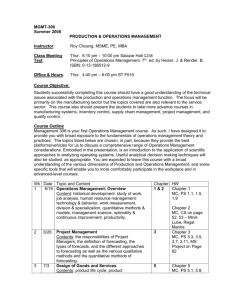

forecasting

advertisement

StratSimMarketing Forecasting and Production Planning Manufacturing Decisions Recall there are two levels of manufacturing decisions: Vehicle Production = Target production for a particular vehicle. • Flexible production (+/- 10%) if shortage or > 120 days inventory. • Retooling charges if production increases over previous production. • Watch inventory levels. If vehicle is upgraded, inventory will be written off at 15% loss. Capacity = Overall vehicle production for all product lines combined. • May produce above capacity (with over-capacity charge). • You have total flexibility to divide capacity among vehicles, but consider retooling charges. 3 Setting Production Levels So, how does one set production levels for a vehicle? Default decision is same as last period. Problems with that? • Doesn’t take into account inventory (stock on hand). • Doesn’t take into account unmet demand (shortages). • Doesn’t take into account upgrades: Impact of change in specs on sales. Inventory sold off with any upgrade. • Doesn’t take into account changes in marketing mix decisions (changes to price, advertising, or promotion). • Doesn’t take into account growth (or decline) in market demand. • Doesn’t take into account competitor moves. • But, no retooling costs for increases in production. 4 Setting Production Levels If the goal is to have zero units without shortages: • Set Production Level = Demand – Current Inventory Example: If demand is 200 units, and you currently have 50 units in stock, set production at 150 to have zero units in inventory at the end of the period: Production level = 200 – 50 = 150 • Why is zero good? Cash not used to build inventory. No risk of obsolescence (15% write-off cost if upgraded). • Why is zero bad? If demand is greater than you expect, you may have shortages. • Remember about 10% flex production. 5 Setting Production Levels Example: If we expect demand to be 800 units for Alec, 700 units for Alfa, and our goal is zero inventory, how many of each should we produce? Answer: 707 for Alec (800-93) 700 for Alfa (700-0) (0 b/c of upgrade) 6 Forecasting Demand So, the logistics of calculating appropriate production levels is fairly simple . . . know your existing inventory levels, set a target ending inventory (possibly zero), take into consideration upgrade write-offs, and estimate demand . . . Estimating Demand is the hard part! • Many moving parts: changes to marketing mix, potential changes in the product, changes in the environment, changes made by the competition. • It is the dynamic aspect of forecasting that makes it so difficult. • One approach is to use statistical methods to calculate next year’s demand, but here we will focus on more fundamental analysis. 7 Forecasting Demand Unit Sales – (Market Size x Share) (Demand) • • • • Economy Industry Dynamics Underlying Growth "Quality" • • • • Relative $Ad Price Distribution Firm Preference 8 Forecasting Demand (Market Size) First, you may want to better understand where your current vehicles sell: (Tools = Vehicle Sales by Customer $, select Vehicle = share). Use the Vehicle Sales by Customer Research. Units sold to Customer (e.g. 2F purchased 355K Alfas). Share of consumer customer (e.g. Alfa has 40.9% share of 2F. Overall market share. Overall total unit sales. 9 Forecasting Demand (Market Size) Consumer Customers Report: Provides total unit sales by customer and forecasts units sales for next year. Next, you may want to use the Consumer Customer report to see next year’s forecast for your most important target markets / customers. This value already takes into account economic forecasts. Forecast for next year’s unit sales by customer. A good starting point for demand. 10 Forecasting Demand (Market Size) For completely new target markets / customers, look at the New Customers report, but remember this estimate of demand is much less precise and has more risk associated with it. Potential demand forecast if new customer emerges. Sample New Customers Report 11 Forecasting Demand (Market Share) To estimate the potential impact of changes in advertising, promotion or price, you can use the Test Market and this can be used to improve your forecast. Note: This study presumes no changes in product or competition. "Baseline" is the base case for this vehicle and reflects last period’s marketing mix decisions. Test is the marketing mix from your test market inputs. Projected impact in test market of new set of marketing mix decisions on awareness, market share and net contribution. 12 Forecasting Demand (Market Share) To estimate the potential market share for a new product launch or major upgrade, use the Concept Test. But remember this presumes no change in the competitive products and does not take into consideration firm-wide preferences or dealers. Summary of concept test information (Note: price = MSRP = retail price) Focus group style feedback on concept based on existing competition. Likely to buy = percent of people in chosen customer profile who indicate they would purchase (all things being equal). 13 Forecasting Demand (Market Share) Final thoughts on forecasting vehicle demand: • Remember to check the Industry News for information on whether firms are launching new class vehicles that might significantly impact your market share. • You may also want to track competitive spending and pricing patterns and the impact their decisions have had on your market share in the past. • Know and compare the value / cost of a lost sale versus holding a vehicle in inventory. 14 Setting Capacity Levels So, how does one decide the overall manufacturing capacity for your firm? Basically, capacity is just what you need for the total production planning for all of your product lines. Just remember that… Decision is to increase or decrease capacity (50% of current max). It takes a year to build capacity (see next slide). Cash is used to build capacity – cost is depreciated over 10 years. Capacity can also be decreased. Having unused capacity is just an additional fixed cost to bear each year. • You may produce over your capacity. Financially it doesn’t make sense to do this long-term, but sometimes paying a little extra for a spike in demand or to cover risk is better than taking on the fixed costs. • • • • 15 Timeline: Capacity Increase Capacity Round 1 Round 2 Cash used to build, but new capacity not available Round 3 Round 4 Round 5 Round 6 Up to 10 Capacity available 16 Production & Capacity: Pro-forma Use the Pro-forma Analysis toward the end of your decision-making process to: Estimate ending inventory (check production levels with your forecasts and decisions). View projected Income Statement and Balance Sheet for impacts of retooling and capacity additions. BEWARE! The Pro-forma results are based on YOUR unit sales estimates. • Actual results (after advance) will vary. • Default sales estimate = last period’s sales. • Costs / Expenditures based on your decisions. 17 Pro-forma: Example 1 Checking Production Team D decided to do a minor upgrade to Detonka but forgot that old inventory is disposed. Pro-forma "Inventory Forecast" can help catch this kind of oversight. 18 Pro-forma: Example 1 impact of upgrade on Detonka forecast. Don't they expect a change in sales based on the upgrade? What else did they potentially forget? 19