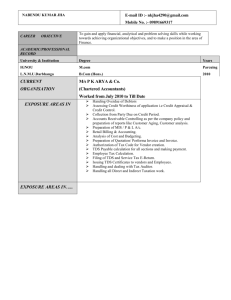

W_Tues_AM_08.35_Bell

advertisement

Technical and Cost Evaluation of Alternative Treatment Trains for Indirect and Direct Potable Reuse Bill Dowbiggin, P.E.; Bruce Chalmers, P.E.; Sheri Smith, P.E. November 2015 2015 Annual Conference Raleigh, NC Indirect Potable Reuse Includes an Environmental Buffer like a Reservoir, River or Aquifer Between the WWTP and the WTP NC has lots of Indirect Potable Reuse (IPR) – at each WTP with intake downstream of one of the major NPDES discharges below (each colored area is a river basin). This is termed De Facto or Unplanned IPR. 3 What is the California Approach? Microfiltration, reverse osmosis, advanced oxidation process (MF/RO/AOP) Why look for alternatives to MF/RO/AOP? Primary reason is the cost Second reason is brine disposal Lack of operator experience Existing tertiary facilities Abundant surface recharge capacity Good water quality Demineralization isn’t necessary Nitrogen reduction isn’t necessary What Else is There? Treatment capabilities: depends on treatment process used, some removal is possible for nutrients (e.g. total nitrogen and total phosphorus, TN and TP), total dissolved solids (TDS), total organic carbon (TOC), and contaminants (or constituents) of emerging concern (CEC) Treated water quality will depend on selected alternative treatment process and the wastewater influent quality Alternative Treatment Method 1 Tertiary recycled water 2 MF/RO Blend 3 GAC or Ozone/Biologically-Activated Carbon (BAC) 4 Nanofiltration 5 Electrodialysis California Model MF/RO/AOP MF/RO/AOP to produce highest quality water AOP often with UV-peroxide Pre-approved by CA as part of 2013 draft GWR Regulations for surface and subsurface application Recharge facilities: Surface spreading and groundwater injection Treatment capabilities: nutrient, TDS, TOC, CEC removals Recycled Water Contribution (RWC): start at 75%-100%, lowest blend water requirements RWC will vary by project and regulator Simplifies operations because of less reliance on blend water California Model MF/RO/AOP WWTP To WWTP California Model MF/RO/AOP Advantages Approved by CA for surface percolation and injection wells Best Available Technology Numerous existing facilities Produces highest-quality water Removes TOC, TDS, TN & CECs Accepted by the public Shorter travel time/lower initial diluent requirement Potential elimination of diluent water Disadvantages Expensive to construct High O&M cost for power and chemicals Brine management required Alternative Treatment Alternative 1 - Tertiary Filtered Recycled Water Disinfected tertiary recycled water CA Recharge facilities: Surface spreading only Treatment capabilities: no nutrient, TDS, CEC removal, some TOC RWC in CA: start at 20% RWC, blending req’d Montebello Forebay: permitted at 35% RWC, TOC reduction to increase to 50% RWC Chino Basin (IEUA): permitted RWCs range from 25 to 45% Alternative Treatment Alternative 1 - Tertiary Filtered Recycled Water Alternative Treatment Alternative 1 - Tertiary Filtered Recycled Water Advantages Approved by CA for surface spreading Meets T22 (CA reg for reuse water) water quality Less expensive to construct Many WRPs already have tertiary effluent facilities for discharge No brine management required Proven history (Montebello Forebay since 1962) Disadvantages Percolation only May not meet basin plans for TDS and TN Requires extensive amounts of diluent water Requires long travel time (> 6 months) CEC, TN removal by Soil Aquifer Treatment (SAT) only Alternative Treatment Alternative 2 – Blend of Tertiary Recycled Water/Reverse Osmosis Permeate Blend of tertiary effluent and RO permeate Partial advanced wastewater treatment (AWT) train with MF/UF and RO Phased AWT train with tertiary effluent (TE) initial phase followed by MF/RO phase Combined or separate disinfection or disinfection/AOP Recharge facilities: Surface spreading only Treatment capabilities: Partial nutrient, TDS, TOC, CEC CA RWC: Begin at 20% RWC because of tertiary component Higher RWCs than tertiary effluent alone RO Capacity RO capacity determined for TOC reduction for desired RWC RO capacity can also be sized for TDS reduction Alternative Treatment Alternative 2 – Blend of Tertiary Recycled Water/Reverse Osmosis Permeate 16.6 mgd 5 mgd 10 mgd 11.6 mgd To WWTP 0.8 mgd 15 mgd 0.8 mgd Alternative Treatment Alternative 2 – Blend of Tertiary Recycled Water/Reverse Osmosis Permeate Advantages Good water quality Removes some TDS, TOC, TN & CECs Requires diluent water (but not as much as TE) Implementation can be phased AOP not required Less expensive than MF/RO/AOP Disadvantages More expensive to construct than tertiary effluent Moderate O&M cost for power and chemicals Some brine management required Percolation only Alternative Treatment Alternative 3 – GAC or Ozone-BAC Ozone & BAC in various configurations to produce high quality water Processes: Ozone, BAC, optional MF/UF polishing, disinfection Recharge facilities: Surface spreading only in CA Treatment capabilities: No nutrient or TDS removal, some TOC removal, CEC removal Filtered WW Disinfection Percolation Pond or Raw Water Reservoir Alternative Treatment with GAC or Ozone-BAC Existing Facilities: Goreangab WTP (Windhoek, Namibia) – Ozone-BAC, direct potable reuse Fred Hervey WRP (El Paso, TX) – Ozone-BAC, indirect potable reuse, irrigation and cooling water F. Wayne WRP (Georgia) – Ozone-BAC, indirect potable reuse into Lake Lanier UOSA (Virginia) – GAC (pilot testing Ozone-BAC), indirect potable reuse into Occoquan Reservoir Pathogen CDPH Reqmt WWTP Title 22 Treatment Ozone BAC UV Virus 12 2 Up to 5 total 6 0 0 Giardia 10 2 - 4 0 6 Cryptosporidium 10 1 - 0 0 6 Travel Time/ SAT 6 Total >0 TBD >0 TBD >10 >12 >10 Alternative Treatment Alternative 3 – GAC or Ozone-BAC (optionally with Sidestream MF/RO) 15.5 mgd 15 mgd 3.4 mgd 2.9 mgd To WWTP 0.26 mgd 0.24 mgd Alternative Treatment Alternative 3 – GAC or Ozone-BAC Advantages: Removes some TOC so less blend water Effective at removing CECs Elimination of concentrated brine stream Potential for reduced energy requirements Disadvantages: Must be permitted as an “Alternative” process to increase RWC for initial operation above 20% in CA Does not reduce TDS or chlorides Limited removal of nitrogen and phosphorus compounds Does not remove as much TOC as MF/RO/AOP, higher blending water require Potential to form bromate when high bromide in source water Ozone-BAC Pilot Testing Projects are Underway for Gwinnett County GA and UOSA VA Alternative Treatment Alternative 4 – Nanofiltration Produces high quality water Processes: MF/UF, NF, UV-AOP (NF replaces RO) Recharge facilities: surface spreading, potential for groundwater injection if CA approved “Alternative” Treatment capabilities: No nutrient removal, some TDS removal, TOC & CEC removal Alternative Treatment Alternative 4 – Nanofiltration Advantages Potential lower power cost than RO Removes TOC nearly as well as RO Better water quality than T22, CA might allow subsurface injection Disadvantages Power savings may be temporary Less TDS removal than RO No reduction of concentrate compared to RO No MF/NF/UV-AOP installations in California for IPR Poor removal of inorganic nitrogen No capital cost savings Alternative Treatment Alternative 5 – Electrodialysis Reversal (EDR) Process uses Replacement for RO for TDS removal Sidestream TDS reduction Zero liquid discharge (ZLD) process Existing Facilities North City WRP (San Diego, CA) TDS reduction for irrigation Design/build: EDR vs RO 6 mgd Fort Irwin 2014 (Barstow, CA) EDR is proprietary with GE as the main manufacturer Alternative Treatment Alternative 5 – Electrodialysis Reversal Advantages Slightly higher recovery than MF/RO/AOP at 85% Can reduce TDS and TN Can be used for ZLD Disadvantages Not a barrier process No TOC or CEC reduction Few full size installations with no CA-permitted IPR facilities Time-consuming manual membrane maintenance Potential electrical and leakage problems How to Decide? Influent and product water quality are critical to determining which treatment process to use: Primary focus is on TOC/COD reduction in CA and some other locations Secondary focus is on TDS, Nutrients and CEC reduction Consider whether current TDS and NO3 concentrations are acceptable for example Consider what brine management options are available How much diluent water is available and at what cost? How to Decide? Has the process been permitted for IPR? Consider sidestream treatment if needed: South Bay Water Recycling Project – MF/RO to reduce TDS Consider phasing of treatment: Reduces initial costs Helps meet water quality requirements Extends time for brine management technologies Impact of future regulations: Will facilities be applicable to DPR? How to Decide? CA Example Evaluation Objective Sub-objective Maximize Cost-Effectiveness Initial Net Present Value (NPV) Maximize Reliability Water Supply/Discharge Benefit Minimize Environmental Impact Environmental Permitting Complexity Maximize Implementation Permitting Complexity Build-out Net Present Value (NPV) Negative Impact on GW Wells Environmental Value /Stewardship (Sustainability) Public Acceptability Improve Groundwater Basin Basin Salt Concentration Water Quality Minimize Operational Complexity Integration/Operational Complexity Reliability of Technology Compliance Sampling Frequency How to Decide? CA Example Evaluation (NF & EDR already eliminated) Tertiary Filtration Ozone – BAC Partial MF/RO MF/RO/AOP Phased TE And MF/RO Cost Effectiveness Environmental Impact Groundwater Quality Reliability Implementation Operations Cost of Alternative Treatment Trains for a 10 mgd facility Process Capital Cost Range O&M Cost Range MF/RO/AOP* $ 7-10/gpd $ 1-2.5/thou gal Ozone/BAC $ 2.5-4/gpd $ 0.3-1.2/thou gal *Assumes ocean outfall available for RO Conclusions MF/RO/AOP is still a popular and viable alternative in CA MF/RO/AOP is the only proven process for injection wells “Alternative” treatment processes should be investigated Partial or phased MF/RO offers advantages of less cost and lower brine production Ozone-BAC can be less expensive and requires less blend water but may need sidestream TDS and TN reduction Ozone-BAC use is increasing outside of CA due to costeffectiveness for the quality and sustainability factors Nanofiltration may have lower O&M costs than RO EDR is not a barrier but can work as a sidestream or part of a zero liquid discharge brine treatment process Questions William B. Dowbiggin, P.E., BCEE CDM Smith (919) 623-7964 dowbigginwb@cdmsmith.com