • • • Brainstorming Checklists Regulations (OSHA, EPA, DOT etc.) Standards (ANSI, ASTM, NFPA, etc.) Experts (external or internal) Job Hazard Analyses/Job Safety Analyses Accident/incident investigations OSHA Injury and Illness Records Insurance claims Formal hazard/risk identification techniques (31 listed in ANSI Z690.3-2011) Risk Analysis 1. Severity of Consequences (S) 2. Likelihood of Occurrence (L) 3. Effectiveness of Existing Controls 4. Estimated Risk Levels Establishing the context (5.3) Risk assessment (5.4) Risk identification (5.4.2) Communication and consultation (5.2) Risk analysis (5.4.3) Risk evaluation (5.4.4) Risk treatment (5.5) Monitoring and review (5.6) Risk Analysis Determine Consequence(s) and their Severity Fertilizer Warehouse Fire Employees Public Environment Building Liability Risk Analysis Estimate Severity Level (S) for each Consequence Severity Ranking Severity Level (S) 4 Catastrophic 3 Critical 2 Marginal 1 Low Severity of Consequence Description One or more fatalities; multiple serious hospitalizations; incident resulting in more than $250 K Disabling injury or illness; permanent impairment; incident resulting in more than $ 50 K Medical treatment or restricted work; recordable incidents; incident resulting in more than $ 1 K First aid or non-treatment incidents; incident resulting in less than $ 1 K Risk Analysis Estimate Likelihood (L) • Review historical data • Consider exposure frequency, duration and population • Estimate Likelihood of Occurrence Risk Analysis Assess Existing Controls (PE) • Adequacy and Effectiveness • Consider the type of controls and their effectiveness according to the ‘Hierarchy of Controls’ Risk Analysis Estimate Risk Level • Using the Risk Scoring System calculate the Risk Level Take care not to dilute severity if using multiple risk factors in the formula (i.e. severity, probability, exposure, protection effectiveness, failure detectability, frequency, duration, etc.) Examples: Severity + Likelihood = Risk Level Severity x (Likelihood x Protection Effectiveness) = Risk Level Risk Evaluation • Compare estimated Risk Levels with established Risk Criteria • Determine if Risk is Acceptable or if Treatment is needed • Prioritize Actions based on Risk Levels Establishing the context (5.3) Risk assessment (5.4) Risk identification (5.4.2) Communication and consultation (5.2) Risk analysis (5.4.3) Risk evaluation (5.4.4) Risk treatment (5.5) Monitoring and review (5.6) Risk – ‘As Low As Reasonably Practicable’ Decisions on treating a risk will depend on the risk level and the costs and benefits of implementing improved controls. Risk Treatment ‘The process of reducing or modifying risk using Risk Treatment Options.’ Risks that are judged unacceptable must be ‘treated’ to reduce risk. Establishing the context (5.3) Risk assessment (5.4) Risk identification (5.4.2) Communication and consultation (5.2) Risk analysis (5.4.3) Risk evaluation (5.4.4) Risk treatment (5.5) Monitoring and review (5.6) Risk Treatment Options 1) Avoidance - avoiding the risk by deciding not to start or continue with the activity that gives rise to the risk 2) Elimination - removing the risk source 3) Substitution - changing the consequences 4) Engineering and Administrative controls - changing the likelihood 5) Transfer & Financing - sharing the risk with another party such as insurance contracts and risk financing 6) Retain - retaining the risk by informed decision Hierarchy of Controls Most Preferred Least Preferred Risk Avoidance: Prevent entry of hazards into a workplace by selecting and incorporating appropriate technology and work methods criteria during the design processes. Eliminate: Eliminate workplace and work methods risks that have been discovered. Substitution: Reduce risks by substituting less hazardous methods or materials. Engineering Controls: Incorporate engineering controls/safety devices. Warning: Provide warning systems. Administrative Controls: Apply administrative controls (the organization of work, training, scheduling, supervision, etc.). Personal Protective Equipment: Provide Personal Protective Equipment (PPE). Documentation Virtually all aspects of the process should be documented Selecting the risk assessment matrix Determining the purpose and scope (context) Forming the team Selecting the hazards or operations to be assessed Identifying Hazards/risks Analyzing Risks Evaluating Risks Communicating and documenting Monitoring and continuous improvement Documentation Risk Register Current State Risk Level Additional Controls Completion Date Future State Risk Level 14 Yes 2/20/2015 12 burns 15.2 Yes 3/15/2015 12 1.3 arc flash 11.2 Yes 2/20/2015 9.8 Plasma cutter 1.4 noise 19 Yes 3/15/2015 8.4 QC Lab - Weld Plasma cutter 1.5 fire 14 Yes 3/15/2015 12 1 QC Lab - Weld Plasma cutter 1.6 dust 11.2 Yes 3/15/2015 9.6 2 QC Lab - Weld Weld Destruct 2.1 ergo-strains 14 Yes 4/15/2015 14 2 QC Lab - Weld Weld Destruct 2.2 vibration 19 Yes 4/15/2015 4.8 2 QC Lab - Weld Weld Destruct 2.3 noise 11.2 Yes 4/15/2015 10.8 2 QC Lab - Weld Weld Destruct 2.4 struck by 15.2 Yes 2/20/2015 14.4 2 QC Lab - Weld Weld Destruct 2.5 dust 16 Yes 4/15/2015 8.4 2 QC Lab - Weld Weld Destruct 2.6 struck against 11.4 Yes 3/15/2015 6.3 2 QC Lab - Weld Weld Destruct 2.7 falls same level 16 Yes 3/15/2015 11.2 3 Finishing Wash Station 3.1 hot liquid 9 Yes 4/15/2015 6.3 3 Finishing Wash Station 3.2 struck against 14.25 Yes 4/15/2015 0.2 3 Finishing Wash Station 3.3 chem-corrosive 11.2 Yes 4/15/2015 4.2 3 Finishing Wash Station 3.4 hot surfaces 14.25 Yes 4/15/2015 2.1 3 Finishing Wash Station 3.5 mechanical 9.6 Yes 3/15/2015 4.8 3 Finishing Wash Station 3.6 ergo-strains 11.2 Yes 4/15/2015 0.2 Case # Location Task Hazard # Hazard 1 QC Lab - Weld Plasma cutter 1.1 Electrical Shock 1 QC Lab - Weld Plasma cutter 1.2 1 QC Lab - Weld Plasma cutter 1 QC Lab - Weld 1 Monitoring & Continuous Improvement Hazards and operations change Changes can effect existing controls and their effectiveness Update risk assessments to consider these possible changes Establishing the context (5.3) Risk assessment (5.4) Risk identification (5.4.2) Communication and consultation (5.2) Risk analysis (5.4.3) Risk evaluation (5.4.4) Risk treatment (5.5) Monitoring and review (5.6) Communication The importance of communication can not be overstated. Successful risk assessments are dependent on effective communication among stakeholders prior to, during and after the process. Establishing the context (5.3) Risk assessment (5.4) Risk identification (5.4.2) Communication and consultation (5.2) Risk analysis (5.4.3) Risk evaluation (5.4.4) Risk treatment (5.5) Monitoring and review (5.6) The Take Away Message Take a ‘Risk-based’ Approach Establish a Strategy for Performing Risk Assessments Lead the Way