cabinet shop safety - Alabama Home Builders Self Insurers Fund

advertisement

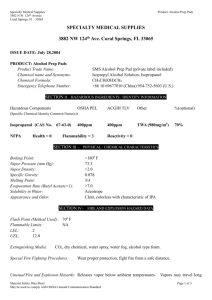

CABINET SHOP SAFETY These handouts and documents with attachments are not final, complete, or definitive instruments. This information is for guidance purposes only. You should independently verify and satisfy yourself as to its accuracy. The AHBSIF does not assume any liability for damages arising from the use of this information or exhibits and attachments thereto and renders no opinion that any of the terms, conditions, and/or cited federal standards in this document and the exhibits and attachments should be explicitly followed by the fund member. Seek specific guidance from the appropriate regulator (OSHA) or professional advisor. Scope • This guide was created to assist cabinet shop/wood fabrication shop owners on how to eliminate or control common safety exposures. • This is not a definitive or comprehensive plan for this type of work. • Please consult necessary safety sources when developing your own site specific plan. TABLE OF CONTENTS • • • • • • • • • Signage Material Storage and Handling Tool/Machine Hazards Electrical Paint & Stain Operations Dust Collection Systems Hazard Communication Personal Protective Equipment Emergency Procedures Signage • Walking and Working Surfaces – Permanent Aisles and passageways must be appropriately marked – Routes can be delineated with floor paint or physical barrier • Exit Routes – Each exit must be clearly visible and marked – “EXIT” must be legible and no less than six inches high and three quarters of an inch wide – Must have an illumination rating of 5 foot-candles on permanent power, self luminescent or electroluminescent .06 footlamberts – All doors not an exit must be labeled as such (e.g. closet) • Visitor Warnings – Must alert all visitors to potential exposures/hazards of facility – Prevent entrance from unauthorized personnel • Hazardous Material Storage – Location must be fenced and posted to prevent entrance from unauthorized personnel Signage • Flammable and Combustible Liquids – Storage cabinet where flammable and combustible liquids are stored must be conspicuously labeled • Spray Finishing – “NO SMOKING” – All spraying areas and paint storage rooms • Personal Protective Equipment – For processes that require specific protective equipment • Accident Prevention Signs – – – – – Color specifications are found in Subpart J 1910.145 “DANGER” (red-black-white) “CAUTION” (yellow-black) “WARNING” (no uniform color code) Listed colors must meet ANSI Z53.1-1967 Signage • Fire Protection – Location of extinguishers shall be labeled so location is easily identifiable • Materials Handling – All permanent aisleways where mechanical equipment operates will be appropriately marked – Sufficient safe clearances maintained with no aisle obstruction – Overhead gantry cranes must display rated load mark on both sides – Each hoisting unit must display rated load – Rated load marks must be visible from floor – During maintenance crane must be labeled “OUT OF ORDER” and floor space below must also be labeled • Radial Arm Saws – The direction of saw rotation must be conspicuously marked on the hood Signage • Electrical – Breaker panel must display manufacturer’s name, trademark, or other descriptive identification – Must provide voltage, current, wattage, and other ratings – Labels must withstand the environment – All breaker switches inside the panel must be labeled – Covers for boxes ≥ 600v must be permanently marked “HIGH VOLTAGE”, must be on the outside of the box and highly visible – Lock out Tag Out, see electrical portion of guide • Hazard Communication – See Hazard Communication portion of guide Signage • Mandatory Postings – “It’s the Law” poster – OSHA poster 3165 (English), 3167 (Spanish). Signage • Mandatory Postings – OSHA 300 logs • 300A, Summary of Work-Related Injuries and Illnesses • Must be filed on an annual basis even if there are no injuries • Summary from the following year must be posted from February 1st to April 30th of current year • Must be certified by a companies highest officer – Citations • Employer must post copy of citations at inspection location for three days or until violations are abated, whichever is longer. Log 300A OSHA's Form 300A (Rev. 01/2004) Year Summary of Work-Related Injuries and Illnesses U.S. Department of Labor Occupational Safety and Health Adm inistration Form approved OMB no. 1218-0176 All establishments covered by Part 1904 must complete this Summary page, even if no injuries or illnesses occurred during the year. Remember to review the Log to verify that the entries are complete Using the Log, count the individual entries you made for each category. Then write the totals below, mak ing sure you've added the entries from every page of the log. If you had no cases write "0." Employees former employees, and their representatives have the right to review the OSHA Form 300 in its entirety. They also have limited access to the OSHA Form 301 or its equivalent. See 29 CFR 1904.35, in OSHA's Recordk eeping rule, for further details on the access provisions for these forms. Establishment information Your establishment name Street City Number of Cases State Zip Industry description (e.g., Manufacture of motor truck trailers) Total number of deaths 0 Total number of cases with days away from work 0 (G) (H) Total number of cases with job transfer or restriction 0 (I) Total number of other recordable cases 0 (J) Number of Days OR North American Industrial Classification (NAICS), if known (e.g., 336212) Employment information Total number of days away from work Total number of days of job transfer or restriction 0 0 (K) (L) Annual average number of employees Total hours worked by all employees last year Injury and Illness Types Total number of… (M) (1) Injury (2) Skin Disorder (3) Respiratory Condition Standard Industrial Classification (SIC), if known (e.g., SIC 3715) Sign here Knowingly falsifying this document may result in a fine. 0 0 (4) Poisoning (5) Hearing Loss 0 0 0 (6) All Other Illnesses 0 Post this Summary page from February 1 to April 30 of the year following the year covered by the form Public reporting burden for this collection of information is estimated to average 50 minutes per response, including time to review the instruction, search and gather the data needed, and complete and review the collection of information. Persons are not required to respond to the collection of information unless it displays a currently valid OMB control number. If you have any comments about these estimates or any aspects of this data collection, contact: US Department of Labor, OSHA Office of Statistics, Room N-3644, 200 Constitution Ave, NW, Washington, DC 20210. Do not send the completed forms to this office. I certify that I have examined this document and that to the best of my knowledge the entries are true, accurate, and complete. Company executive Title Phone Date Material Storage & Handling • • • • • • General Storage Requirements Flammable and Combustible Liquids Manual Handling General Mechanical Handling Fork Trucks Waste Material Disposal General Storage Requirements • Storage areas must be kept free from materials that may cause tripping, fires, or explosions. • Storage areas should not block or intrude on facility pathways • When stacking and piling materials consider – – – – Height Weight Accessibility Condition of the container General Storage Requirements • Compressed gas cylinders must be secured and upright. Different gases must be separated by at least 20 ft. or by partition with specific dimension and fire retardant capabilities. • Observe height limitations for stacked materials. – Ex. Lumber must be stacked no more than 16 ft. high if it is handled manually, 20 ft. for forklift use • Used lumber must have all nails removed before stacking. • Lumber must be stacked and leveled on solidly supported bracing. General Storage Requirements • Bags and bundles must be stacked in interlocking rows. • Drums, barrels, and kegs must be stacked symmetrically. If stored on their sides, the bottom tiers must be blocked. • Boxed materials must be banded and baled. • Paper or rags stored inside a trailer must not be closer than 18 inches to walls, partitions, or sprinkler heads. • Non-compatible materials must be separated in storage. General Storage Requirements • Consider availability of the material, safe movement of material handling equipment, and personnel. • Any employee required to work in stored material vessels shall be equipped with a personal fall arrest system. • When a difference in work levels exists, some means of smooth transition must be employed, i.e. grading, ramps, blocking. General Storage Requirements • If space above office or any other elevated area is used for storage, handrails must be installed per the OSHA’s handrail requirements – Top Rail height: 42” (+ or – 3”) – Mid Rail height: 21” (+ or – 3”) – Must be able to support 200 lbs of outward and downward force on the top, 150 lbs on the mid rail – Toe Boards are necessary only if an exposure exists for those below Flammable Liquid Classification Flammable Liquid refers to any liquid having a flash point below 100° F FP - Flash Point BP - Boiling Point Class IA Class IB Class IC FP < 73° FP < 73° FP ≥ 73° BP < 100° BP ≥ 100° BP < 100° Combustible Liquid Classification Combustible Liquid refers to any liquid having a flash at or above 100° F FP - Flash Point Class II Class IIIA Class IIIB FP ≥ 100° FP ≥ 140° FP ≥ 200° FP < 140° FP < 200° Flammable and Combustible Liquids • The quantity of flammable or combustible liquid that may kept outside of a storage room or cabinet inside the building shall not exceed: – 25 gallons of Class IA liquids in containers – 120 gallons of Class IB, IC, II, III liquids in containers – 660 gallons of Class IB, IC, II, III liquids in a single portable tank Inside Storage Rooms • Shall be of fire resistant construction • Liquid tight were the walls join the floor • Have approved self closing doors at all openings • At least 4” sills, ramps, or depressed floors or open integrated trench which drains to safe location Inside Storage Rooms • A ventilation system that provides at least six room changes / hour • For Class I liquids, electrical wiring approved for hazardous locations • Explosion resistant lighting fixtures • Wood at least 1 inch nominal thickness for shelving, racks, dunnage, scuffboards, floor overlay, and similar installations Flammable Storage • All solvent wastes and flammable liquids must be kept in fire-resistant, covered containers until they are removed from the worksite • Firm separation should be placed between containers of combustibles or flammables, when stacked one upon another, to assure their support and stability • Permanently installed sprinkler system heads must not spray into operating electrical switch boards and equipment Flammable Liquids • Spills of flammable or combustible liquids must be cleaned up promptly • Storage tanks must be adequately vented to prevent the development of excessive vacuum or pressure as a result of filling, emptying, or atmosphere temperature changes • Storage tanks must also be equipped with emergency venting that will relieve excessive internal pressure caused by fire exposure • Insure that all connections on drums and combustible liquid piping and vapor are liquid tight Flammable Liquids • Use approved metal safety cans for handling of any flammable liquids in quantity greater than a gallon • Keep flammable liquids in closed containers when not in use (example: parts cleaning tanks, pans, etc.) • Ground and bond bulk drums of flammable liquids to containers during dispensing Combustible Storage • Combustible scrap, debris, and waste materials (oily rags, etc.) should be stored and removed from the worksite as promptly as possible • Proper storage practiced to minimize the risk of fire including spontaneous combustion • Keep combustible materials away from potential ignition sources • Never store flammable or combustible liquids in access or egress areas General Requirements For Manual Handling • Employees should seek help when: – A load is so bulky it cannot be properly grasped or lifted – An employee can’t see around or over it – A load cannot be safely handled. • Personal Protective equipment is an integral part of safe handling procedures. – – – – Boots with sturdy soles Gloves Forearm Protection Safety Glasses Mechanics of Proper Lifting • The following slides will demonstrate the basics of proper lifting technique • Don’t forget these basics; – Warming up before attempting to lift is good practice, don’t be afraid to get your blood flowing with some simple stretches. – There is no shame in the buddy system, get help if you think you’ll need it! – If management has provided equipment for helping you lift something, use it. Never take a short cut or put yourself in an unsafe position with a load. - Establish a solid base - Bend your knees - Position yourself close to the load - Lift with your legs -Complete the lift before twisting or turning General Requirements For Mechanical Handling • When moving materials avoid overloading, consider the weight, size, and shape of the material • Equipment capacity ratings must be displayed on each piece of equipment and must not be exceeded. • Follow safe lifting procedures for the specific machinery in use • OSHA requires that all machine operators are trained. Powered Fork Trucks • Research data estimates 90 deaths per year attributed to fork truck operation. • Operator training was made mandatory for all industries as of March 1, 1999. • Employer must train operators using federal guidelines for certification. • Equipment that was designed to move earth but will accept forks is not covered, nor are over the road haulage trucks. Powered Fork Trucks Training must incorporate the following subject matter: Familiarization with the Machine Understanding the basics of stability Understanding the forces that cause tip-over Vehicle Inspection Vehicle Operation Load Handling Power Source LGP Handling and Use Battery Charging Other Hands-On Training Powered Fork Trucks Refresher Training must be provided when: • An operator has an incident or near-miss incident • An operator is asked to run a different type of truck • The operator has been evaluated as not operating in a safe manner Training records must be kept on file after the date of completion for at least three years Operators are not subject to fitness tests OSHA does not require certification cards Waste Material Disposal • All scrap lumber, waste material, and garbage should be removed as work progresses. • Disposal of waste material or debris by burning must comply with local fire regulations, borough ordinances, and property owner requirements. • All solvent waste, oily rags, and flammable liquids shall be kept in fire resistant covered containers until removed from the worksite. Tool/Machine Hazards • • • • • • • Point of Operation Pinch Points Kickbacks Flying Chips, Material Tool Projection Machine Guarding Tool Safety Point of Operation •The point of operation is the place where work is performed on the material. •It is the point at which the stock is cut, shaped, bored, or formed. • Most woodworking machines use a cutting and/or shearing action. Nip/Pinch Points Nip/pinch points are a special danger arising from rotating or reciprocating parts. They occur whenever machine parts move toward each other or when one part moves past a stationary object. Parts of the body may be caught between or drawn into the nip/pinch point and crushed, mangled, or severed. How do injuries occur at the point of operation? • Employees can be injured if their hands get too close to the blade, particularly when working on small pieces of stock. • Stock can get stuck in a blade and actually pull the operator’s hands into the machine. • Employees can be injured if the machine or its guard is not properly adjusted or maintained. • Contact can occur during machine repair or cleaning if care is not taken to de-energize the machine. Kickbacks Kickbacks occur when a saw seizes the stock and hurls it back at the operator. This can happen when the stock twists and binds against the side of the blades or is caught in the teeth. Flying Chips/Material Employees may be exposed to splinters and chips that are flung by the cutting actions of woodworking equipment. Tool Projection Many pieces of woodworking equipment employ rotating cutter heads with multiple knives. Cutter heads that are not properly adjusted, or that are poorly mounted or have broken knives, can become unbalanced. The centrifugal forces on an unbalanced cutter head can fling the knives from the tool and injure or kill the operator or other nearby personnel. Machine Guarding • Moving machine parts have the potential to cause severe workplace injuries – Crushed fingers or hands – Amputations – Burns or Blindness • Safeguards are essential for protecting workers from these preventable injuries. • Any machine part, function, or process that may cause injury must be safeguarded. • If operation of a machine or accidental contact could injure the operator or others in the vicinity, the hazards must be eliminated or controlled. Tool Safety • Ensure all guards are in place and working properly • Use push sticks when needed Tool Safety • • • • Ensure employees are properly trained Inspect tools/machines before using Wear appropriate PPE Operate machines in accordance with manufacturers specifications • Don’t wear loose clothing • Keep long hair tied back Tool Safety • Ensure dust collection devices are working properly • Tool energy source must be disconnected or locked out during repair • Work areas must be well lit Standards for Woodworking Machinery • General Requirements for All Machines, 29 CFR 1910.212 • Woodworking Machinery Requirements, 29 CFR 1910.213 • Mechanical Power Transmission Apparatus, 29 CFR 1910.219 • Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities, NFPA 644-1993 • Woodworking Machinery—Safety Requirements, ANSI O1.1-1992 Electrical • • • • • • • • • Applicable Standards Basic Terminology Physical Effects Influencing Factors of a Shock General Requirements Guarding Lock Out/Tag Out Extension Cords Checklist Applicable Standards Electrical standards are among the mostly frequently cited by OSHA No Lock Out/Tag Out Improper Wiring Methods Inadequate Components and Equipment OSHA references the following for guidelines Electric Code (NEC or NFPA 70) Electric Safety Requirements for Employee Workplaces (NFPA 70E) Basic Terminology Amps – The amount of electricity flowing Volts – The force at which the power flows Ohms – A unit of electrical resistance Watts – A unit of electrical power Physical Effects Amps are the true measure of current absorbed, not volts We are good conductors, the human body is 70% water Involuntary muscle contraction is the reason we are affected Can’t let go of energized object Breathing is impaired Heart rhythm is disrupted Influencing Factors of a Shock Circumstances that affect the outcome of an electric shock; Circuit voltage The bodies external (skin) and internal resistance Total current flowing through the body Current path The duration of the shock General Requirements Equipment must be free from recognized hazards Equipment must be suitable and identified as such through listing, labeling, or certification for identified purpose. Parts designed for mechanical strength and durability must be adequate and protective Permanent work stations must be hardwired, wiring must be supported and/or protected by conduit Other items for consideration Electrical insulation under high temperatures Arcing effects Use classifications Guarding Live parts of electrical equipment operating at 50 volts or more must be guarded against accidental contact. Means of acceptable guarding include: Isolation in a cabinet, room, or vault only accessible by qualified persons Use of partitions or screens to exclude unqualified persons Elevation of eight feet or more above the floor Electric installations over 600 volts must be metal-enclosed, enclosed in a vault, or controlled by lock. Lock Out / Tag Out LOTO written program Components Documented energy control procedures Employee Training program Inspection program Lock Out / Tag Out Purpose is to draw attention to and disable a live energy source during service and repair work. Lock Out physically disables the energy source, Tag Out provides a warning only Only the employee who placed the lock or tag may remove it! Safe Power Shutdown - 5 Steps Preparation and Notification– Understanding energy source and alerting all affected employees Shutdown – De-energizing procedure Isolation – Properly locking all power sources Lock & Tag Application Color coding for different trades Employee assigned locks Photo tags, helps locate employee, makes association Control and Verification– Control stored and residual energy with locks in place Reenergizing - 3 Steps Inspection – checking the work area and surrounding machinery and for employees Notification – Make notice to all affected employees as to what will be re-energized Removal of Tags and Locks Tags and Locks Tags and Locks must be: Durable – resist conditions of environment Standardized – color code and format Substantial – strong enough to minimize false removal Identifiable – clear message, know who it is protecting Extension Cords Cords with missing ground prongs, insulation breeches, crimping or crushing, must be removed from service. Splicing is prohibited, but new connectors are acceptable When unplugging, pull the plug, never tug on the cord If a cord must cross a vehicle pathway it must be protected OSHA considers an extension cord temporary power, no matter the power source! Service Ratings Hard Service (types S, ST, SO, STO) Junior Hard Service (types SJ, SJO, SJT, SJTO) Home use, small appliance (type SP) Electrical Checklist Extension cords: - No crimping or crushing - No missing insulation - No signs of stress at plug All extensions cords out of high traffic areas: - Aisleways - Lift Truck Paths - Hallway, entrance, stairwell Lock Out / Tag Out plan for all maintenance operations Equipment rated for duty and environment Proper PPE when necessary GFCI protection cord or tool Awareness of all overhead power lines All tools double insulated Paint & Stain Operations • Spray Booth/Room General Requirements • Spray Booth/Room Construction • Ventilation • Employee Education • Standard References General Requirements • No smoking in or around spray booths/rooms • Respirators, eye protection, and gloves should be worn during all finishing operations • Maintain an eyewash station near area • Exhaust filters should be cleaned or replaced on a regular basis Spray Booth/Room Construction • Explosion resistant lighting shall be used inside spray booths/rooms • Explosion resistant motors shall be used • Motors are not guaranteed as such. Design specifies, – “If there is an explosion within the motor, the design will contain it and not allow it in to the atmosphere.” Spray Booth/Room Construction • Must be substantially constructed • Floors and walls must be non combustible materials • Interiors must be smooth and continuous, without edges, and designed to prevent accumulation of residues • Must be separated from other operations by at least three feet or a wall partition Spray Booth/Room Construction • Installed so that all portions are easily cleaned • Hot surfaces such as space heaters, appliances, and steam pipes must be located away from spray-finishing operations • All metal parts of spray booths, exhaust ducts, and piping systems must be permanently grounded Ventilation • Spray booth/rooms must enclose or confine all paint/spray/finishing operations • All spraying areas shall have mechanical ventilation adequate to remove flammable vapors, powders, or mists to a safe location and control combustible residues • Is your ventilation adequate for the size of your spray booth/room? Ventilation • Open Booth H x W x 100 = Minimum CFM H = Height of booth opening W = Width of booth opening 100 = minimum fpm over face of booth when operator is present Minimum CFM, Fan must meet or exceed velocity. Ventilation • Enclosed Booth – Concentrations of solvents must not exceed 25% of the lower explosive limit – A gallon of paint is roughly 50% solvent – A conventional gun at full discharge releases up to 12oz/min – Consult MSDS for LEL’s of material used – Consider size of booth and fan draw (CFM) Ventilation • Make up air must be fresh • If outdoor temp is < 55°, make up air must be heated • The electric motor driving the exhaust fan must be placed outside the booth or duct • Belts and pulleys used to drive the fan must be enclosed • Exhaust ducts must be fitted with access doors for cleaning Spray Booth/Room Safety • Ensure employees are familiar with Material Safety Data Sheets (MSDS) • The OSHA standard for spray finishing operations, 29 CFR 1910.107, provides detailed requirements for the design and construction of spray booths/rooms, air filters, velocity and air flow requirements, and the (make-up) air supplied to the booth/room OSHA REFERENCES FOR FINISHING OPERATIONS • Ventilation, 29 CFR 1910.94(c) and (d) • Flammable and Combustible Liquids, 29 CFR 1910.106 • Spray Finishing Using Flammable and Combustible Materials, 29 CFR 1910.107 • Respiratory Protection, 29 CFR 1910.134 • The Air Contaminants Standards 29 CFR 1910.1000 • NFPA 33-1969 Dust Collection Systems • Power Requirements • Bag Size • Noise Exposures • Collection Type • Accessibility Hazard Communication Four Components Written Program Contains information on how the employer will meet the requirements of the standard Labeling Labels must include information such as the name of the material, manufacturer’s name and address, and hazard warnings (SDS) Safety Data Sheets Contain all important information on a material and must be accessible to employees at any time Employee Training Employees learn the characteristics of the materials Written Plan • A Written Plan must address the following issues; • Procedures • Related Safety & Health Issues • Training • Chemical Inventory • Labeling Procedures Written Plan • What are the chemicals on the job or in the shop? • Who will be exposed to specific chemicals? • Are the employees trained prior to work? • What is the procedure for clean-up? • What is the procedure for first-aid and emergency contact? Labeling – The NFPA Placard The placard is used on all storage tanks and transfer containers (gas cans, storage vessels). Fire Hazard 4 – Below 73°F 3 – Below 100°F 2 – Above 100°F 1 – Above 200°F 0 – Will Not Burn Health Hazard 4 – Deadly 3 – Extremely Dangerous 2 – Hazardous 1 – Slightly Hazardous 0 – Normal Material 1 3 O 2 Reactivity 4 – Detonate 3 – Shock and Heat may Detonate 2 – Violent Chemical Change 1 – Unstable if Heated 0 - Stable Specific Hazard ACID – Acid COR – Corrosive OXY - Oxidizer GHS - Globally Harmonized System 1910.1200 All existing training and right-to-know requirements remain MSDS will be referred to as “Safety Data Sheets” Revision to hazard classification • Hazard Category System • Classification based on defined chemical data Sheet structure will be uniform New pictures will enhance communication for non-english speaking employees GHS Hazard Communication Additions to the new standard include: • Combustible dust • Pyrophoric Gases • Simple Asphyxiants Hazards Not Otherwise Classified (HNOC) – any substance that is known to be hazardous but does not conform to the hazard categories • Classification allows additions to be made at a later date Labeling • Product Identifier - Must match the identifier on the SDS and include the chemical identity of the substance /mixture ingredients that create hazard. • Pictograms - Image conveys chemical hazards. (black symbol, white field, all inside red diamond) • Signal Word - indicates the severity of the product’s hazard. – “Danger” = severe hazards – “Warning” = less sever hazards. • Hazard Statements - based on the nature of the product’s hazardous contents. • Supplier Identification – must include the name, address and telephone number used to locate or communicate with the manufacturer or supplier. Labeling • Precautionary Statements - informs the reader about how to prevent the hazards of storing or handling the product . Four categories: – Prevention – Response – Storage – Disposal • Other Elements – A competent person may add content to the label as long as it does not interfere with the label structure or confuse the user – Transport pictograms – Precautionary pictograms – First-aid recommendations – Universal product codes – General usage information Labeling Identifier 1 Pictograms 2 Signal words 3 Hazard Statement 4 Precautions 5 Supplier Identification 6 Labeling • It is the employer’s responsibility to ensure that all containers of hazardous substances in the workplace are labeled • Never remove a label • Container size is irrelevant, all containers must be labeled • The only labeling exception is “Immediate Use”, employee has 100% control of material. (SDS) Safety Data Sheets The SDS give vital information on the behavior of a material: • Physical Data • Reactivity with other chemicals • Emergency First-Aid Procedures • Hazard Information • Prolonged and Acute Health Effects New SDS Structure The format should include the following sections: 1. Identification 2. Hazard(s) identification 3. Composition/information on ingredients 4. First-Aid measures 5. Fire-fighting measures 6. Accidental release measures 7. Handling and storage 8. Exposure controls/personal protection New “SDS” Structure Format cont… 9. Physical and chemical properties 10. Stability and reactivity 11. Toxicological information 12. Ecological information 13. Disposal considerations 14. Transport information 15. Regulatory information 16. Other information, including date of preparation or last revision Definition of Physical States • Gas - a substance or mixture which at 50°C (122°F)has a vapor pressure greater than 300 kPa; or is completely gaseous at 20°C (68°F) and a standard pressure of 101.3 kPa. • Liquid - a substance or mixture that is not a gas and which has a melting point or initial melting point of 20°C (68°F) or less at standard pressure of 101.3 kPa. • Solid - a substance or mixture that does not meet the definitions of a liquid or a gas. SDS Pictograms • Provides a visual representation of the hazard Hazard Categories Health Hazard Explosion Corrosives Toxicity Flammable Environmental Irritants Compressed Gas Oxidizer Health Hazard Carcinogen Mutagenicity Reproductive Toxicity Respiratory Sensitizer Target Organ Toxicity Aspiration Toxicity Corrosives Skin Corrosion/ burns Eye Damage Corrosive to Metals Flammable Flammables Pyrophorics Self-Heating Emits Flammable Gas Self-Reactives Organic Peroxides Irritant Irritant (skin and eye) Skin Sensitizer Acute Toxicity (harmful) Narcotic Effects Respiratory Tract Irritant Explosion Explosives Self-Reactives Organic Peroxides Toxicity Acute Toxicity (fatal or toxic) Environmental Hazardous to Ozone Layer Aquatic Toxicity Compressed Gas Gases under Pressure Oxidizer Could yield oxygen and contribute to combustion. (SDS) Safety Data Sheets • Small quantities of (household use) products purchased from retail stores do not require an SDS, unless exposure is increased and constant. • If a supplier will not provide an SDS, they are required to tell you how to get it. • It is good practice to carry an SDS manual in a field vehicle, but not necessary. SDS’s must be accessible to an OSHA inspector during the shift. Faxing from the main office is acceptable. (SDS) Safety Data Sheets Materials and Chemicals that require an SDS: Paint & Stains Brick & Block Fuels & Lubricants Sheetrock Solvents Compressed Gas Pesticides, Insecticides Welding Rods Adhesives Insulation Cleaning Agents Treated Lumber Employee Training • Employees must be trained on every new chemical in which they come in contact • Acute and chronic health effects • Proper handling and use • Proper storage • Clean-Up procedures • Proper disposal • Accessing information (SDS Manual) Job-Site Compliance • All contractors are responsible for providing SDS for the chemicals/materials they bring to the site. • Other contractors must be made aware of potential hazards created by chemicals/materials brought on-site. Common Job-Site Exposures • • • • • • • Sheetrock work – sanding and cutting Lawn Maintenance and Landscaping – fertilizers and fuels Masonry - cutting and mixing Insulation - blown and batting, cutting or spraying installation Fabrication or repair - compressed gas welding rods Pest control - mixing and spraying Carpentry – cutting, sanding, installation Additional OSHA Requirements • Employers must present information in a manner and language that their employees can understand. • Employers must communicate the training in the employee’s language. • If the employee has a limited vocabulary or is illiterate the training must account for that. Compliance Dates Dec. 1, 2013 Train all employees on the new label elements and Safety Data Sheet format June 1, 2015 Comply with all modified provisions of this rule, except distributors that are allowed to ship products labeled by manufacturers under the old system until Dec 1, 2015 Dec 1, 2015 Comply with all modified provisions of the rule June 1, 2016 Update alternative workplace labeling and hazard communication program as necessary and provide additional employee training for newly identified physical or health hazards Hazard Communication Checklist Inventory of Chemicals Used Match Chemicals With Exposures Obtain all SDS Safe Work Practices for Each Chemical Identify SDS Storage Location Employees Educated on Potential Exposures Employees Know Location of SDS Employees Trained on Use of Material All Containers Labeled Notify Other Contractors When Necessary Personal Protective Equipment • • • • • • General Requirements Foot Protection Head Protection Hearing Protection Eye & Face Protection Respiratory Protection General Requirements • Personal Protective Equipment (PPE) must be maintained and provided by the employer when necessary. • If an employee provides his/her own equipment, the employer is still responsible to make sure it is adequate and well maintained. • PPE is to be used as a last means of controlling an exposure. Engineering and administrative controls should be used first when possible. Foot Protection • Safety footwear must comply with ANSI Z41.1 • Required for: Any material handling process where something could be dropped on the foot Bulk material handling processes Work around sharp objects that could penetrate and puncture foot Head Protection • All hard hats must comply with ANSI standard Z89.1, and Z89.2 for employees exposed to high voltage electric shock. • Bump Caps are not acceptable for construction use under these standards. Head Protection • Employees must wear hard hats if there is any possibility of; Being struck by an object falling from a higher level A flying object Electrical shock Hearing Protection • Engineering and Administrative controls should be applied when feasible. • Ear plugs must be fitted under the direction of a competent person. • Plain cotton is not an acceptable hearing protection device. **Remember** If you are arms length from the person talking to you and cannot hear them, its time for hearing protection! Three Components of Hearing • Sound A sound can be intermittent or continuous or a combination of both. Intensity is also a factor. • Path Distance, terrain, and medium of travel play a part. • Receiver The average unimpaired hearing range of a person is 20 to 20,000 Hz Facts and Numbers • 85 decibels is considered the “Action Level” or the level at which an employee must be enrolled in a HCP (hearing conservation program) and notified of their results. • The permissible exposure level for a time weighted average over an eight hour period is 90 decibels. • The level at which dual hearing protection must be worn is 105 decibels. • The maximum allowable exposure level at any one time during the shift is 115 decibels. Components of a Hearing Conservation Program • • • • • Monitoring Hearing Protection Audiometric Testing Training Record Keeping Muffs vs. Plugs • Product will have a Noise Reduction Rating or NRR • Rating indicates the performance of the device Muffs Plugs Average NRR for devices shown: 28.66 Average NRR for devices shown: 23.66 Calculating Noise Reduction using the NRR • When C-weighted sound level measurement is available, the following formula should be used to calculate the required NRR • Noise Level in dB(C) - Protector NRR = 90 dB(A) or less. • When A-weighted sound level measurement is available, the following formula should be used to calculate the required NRR. • Noise Level in dB(A) - (Protector NRR - 7 dB) = 90 dB(A) or less How to insert an Ear Plug • Grab the top/back of the ear. • Gently pull up and backward. • (If disposable foam) Roll the plug between the forefinger and thumb until it is completely compressed. • Gently slide the plug in the ear canal. • (If disposable foam) Let the plug expand. Eye & Face Protection • All eye and face equipment must comply with ANSI Z87.1 standards. • Employers must provide protection when employees are exposed to any and all potential flying debris. • ANSI compliant side shields applied to conventional glasses do not make them safety glasses! Eye & Face Protection • The standard covers general eye protection, eye protection for welding, and laser applications. • Tables E-1, E-2, and E-3 tell us minimum performance requirements for our applications. Respiratory Protection • Industry Standard 1910.134 • Employer must choose the right application for the job. Respiratory Protection Dust Masks are for Respirators are nuisance dusts made to filter only. harmful contaminants from the air. Self Contained Breathing Apparatus (SCBA) is suitable for atmospheres that are both oxygen deficient and contain harmful contaminants. Respiratory Protection • Employees that have to wear respirators must receive the following: Pulmonary Function Test Respirator Fit Testing Education on devices capabilities Storage, cleaning, and regular inspection procedures Regularly monitored work area and conditions Respirator Fit Testing Quantitative A pass/fail test to assess respirator fit. Relies on the individual's response to the test agent. (recognizable scents) Qualitative Assesses a respirator’s effectiveness by numerically measuring the amount of leakage into the respirator. Respirator Fit Testing 1. Adjust straps and other connecting or fitting devices so that face seal is snug but comfortable. 2. Positive Pressure Test: Place hand over blowout diaphragm and exhale, the mask should first expand, then release around the face seal. 3. Negative Pressure Test: Place hands over the cartridges and inhale, the mask should collapse into the face. If no leaks are discovered, and wearer can sense no surrounding odors, mask is fitted properly. Facial hair that interferes with a proper seal is prohibited. Emergency Procedures • Emergency Evacuation plan • Fire Safety • Basic First Aid Are you Prepared? • Does the facility have a first aid kit? • Are emergency contact numbers readily available? • Do any of your employees/co-workers have CPR or First Aid training? • Does the facility have an evacuation procedure? Emergency Evacuation Plan • Employees must be educated on all emergency evacuation plan specifics • Exit map must be conspicuously posted • Ensure primary and secondary routes are unobstructed Emergency Evacuation Plan • Assemble outside the facility at predetermined area for a head count • Identify who is responsible for head count • Identify who is responsible for emergency power shut down • Identify who will make appropriate emergency phone calls • No one reenters facility until emergency is over Fire Safety • Good house keeping is key to preventing fires - Do not use compressed air to blow sawdust - Keep evacuation routes/exits clear - Clean up daily Fire Safety • Develop a system to alert employees in the event of a fire • Ensure exits are properly marked (steel roll up doors are not acceptable as fire exits) • Ensure adequate number of extinguishers for size of building (no more than 75 ft. of travel) • Ensure employees know extinguisher location • Train employees on proper operation of extinguishers Fire Extinguishers • Fire extinguishers must be selected and provided for the types of materials in areas where they are to be used • Class A, Ordinary combustible material fires. • Class B, Flammable liquid, gas or grease fires. • Class C, Energized-electrical equipment fires. • Fire extinguishers should be mounted within 75 feet of outside areas containing flammable liquids, and within 10 feet of any inside storage area for such materials • Access to extinguishers should be free from obstructions or blockage • Fire extinguishers must be serviced, maintained, and tagged at least once a year Extinguishers Ordinary Combustibles Includes materials such as wood and paper Flammable Liquids Includes fuels, grease, other liquids Electrical Fires Contains non-conductive smothering agent Fire Extinguisher Inspection • Body of the extinguisher; rust, cracks, dents • Check hose for cracks, dry-rot • All fittings snug, no signs of leaks • Lever and hinge assembly • Safety pin in place, safety tie present • Inspection tag, present and up to date • Pressure gauge, needle in the green How to use a Fire Extinguisher P-A-S-S Pull -- Pull the pin at the top of the extinguisher that keeps the handle from being activated Aim -- Aim the nozzle at the base of the fire Squeeze -- Maintain a distance of eight to ten feet away from the fire and squeeze the handle. Discharge will only occur if the handle is being squeezed. Sweep -- Sweep the nozzle back and forth at the base of the fire until it appears to be out. Basic First Aid • The OSHA First Aid standard (29 CFR 1910.151) requires trained first-aid providers at all workplaces of any size if there is no “infirmary, clinic, or hospital in near proximity to the workplace which is used for the treatment of all injured employees.” Handling an Emergency The three C’s, Check, Call, Care help us remember what to do in an emergency situation. Check – check the area for your own safety first, then the victim's Call – for help, 911 or whom ever is in the immediate area that can provide assistance Care - administer care to the victim, this may be first aid or at least stabilization